Cleaning equipment for elastic element of sensor and cleaning method thereof

A technology of elastic components and cleaning equipment, applied in chemical instruments and methods, cleaning methods and appliances, solid separation, etc., can solve problems such as loud noise, harmful to processors' health, and environmental pollution, so as to reduce labor costs and increase processing output and processing quality, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

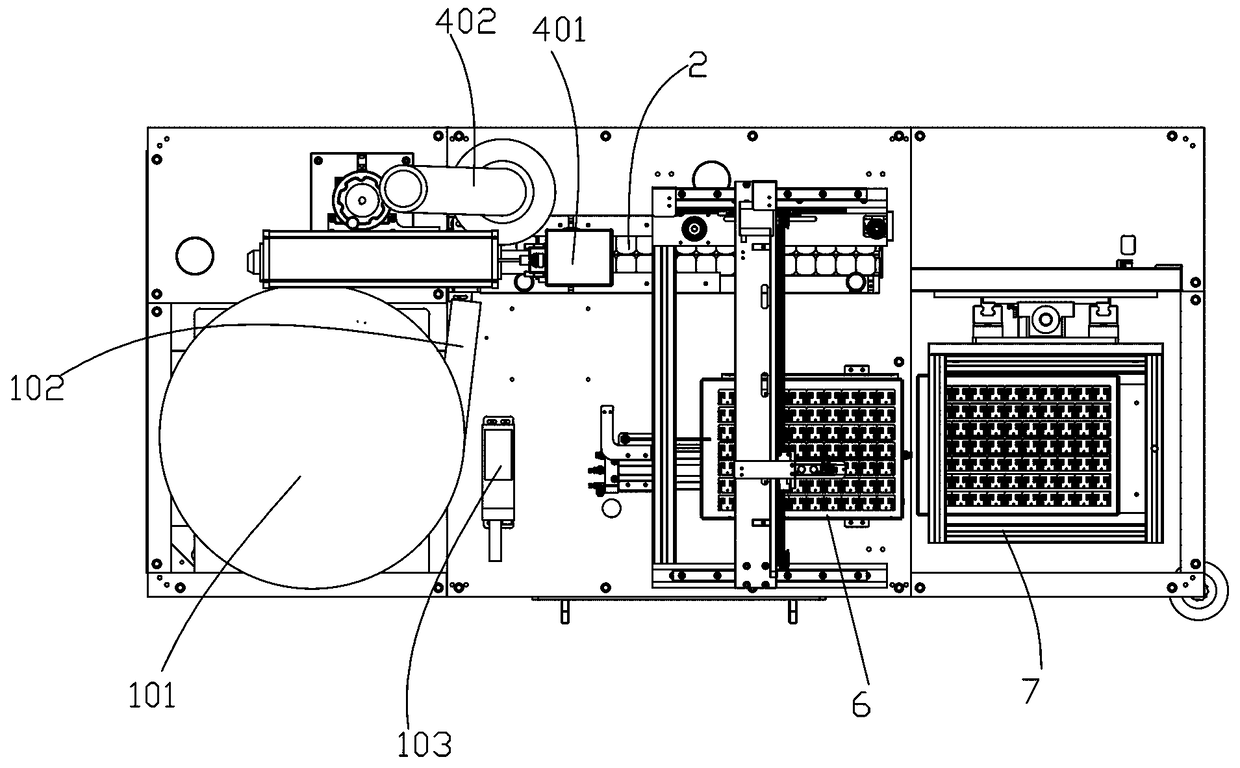

[0038] The cleaning device for the elastic element of the sensor according to the embodiment of the present invention includes a machine body, a controller, a screening assembly, a feeding assembly, a cleaning assembly, a grabbing assembly, a tray, a push-pull assembly, and a material box. The controller of this equipment includes PLC and industrial control host, which can be programmed and issued by PLC to automatically control the equipment; the industrial control host controls the work of the laser. The graphics of the elastic element can be edited on the display screen, and the edited information is input and output through the USB interface of the industrial control host; then the action information of each component of the equipment can be queried on the display screen; since the programmable control system is an existing technology, it is not mentioned here Do go into detail.

[0039] Such as figure 1 As shown, the sieve material assembly includes a sieve material pan ...

Embodiment 2

[0054] The cleaning method of the elastic element of the sensor is to use the above-mentioned cleaning equipment to clean the elastic element, and the steps are as follows:

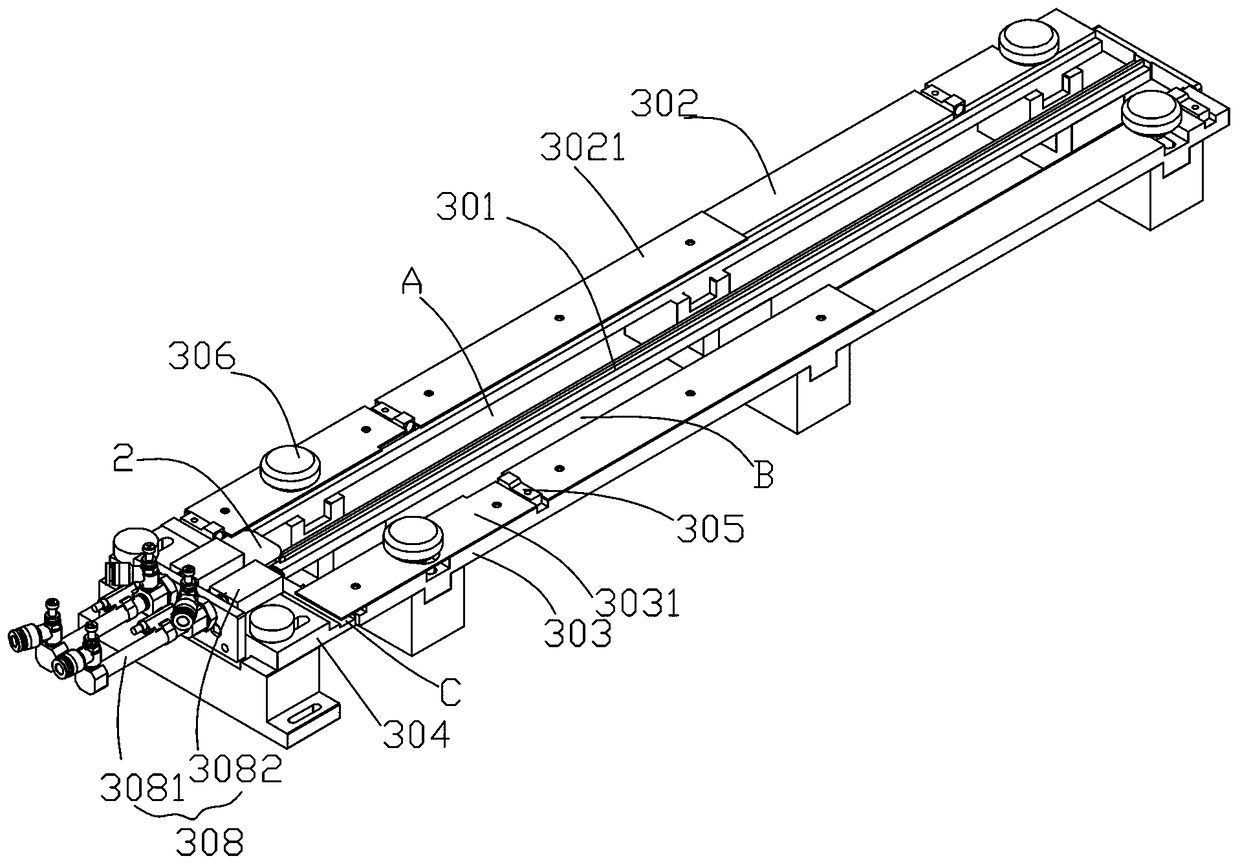

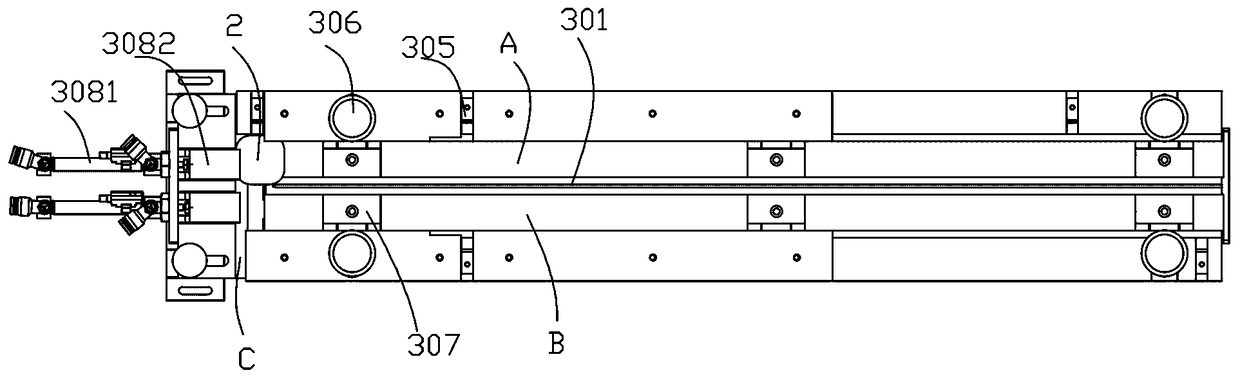

[0055] S1. Make the sieve pan 101 transport the required elastic element 2 to the material delivery channels A and B through the sieve channel 102 .

[0056] S2. When the first induction switch 305 on the feeding channel C senses the elastic element 2, the two first cylinders 3081 on the feeding channel extend the piston rods in turn to push the elastic element 2 to the laser cleaning area in turn, and then The laser 401 respectively cleans the surface of the elastic element 2 on the feeding channel A and the feeding channel B in the area where the components such as chips are bonded. Continue to be pushed to the area to be grabbed by the first cylinder 3081.

[0057] S3. The third motor 7025 lifts the material box 7 to a designated position, and then the linear slide group 801 drives the hook 802 to pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com