Patents

Literature

78results about How to "Improve processing output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

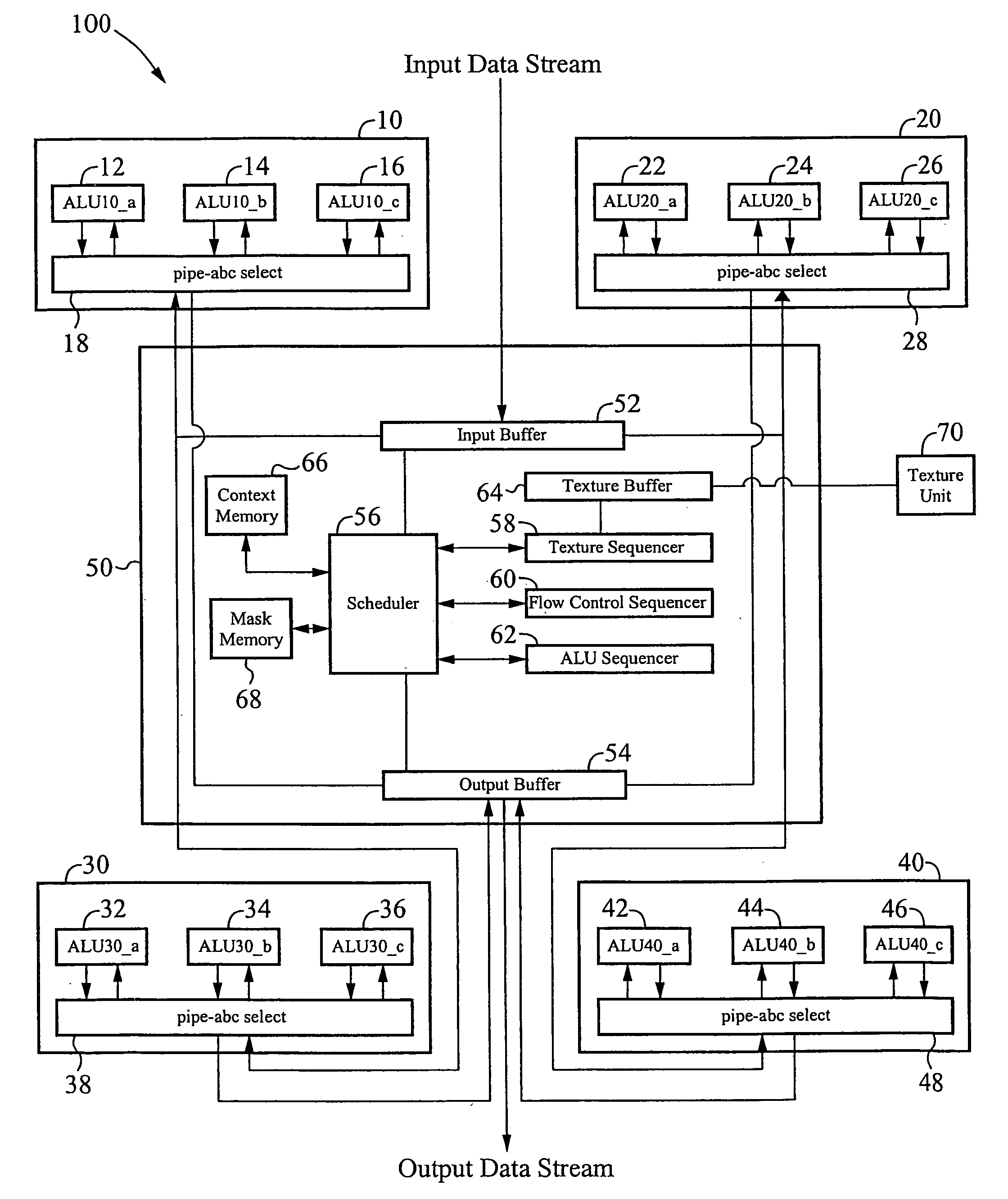

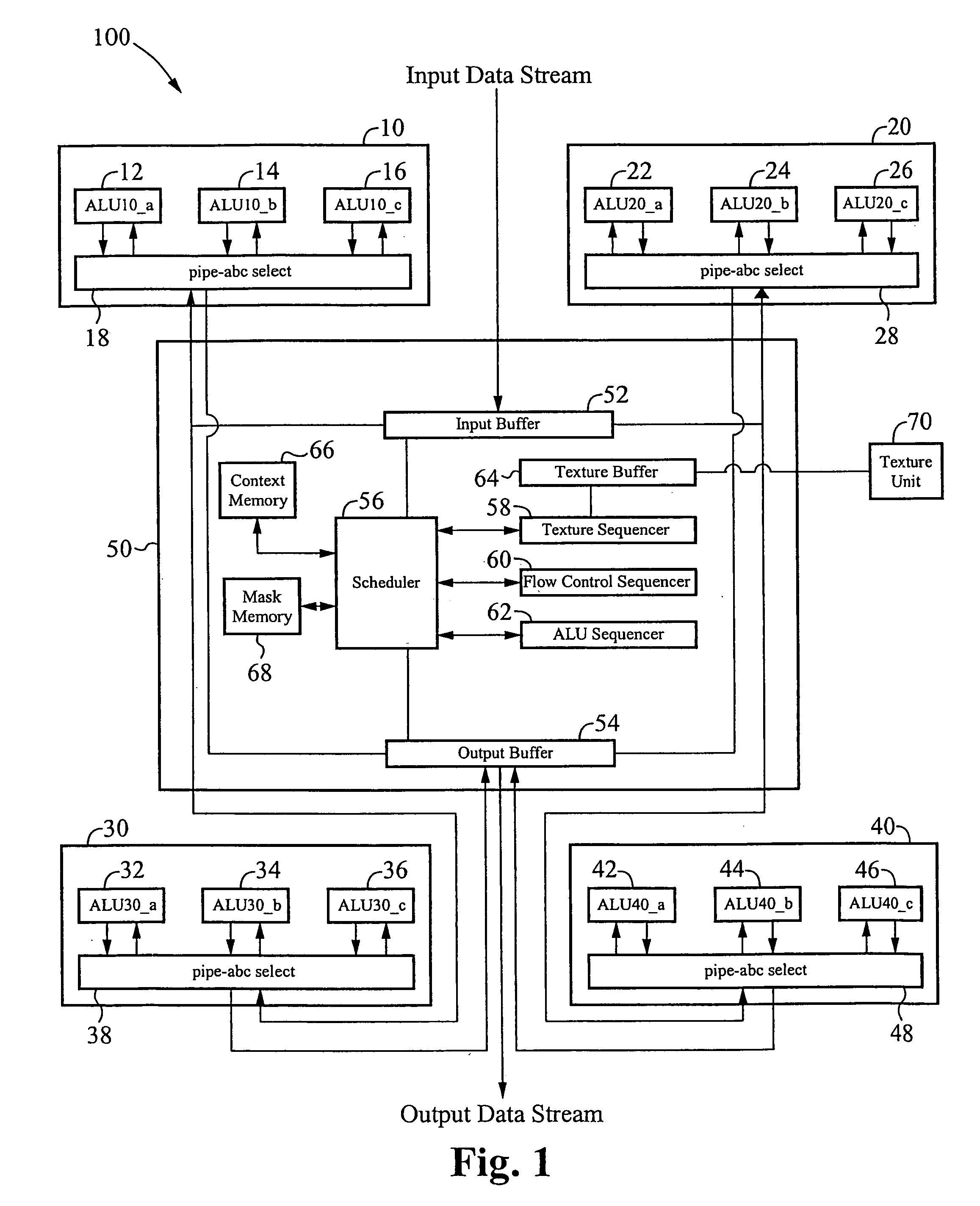

Configurable shader ALU units

ActiveUS20080189524A1Increased dynamically changeable amountReduce power consumptionDigital computer detailsProcessor architectures/configurationComputational scienceData stream

A shader unit is configured to provide an increased and dynamically changeable amount of ALU processing bandwidth. The shader unit includes a plurality of ALUs for processing pixel data according to a shader program. Each of the ALUs is configurable to be enabled and disabled. When disabled, the ALU is powered off, thereby reducing the power consumption of the shader unit. In one embodiment, the plurality of ALUs are logically configured into groups called ALU-pipes, each of which can be enabled and disabled. When an ALU-pipe is disabled, each ALU associated with the disabled ALU-pipe is disabled. The shader unit includes a sequencer that executes the shader program, determines the number of ALUs to be enabled, receives an input data stream of pixel data, assigns groups of pixel data to each enabled ALU, sends the assigned pixel data to their respective ALUs, and sends ALU instructions to the ALUs to process the received pixel data according to the shader program.

Owner:ATI TECH INC +1

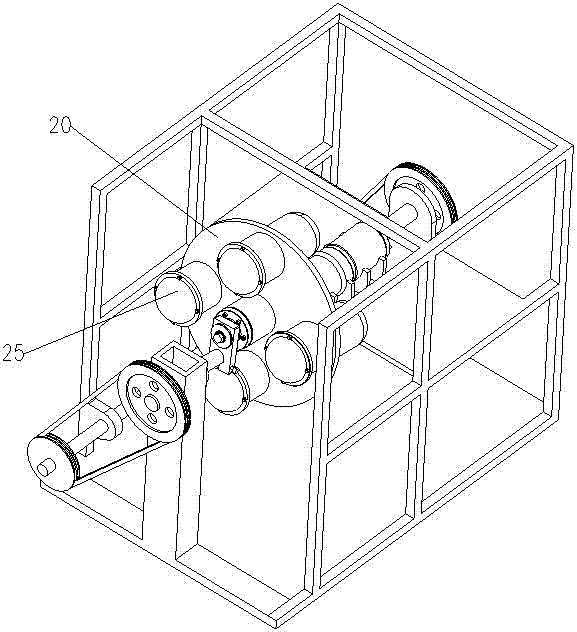

One-axle multi-cylinder multi-dimensional ball hammer type micro-nano high-energy ball mill

InactiveCN104117411AImprove production and efficiencyRun smoothlyGrain treatmentsMicro nanoMultiple dimension

The invention discloses a one-axle multi-cylinder multi-dimensional ball hammer type micro-nano high-energy ball mill. The ball mill is characterized in that a round disk is driven through the rotation of an eccentric shaft driving system and an eccentric shaft support system, a plurality of cylindrical milling tanks are arranged on the round disk, the tank body is driven to regularly swing in a multi-dimension manner up and down, left and right, front and back through the synchronous rotation of the eccentric shaft and the eccentric shaft support system, the ball material in the tank body is thrown up to produce multi-dimensional hammer action, so that fierce impacting, chopping and grinding in multi-dimension can be achieved. Since the multi-dimensional impacting and grinding have no dead angle, the material can be ground into uniform micro-nano powder, the processing efficiency, the yield and the quality of the micro-nano powder are obviously improved; the ball mill has a stable structure, can be easily enlarged to form the scale production, and is suitable for the demand of nanometer application engineering.

Owner:深圳市来源新材料科技有限公司

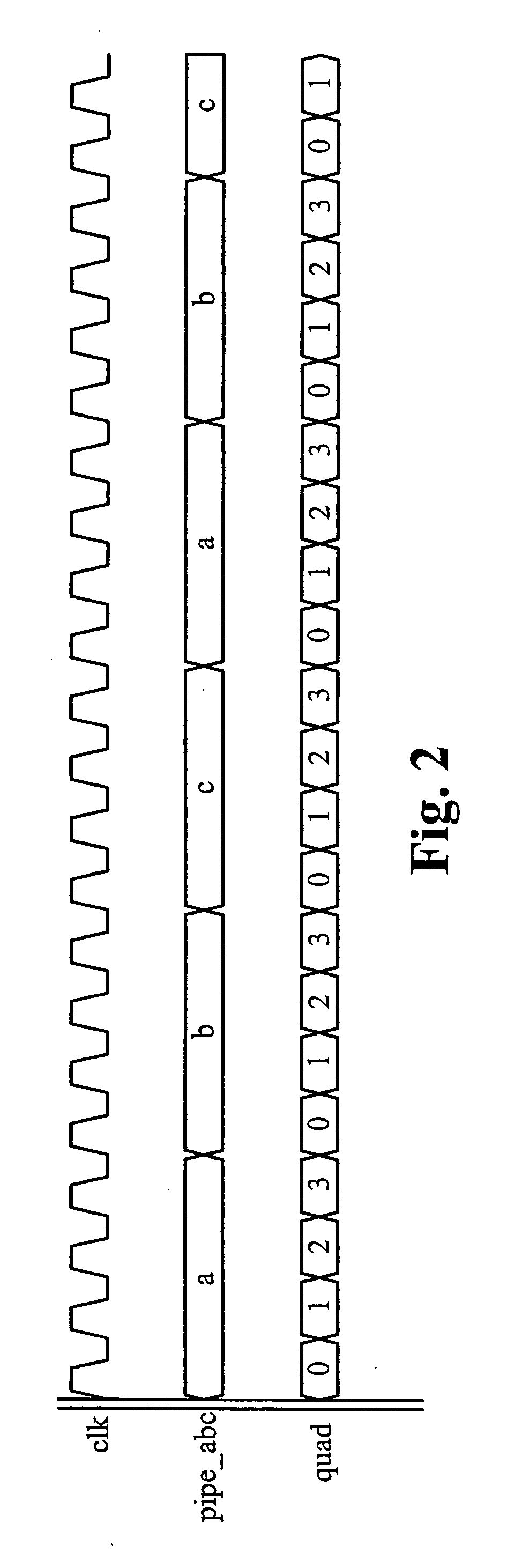

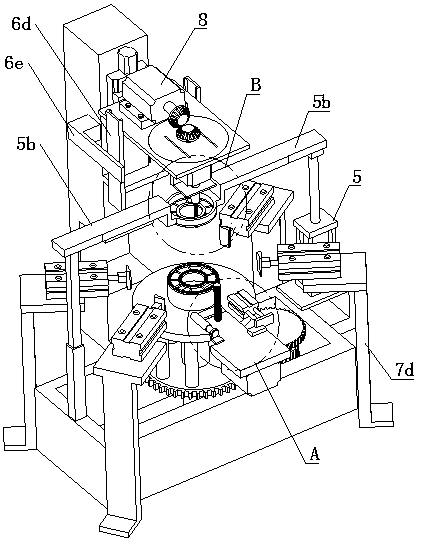

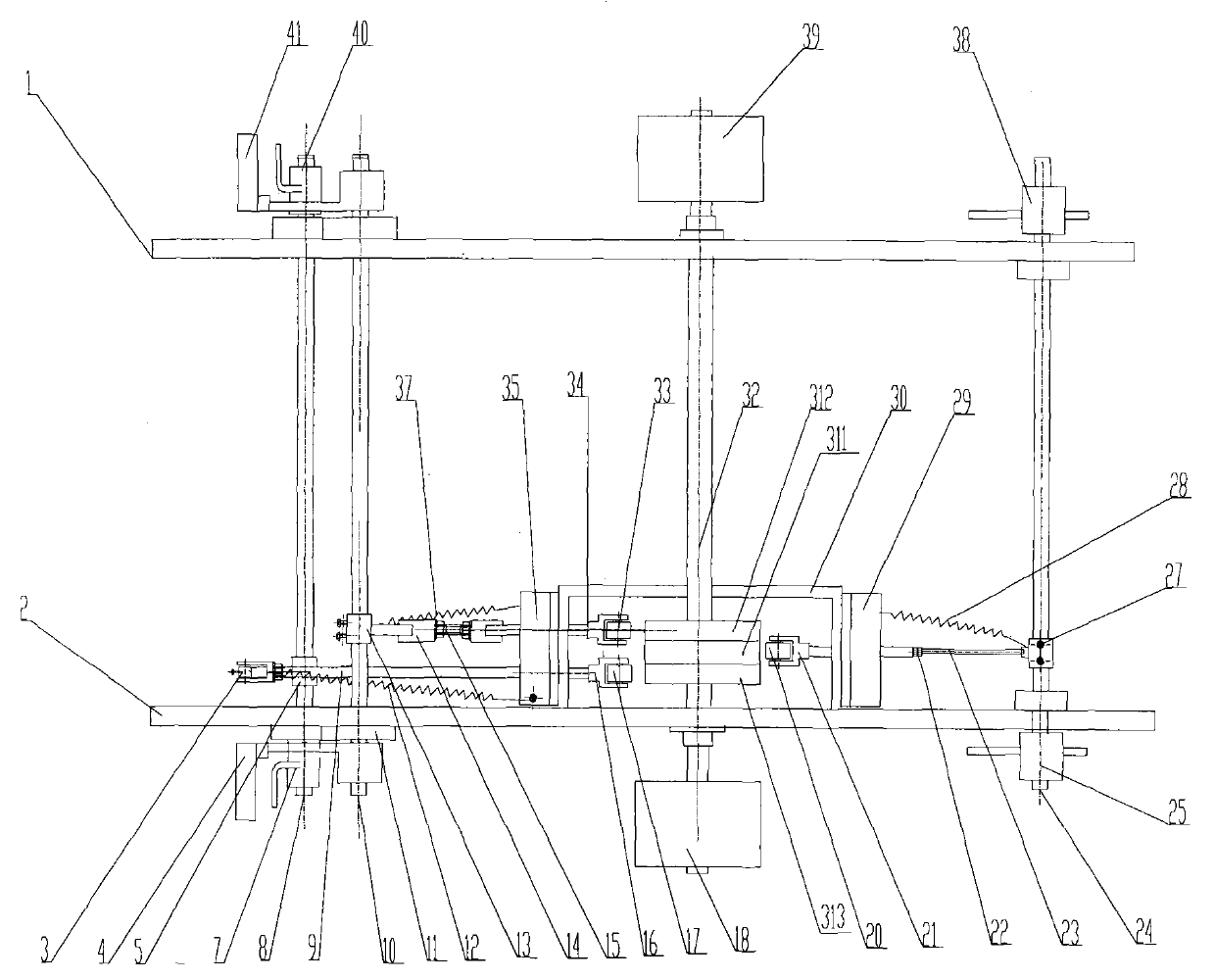

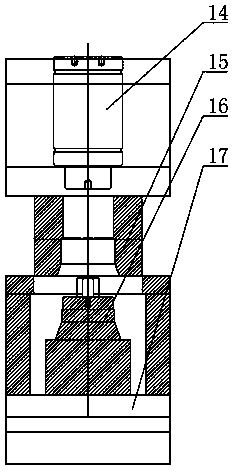

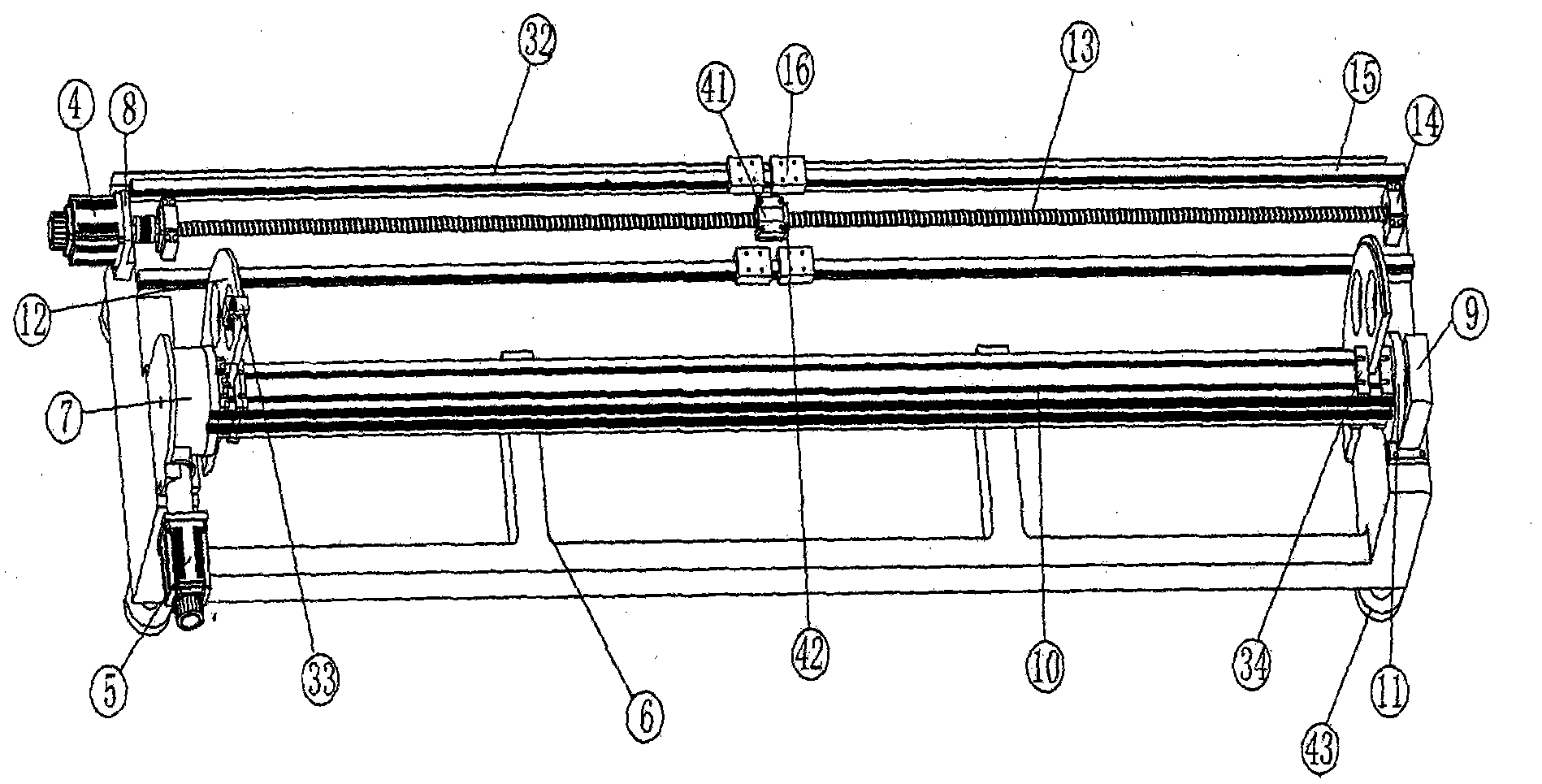

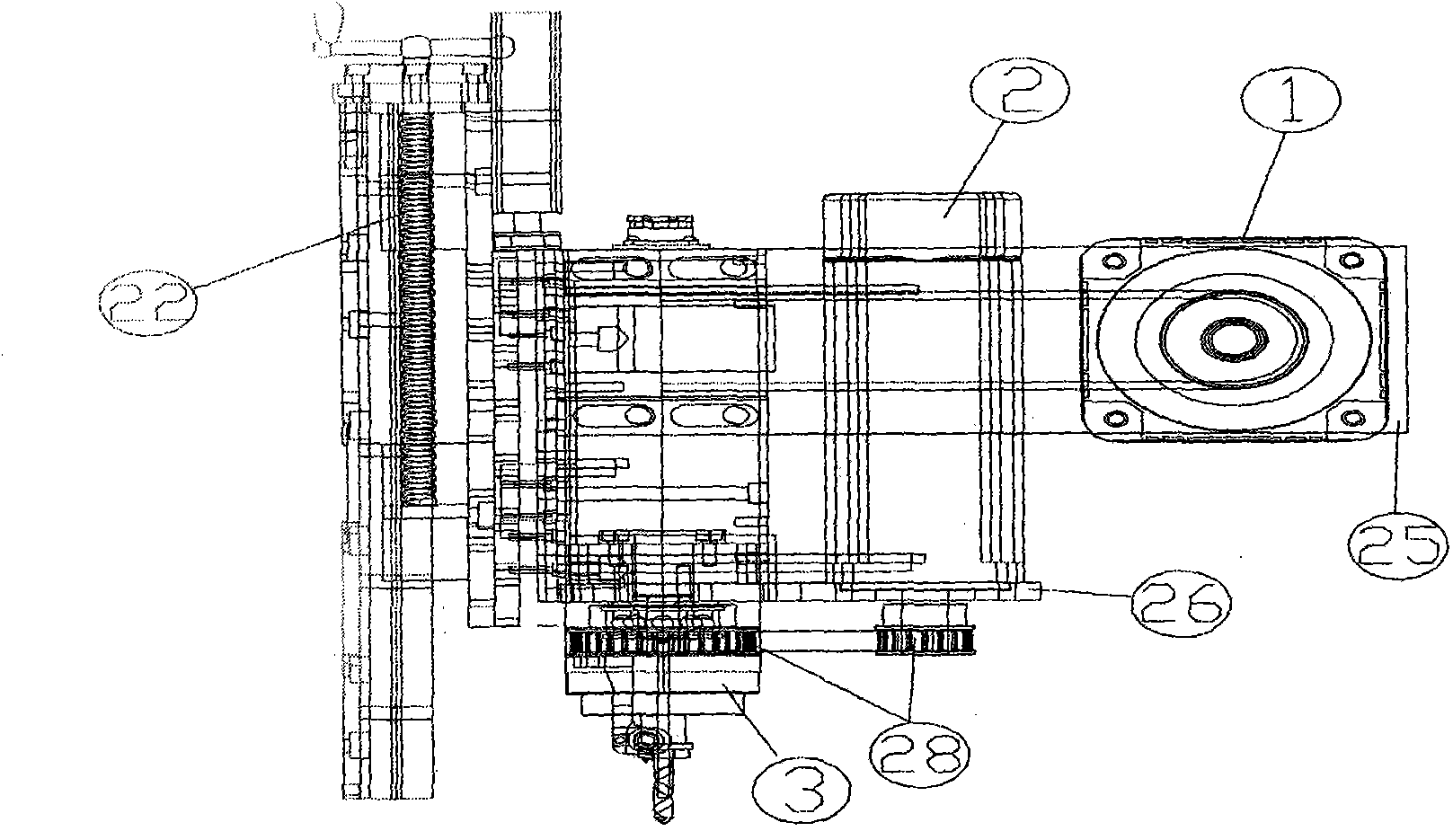

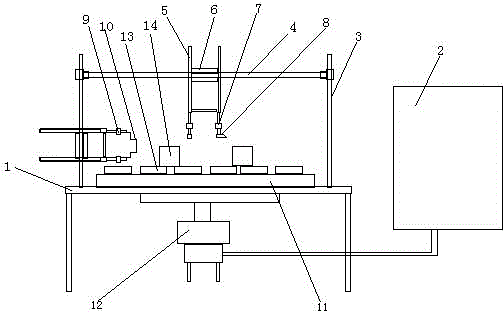

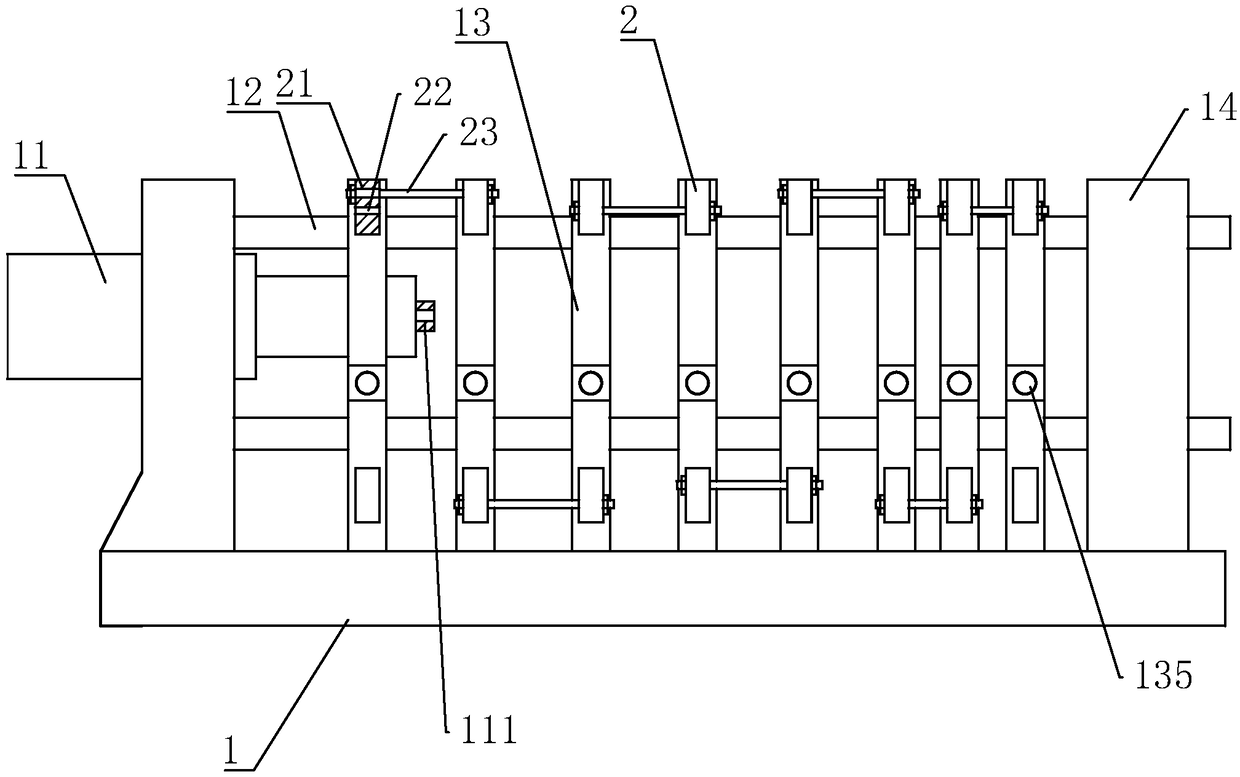

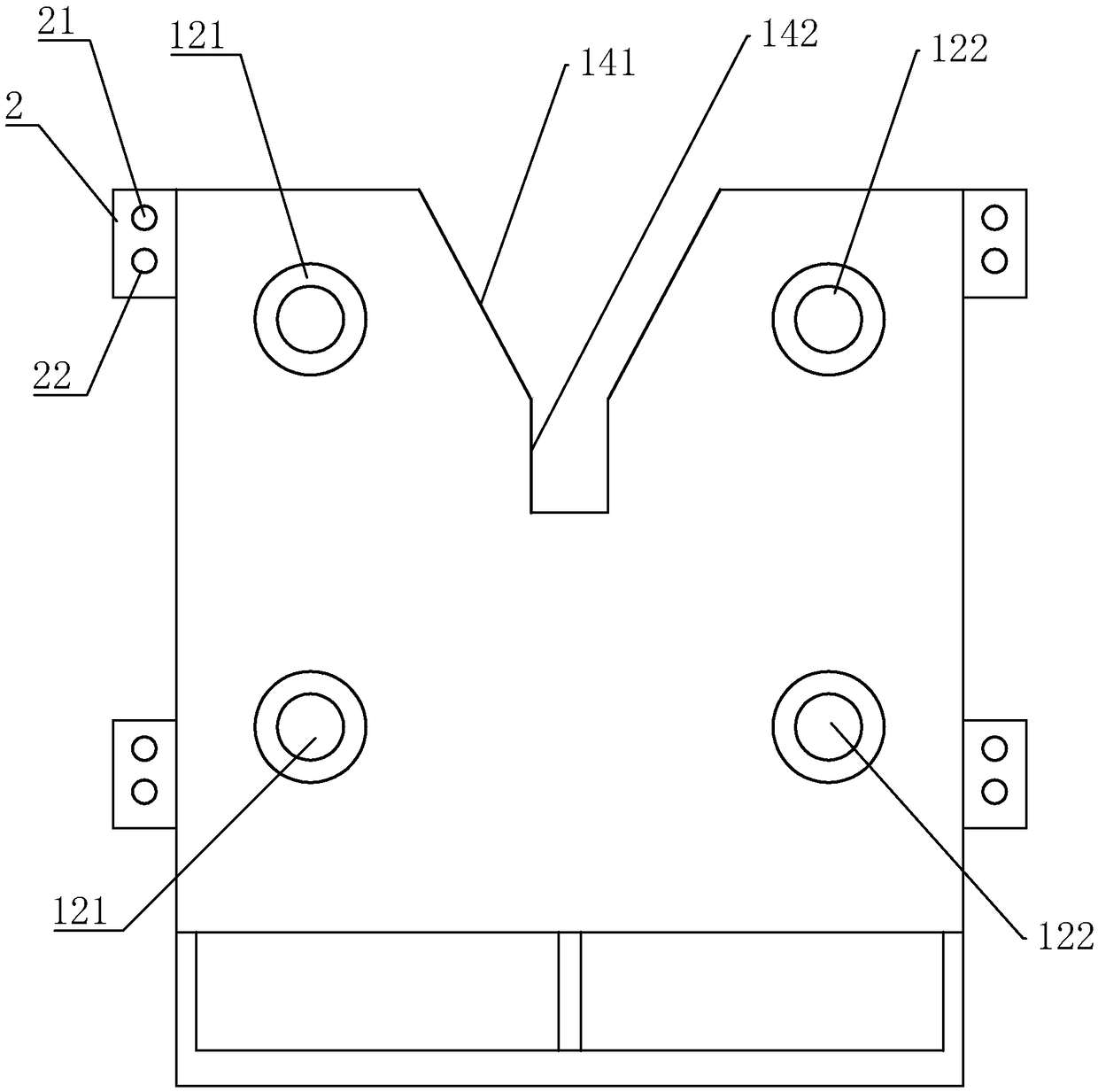

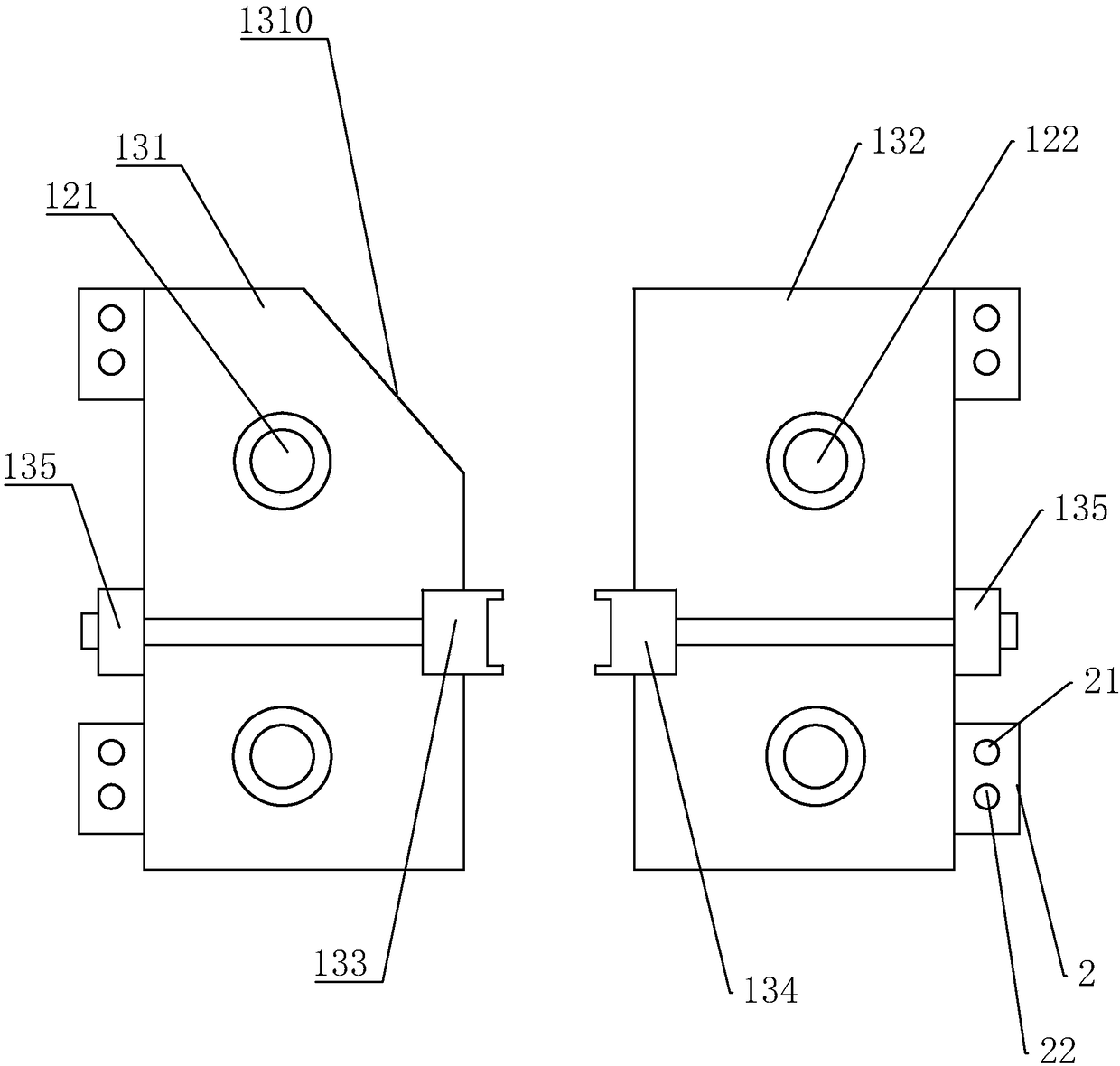

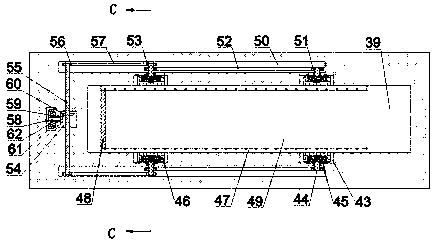

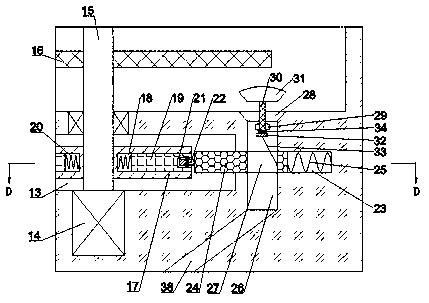

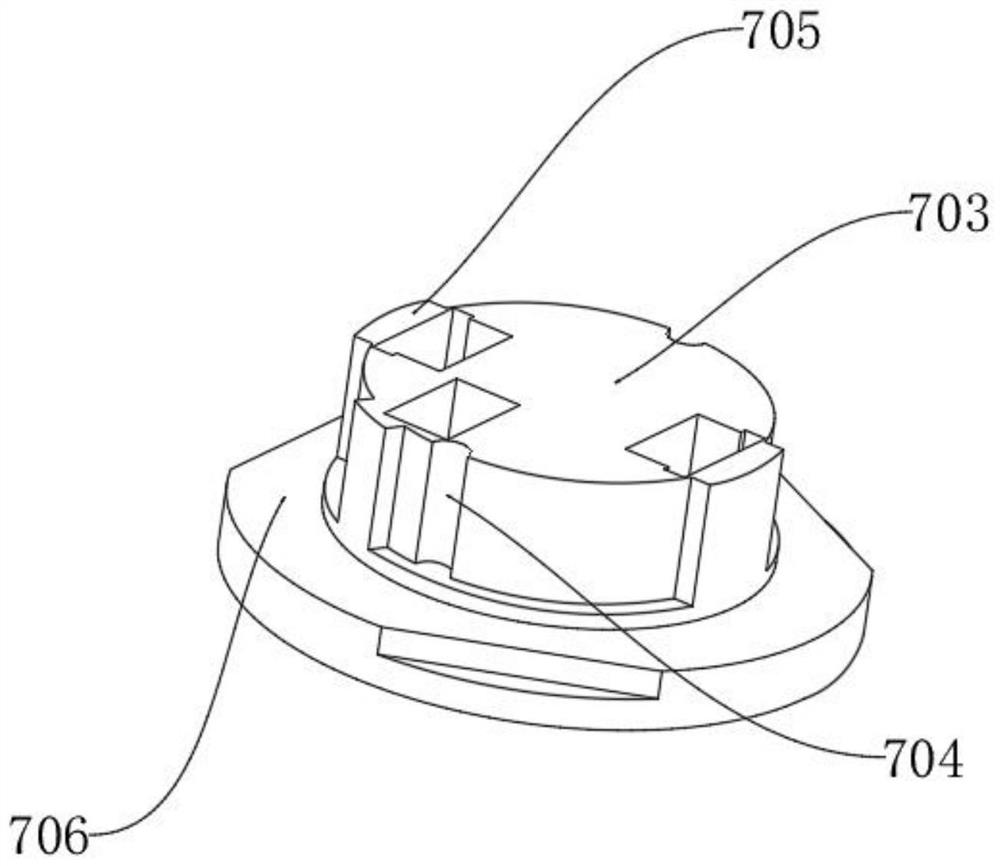

Inner ring and outer ring synchronous polishing device for automobile bearing

InactiveCN108789084AImprove processing efficiencyImprove processing outputGrinding machinesGrinding work supportsReciprocating motionEngineering

The invention relates to the field of bearing machining, in particular to an inner ring and outer ring synchronous polishing device for an automobile bearing. The inner ring and the outer ring synchronous polishing device for the automobile bearing comprises a first polishing device, a second polishing device and four limiting assemblies, wherein the first polishing device is used for supporting the bearing and polishing the surface of the outer ring of the bearing, the second polishing device is arranged over the first polishing device and used for polishing the inner ring of the bearing, andthe four limiting assemblies are arranged on the periphery of the first polishing device. The first polishing device comprises a machining column, a lower locating block arranged at the top end of the machining column and an upper locating block. The upper locating block can be arranged over the lower locating block through a receding assembly and is a vertically movable manner. The upper half section of the machining column is sleeved with an edging rotating disk capable of rotating around own axis. The edging rotating disk is provided with an outer ring polishing assembly capable of conducting reciprocating motion in the radial direction of the edging rotating disk. The four limiting assemblies are arranged on the periphery of the edging rotating disk and are symmetrical in pairs. The inner ring and the outer ring synchronous polishing device for the automobile bearing can synchronously polish the inner ring and the outer ring of the bearing and greatly improves the machining efficiency of the bearing and the overall machining yield.

Owner:胡良田

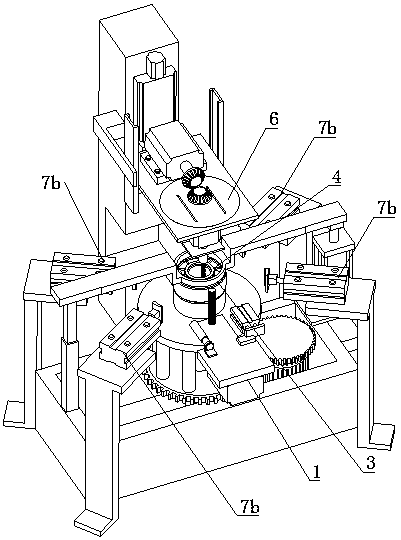

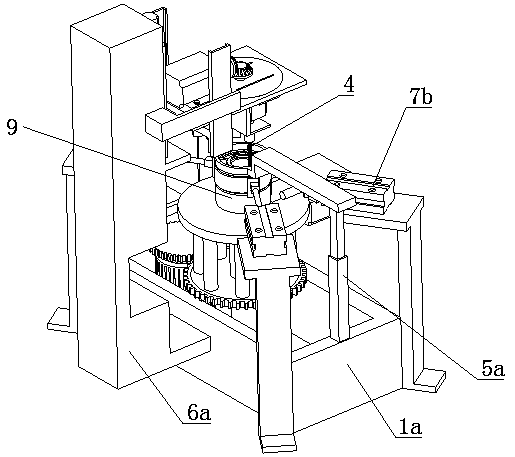

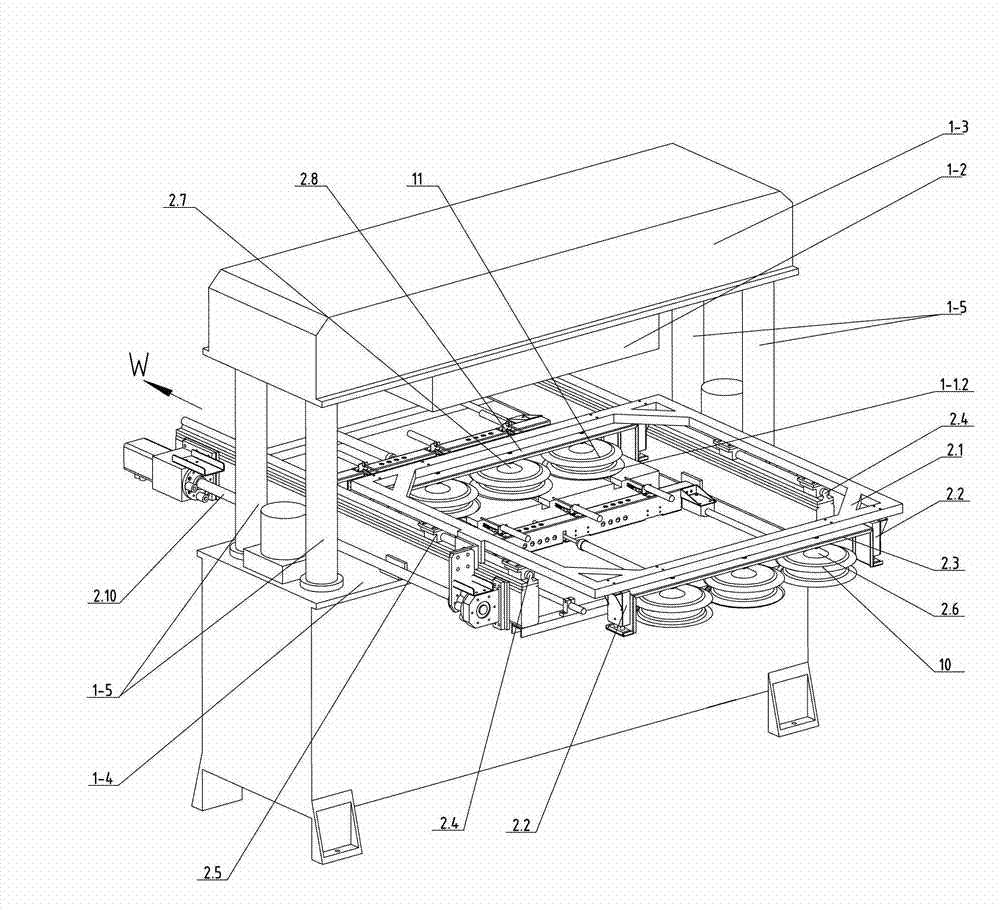

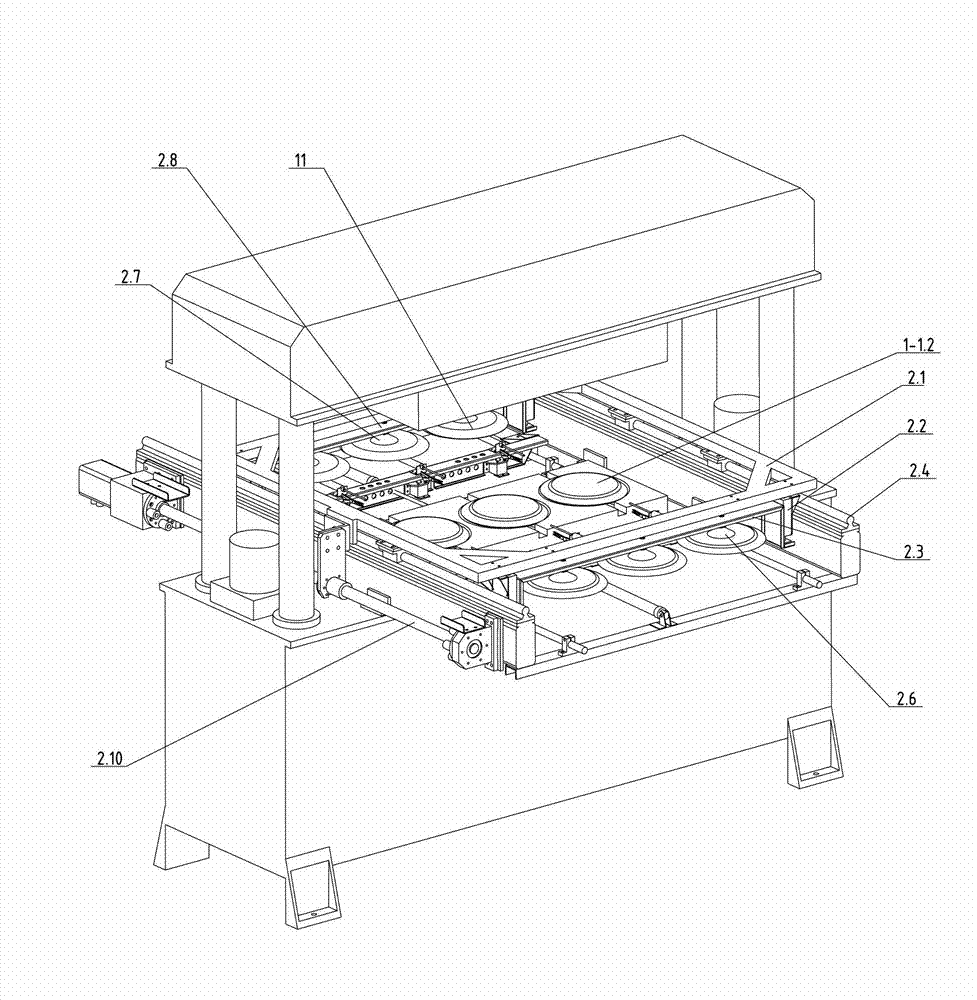

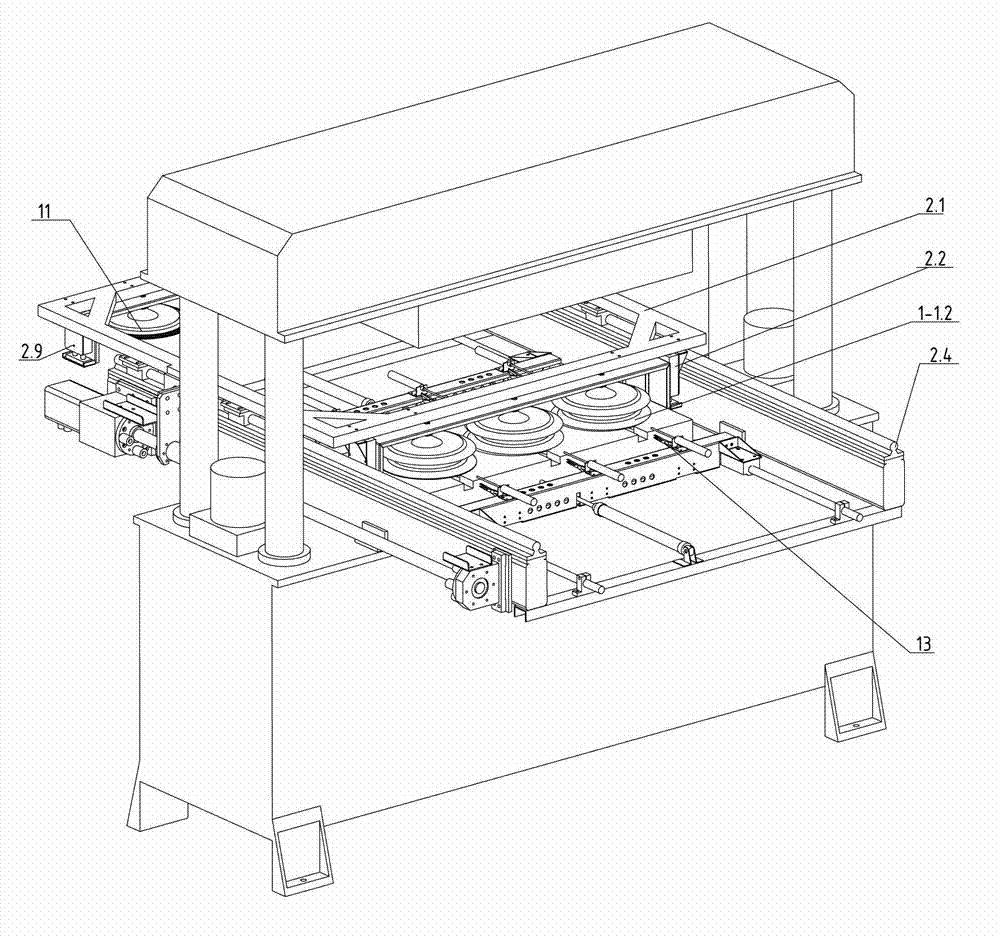

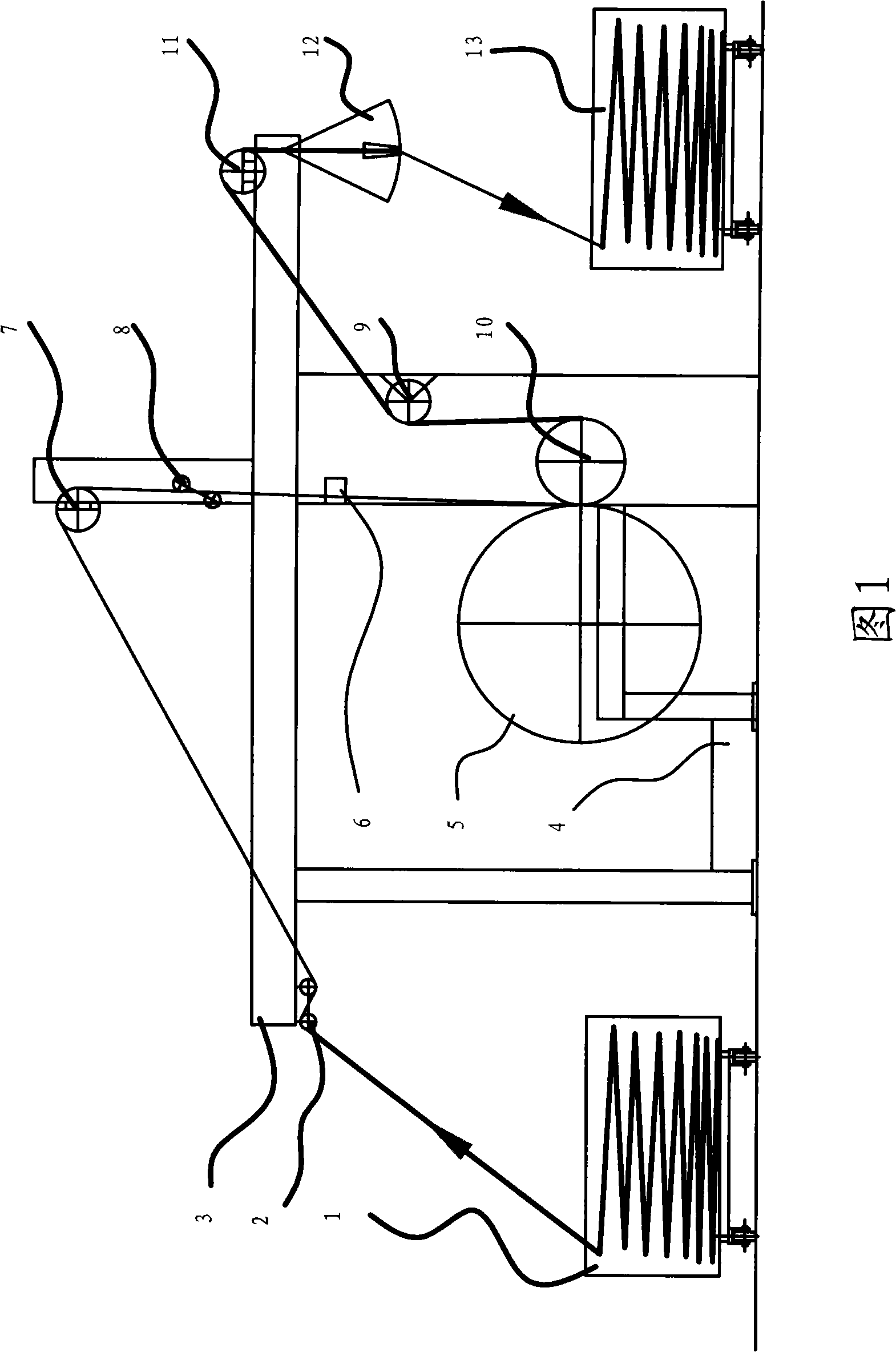

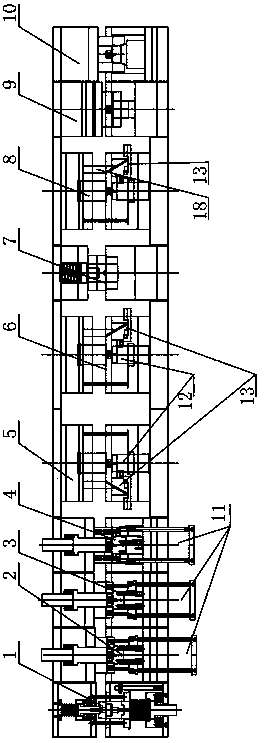

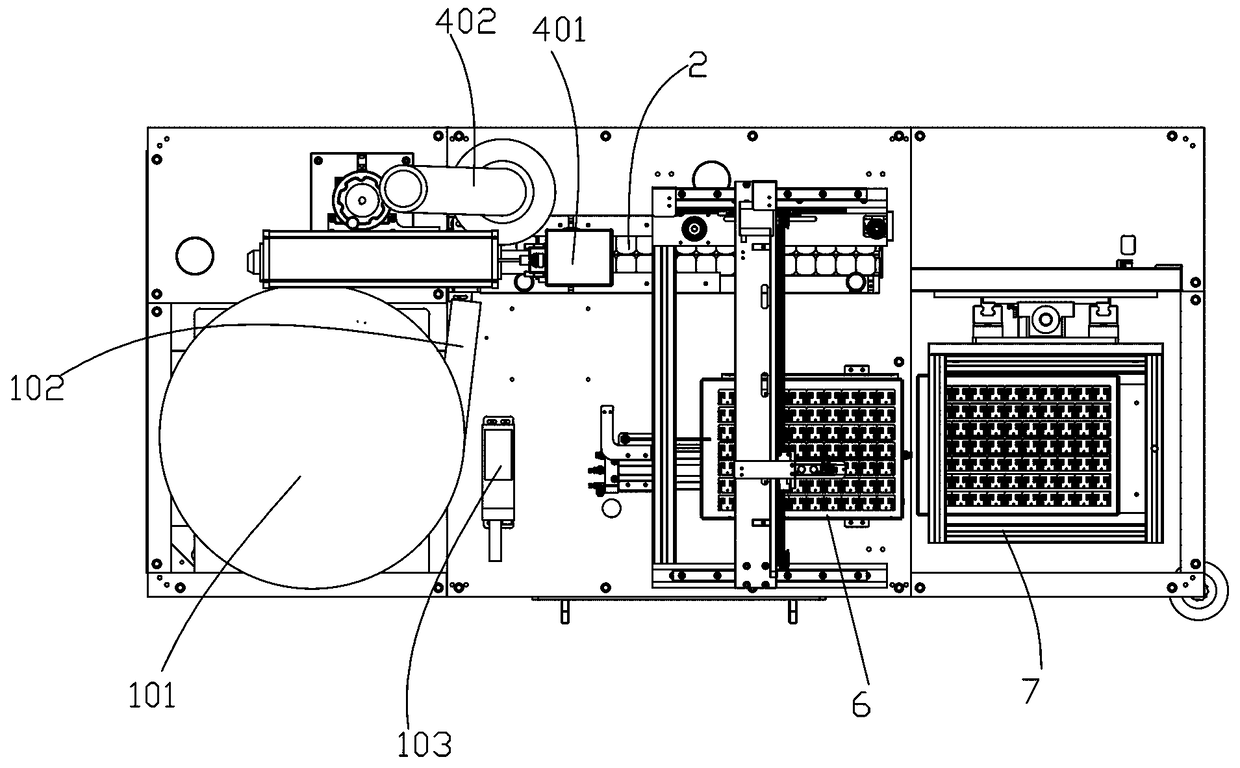

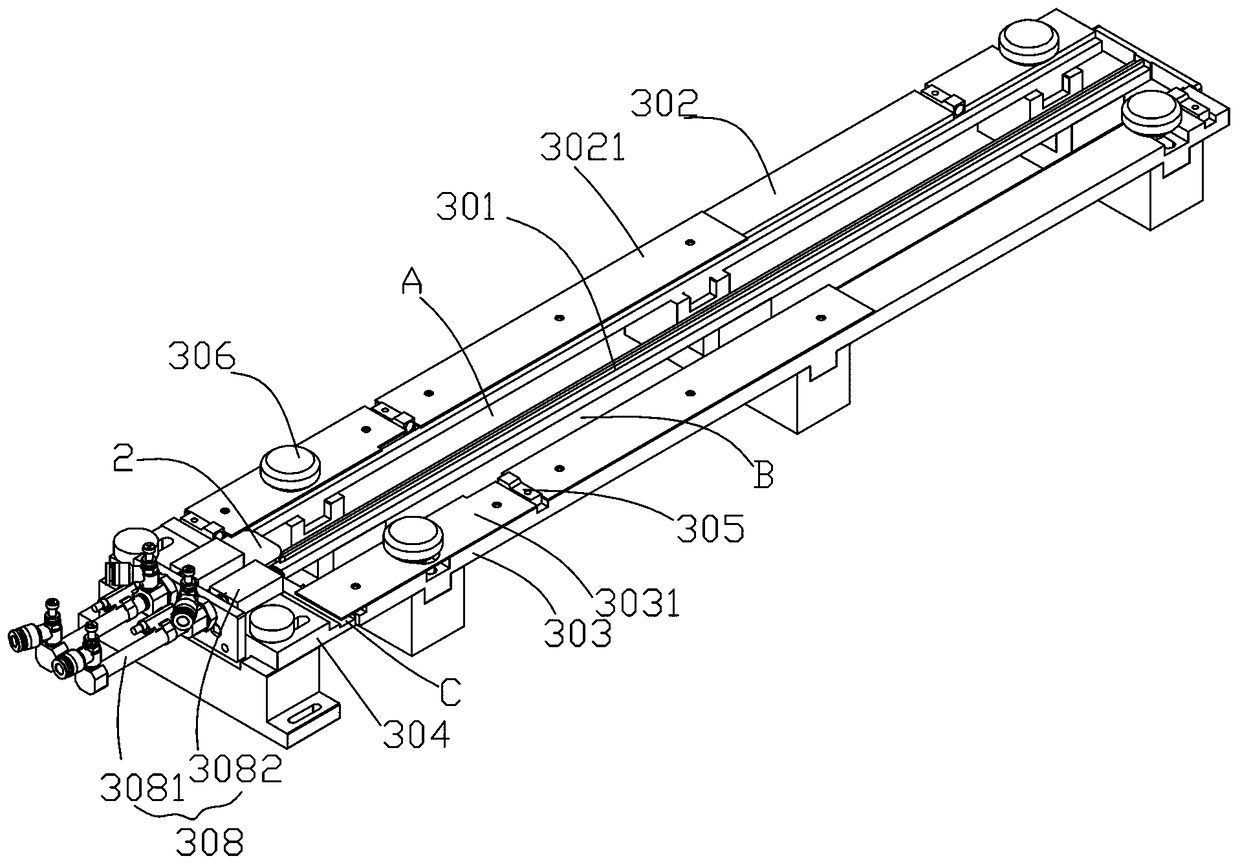

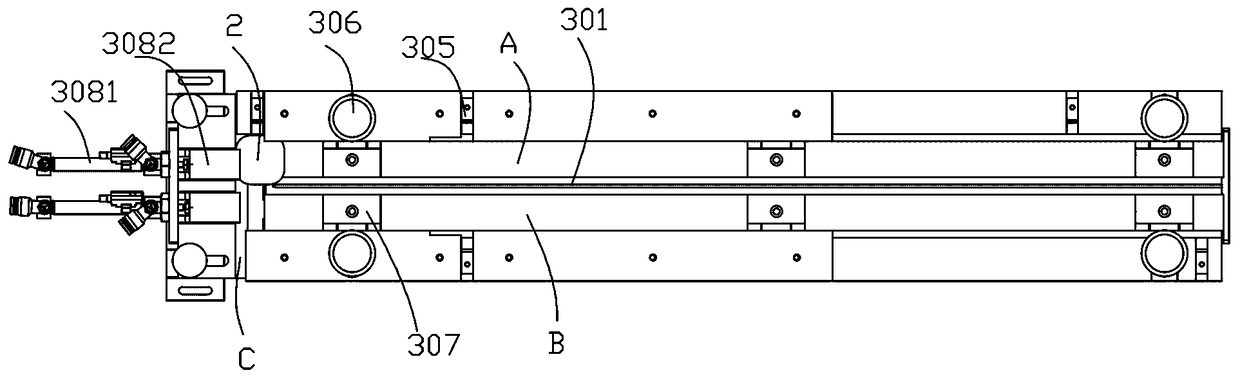

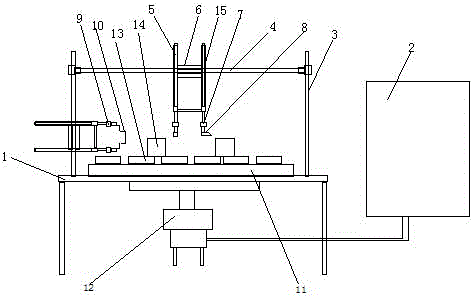

Automatic edge cutting method for plant fiber molding product and automatic edge cutting machine

ActiveCN103042639AAccurate cutting edge positioningHigh speedMetal working apparatusFiberEngineering

The invention relates to an automatic edge cutting method for a plant fiber molding product and an automatic edge cutting machine. The purposes are that the method has the characteristic of automatic and accurate location, and the automatic cutting machine has the characteristic of stable work. The technical scheme includes that the automatic edge cutting method for the plant fiber molding product proceeds as follows: 1), sucking the product with edges to be cut; 2), driving away waste edges from an edge cutting position; 3), positioning the product to be cut and a product with cut edges respectively; 4), cutting out deckle edges; 5), enabling a front row and a rear row of sucking disk sets to reach the corresponding positions respectively; and 6), sucking the product with edges to be cut and the product with cut edges; repeating from the step 2) to the step 6), and proceeding the circulation over and over again. The automatic edge cutting machine for the plant fiber molding product comprises an edge cutting and die assembly mechanism, wherein the edge cutting and die assembly mechanism comprises an upper edge cutting mold, a lower edge cutting mold, an upper installation plate, a lower installation plate and a power mechanism. The automatic edge cutting machine for the plant fiber molding product is characterized in that a product transferring mechanism and a waste edge moving out mechanism are also arranged on the automatic edge cutting machine.

Owner:EURASIA EP MACHINERY +1

Quick fermentation process of bagasse and method for preparing float breeding matrixes through bagasse

InactiveCN104012336AShorten fermentation timeUse fast turnaroundCultivating equipmentsFertilizer mixturesMicroorganismBrown coal

The invention provides a quick bagasse fermentation process and a method for preparing float breeding matrixes through bagasse. The method includes the implementing steps that sugar mud and brown coal are added into the smashed bagasse and are mixed evenly, then the carbon-nitrogen ratio is adjusted through nitrogenous fertilizers, the microorganism probiotic bacteria are added into the bagasse mixtures in proportion after being subjected to activating and propagating expanding and are mixed evenly to serve as fermentation materials, the fermentation materials are put into a fermentation tank, static fermentation is conducted for 50-60 days, decayed fermentation bagasse is obtained, the decayed fermentation bagasse is mixed with extrusion perlite and vermiculite are mixed in proportion, the float breeding matrixes are obtained after the mixtures are stirred evenly, and the moisture content of the adjustment matrixes ranges from 30% to 40%. By means of the method, the bagasse fermentation time is shortened by 44% to 67%, the fermentation time is short, the use cycle of the fermentation tank is short, the occupied field is small, the investment cost is low, the preparing yield is large, the benefits are high, the bagasse type float breeding matrixes can replace the method of grass carbon type float breeding matrixes, the exploit and utilization of non-renewable resources are reduced, and ecological benefits are remarkable.

Owner:YUNNAN SOURCE DAY BIOLOGY GRP CO LTD

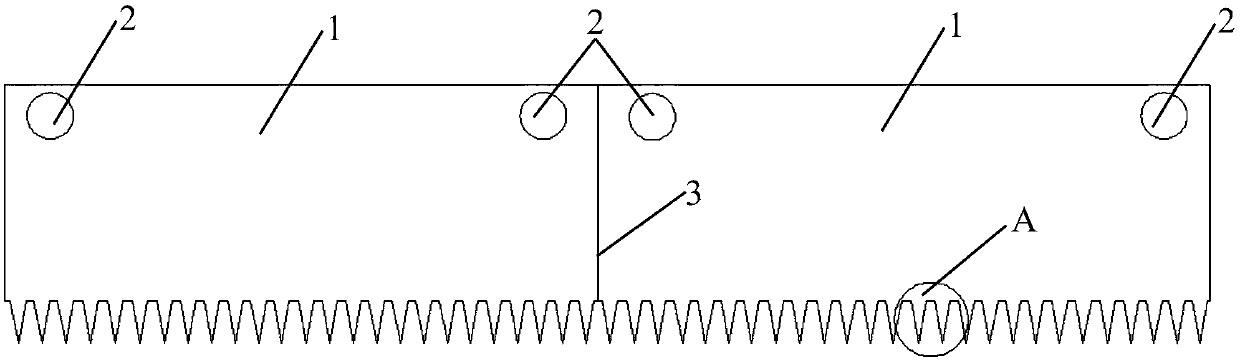

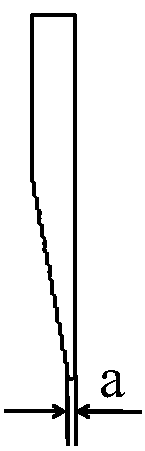

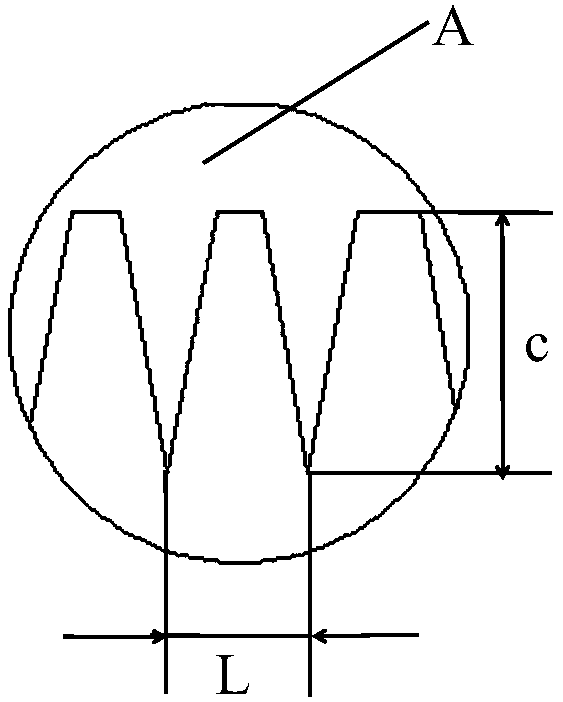

Serrated knife for high-speed carpet textile machine and machining method thereof

The invention discloses a serrated knife for a high-speed carpet textile machine. The serrated knife comprises a knife rest and a blade component, wherein the blade component comprises a plurality ofblade bodies; a plurality of sawteeth are arranged on one side of each blade body; the plurality of sawteeth are arranged at equal intervals; a plurality of mounting holes are formed in one side, farfrom the sawteeth, of each blade body; the plurality of blade bodies are detachably connected with the knife rest through the plurality of mounting holes; the end parts of the plurality of blade bodies are correspondingly spliced with one another; splicing lines are formed in spliced positions; the splicing lines are positioned at the roots of the sawteeth, so that the phenomena that the splicinglines have cracks at cutting edges of the splicing lines and the shearing quality of carpet fabric is reduced are avoided; meanwhile, the invention further discloses a machining method of the serratedknife. The serrated knife machined through the method is high in quality, sharp in cutting edges and long in service life, and improves the shearing efficiency of the carpet fabric.

Owner:昆山立达纺织实业有限公司

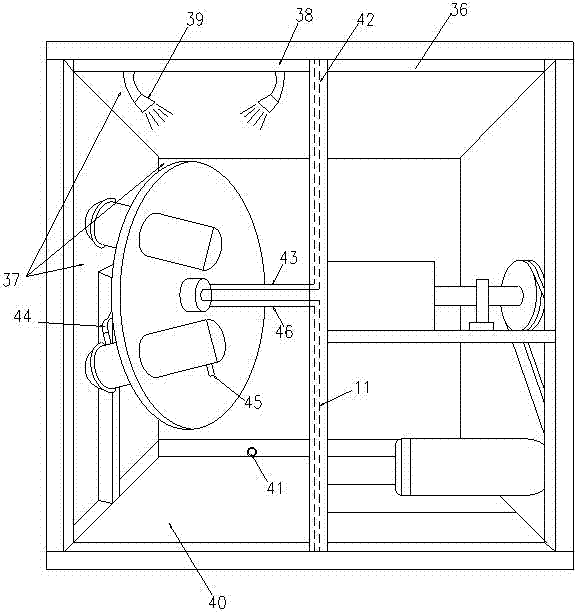

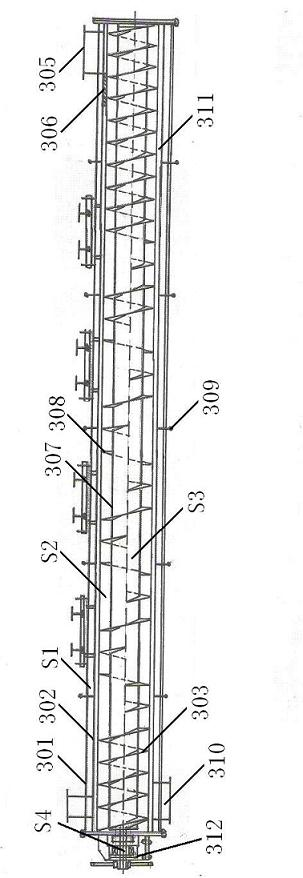

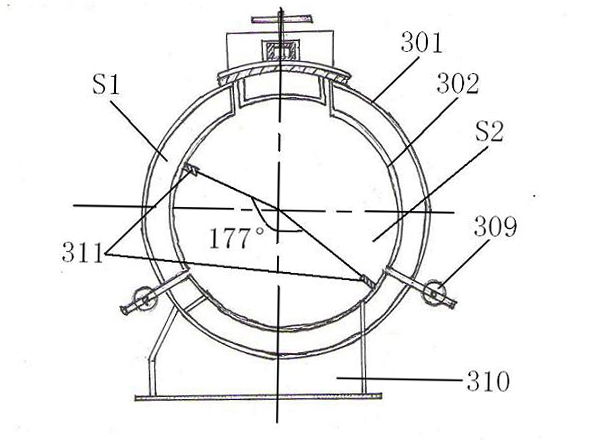

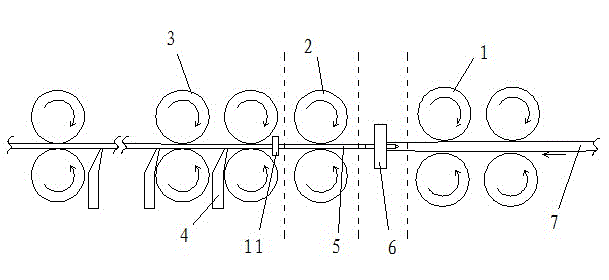

Multi-level flipping type proteopexy cooking machine and fishmeal machine

InactiveCN101926424AImprove processing outputNo raw meal phenomenonFood preparationElectricitySpiral blade

The invention discloses a multi-level flipping type proteopexy cooking machine and a fishmeal machine. The cooking machine comprises a cylindrical outer shell, a cylindrical inner shell, a heave dragon shaft, a feeding hole and a discharging hole, wherein the outer shell and the inner shell are coaxially sleeved; a confined space S1 is formed between the inner shell and the outer shell and is used for heating gases; both ends of the heave dragon shaft are respectively connected with a shaft head; the feeding hole is arranged on one end of the outer shell, and is communicated with an inner cavity S2; the discharging hole is arranged on the other end of the outer shell, and is communicated with the inner cavity S2; and a plurality of half-leaf spiral blades are arranged on the heave dragon shaft. The fishmeal machine comprises a multi-level flipping type proteopexy heating cooking machine, a heating type forced fat separation squeezing machine, a fishmeal drying chamber and a fishmeal sifting machine, which are sequentially connected. The invention has the advantages of stable mechanical property, simple and convenient operation, high security, electricity saving, no noise, large output, product purity, and simple and convenient maintenance, repair, installation and debugging.

Owner:孙仁和

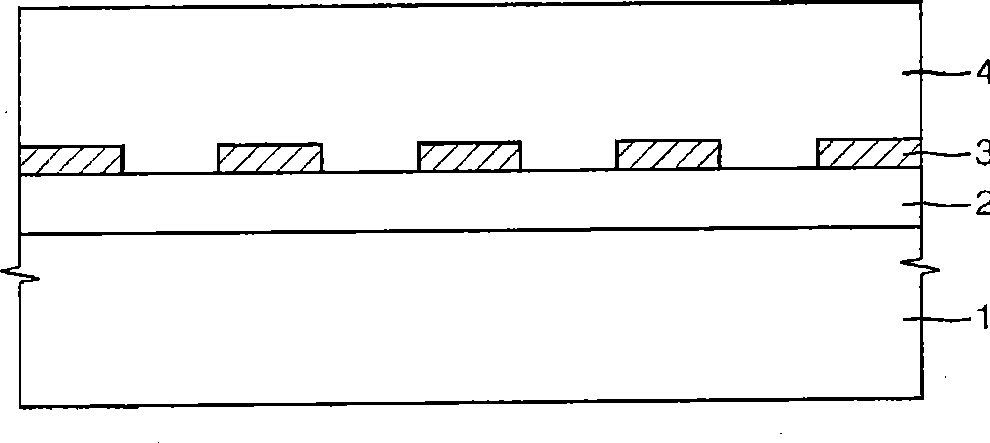

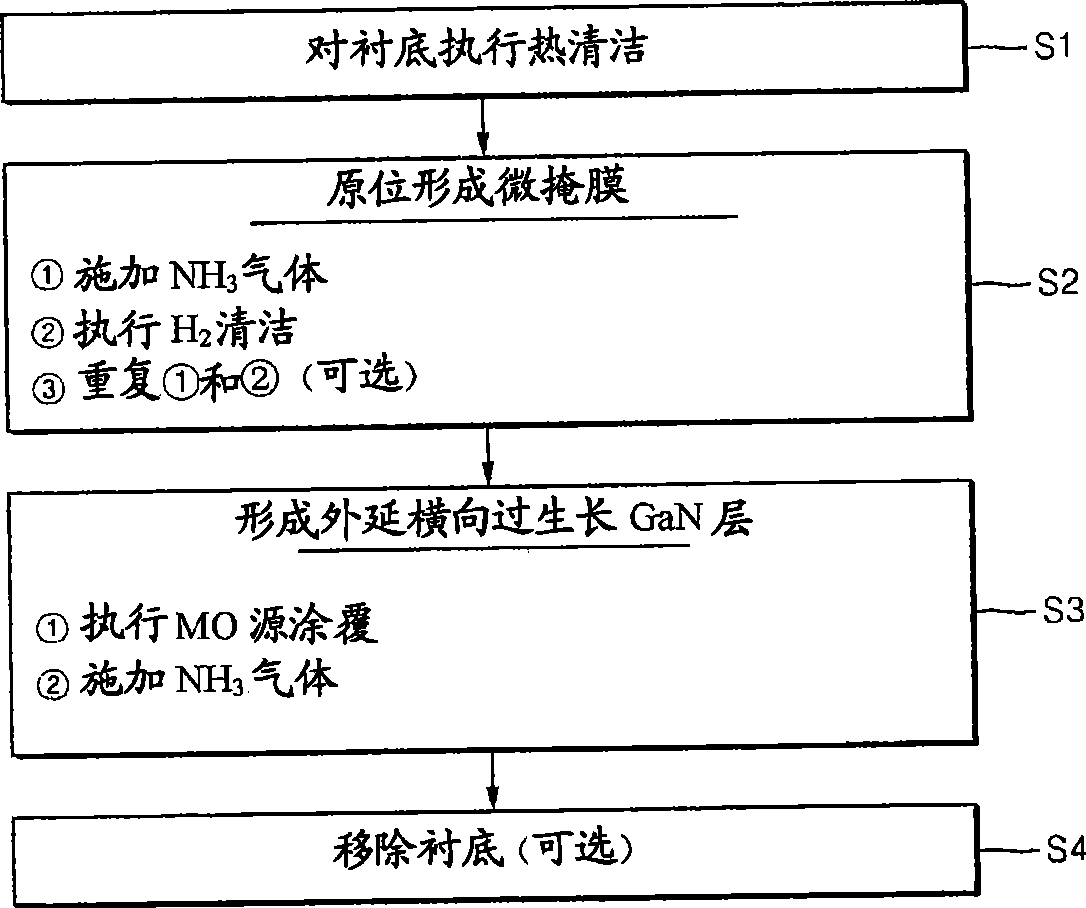

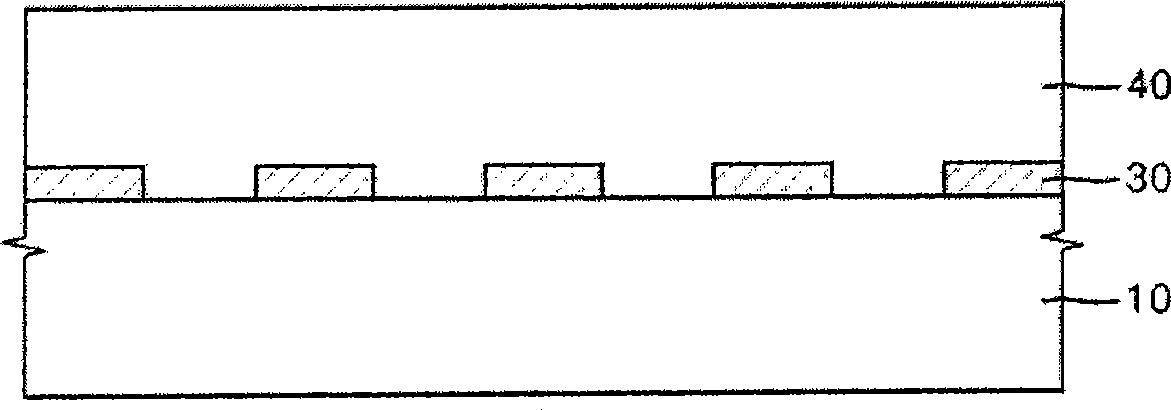

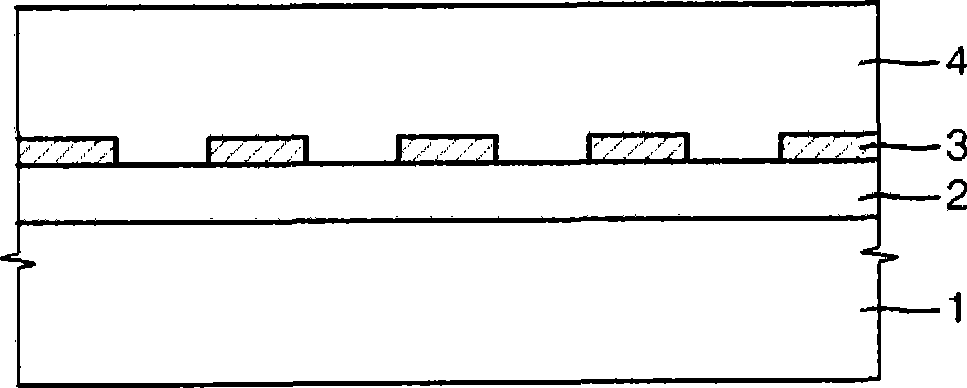

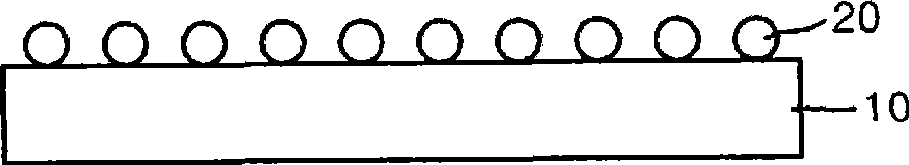

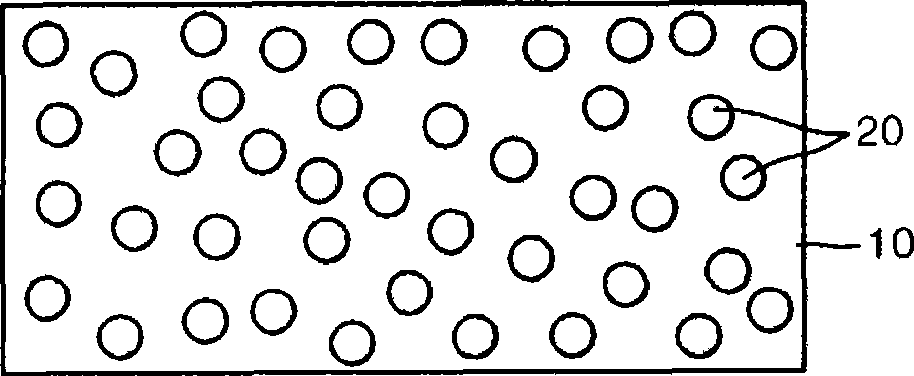

Method for preparing substrate for growing gallium nitride and method for preparing gallium nitride substrate

ActiveCN101388338AEliminate economic effectsAvoid time costPolycrystalline material growthSemiconductor/solid-state device manufacturingLateral overgrowthGallium nitride

Provided is a method for preparing a substrate for growing gallium nitride and a gallium nitride substrate. The method includes performing thermal cleaning on a surface of a silicon substrate, forming a silicon nitride micro-mask on the surface of the silicon substrate in an in situ manner, and growing a gallium nitride layer through epitaxial lateral overgrowth using an opening in the micro-mask. According to the method, by improving the typical ELO, it is possible to simplify the method for preparing the substrate for growing gallium nitride and the gallium nitride substrate and reduce process cost.

Owner:LG SILTRON

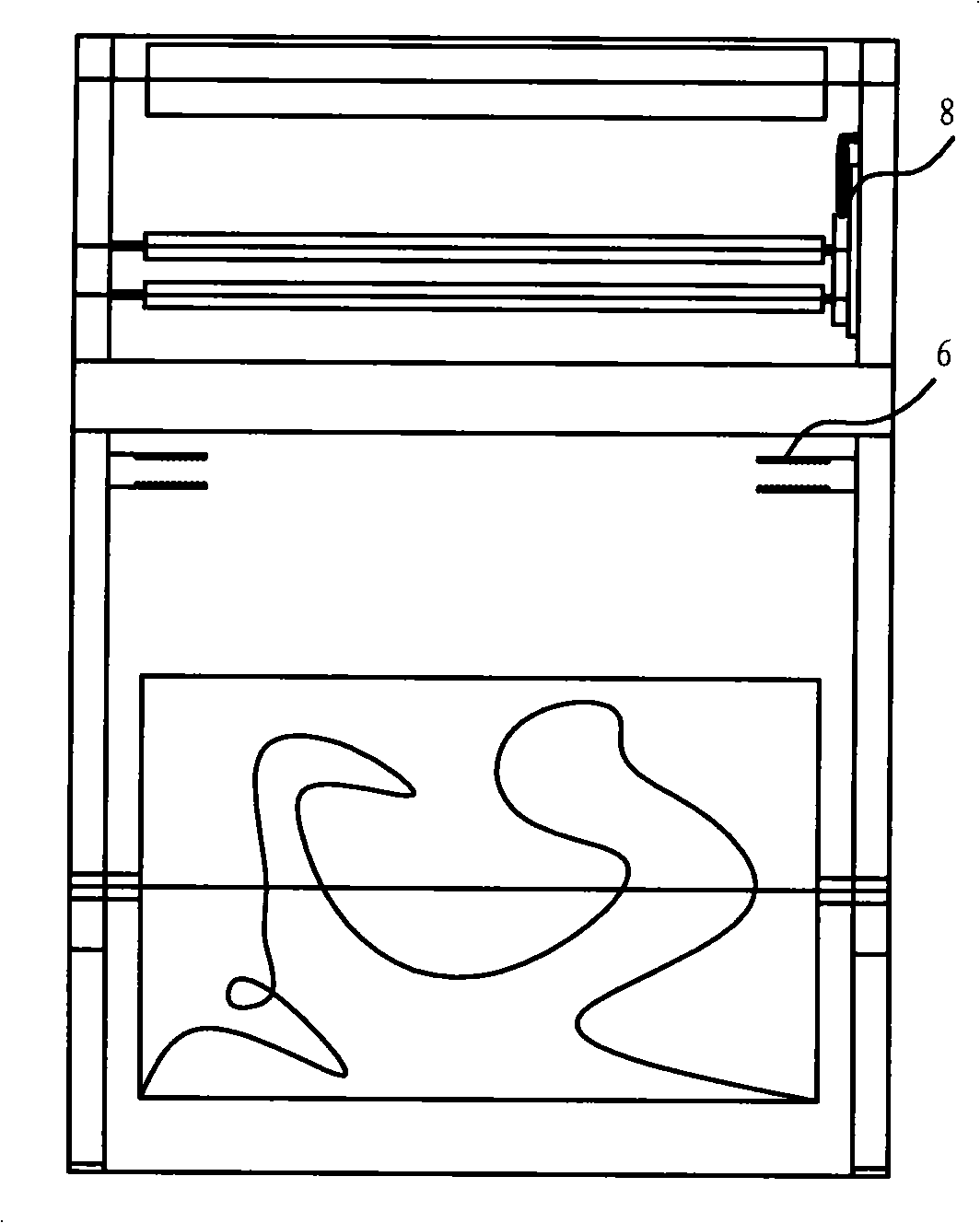

Printing and embossing machine and printing and embossing method thereof

ActiveCN101311402AKeep closedNo longitudinal deformationPattern makingWebs handlingBlanketElectric heating

The invention relates to a production method of fabric and production equipment thereof, in particular to an embossed printing machine for manufacturing embossed printing blankets with an automatic centering device and an embossed printing method thereof. Aiming at the existing electric heating printing machine, the technical improvement of the invention realizes grey cloth always to keep superposing with the center of a design plate in the advancing process, reduces the design difference and edge press leakage and improves the certified product rate. The main content of the invention is that the embossed printing machine comprises a cloth feeding machine, a frame, an embossed die roller, a draw-out roller and a cloth accepting cart. The embossed printing machine further comprises a cloth feeding tension adjusting device, an electronic automatic tracking centering device and a draw-out cooling device.

Owner:ZHEJIANG TRUELOVE GROUP

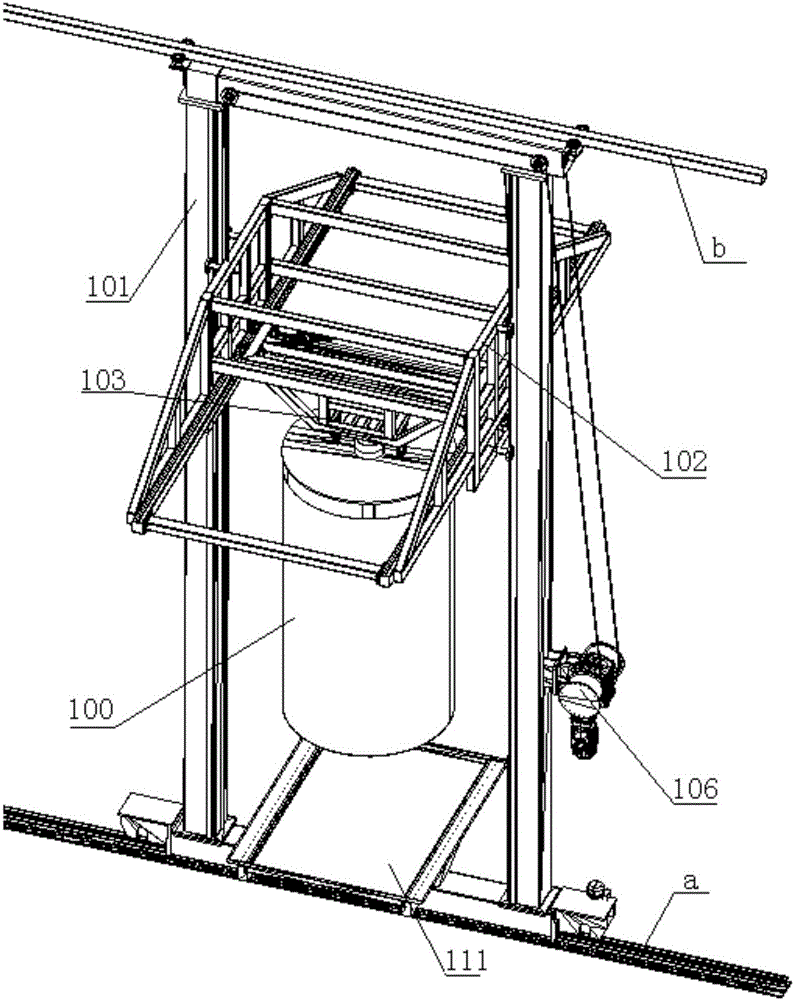

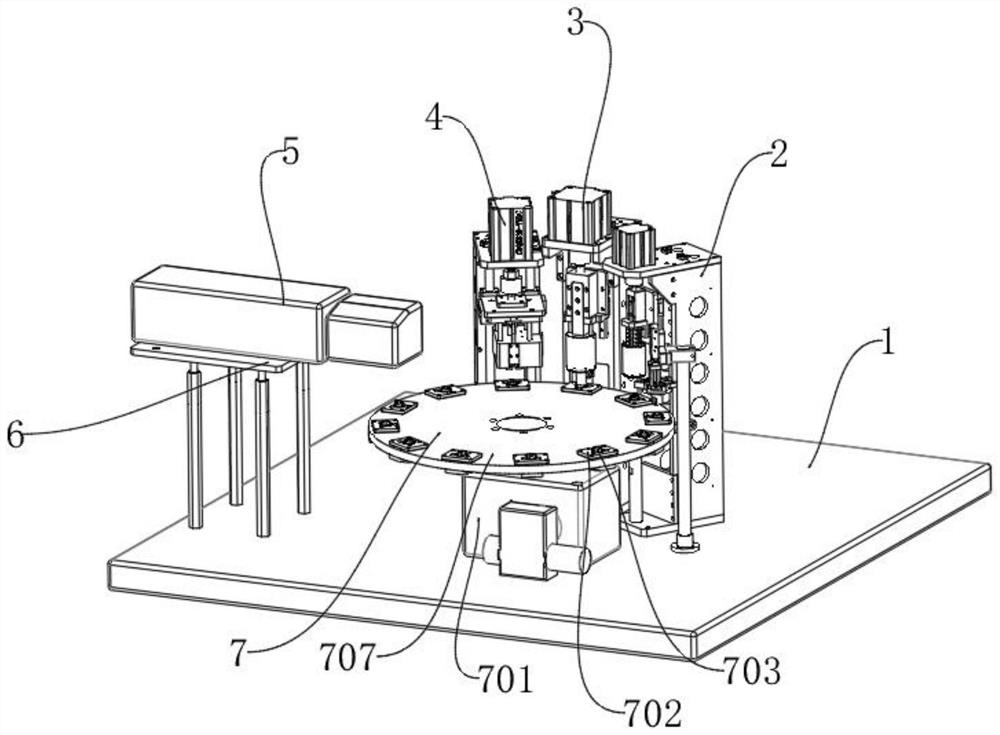

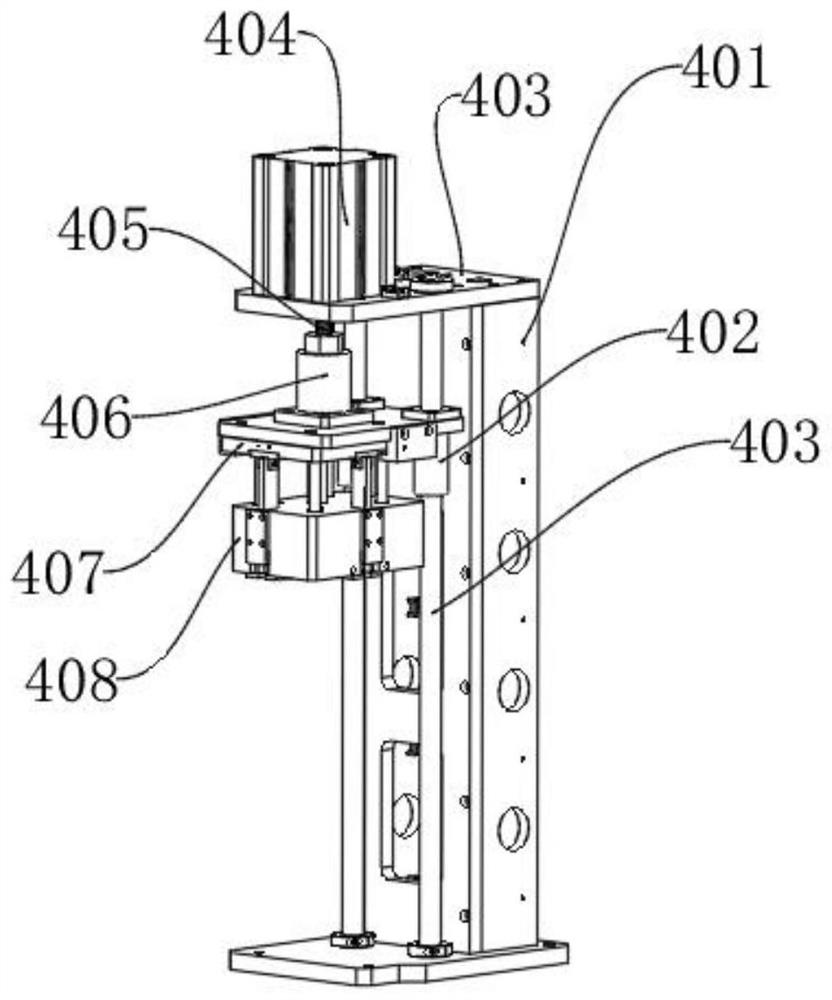

Medicine basket extracting machine and medicine basket extracting control system

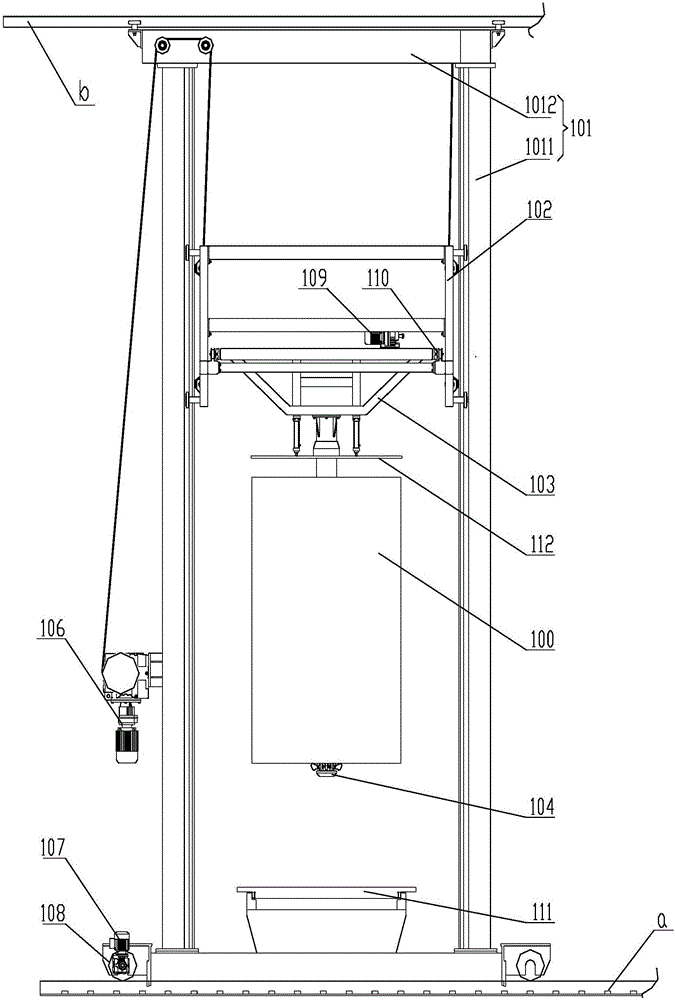

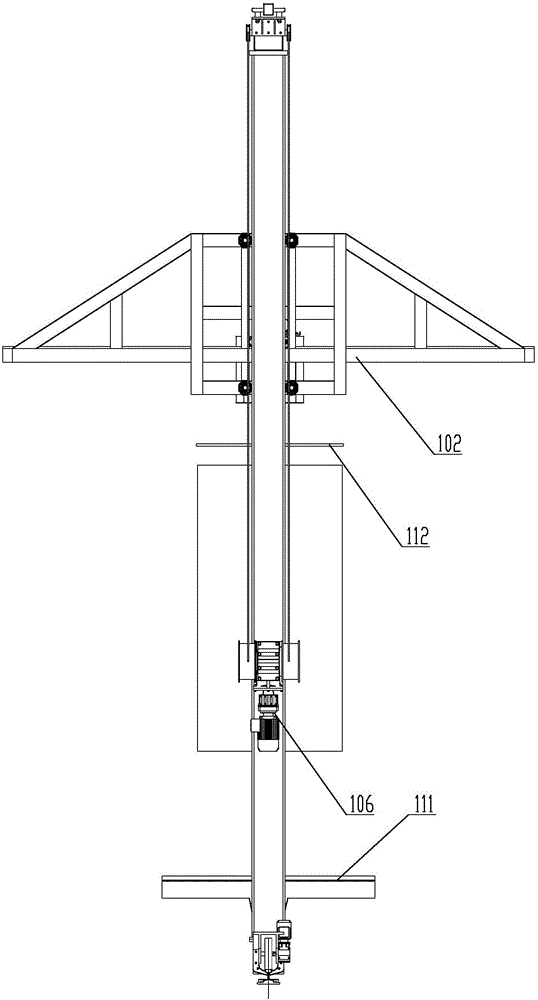

ActiveCN106044575AReduce labor intensityImprove processing outputTrolley cranesLoad-engaging elementsControl systemProcess engineering

The invention discloses a machine basket extracting machine and a machine basket extracting control system. The medicine basket extracting machine comprises a main frame. The main frame is provided with an extracting device, a first drive device and a second drive device. The first drive device is used for driving the extracting device to relatively move relative to the main frame in the horizontal direction and the vertical direction. The extracting device is provided with an extracting part conducting grabbing in cooperation with a medicine basket set. The second driving device is used for driving the extracting part to act to enable the extracting part to be matched with the medicine basket set to be in a grabbing state, and the second driving device is used for driving the extracting par to act to enable the extracting part to be in a non-grabbing state. The medicine basket extracting machine can be used for extracting the medicine basket set from a traditional Chinese medicine extracting tank and conveying the medicine basket set to a next station, the labor intensity of workers is greatly lowered, the machining yield is increased, and automatic production and intelligent management are facilitated. In addition, the medicine basket set is extracted from the traditional Chinese medicine extracting tank through the mechanical equipment so that the traditional extracting quality can be ensured.

Owner:SHINVA MEDICAL INSTR CO LTD

Preparation and use method of plant enzyme prepared from agricultural product residual fruits

InactiveCN108513996AReduce manufacturing costImprove processing outputBiocidePlant growth regulatorsHigh concentrationGrowth plant

The invention belongs to the technical field of agricultural production, relates to a plant growth regulator and especially relates to preparation and a use method of plant enzyme prepared from agricultural product residual fruits. The technological method comprises the steps: 1, preparing a nutritional material; 2, performing expanding propagation on enzyme microorganism; 3, preparing a raw material; 4, performing expanding propagation on culture; 5, manufacturing ferment powder; 6, manufacturing enzyme. The plant enzyme disclosed by the invention is prepared by fermenting non-commercial agricultural product residual fruits of melons, tomatoes and the like, so that production cost is low, and a processing yield is large; the prepared natural enzyme has the advantages of high concentration, high activity, more safety in use, ability in effectively promoting plant growth and ability in improving product quality.

Owner:宁夏中青农业科技有限公司

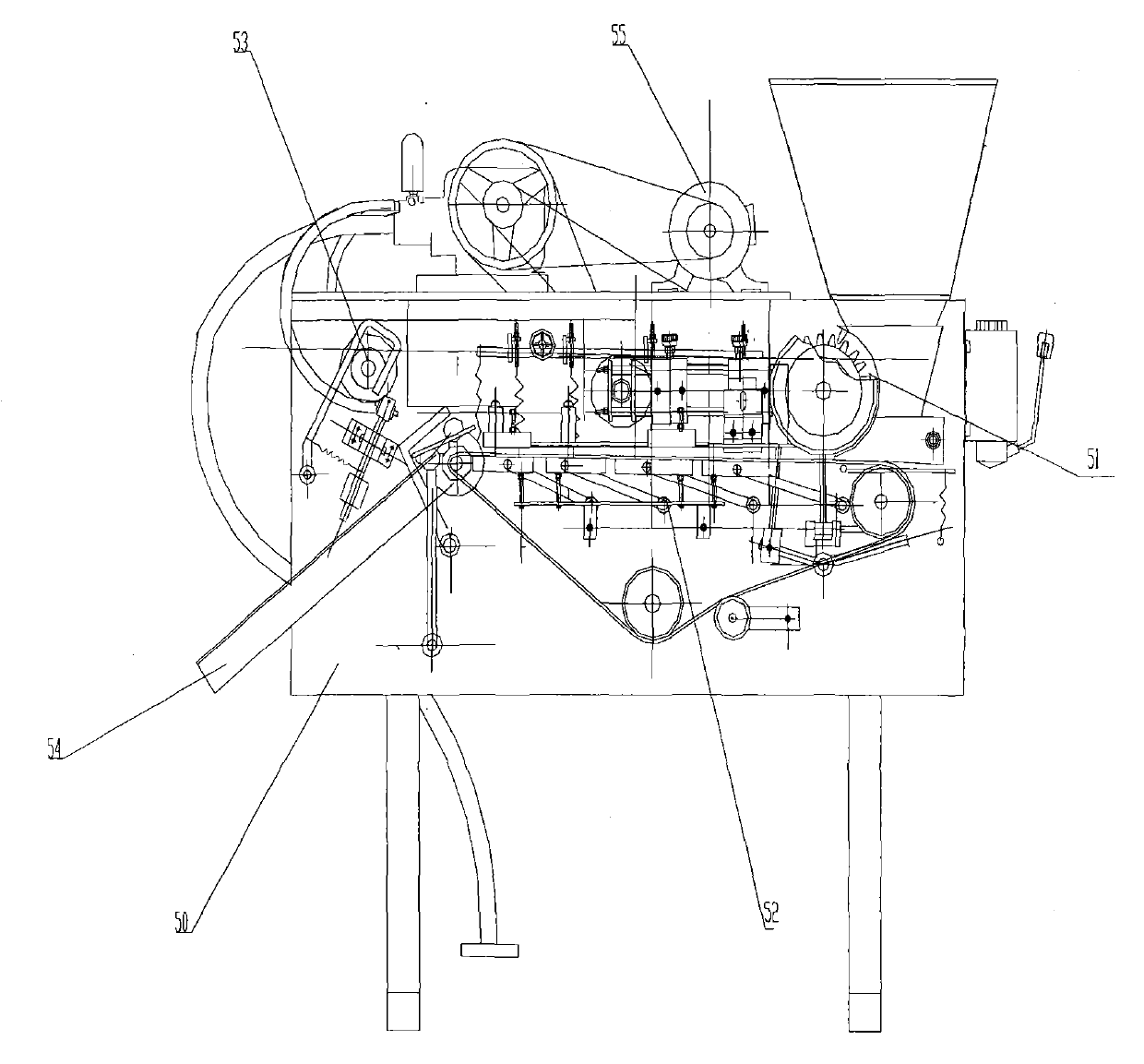

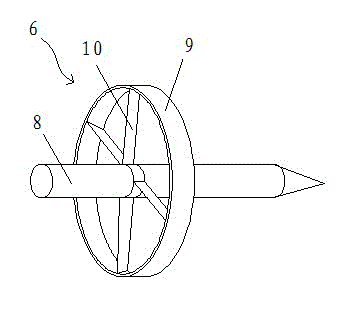

Integrated husking and peeling machine for lotus seeds

The invention discloses an integrated husking and peeling machine for lotus seeds. The integrated husking and peeling machine comprises a machine frame, wherein a feeding device, a husking device, a peeling device, a discharging device, a cam transmission mechanism and a conveying device are arranged on the machine frame; the machine frame comprises two wallboards; a conveying belt is positioned on the outer sides of the two wallboards; the cam transmission mechanism is mounted between the two wallboards and comprises a feeding cam, a water baffle cam and a discharging cam; the feeding cam, the water baffle cam and the discharging cam are mounted on a cam shaft respectively; the cam shaft is rotatably mounted on the two wallboards; a conveying wheel is mounted at each of the two end parts, extending out of the wallboards, of the cam shaft. According to the integrated husking and peeling machine for the lotus seeds, provided by the invention, the service life of the cam transmission mechanism is longer, the machine transmission is stable, and the quality of the machined lotus seeds is higher.

Owner:贾金星

Method for preparing compound semiconductor substrate

ActiveCN101436531AReduce dislocation generationQuality improvementSemiconductor/solid-state device manufacturingDislocationSelf-separation

Owner:硅得荣株式会社

Lock support transferring die structure

The invention relates to a lock support transferring die structure which comprises a rack. A feeding device, a first drawing die, a second drawing die, a sizing pressure foot small die, a first side punching die, a second side punching die, a third side punching die, an edge shearing die, a punching and typing die and a rolling foot small die. A sensor is arranged in the feeding device, the middles of the dies are used for conveying workpieces through conveying belts, clamps for clamping the workpieces are arranged in the middle positions of the sets of dies, and each single set of die structurally comprises an upper die assembly and a lower die assembly. The upper die assemblies are provided with male die assemblies through nitrogen spring material pressing assemblies, lower die seats of the lower die assemblies are installed on female die assemblies matched with the male die assemblies, and the lower die assemblies are further provided with lower air cylinder material jacking assemblies. Machining is easy and convenient, and the working efficiency is improved and is high.

Owner:无锡市振华亿美嘉科技有限公司

Preparation method of methyl pheophorbide-a

The invention belongs to the field of chemical pharmacy synthesis. More particularly, the invention relates to a preparation method of methyl pheophorbide-a, and an application of the methyl pheophorbide-a obtained by the method to preparation of a photosensitizer. The method disclosed by the invention is economical, environment-friendly and high in primary processing amount, and the purity and the yield of the target product is high.

Owner:康俄(上海)医疗科技有限公司

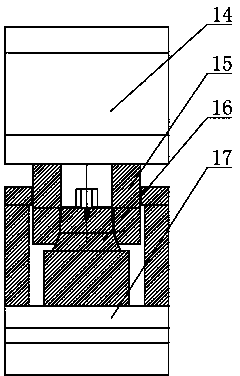

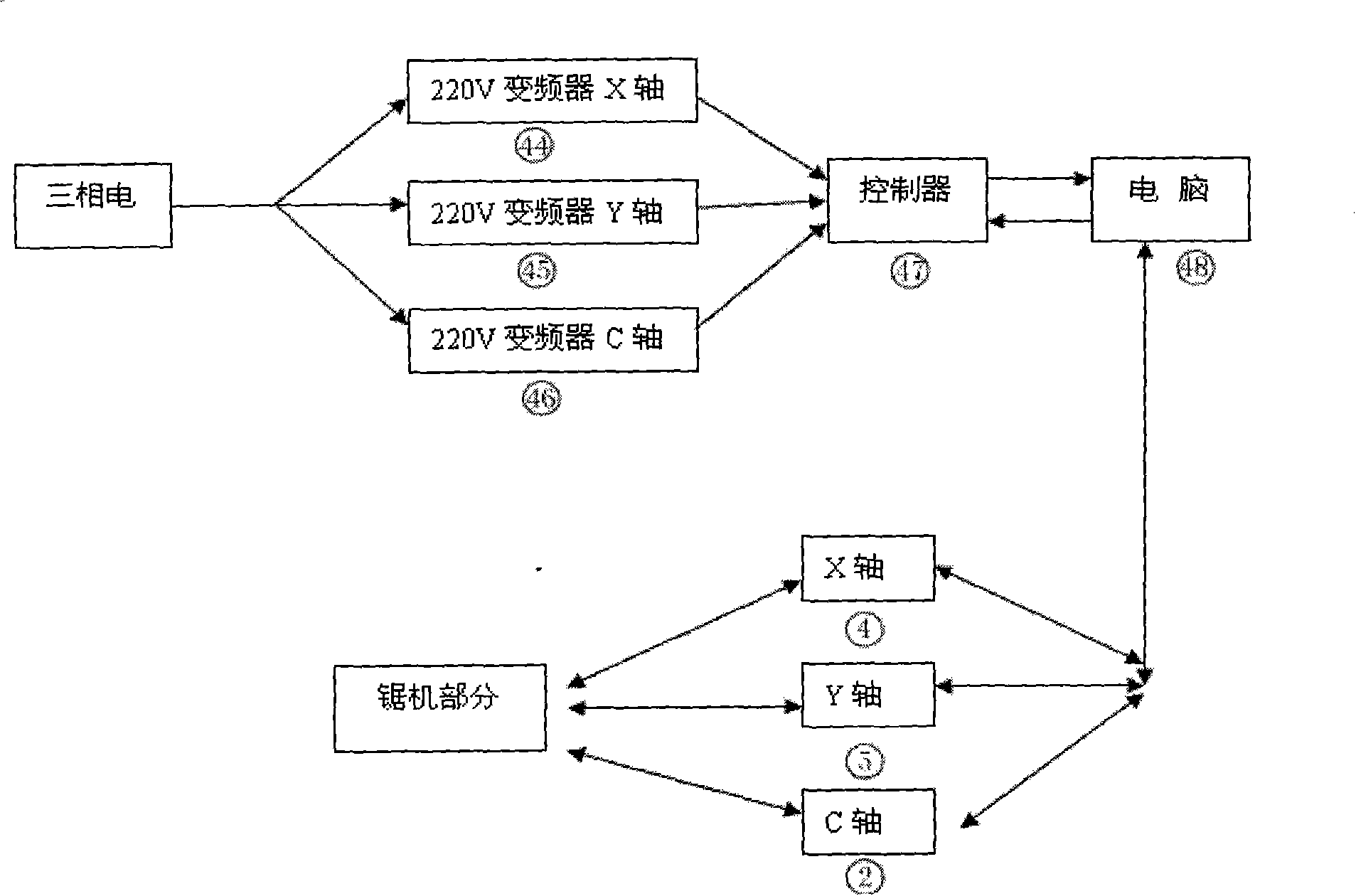

NC perforating machine for arc plank

InactiveCN102049881AIncrease demandConvenience needsPaper-makingBox making operationsNumerical controlComputer Aided Design

The invention relates to an NC (Numerical Control) perforating machine for an arc plank, which is characterized in that servo technology, two- dimension software CAD (Computer Aided Design) and three-dimension software PORE (Pro-Engineer) are adopted to perform drawings for rotational motion of the arc plank for horizontally feeding to a machine, front / back reciprocating motion of a sawing machine, and motion of an advanced linear guide rail bearing and a precise rotating object, so that mechanical sawing and molding are completed at one time via commands applied in a computer without any manual operation, the quality is improved, the processing cost is lowered, the labor intensity is reduced, and the processing output is increased. By adopting the NC perforating machine for the arc plank manufactured according to the design scheme provided by the invention, a complete set of production process of arc dies from production, processing to sawing is completed, the single die production in the past is changed and patterns required by consumers can be processed at one time, so that the development of enterprises is expanded, the market requirements are promoted, the domestic demand is stimulated, and a leading role is played in wood processing industry.

Owner:张连玉

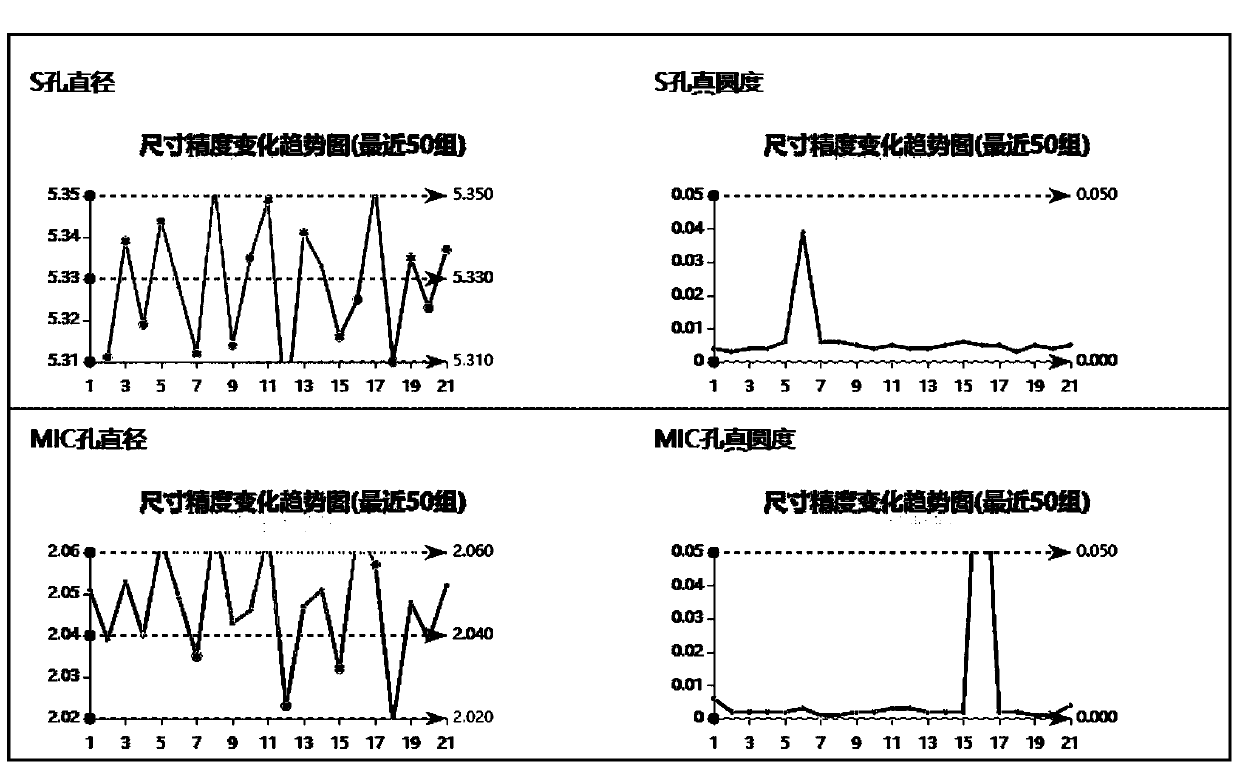

Cutter compensation and correction method and system of machine tool

ActiveCN111113268AImprove processing outputReduce machine set-up timeProgramme controlComputer controlCorrelation factorMachine tool control

A cutter compensation and correction method of a machine tool comprises the following steps that an abrasion wheel wear trend coefficient S is calculated; a correlation factor coefficient P of the influence of cutting force changes and abrasion wheel deflection on the machine tool control accuracy is calculated; a correlation factor M1 of the influence of the mechanical factor of the machine toolon the machining size is calculated; a first part actual compensation value M2 is calculated according to the effective machining diameter, deflection data and rigid deformation data of an existing abrasion wheel installed on the machine tool; the size of a product to be machined is measured, and the size deviation of the product is calculated; a cutter compensation value X is calculated through acompensation and correction algorithm according to the abrasion wheel wear trend coefficient S, the correlation factor coefficient P, the correlation factor M1, the first part actual compensation value M2 and the size deviation of the product; and when the product is machined by the machine tool, the cutter position is compensated and corrected according to the cutter compensation value X. By theadoption of the cutter compensation and correction method of the machine tool, the cutter position can be automatically compensated and corrected, the time adjustment time is shortened, the product yield can be improved, and the machining output of a machining facility is improved.

Owner:福建省嘉泰智能装备有限公司

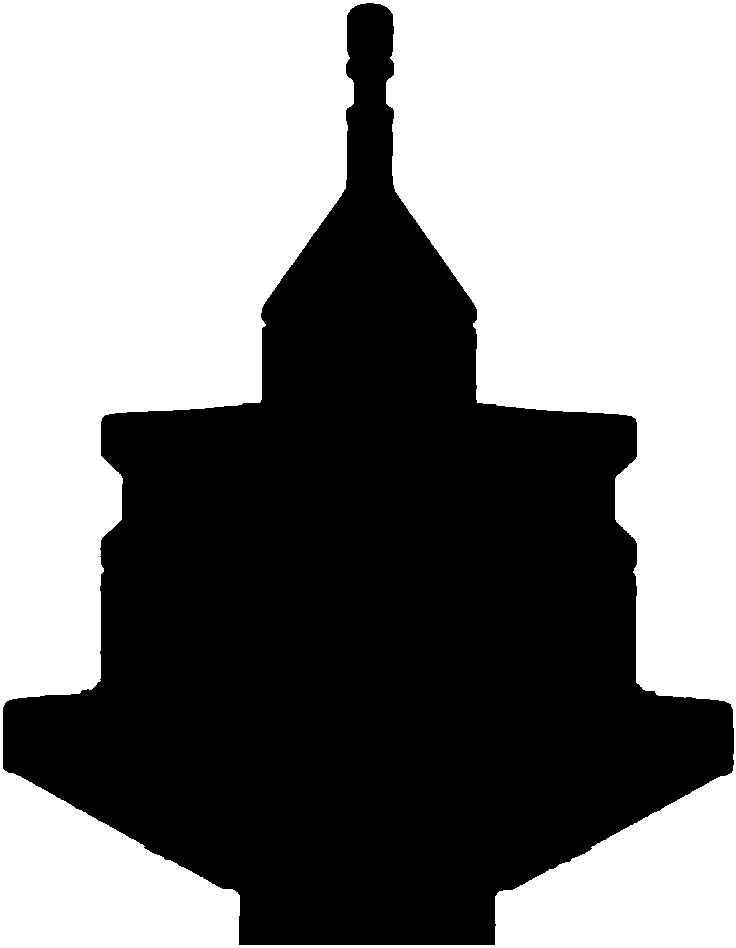

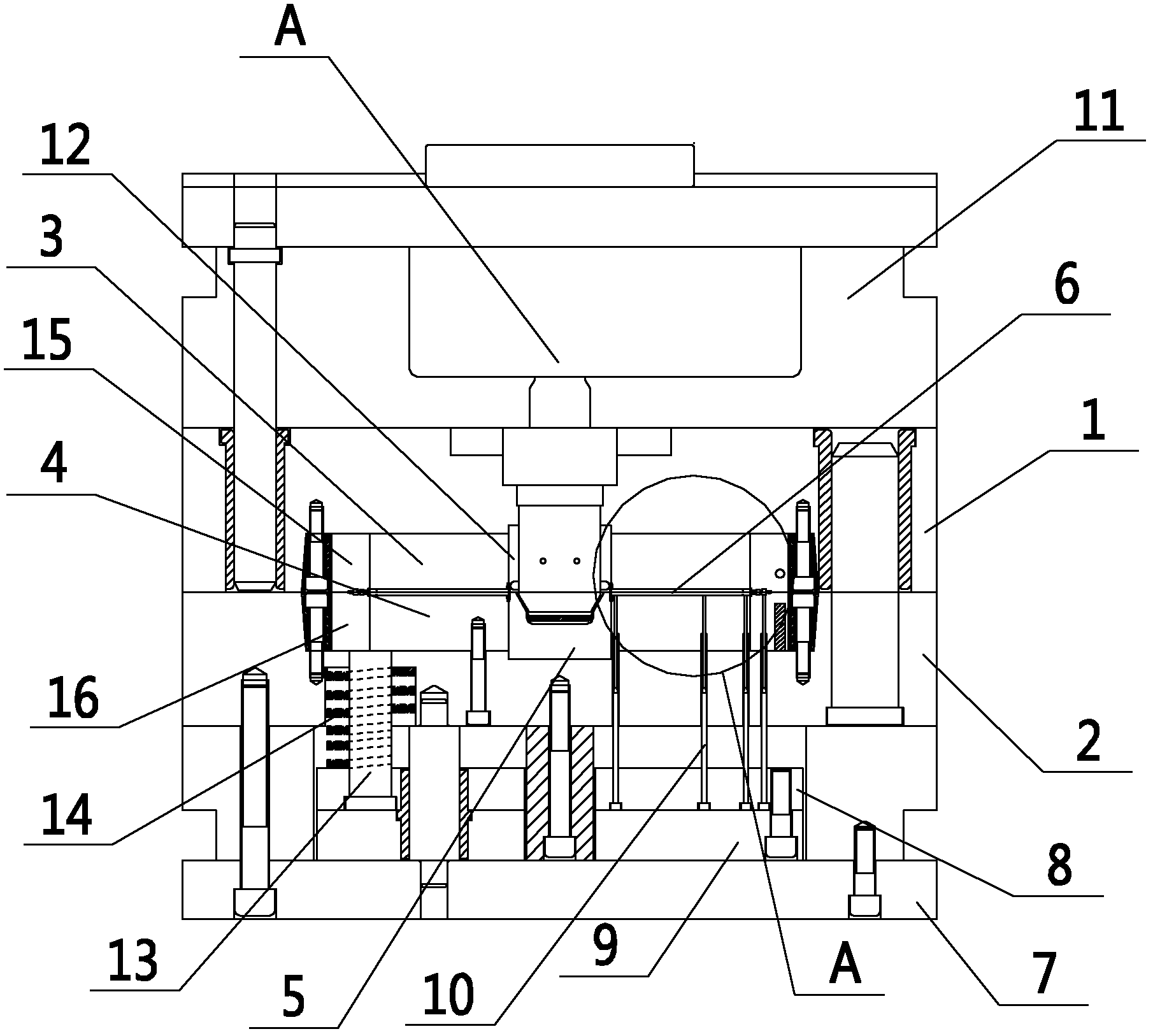

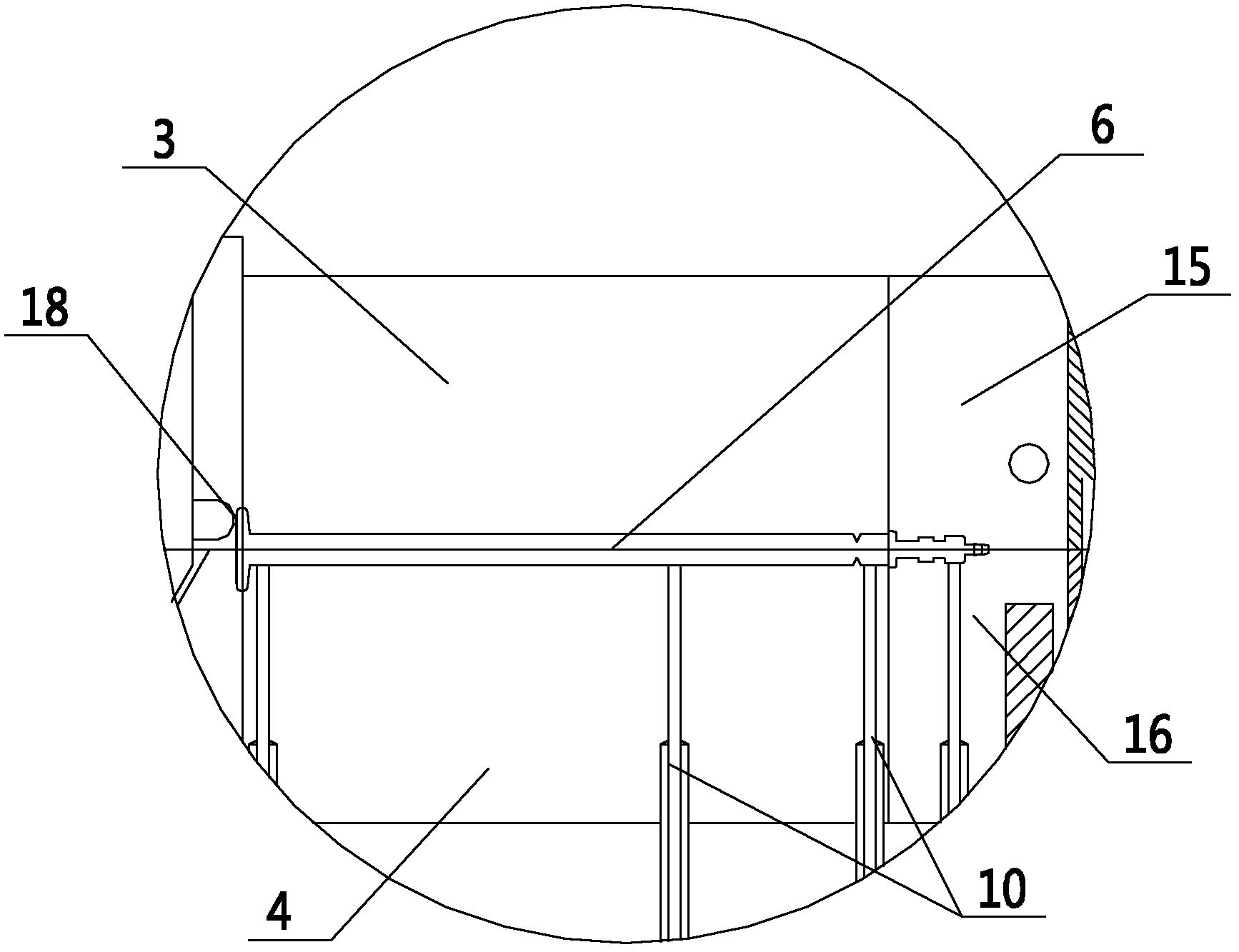

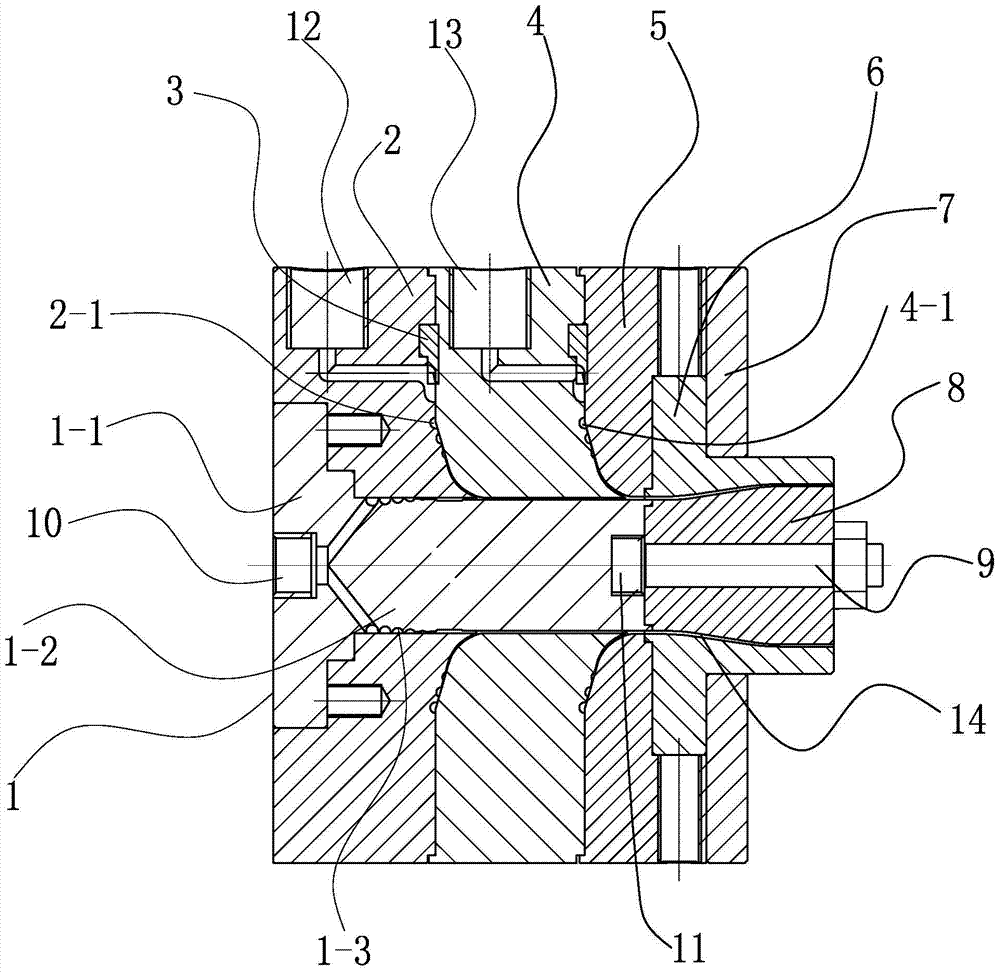

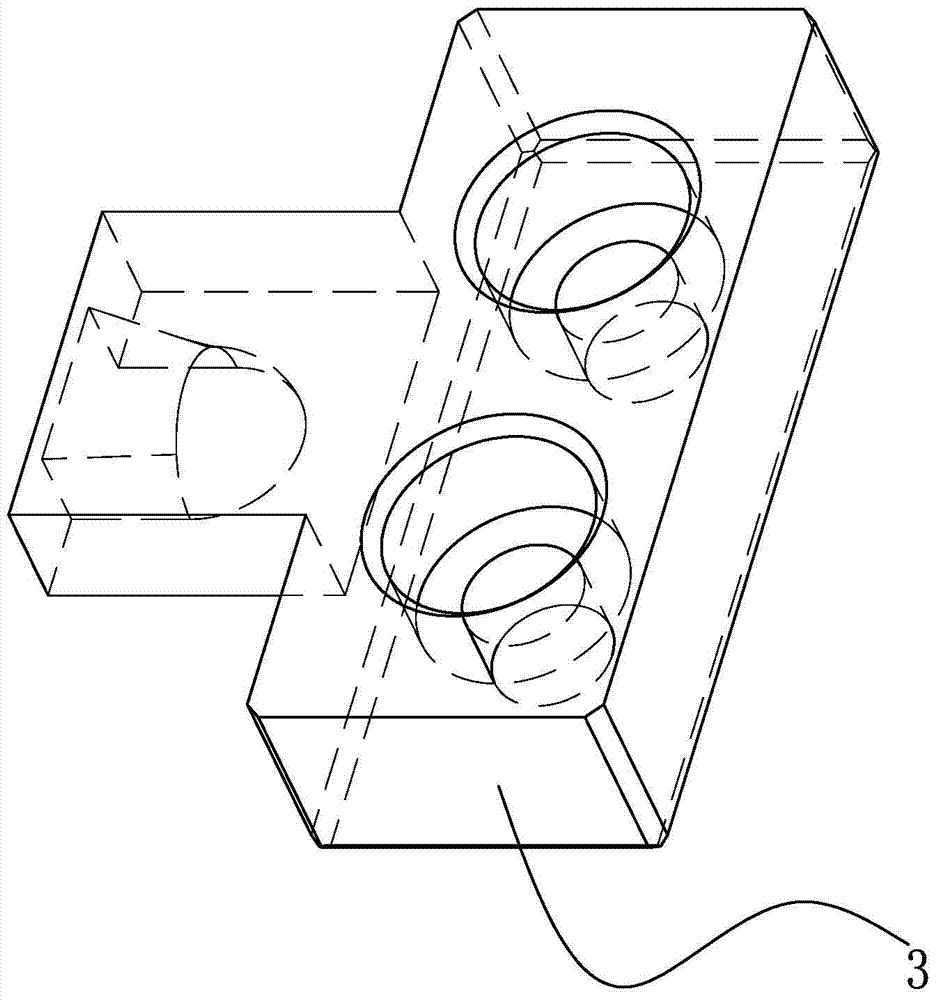

Injection mold for processing elongated push rod

The invention discloses an injection mold for processing an elongated push rod. The injection mold comprises four pairs of fixed mold kernels and movable mold kernels, wherein each pair of the mold kernels are uniformly distributed on mold plates; two movable mold intermediate insert blocks are arranged in the middle of the movable mold plate; fixed mold spray nozzle frames are arranged in corresponding positions on the fixed mold plate; a plurality of spray nozzles are arranged in each fixed mold spray nozzle frame; the spray nozzles are communicated with sprue gates of mold cavities; a hot melt in a hot runner system is injected into the mold cavities through the spray nozzles; a plurality of the mold cavities are arranged on each pair of the mold kernels, and each mold cavity is provided with a sprue gate; each mold cavity is formed by combining a plurality of pairs of insert blocks according to the thickness of an injection-molded piece; an ejection mechanism comprises a plurality of ejector rods; and the ejector rods are respectively arranged at the head ends and tail ends of the mold cavities, and two or more ejector rods are arranged at the middle parts of the mold cavities and the thick-thin transition sections of the mold cavities. The injection mold for processing the elongated push rod, disclosed by the invention, has a compact structure and can effectively improve the processing yield, improve the working efficiency and reduce the product rejection rate.

Owner:SUZHOU YAER PLASTIC TECH

A head body of a three-layer co-extrusion film blowing unit

ActiveCN105291399BRealization of film productionGood for high-speed compoundingFlat articlesLow-density polyethyleneComposite effect

Owner:嘉兴高正新材料科技股份有限公司

Cleaning equipment for elastic element of sensor and cleaning method thereof

The invention provides cleaning equipment for an elastic element of a sensor and a cleaning method thereof. The cleaning equipment comprises a controller, a material screening assembly, a material transporting assembly, a cleaning assembly and a material grabbing assembly. A discharging outlet of the material screening assembly communicates with a feeding inlet of the material transporting assembly, and the material grabbing assembly is arranged at the output end of the material transporting assembly. The material transporting assembly is provided with a material transporting channel for transporting the elastic element, and the channel direction of the material transporting channel is towards the X axis. The cleaning assembly includes a laser arranged above the material transporting channel. The material grabbing assembly is provided with an elastic element clamp, and the elastic element clamp grabs and transports the cleaned elastic element under the action of an X-axis driving assembly, a Y-axis driving assembly and a Y-axis driving assembly. According to the cleaning equipment for the elastic element of the sensor and the cleaning method thereof, manpower is replaced by machines, the labor cost is reduced, the machining output and machining quality are enhanced, and the environment pollution is reduced.

Owner:漳州汤姆森智能科技有限公司

Coloring agglomerate for polyethylene packing film and its prepn process

Owner:CHUNHUI PIGMENT MATERIAL XINTAI

Numerically controlled cutting and molding table for lost foam

InactiveCN104588583AImprove surface smoothnessImprove processing outputFoundry mouldsFoundry coresMechanical engineeringIndustrial engineering

The invention provides a lost foam numerically controlled cutting and molding table. The cutting and molding table comprises a cutting table, a numerically controlled controller, lost foam base fixing devices arranged in the cutting table, and a lost foam cutting and molding device arranged on the cutting table, and is characterized in that the lost foam cutting and molding device comprises a vertical cutting and molding device and a horizontal cutting and molding device. The cutting and molding table has the benefits that the cutting and molding table is simple in structure, and convenient to use; the manufactured lost foam is high in surface smoothness; the cutting and molding table is high in manufacturing yield, particularly suitable for manufacturing of mass lost foam, and safe in operation, and can efficiently prevent industrial accidents.

Owner:范继安

Process of pickled bamboo shoots

InactiveCN1679410AProtect freshnessProtect colorFood preservationFood preparationBamboo shootChemistry

A technology for preparing the preserved bamboo shoot includes such steps as preboiling the bamboo shoot, cooling in cold water, removing shells, shaping, washing, loading in cans, sterilizing, and storing. Before eaten, it is slightly dried for drying its surface, then fried in oil until it becomes golden, and finally cooked.

Owner:ZHEJIANG JINGNING NATURE FOOD

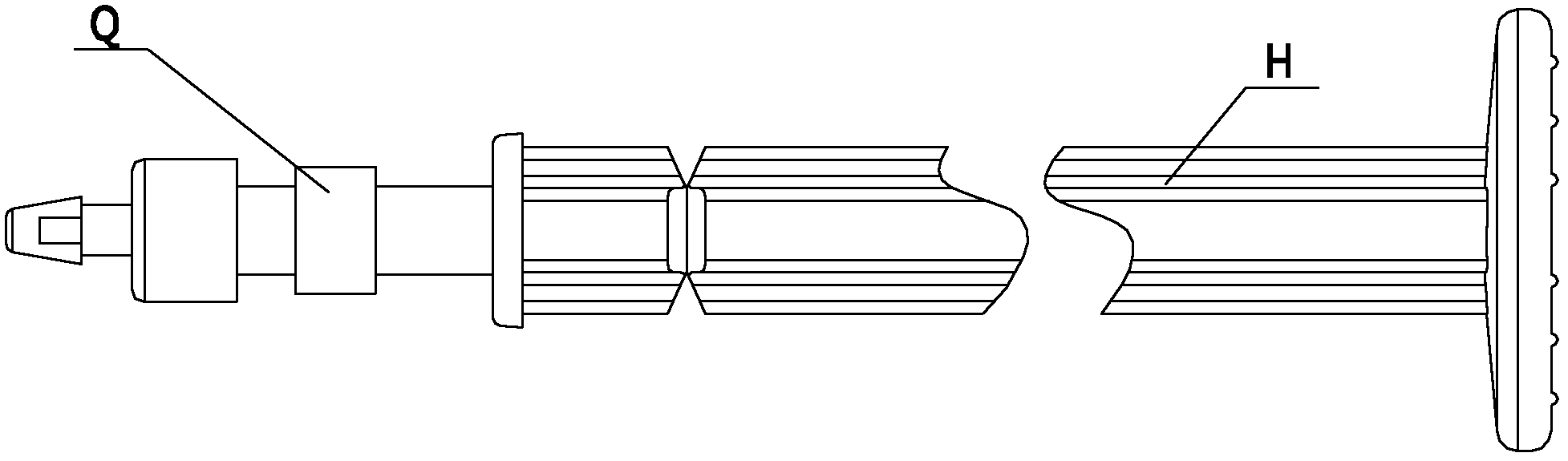

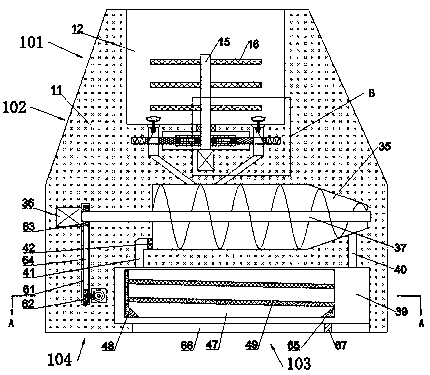

Lashing bar numerical control hydraulic high-speed horizontal forging machine and using method thereof

PendingCN108772521AImprove processing efficiencyImprove processing outputForging/hammering/pressing machinesForging press detailsNumerical controlHydraulic cylinder

The invention discloses a lashing bar numerical control hydraulic high-speed horizontal forging machine and a using method thereof. The lashing bar numerical control hydraulic high-speed horizontal forging machine comprises a base, wherein a spindle hydraulic cylinder placed horizontally is arranged at one end of the base, and guiding rods are arranged on the positions, located on the two sides ofa spindle piston rod of the spindle hydraulic cylinder, of the spindle hydraulic cylinder; the guiding rods are provided with mold bodies, the guiding rods and the spindle piston rod are coaxially arranged, and a supporting seat for fixing the guiding rods is arranged at the end, far away from the spindle hydraulic cylinder, of the base; the guiding rods include a pair of left guiding rods and apair of right guiding rods, and a plurality of left mold bodies are jointly disposed on the left guiding rods in a penetrating mode; and left mold cavities are vertically formed in the positions, facing the axis of the spindle piston rod, in the left mold bodies, and the left mold cavities are connected with an auxiliary hydraulic cylinder to drive the left mold cavities to move towards or away from the axis of the spindle piston rod; and correspondingly, a plurality of right mold bodies corresponding to the left mold cavities one to one are jointly arranged on the right guiding rods in a penetrating mode, and the right mold bodies are provided with right mold cavities and are connected with the auxiliary hydraulic cylinder. The lashing bar numerical control hydraulic high-speed horizontalforging machine can realize multi-stage forging rough on workpieces, and the spacing of the adjacent forged rough portions can be adjusted according to actual requirements.

Owner:NANJING AIMANDA SHIP EQUIP MFG

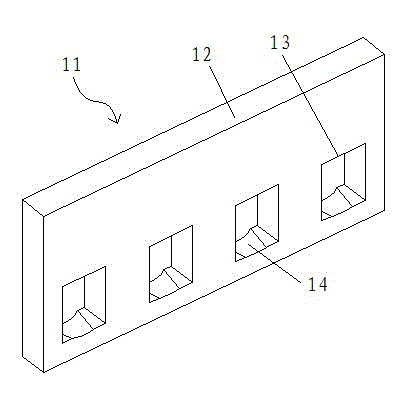

Automatic processing device of bamboo shavings

InactiveCN102941590ANovel structural designSimple and efficient operationMetal working apparatusAutomatic processingEngineering

The invention relates to the technical field of deep processing of bamboos, in particular to an automatic processing device of bamboo shavings. The automatic processing device comprises a material feeding device, a bamboo cutting device arranged at the outlet end of the material feeding device and used for processing the bamboos into bamboo sheets, a bamboo sheet driving device used for conveying the bamboo sheets processed by the bamboo cutting device to a bamboo shavings scraping device and a guiding device arranged between the bamboo sheet driving device and the bamboo shavings scraping device and used for controlling a feeding direction of the bamboo sheets entering the bamboo shavings scraping device. The guiding device comprises a cuboid-shaped guiding plate in which a plurality of square through holes are formed in parallel; and each square through hole is provided with an arc concave groove at the bottom end; the arc length of the two ends of each arc concave groove is unequal, so that the arc groove takes an inverted-V shape. The automatic processing device integrates the feeding operation, the bamboo cutting operation, the guiding operation, the positioning operation and the scrapping operation, so that high processing efficiency is achieved. Under double control of the bamboo sheet driving device and the guiding device, the bamboo sheets cut by the bamboo cutting device can slowly, stably and precisely enter the scrapping device so as to effectively increase the processing efficiency and the output of the bamboo shavings.

Owner:安徽霍山县吉元竹纤维有限公司

Efficient porcelain clay desanding separator

ActiveCN111299133AReduce complexityImprove sand removal efficiencySievingRotary stirring mixersPhysicsElectric machinery

The invention discloses an efficient porcelain clay desanding separator. The efficient porcelain clay desanding separator comprises a machine body, wherein the machine body is internally provided witha desanding device, the desanding device comprises a stirring cavity which is arranged on the upper end surface of the machine body and is provided with an upward opening, a rotating disc cavity is formed in the lower wall of the stirring cavity, a first motor is fixedly arranged in the lower wall of the rotating disc cavity, the upper end of the first motor is in power connection with a first rotating shaft, the upper end of the first rotating shaft extends into the stirring cavity, stirring rods are uniformly distributed and fixedly arranged on the circumferential end surface of the first rotating shaft, located in the stirring cavity, a liquid path opening and closing device is arranged in the desanding device, a vibrating device is arranged on the lower side of the desanding device, and a transmission device is arranged between the desanding device and the vibrating device. According to the efficient porcelain clay desanding separator, a liquid path can be automatically opened orclosed when stirring is carried out or after stirring of porcelain clay slurry is completed, the operation complexity is reduced, the desanding efficiency is high, and the desanding quality is good; and compared with a traditional processing technology, the processing efficiency and the yield are remarkably improved, the contents of manual operation are reduced, and the labor intensity is reduced.

Owner:南京棠邑科创服务有限公司

Agricultural machinery gear machining device and machining method thereof

PendingCN114131348ARealize automatic circulationReduce turnaround timeOther manufacturing equipments/toolsGear wheelAgricultural engineering

The invention discloses an agricultural machinery gear machining device and a machining method.The agricultural machinery gear machining device comprises a bottom plate, and a feeding assembly used for automatic feeding is installed above the bottom plate; a punching assembly used for machining the agricultural machine gear connecting hole, an inner hole grinding assembly used for grinding the connecting hole and a cleaning assembly used for cleaning burrs of the agricultural machine gear connecting hole and the outer wall are sequentially installed on the outer side of the feeding assembly. By installing the punching assembly, the inner hole grinding assembly, the cleaning assembly and the feeding assembly, agricultural machine gear blanks can be conveyed above the feeding assembly and sequentially machined through the punching assembly, the inner hole grinding assembly and the cleaning assembly, automatic circulation and automatic machining among all procedures are achieved, meanwhile, the machining process is stable, and the machining quality is high; the overall machining efficiency is improved, and the yield is improved.

Owner:盐城泽华精工机械有限公司

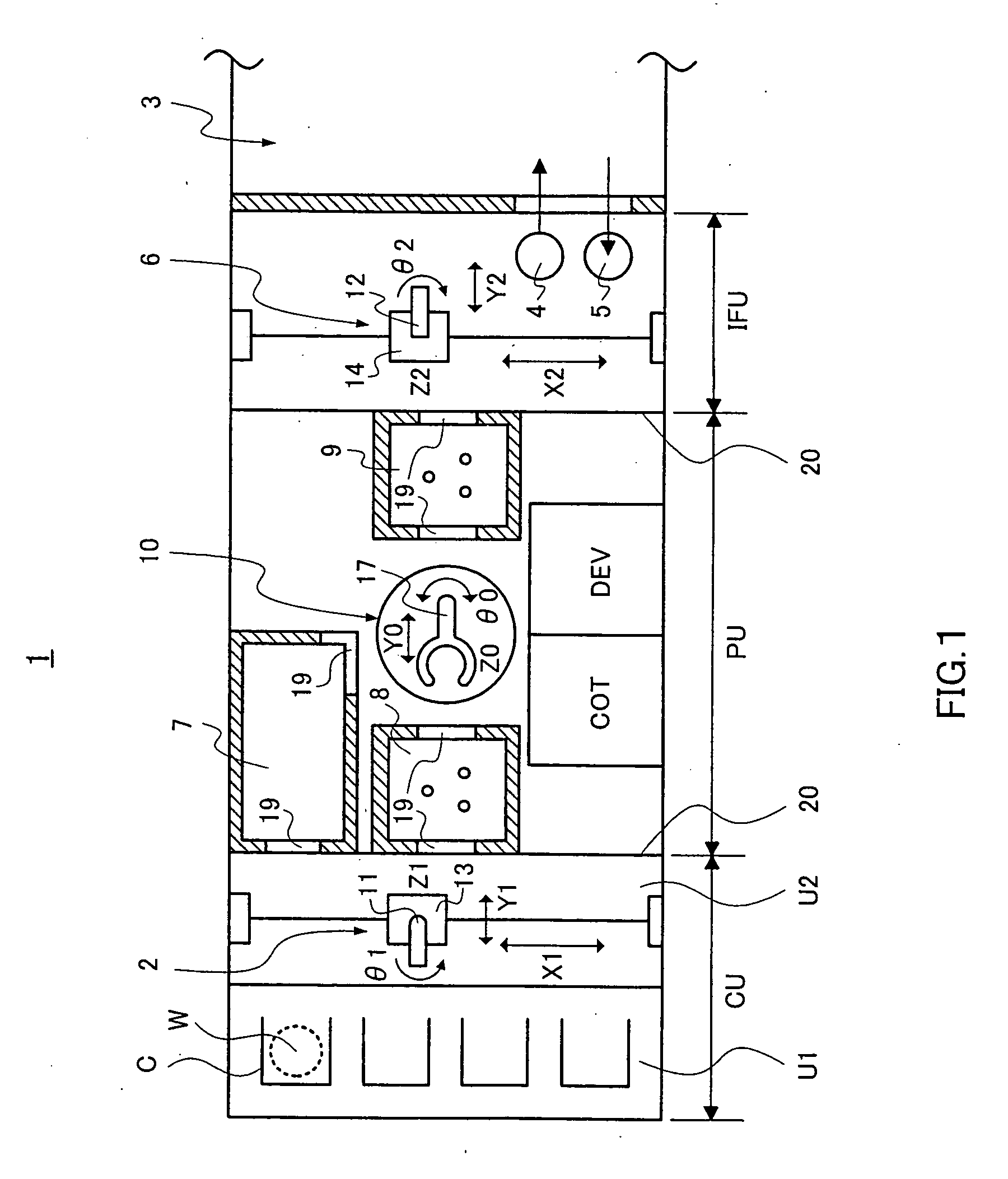

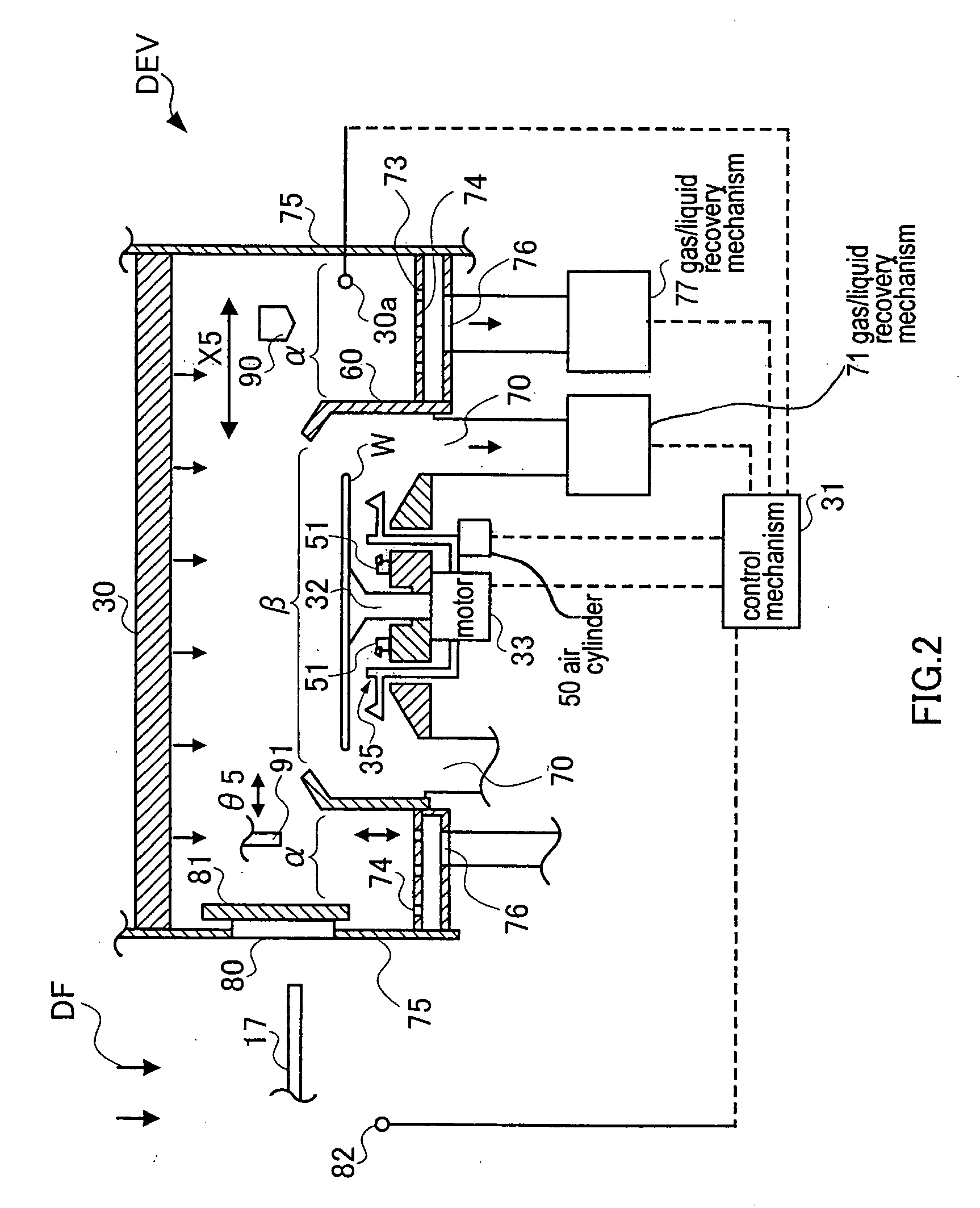

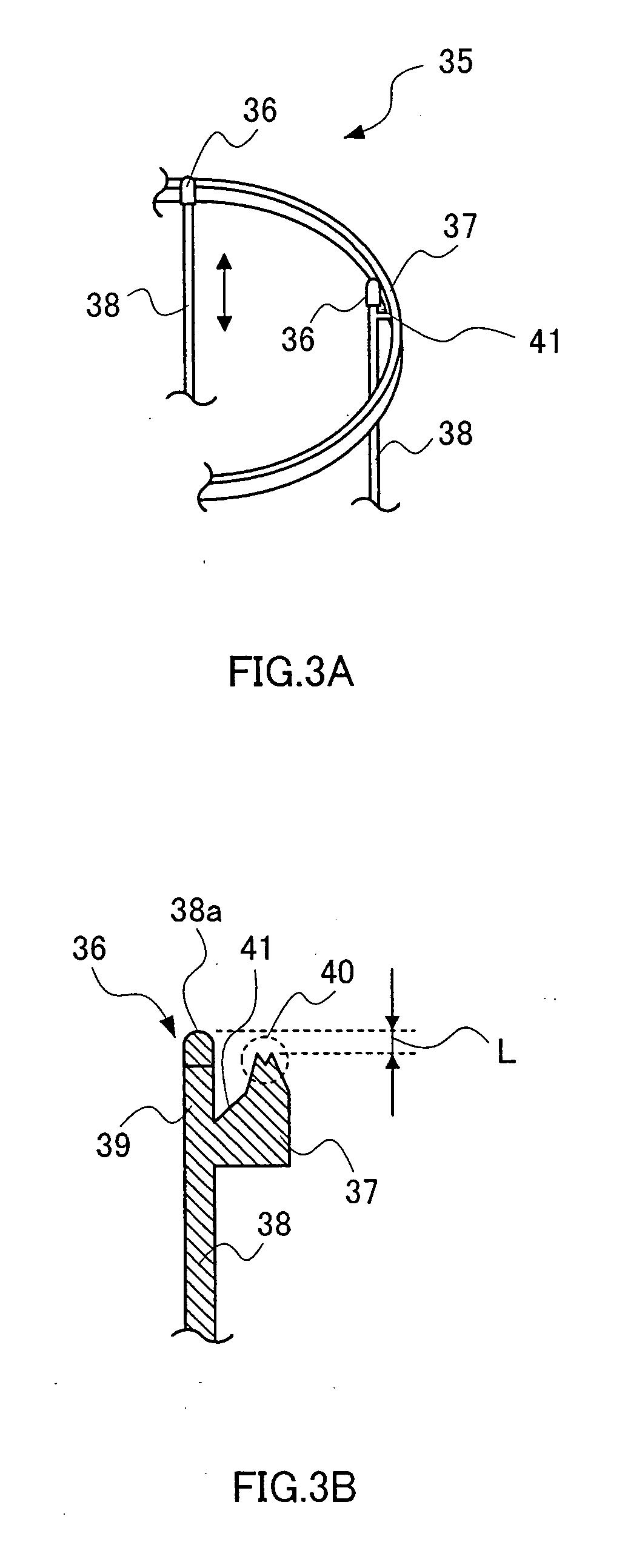

Substrate processing apparatus and substrate processing method

InactiveUS20070065760A1Reduce yieldGood effectLiquid surface applicatorsLiquid processingResistTransfer mechanism

A substrate processing apparatus has at least one of a developing processing apparatus that supplies a developing solution as a processing solution to a non-processed substrate to process and a resist coating processing apparatus that supplies a resist solution as a processing solution to the non-processed substrate. A transfer mechanism enables the non-processed substrate to be transferred to the developing processing apparatus and / or the resist coating processing apparatus. In a substrate processing method processes, an exposed resist is developed on a processing surface of the non-processed substrate inside a cup mechanism of the developing processing apparatus, and a resist solution is supplied to the processing surface of the non-processed substrate inside a cup mechanism of a resist coating processing apparatus. the non-processed substrate is transferred to the developing processing apparatus or the resist coating processing apparatus.

Owner:ITO YOSHITAKE

Making method of ready-to-eat pork skin with pine flower-like layered surface

The invention discloses a making method of ready-to-eat pork skin with a pine flower-like layered surface. The making method comprises the following specific steps of performing unfreezing, performingcleaning, removing grease, removing hair, performing skin cooking, performing soaking, performing skin slicing, performing cutting (shredding, slitting and slicing), performing airing, performing deep-frying or puffing, performing soaking, performing flushing, performing secondary cooking, performing stirring, performing bagging, performing sterilization, and performing packaging and processing so as to obtain seasoning skin powder. Compared with the prior art, the method has the advantages that the steps are simple, practical, clear and easy to understand, the early-stage cost investment issmall, the working requirements of personnel are greatly reduced, the processing yield is high, four series of delicious food products such as pigskin, cow skin, sheepskin and donkey hide can be prepared by utilizing the method according to requirements respectively, and the finished products are filamentous, wide-strip-shaped and sheet-shaped, and are convenient to eat, wide in applicability andconvenient to popularize.

Owner:张正豪

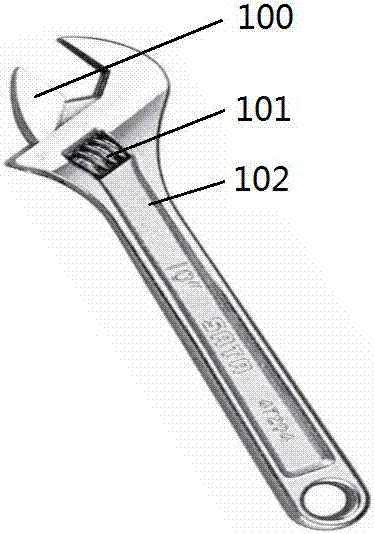

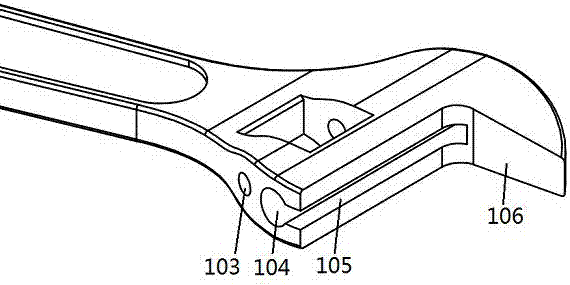

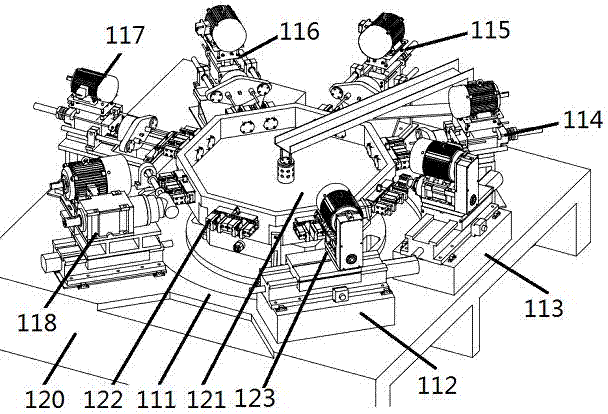

Control system for wrench machine tool

PendingCN107486741AImprove processing qualityImprove processing outputAutomatic control devicesFeeding apparatusAutomatic controlSolenoid valve

The invention relates to a control system for a wrench machine tool. The control system for the wrench machine tool comprises a machine tool body, a machining head, a control device, a hydraulic rotary working table and a hydraulic power clamp which is mounted on the hydraulic rotary working table. The control device comprises a central processing module, a servo feeding system, a spindle system, a hydraulic power clamp oil cylinder solenoid valve which is connected with the central processing module and hydraulic rotary working table solenoid valve which are connected with the central processing module. The servo feeding system comprises a servo driving module connected with the central processing module and a servo motor connected with the servo driving module and used for driving the machining head to move forwards and backwards. According to the control system for the wrench machine tool, the efficient central processing module is adopted to automatically control the wrench machine tool, multi-station drilling and milling simultaneous machining is achieved, and the production efficiency and the product quality are effectively improved.

Owner:HUNAN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com