Cutter compensation and correction method and system of machine tool

A technology of machine tools and cutting tools, which is applied in the field of mobile phone case processing equipment, can solve problems that affect product size accuracy, take a long time to adjust the machine, and deflection of the cutter head, so as to improve product yield, reduce machine adjustment time, and increase processing output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A tool correction method for a machine tool of the present invention comprises the following steps,

[0038] Accumulate a large amount of wear data of the entire life cycle of the grinding wheel, and calculate the wear trend coefficient S of the grinding wheel according to the big data model of grinding wheel wear;

[0039] A large amount of grinding wheel wear-processing time data is analyzed to establish a big data model of grinding wheel wear.

[0040] Accumulate a large amount of grinding wheel deflection data, as well as the cutting force change data under the corresponding grinding wheel deflection and machine tool control accuracy data in the process of processing products, and calculate the impact of cutting force change and grinding wheel deflection on machine tool control based on the big data model of machine tool control accuracy. The correlation factor coefficient P of the influence of precision;

[0041] The establishment method of the big data model of m...

Embodiment 2

[0053] A tool correction method for a machine tool of the present invention comprises the following steps,

[0054]The first piece tool compensation step, the first piece tool compensation step is at the front, the first piece tool compensation step includes: when the machine tool is replaced with a new grinding wheel, calculate the first piece tool compensation value required by the specified D position of the machine tool according to the deflection data of the new grinding wheel, The machine tool corrects the position of the tool according to the tool compensation value of the first piece.

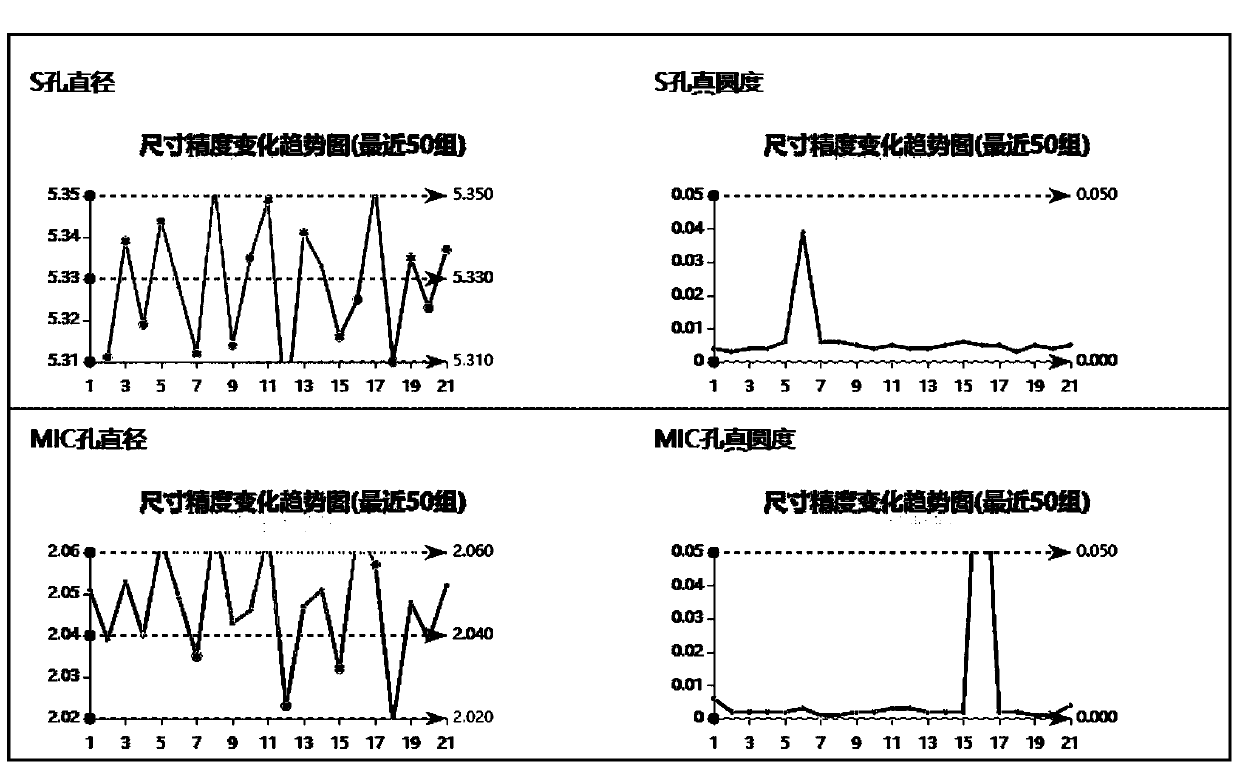

[0055] Accumulate a large amount of wear data of the entire life cycle of the grinding wheel, and calculate the wear trend coefficient S of the grinding wheel according to the big data model of the wear of the grinding wheel; a large number of wear data of the entire life cycle of the grinding wheel are the latest 50 groups.

[0056] Accumulate a large amount of grinding wheel deflectio...

Embodiment 3

[0066] A tool correction system for a machine tool, comprising:

[0067] The grinding wheel data acquisition terminal is used to measure the grinding wheel, collect the effective processing diameter data, deflection data, rigid deformation data, and wear data of the grinding wheel, and send the collected grinding wheel data to the database terminal;

[0068] The machine tool data acquisition terminal is used to collect the cutting force change data, control precision data, motor torque data, spindle deflection data, and spindle box deflection data of the machine tool, and send the collected machine tool data to the database terminal;

[0069] The product size data collection terminal is used to measure the product size, collect product size data, and send the collected product size data to the database side;

[0070] The database end is used to store grinding wheel data, machine tool data, and product size data;

[0071] The data processing background is connected to the data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com