Patents

Literature

89results about How to "Improve sand removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

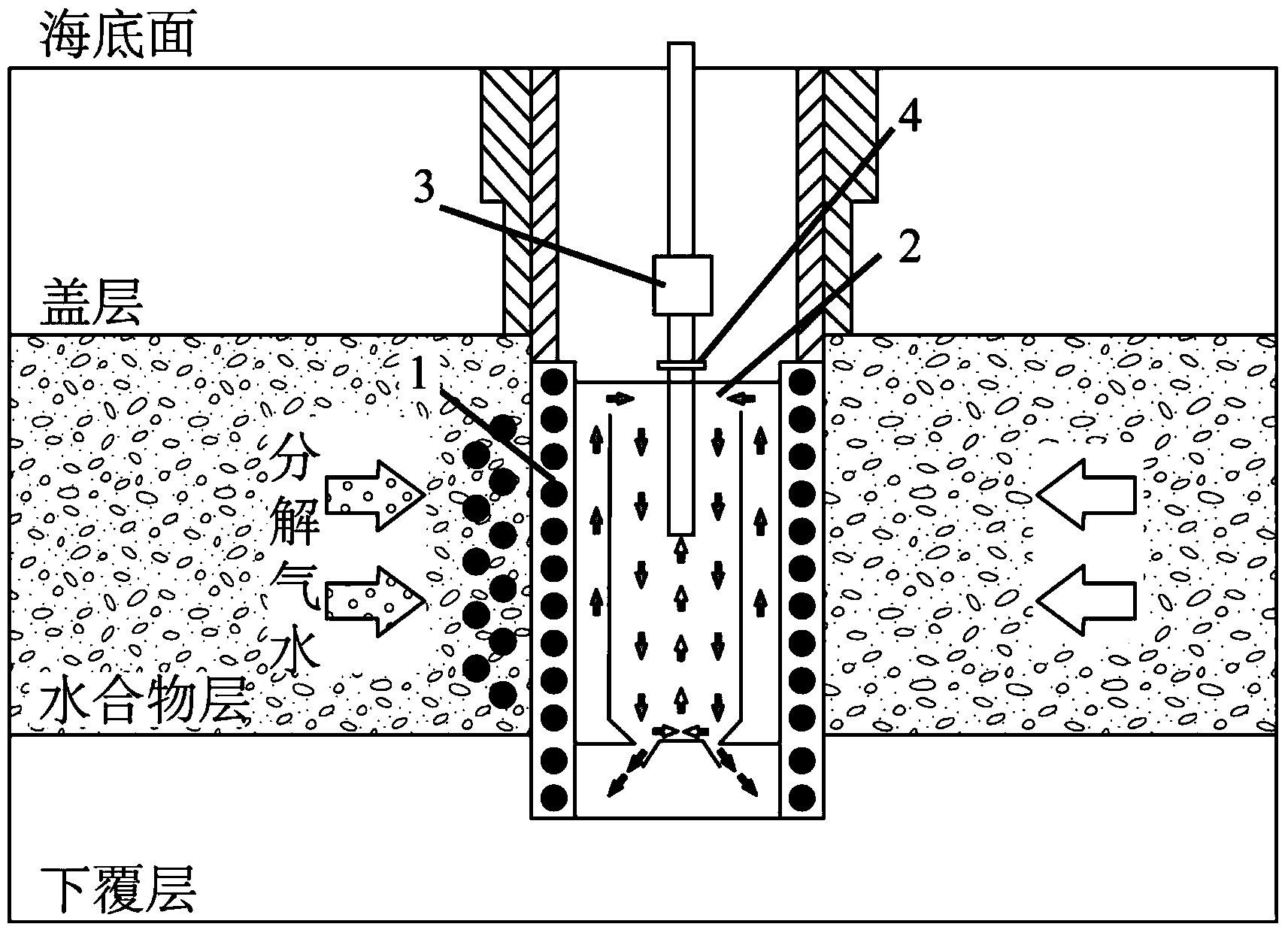

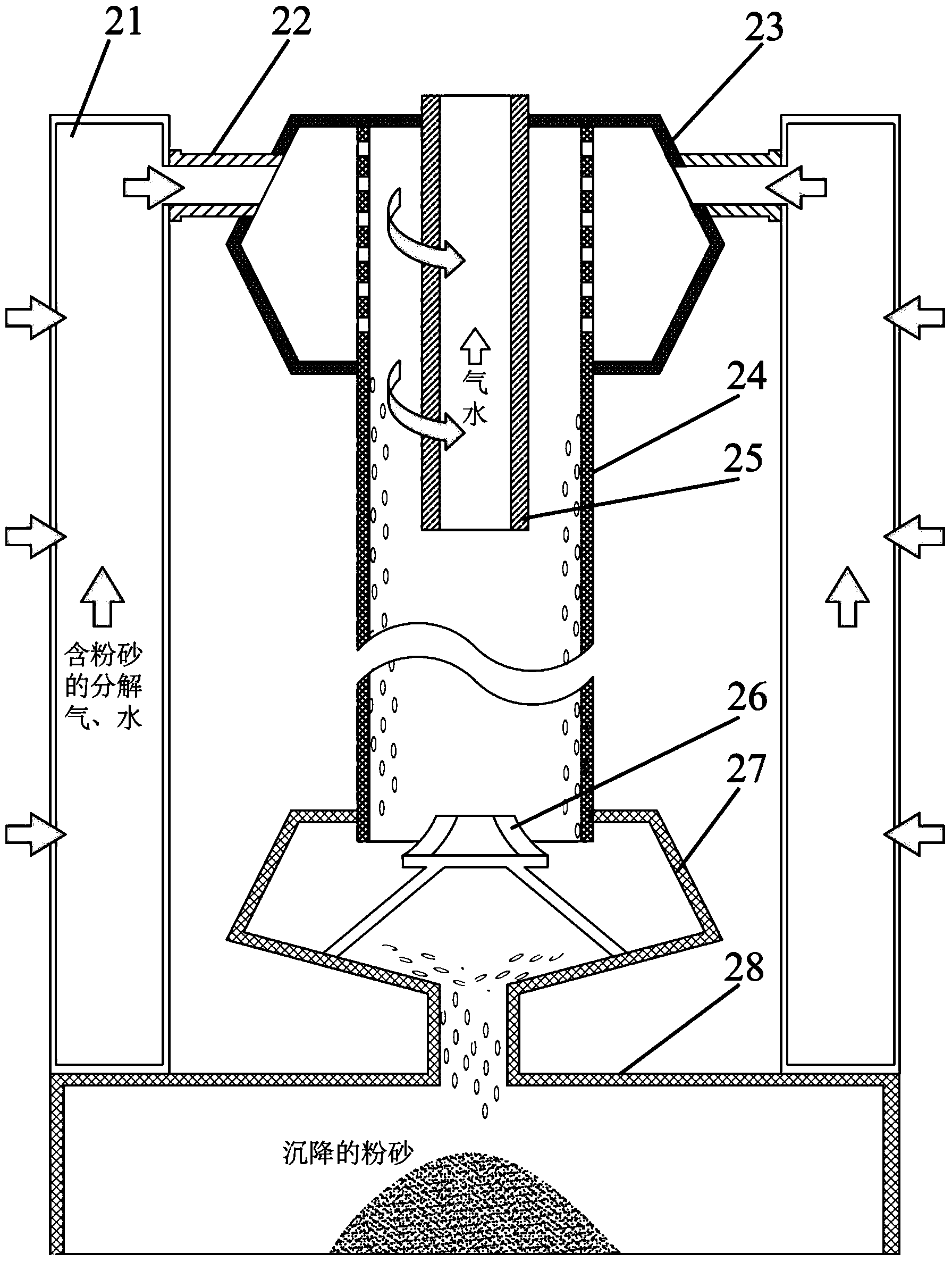

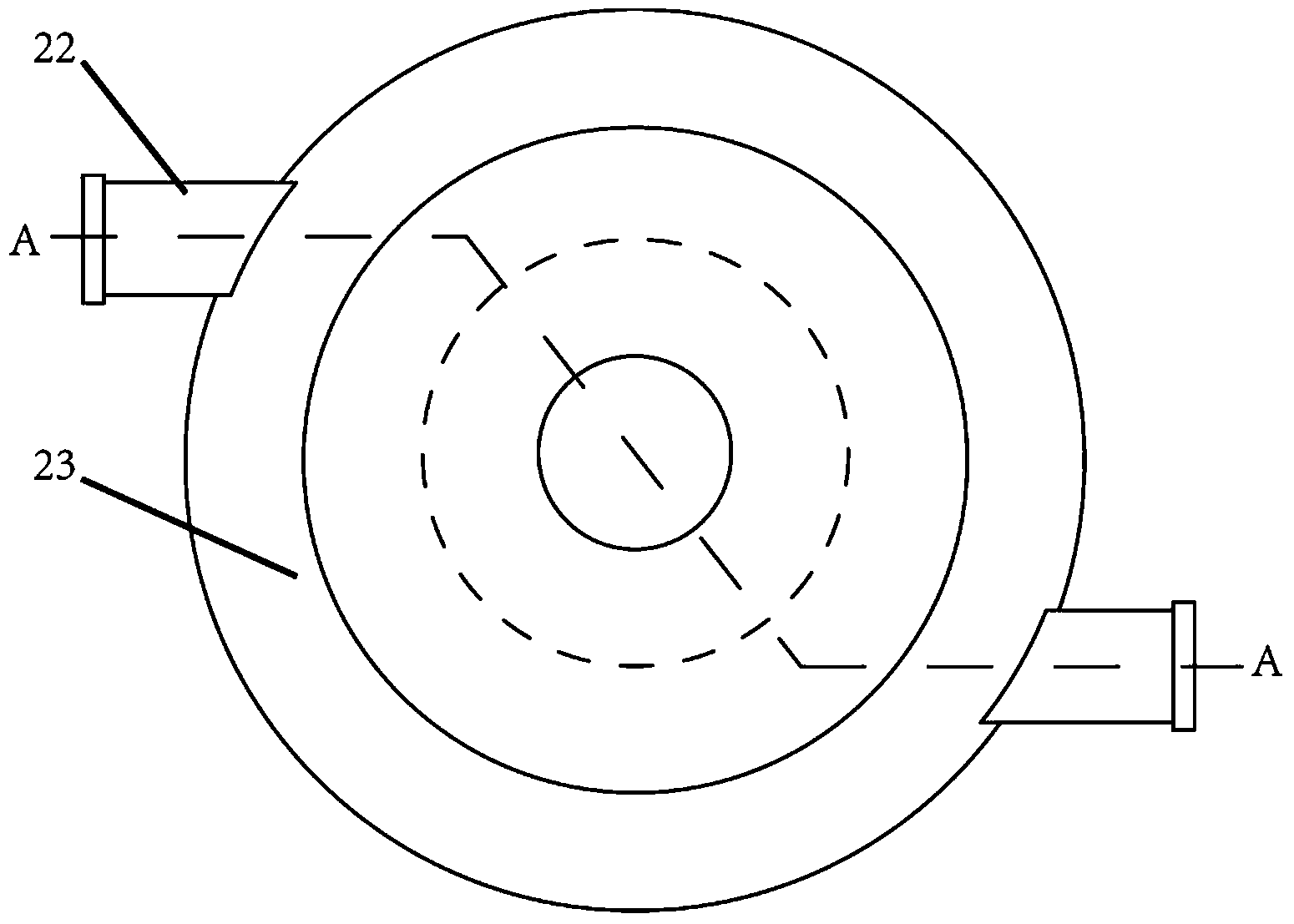

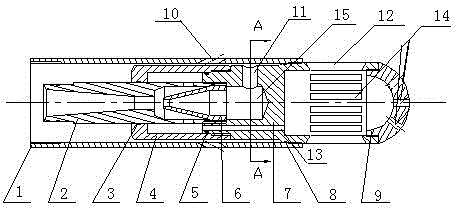

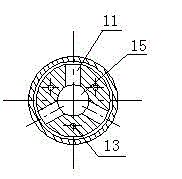

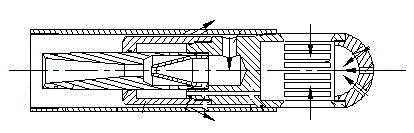

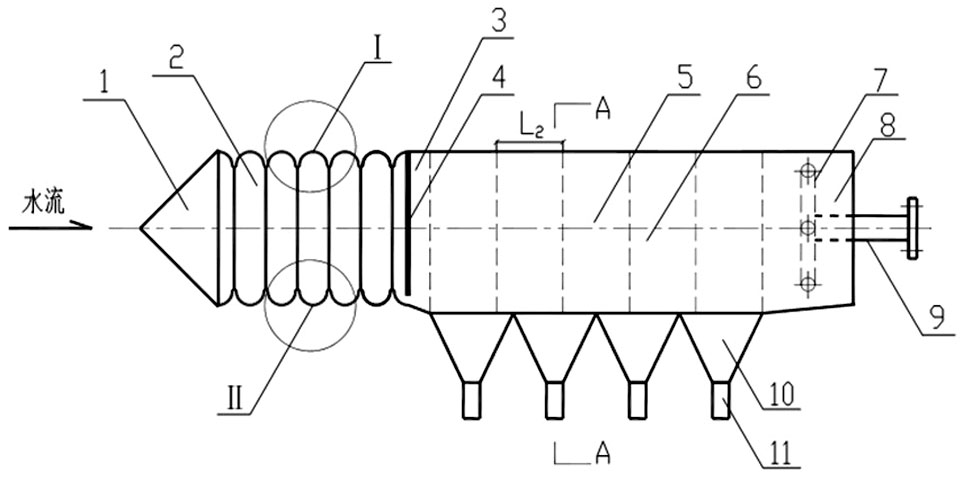

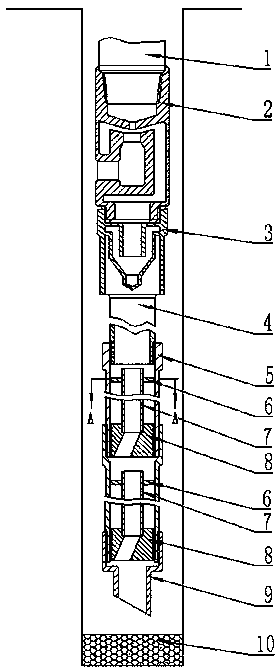

Device and method for desanding of submarine natural gas hydrate exploitation well

ActiveCN103967473ADoes not significantly affect permeabilityAvoid enteringFluid removalDesanderCentrifugal force

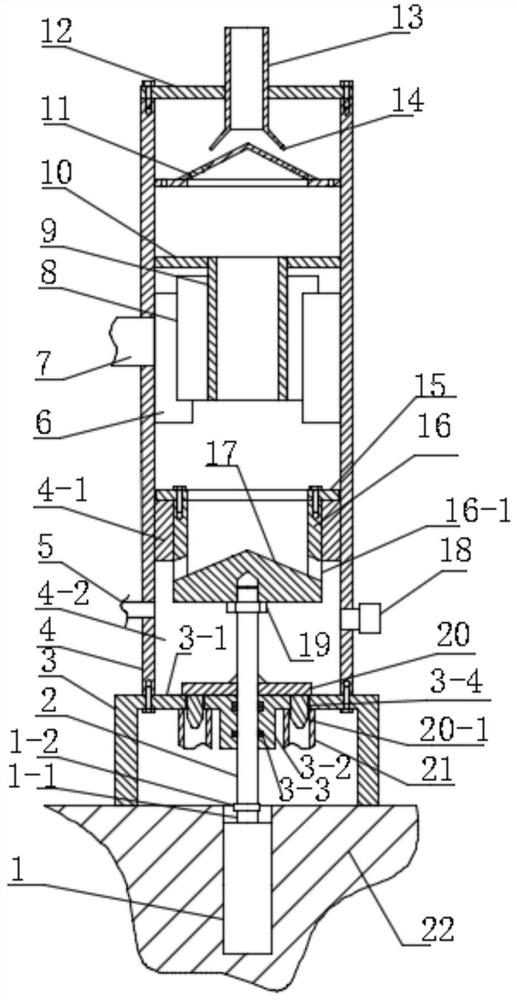

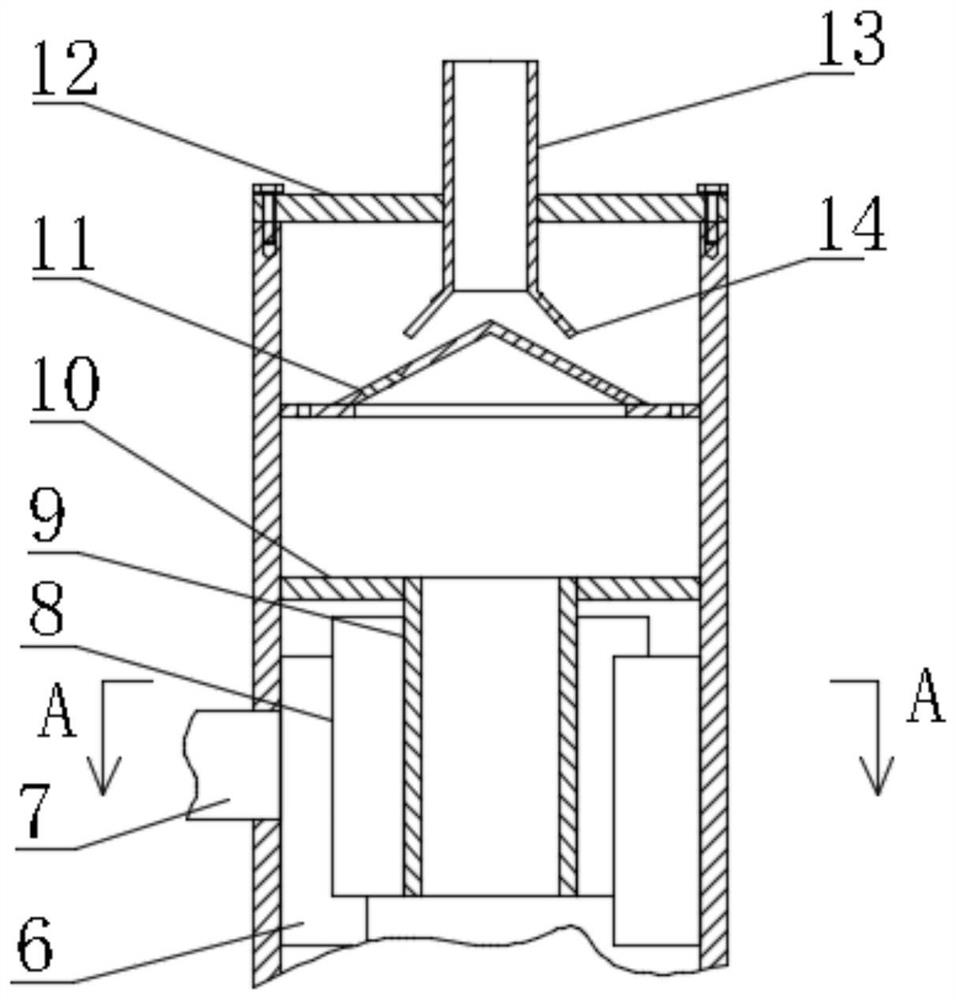

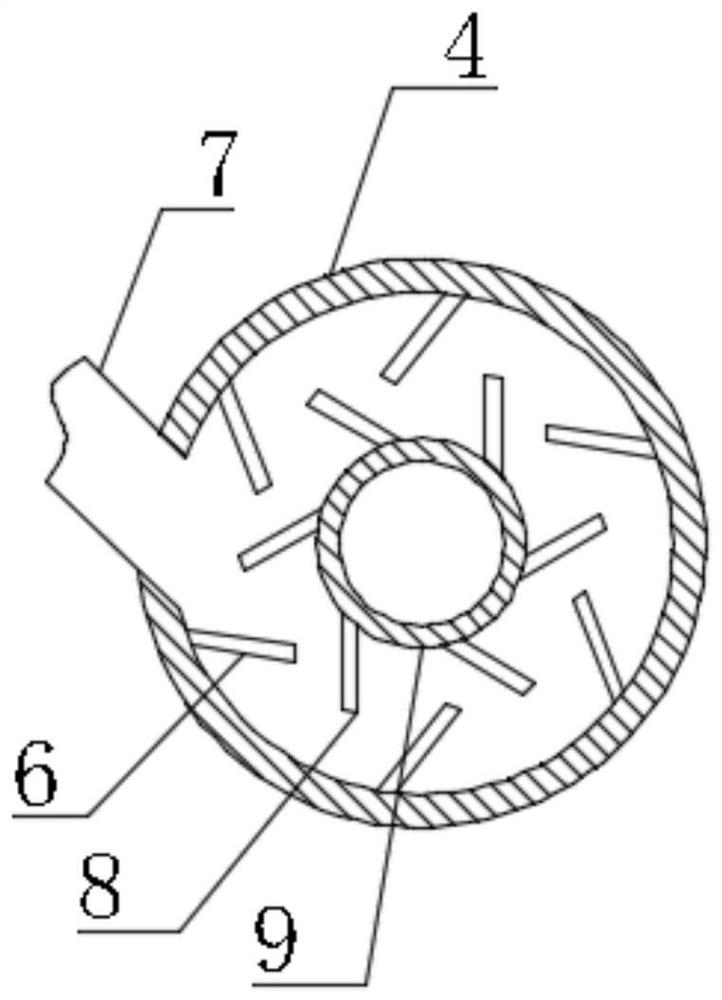

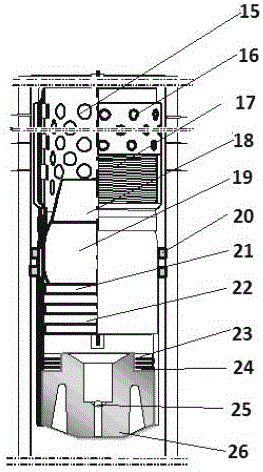

The invention provides a device and method for desanding of a submarine natural gas hydrate exploitation well. The device comprises a gravel filling set, a centrifugal desander, a submerged pump and a connecting flange. The gravel filling set is arranged at the bottom of the exploitation well, the centrifugal desander and the submerged pump are connected through the connecting flange and wholly descend to the bottom of the exploitation well, and the outer wall of a flow guide chamber is attached to the inner wall of the gravel filling set. By the adoption of the device, in the centrifugal desanding process, gas-water sand is firstly decomposed and flows to a shaft, large settled layer sand is blocked by the gravel filling set, and gas and water containing fine sand enters the shaft; gas and water containing the fine sand enter an upper collection box through the flow guide chamber and an inflow port, and cyclones are generated; under the effect of centrifugal force, the fine sand is gathered on the inner wall of a settling chamber and descends into a sand collection box. By the adoption of a secondary desanding method, desanding efficiency is improved, and permeability of a hydrate settled layer cannot be remarkably affected; by the adoption of a cyclone centrifugal mode, the fine sand and decomposed gas and water can be effectively separated, the fine sand is prevented from entering the submerged pump, and equipment wear is reduced.

Owner:DALIAN UNIV OF TECH

Preparation method for sea cucumber intestine oral liquid

ActiveCN103719926AEasy to synthesizeReduce consumptionNatural extract food ingredientsFood ingredient functionsNutritionWell nourished

The invention relates to a preparation method for a sea cucumber intestine oral liquid. The preparation method comprises the following steps: taking sea cucumber intestine as a raw material, grinding the sea cucumber intestine into slurry, heating the slurry, cooling down, adding neutral protease and flavor enzyme double enzyme, and controlling enzymolysis conditions for enzymolysis; conducting primary centrifugal separation on the sea cucumber intestine enzymatic hydrolysate with a centrifugal machine, collecting supernatant fluid, conducting secondary centrifugation, collecting supernatant and conducting desalination treatment repeatedly according to the nano-filtration separation technology to obtain a sea cucumber intestine liquid; adding an auxiliary natural plant extracting liquid extracted from medlar, membranous milkvetch root, angelica and ginseng, as well as a sweetening agent for blending, filling, and sterilizing to obtain the sea cucumber intestine oral liquid. The preparation method is reasonable in technology, simple and convenient to operate, high in operability and easy to realize industrialized production; the sea cucumber intestine oral liquid prepared according to the method not only is rich in nutrition, clear, transparent, moderate in sour and sweet, and natural in sapor, but also has health-care functions of replenishing blood, benefiting vital energy, supporting the healthy energy, enhancing vital essence and marrow, allaying tiredness, improving immunity, and the like.

Owner:SHANDONG HOMEY AQUATIC DEV +1

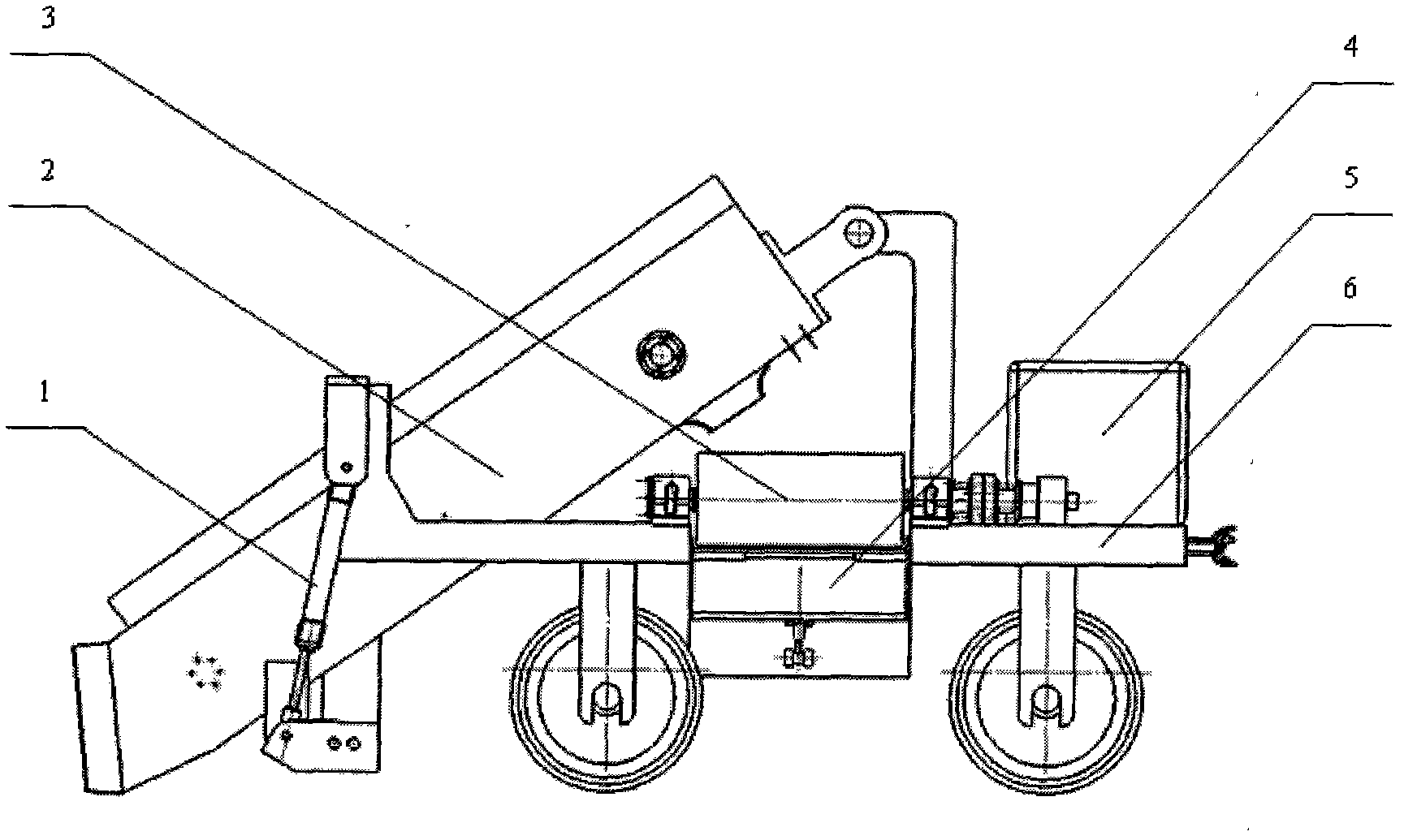

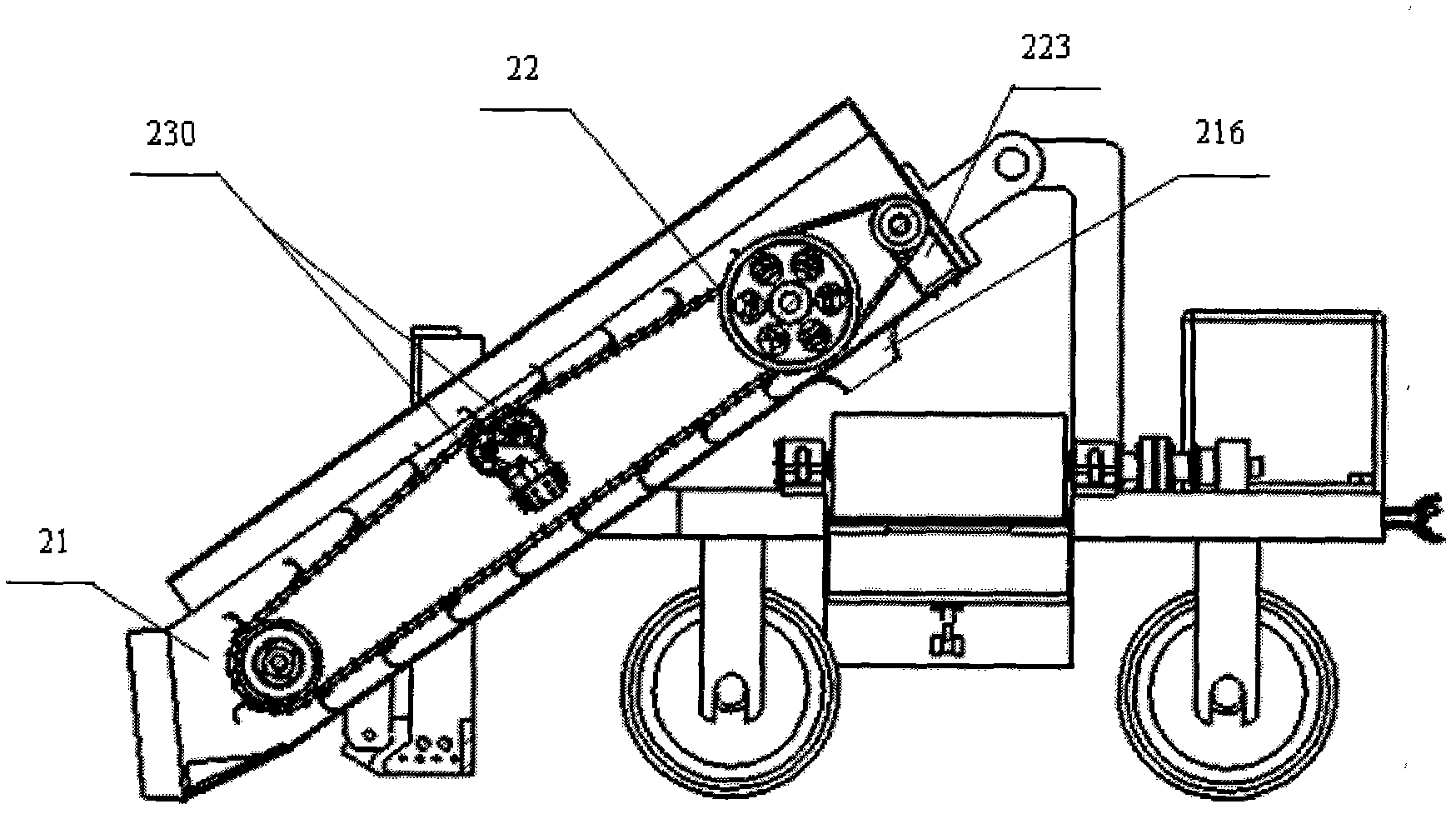

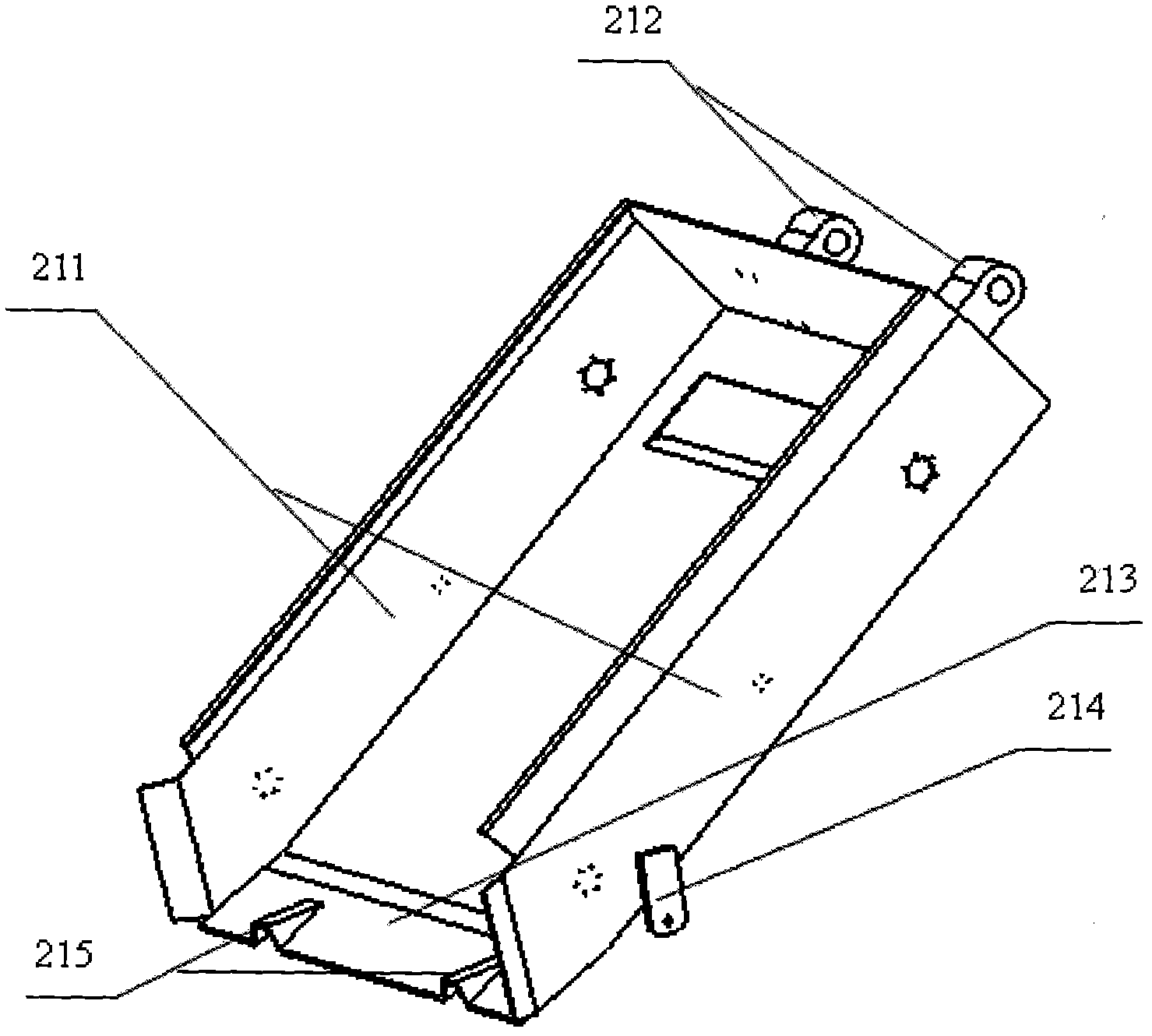

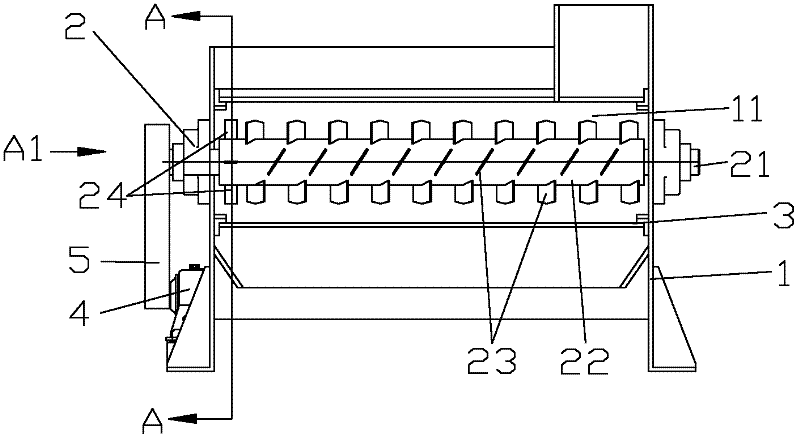

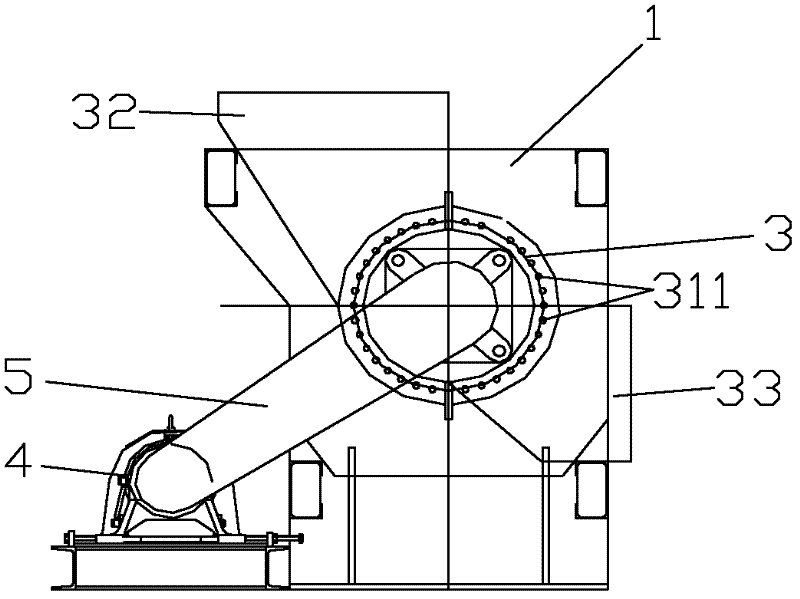

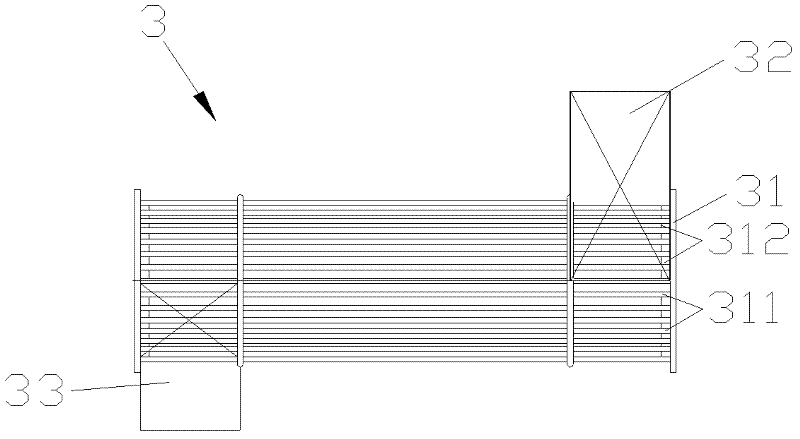

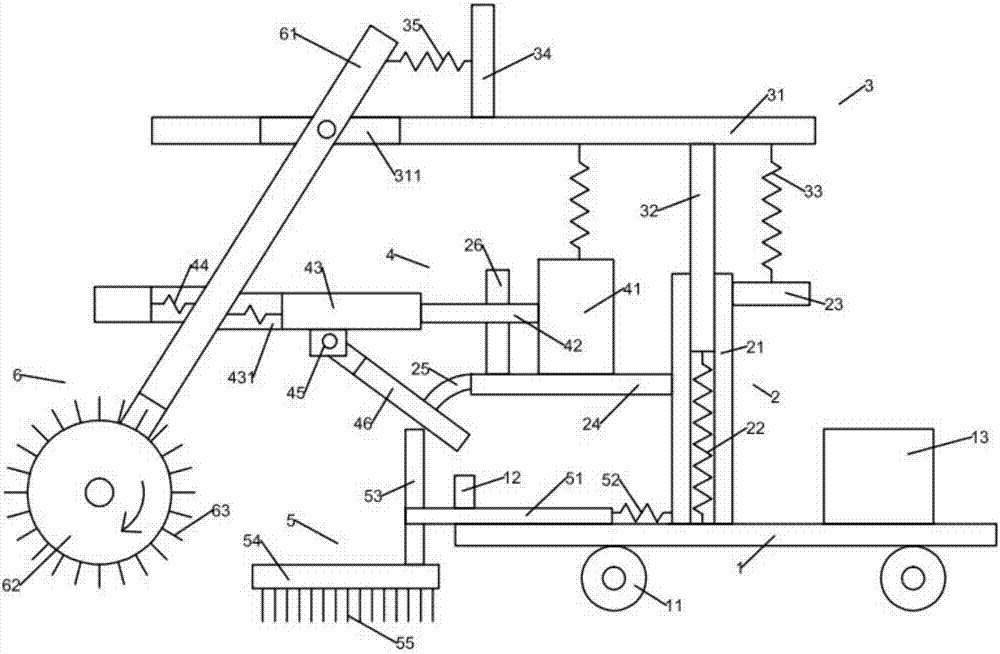

Trailer type sand elimination machine for railway

InactiveCN102433853ASimple structureRealize automatic controlRailway cleaningHydraulic cylinderHydraulic motor

The invention discloses a trailer type sand elimination machine for a railway, which comprises a lift hydraulic cylinder (1), a sand collecting and scraping device (2), a bidirectional sand blowing mechanism (3), a sand blowing transmission mechanism (4), a hydraulic system (5) and a vehicle body (6). When being used, the trailer type sand elimination machine is dragged to a working place by a locomotive, the sand collecting and scraping device (2) is descended to a working position by the control of the lift hydraulic cylinder (1), and the sand blowing transmission mechanism (4), a sand blowing belt (33) and a sand scraping mechanism (22) are sequentially started; and the trailer type sand elimination machine runs forwards with the dragging of the locomotive, a sand collecting box (21) is used for stacking accumulated sand at the middle and at the two sides of a steel rail to a certain height, a hydraulic motor (222) of the sand scraping mechanism is used for driving a drive chain wheel shaft to rotate, a scraper (229) is used for scraping the accumulated sand to a hopper (216), and the accumulated sand falls onto the sand blowing belt (33) and are blown out from the left side or the right side of the steel rail by the positive rotation or reverse rotation of a hydraulic motor (37) of the snow blowing mechanism. The trailer type sand elimination machine is simple in structure and high in automation, and is convenient to operate and easy to promote.

Owner:INNER MONGOLIA UNIV OF TECH

Waste plastic sand remover

The invention provides a waste plastic sand remover comprising a machine rack, a grid, a spiral component and a transmission component. Transmission equipment is connected with spiral equipment so as to drive the spiral equipment to rotate. The spiral equipment is sleeved in the grid. A plurality of transmission blades and a plurality of discharging blades are arranged on the spiral equipment so as to remove sediment substances adhered to waste plastics. The waste plastic sand remover disclosed by the invention has the advantages of simple equipment structure, reliability in operation, low manufacture and maintenance cost and long service life. Meanwhile, the waste plastic sand remover can be used for continuous feeding and discharging and is high in sand-removal efficiency.

Owner:SHANGHAI SHENJIA SANWA +1

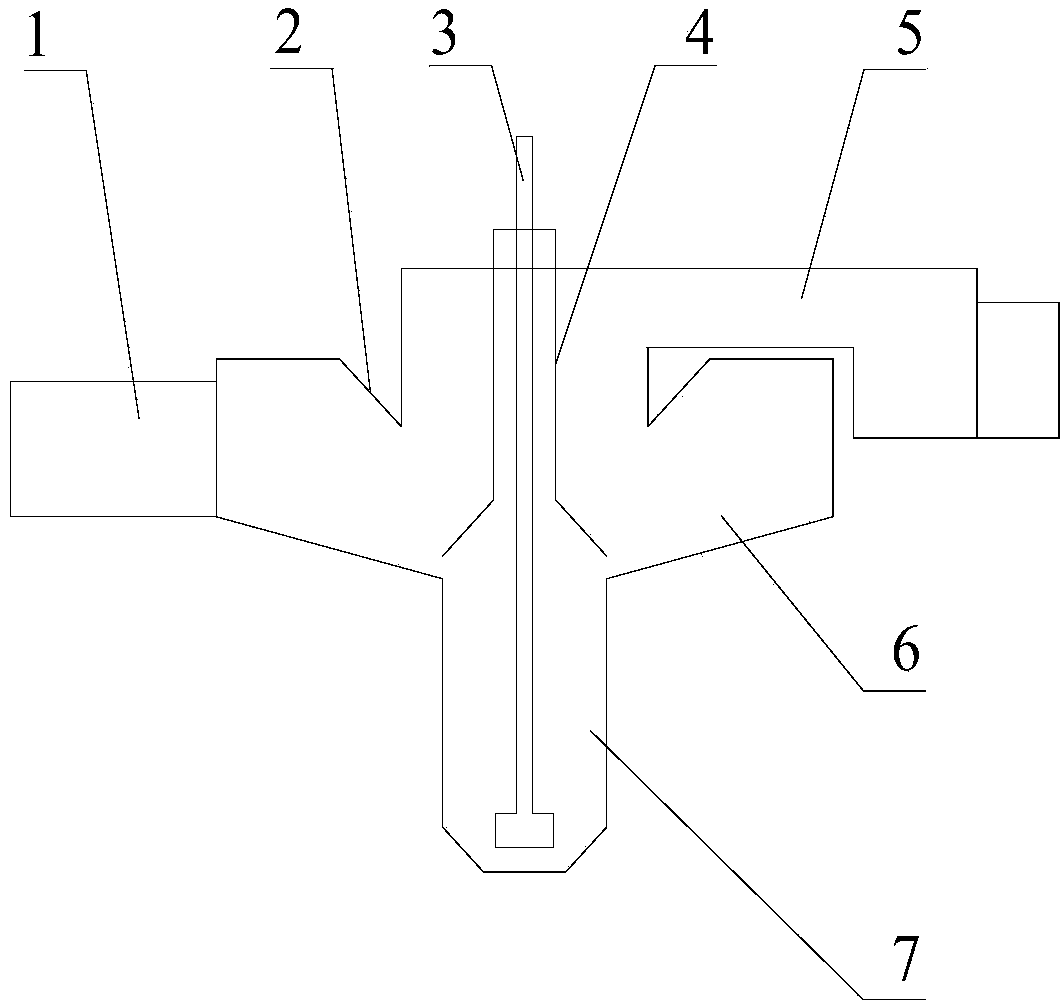

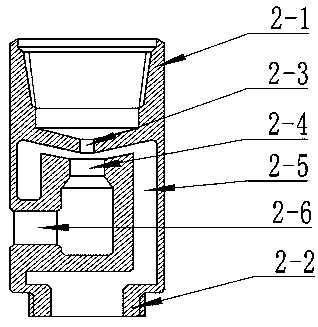

Negative-pressure sand washer of horizontal well

InactiveCN106285523ASimplify the construction processImprove construction efficiencyFlushingEngineeringWellbore

The invention provides a negative-pressure sand washer of a horizontal well. The negative-pressure sand washer comprises an outer barrel, a throat pipe, a center pipe, a nozzle, a connector and a baffle head. The upper portion of the connector is nested in the outer barrel to be in threaded connection with the same, the end face of the lower portion of the connector is connected with the baffle head, the outer wall of the front end of the connector is connected with the lower end of the center tube, the inner hole of the front end of the connector is connected with the lower end of the throat pipe, the throat pipe penetrates the upper end face of the center pipe from the inside of the center pipe, the nozzle is disposed in an inner hole of the lower portion of the throat pipe, the lower end face of the nozzle buttes against the end face of the inner hole of the front end of the connector, and an annular space is formed between the inner wall of the outer barrel and the outer walls of the center pipe and the front end of the connector. Continuous negative-pressure sand washing is realized in the horizontal-section shaft, meanwhile, the negative-pressure sand washer has functions of in-bushing scale removal and cement breaking, and the problem of incontinuity and serious dropout in the horizontal-well sand washing process is solved.

Owner:PETROCHINA CO LTD

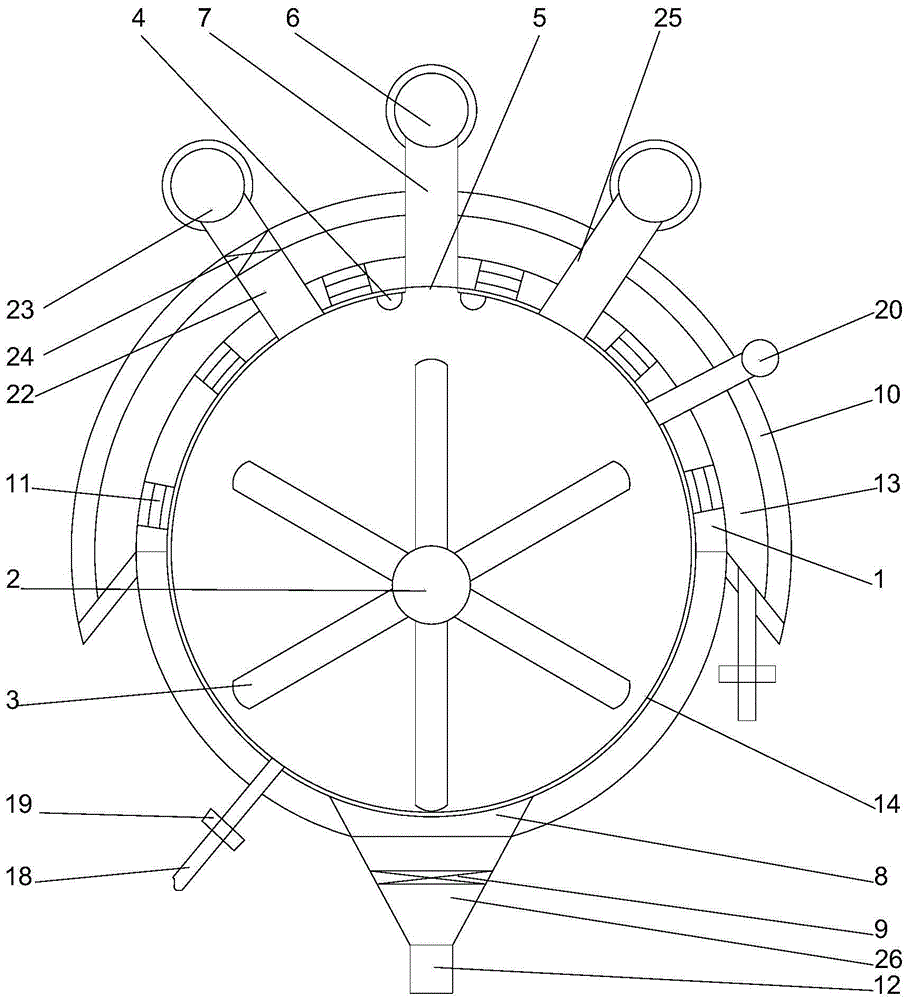

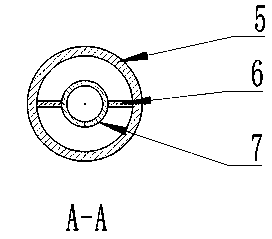

Inclined plate type rotational flow sand setting system

InactiveCN102430271BAccurate control of jet velocityAccurate control of sand lifting flowSettling tanks feed/dischargeCentrifugal force sediment separationDistributed structureEngineering

The invention discloses an inclined plate type rotational flow sand setting system. The system which comprises a tank, a sand lifting pipeline vertically arranged in the middle part of the tank and a sand-lifting air-distributing structure is characterized in that: the lower half part of the tank is a sand hopper part, the upper half part of the tank is a sand setting zone, and an inflow port and an outflow port are arranged on the tank; the upper end of the sand lifting pipeline is connected with a sand-water separator; the bottom surface of the sand setting zone is provided with an inclined plate precipitation structure; the tank is provided with an inner wall jet structure; the lower end of the sand lifting pipeline is provided with a sand lifting pipeline inlet structure; and the sand-lifting air-distributing structure comprises a pressure air pipeline which is vertically arranged and is in parallel with the sand lifting pipeline, the lower port of the pressure air pipeline is transversely communicated with the middle part of a horn body, and the position of the lower port of the pressure air pipeline is higher than the position of the lower inlet of the sand lifting pipeline. The inclined plate rotational flow sand setting system of the invention has the advantages of good sand setting effect, high processing efficiency, low enforcement and maintenance cost (close to no maintenance), good operation continuity, and convenient maintenance and servicing.

Owner:重庆市渝西水务有限公司

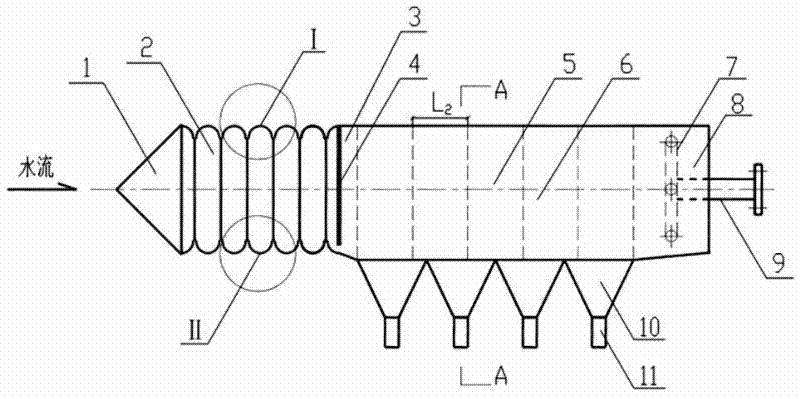

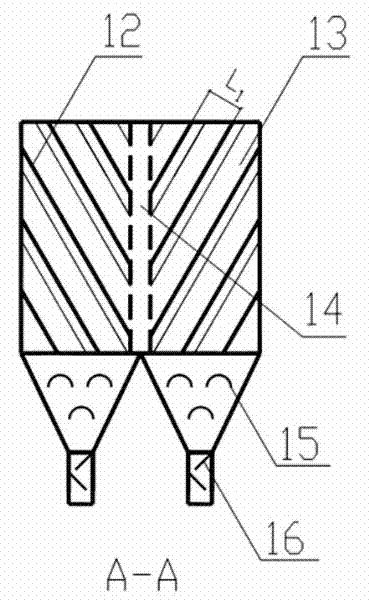

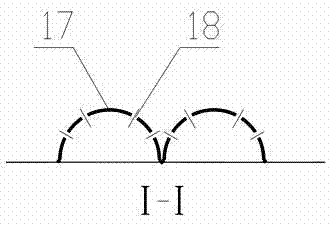

High-efficiency tilted plate sand-removal and water-intake device

InactiveCN101967842ACompact structureReduce volumeSettling tanks feed/dischargeSedimentation settling tanksWater sourceEngineering

The invention relates to a high-efficiency tilted plate sand-removal and water-intake device which is used as water intake equipment in water supply engineering and surface water source heat pump engineering. The device comprises a water inlet chamber, a sand-separating and self-cleaning chamber and a water outlet chamber, wherein the wall of the intake chamber is made of corrugated bent plates and is provided with countless water inlet holes and water inlet / sand discharge dual-purpose holes; and the upper half of the sand-separating and self-cleaning chamber is a sand-separating chamber, the lower half is connected with a self-cleaning sand discharge bucket and a sand discharge pipe, a plurality of lateral flow tilted plates are arranged in bilateral symmetry in the direction of water flow in the sand-separating chamber, the tilted plates are tilted downwards and are provided with fins which are perpendicular to the direction of water flow and the plane of the tilted plates, and a sand-settling channel is left in the symmetry axis position of left and right lateral flow tilted plates and is communicated with the self-cleaning sand discharge bucket at the lower part. The device can be widely used in rivers having a high floater and sand content, and can be also used in water intake engineering using lakes, reservoirs or other water bodies as the water source. Besides, the device can effectively prevent the blocking of weeds and other floaters in water, effectively remove sand in water, omit the special sand basin and simplify the subsequent water treatment process, thereby achieving the purposes of reducing the abrasion of water pump impellers and subsequent water treatment structures, saving the capital investment, saving the occupied area and lowering the water intaking cost.

Owner:CHONGQING UNIV

Rice primary cleaning method

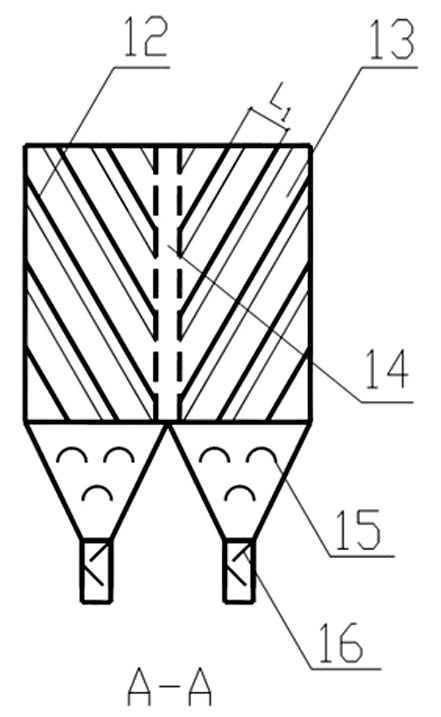

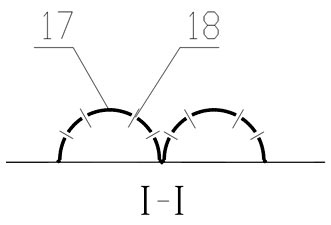

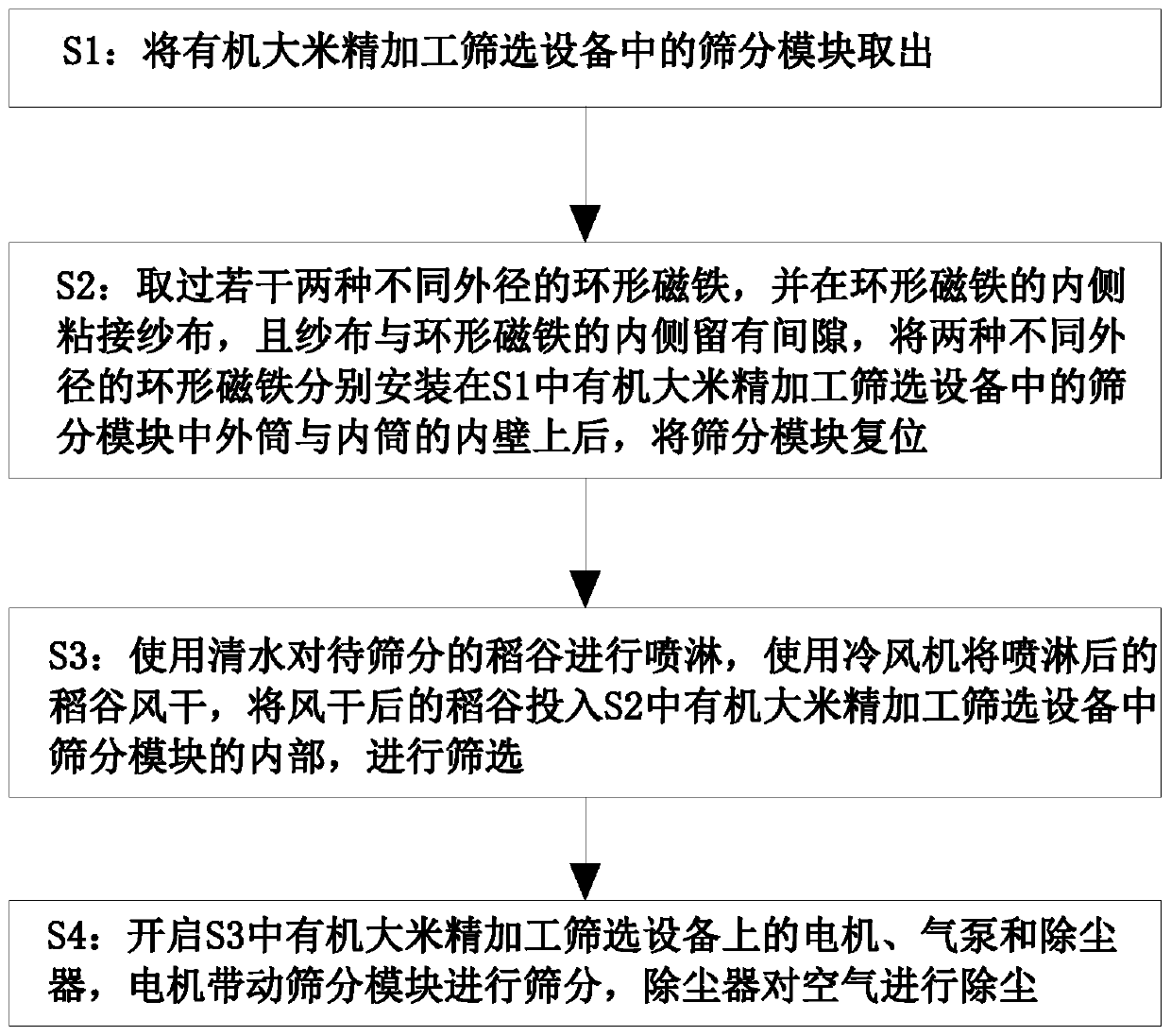

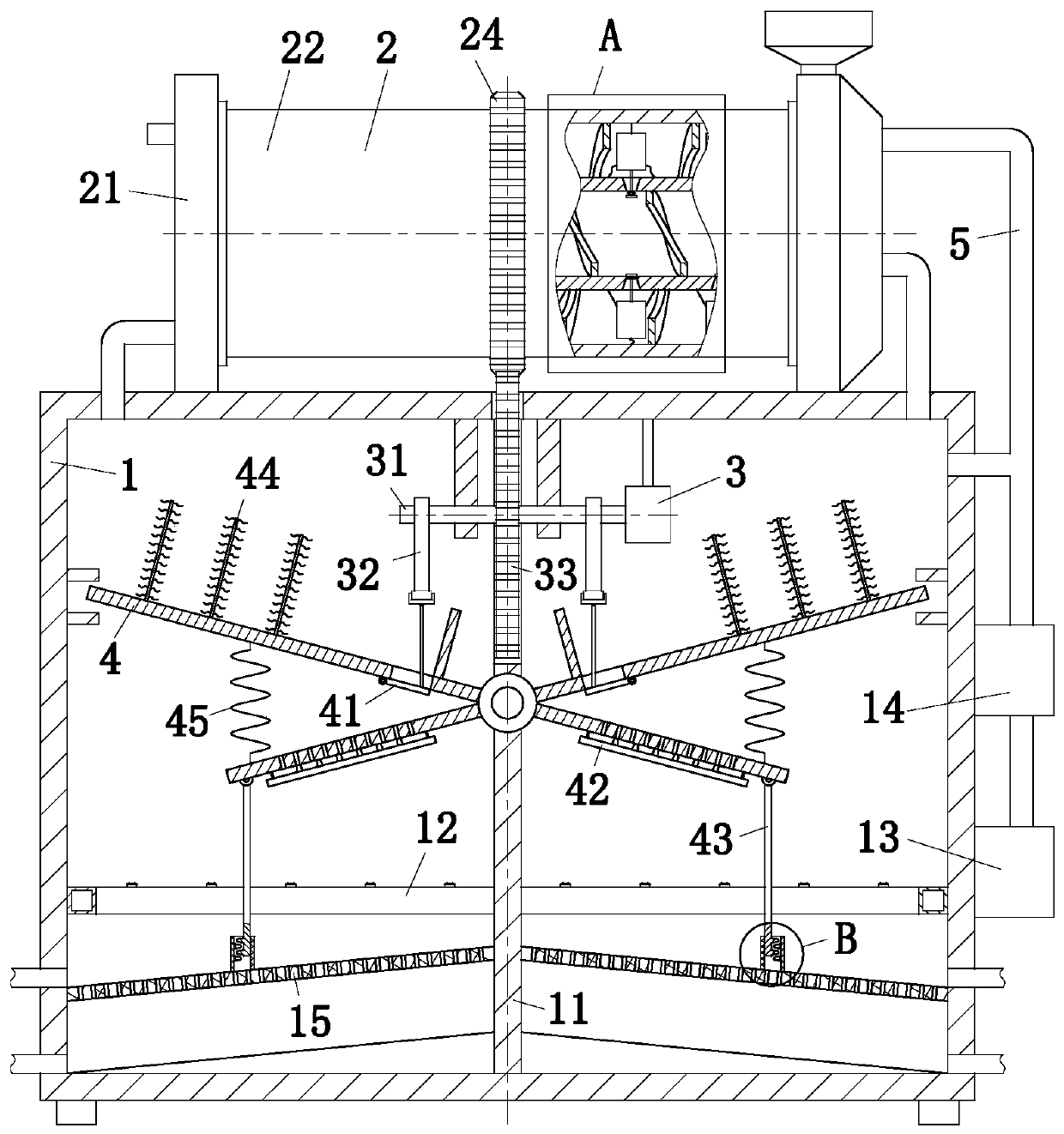

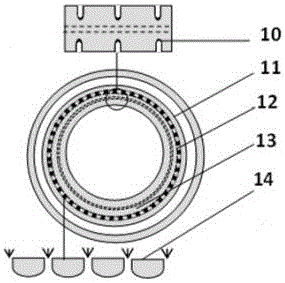

The invention belongs to the technical field of rice production equipment and particularly relates to a rice primary cleaning method. The rice primary cleaning method comprises the following steps ofextracting a screening module from an organic rice fine processing and screening device; preparing a plurality of two types of ring-shaped magnets with different outer diameters, adhering gauze onto the inner side of every ring-shaped magnet with a gap formed between the gauze and the ring-shaped magnet, mounting the two types of ring-shaped magnets with different outer diameters onto the inner walls of the outer barrel and the inner barrel of the screening module of the organic rice fine processing and screening device, and resetting the screening module; spraying clean water onto rice to bescreened, blow-drying the water-sprayed rice with an air cooler, and feeding the dried rice into the screening module of the organic rice fine processing and screening device for screening; starting the motor, the air pump and the dust cleaner of the organic rice fine processing and screening device, wherein the motor drives the screening module the screen the rice and the dust cleaning to clean dust in air. The rice primary cleaning method can improve the cleaning quality and save the workload of secondary cleaning.

Owner:安徽省东全米业股份有限公司

Sewage sand-filtering equipment

InactiveCN105641990AImprove sand removal efficiencyImprove stirring efficiencyStationary filtering element filtersSewageSand filter

The invention discloses sewage sand-filtering equipment which comprises a hollow cylindrical filtering bucket and a rotating shaft arranged on the inner side of the filtering bucket. A water accumulation plate is arranged on the filtering bucket, is of a semicircular structure and is mounted on the upper portion of the filtering bucket in a sleeving manner, a water accumulation cavity is formed between the water accumulation plate and the outer wall of the upper portion of the filtering bucket, through holes are formed in an end face, opposite to the water accumulation plate, of the filtering bucket and communicated with the inner side of the filtering bucket and the water accumulation cavity, a filtering net is arranged on the inner side of each through hole, and a drain valve is arranged on the water accumulation plate. In the process of utilizing the rotating shaft to drive blades to rotate, sewage receives acting force of the blades; in the process when the blades rotate, when the sewage passes one sides of the through holes with the filtering nets under action of inertia force, water enters the water accumulation cavity through the filtering nets, silt is still remained in the filtering bucket, output through discharging holes and collected in a centralized manner when reaching one sides of the discharging holes.

Owner:山东艾克赛尔机械制造有限公司

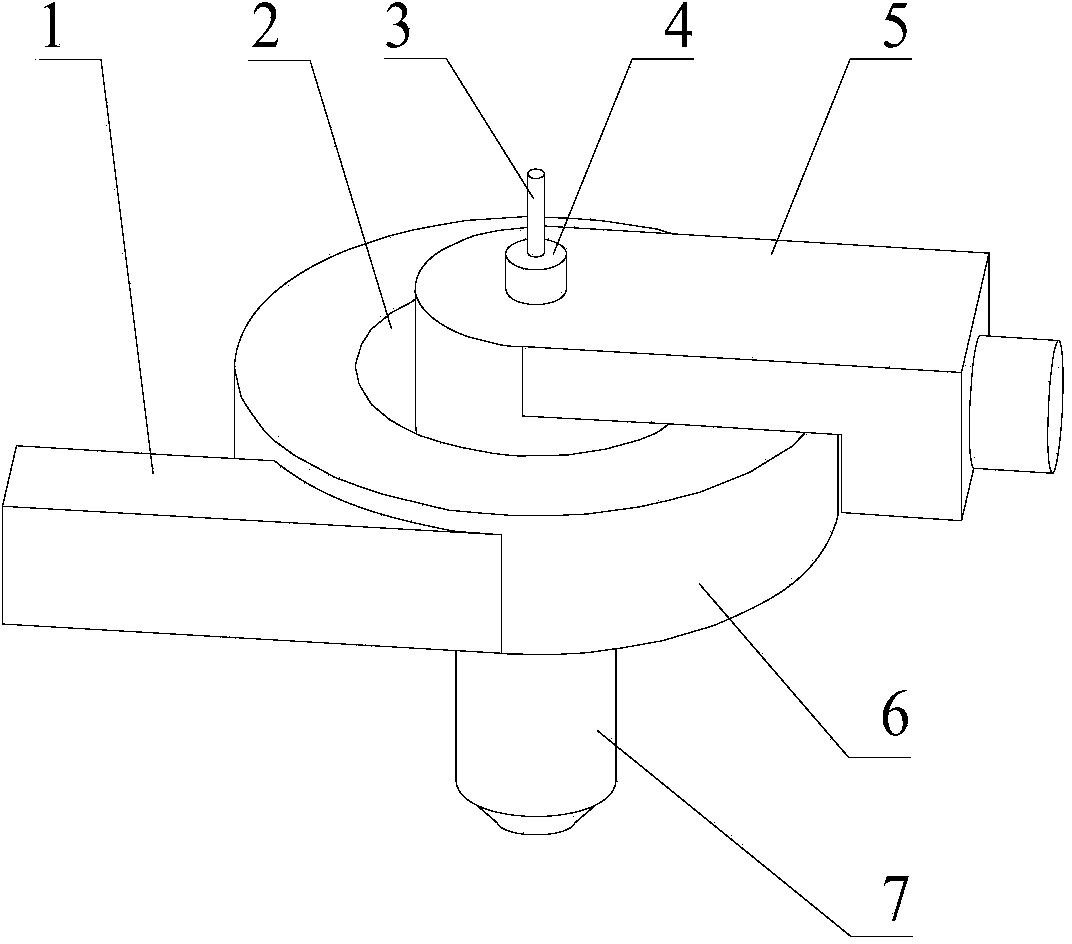

Rainwater pipeline rotational flow grit chamber

InactiveCN104056473ASimple structureImprove sand removal efficiencySettling tanks feed/dischargeCentrifugal force sediment separationPipingStormwater

A rainwater pipeline rotational flow grit chamber comprises a grit chamber body, a water inlet pipe, a water outlet pipe and a sand collecting hopper arranged at the bottom of the grit chamber body. The bottom face of the grit chamber body is inclined, the top of the grit chamber body is provided with a guide plate in an inverted circular truncated cone shape, a center shaft of the guide plate coincides with a center shaft of the grit chamber body, the walking direction of the water inlet pipe is in tangent with the side wall of the grit chamber body, the cross section of the water inlet pipe is in square, the initial end of the water outlet pipe is connected with the lower edge of the guide plate, a center column is arranged above the sand collecting hopper to prevent sediment falling into the sand collecting hopper from overflowing, a sand pump is arranged in the sand collecting hopper, and the sediment in the sand collecting hopper is pumped to the ground through the sand pump via a connecting pipe internally penetrating through the center column. According to the rainwater pipeline rotational flow grit chamber, high sand removing efficiency is kept without arranging a paddle and a filtering device, operation management is conveniently carried out, and the rainwater pipeline rotational flow grit chamber is suitable for reduction control over the rainwater pipeline sediment.

Owner:ANHUI UNIV OF SCI & TECH

High-efficiency tilted plate sand-removal and water-intake device

InactiveCN101967842BCompact structureReduce volumeSettling tanks feed/dischargeSedimentation settling tanksWater sourceEngineering

The invention relates to a high-efficiency tilted plate sand-removal and water-intake device which is used as water intake equipment in water supply engineering and surface water source heat pump engineering. The device comprises a water inlet chamber, a sand-separating and self-cleaning chamber and a water outlet chamber, wherein the wall of the intake chamber is made of corrugated bent plates and is provided with countless water inlet holes and water inlet / sand discharge dual-purpose holes; and the upper half of the sand-separating and self-cleaning chamber is a sand-separating chamber, thelower half is connected with a self-cleaning sand discharge bucket and a sand discharge pipe, a plurality of lateral flow tilted plates are arranged in bilateral symmetry in the direction of water flow in the sand-separating chamber, the tilted plates are tilted downwards and are provided with fins which are perpendicular to the direction of water flow and the plane of the tilted plates, and a sand-settling channel is left in the symmetry axis position of left and right lateral flow tilted plates and is communicated with the self-cleaning sand discharge bucket at the lower part. The device can be widely used in rivers having a high floater and sand content, and can be also used in water intake engineering using lakes, reservoirs or other water bodies as the water source. Besides, the device can effectively prevent the blocking of weeds and other floaters in water, effectively remove sand in water, omit the special sand basin and simplify the subsequent water treatment process, therebyachieving the purposes of reducing the abrasion of water pump impellers and subsequent water treatment structures, saving the capital investment, saving the occupied area and lowering the water intaking cost.

Owner:CHONGQING UNIV

Environment-friendly highway pavement sand cleaning equipment for highway engineering

InactiveCN107476233AClean up effectivelyHigh sand removal efficiencyRoad cleaningBaseboardRoad surface

An environment-friendly road surface sand cleaning equipment for highway engineering, comprising a base plate, a support device located above the base plate, a lifting device arranged above the support device, a driving device, and a first cleaning device arranged on the base plate device, and the second cleaning device arranged on the lifting device. The invention can effectively clean the fine sand on the road surface, has high sand cleaning efficiency, low labor intensity, simple operation, convenient use, manpower saving, and is suitable for popularization and application.

Owner:曹燕红

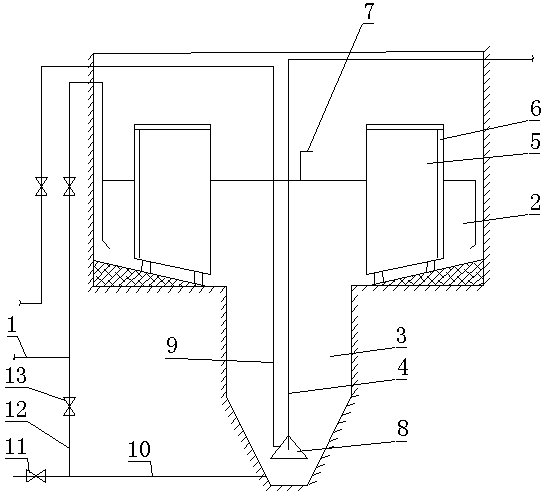

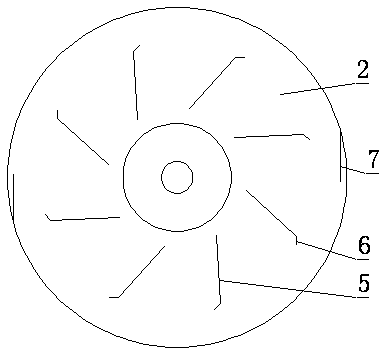

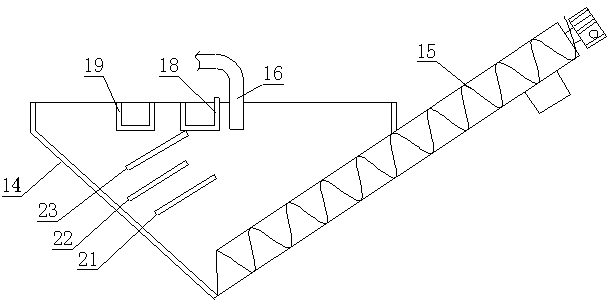

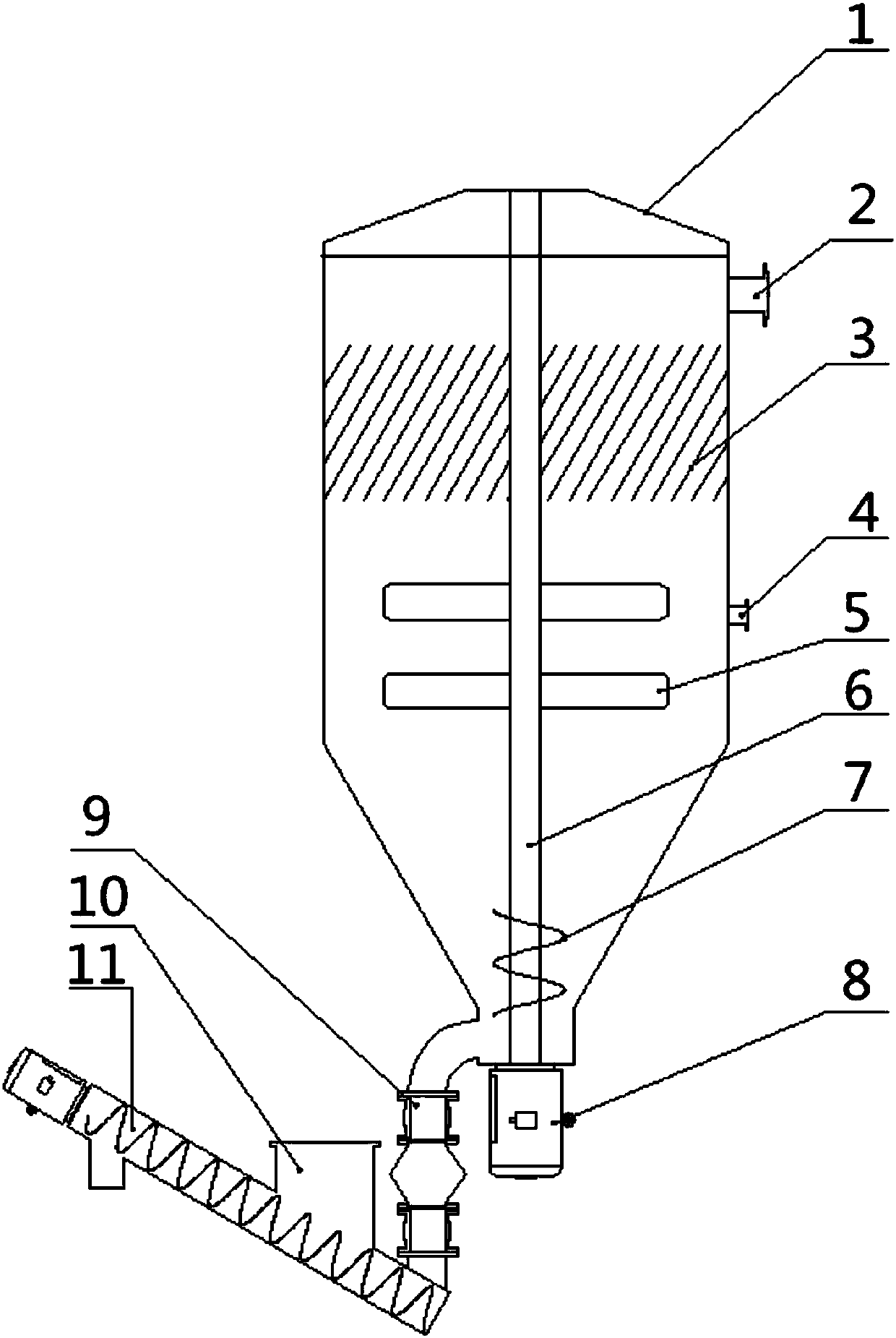

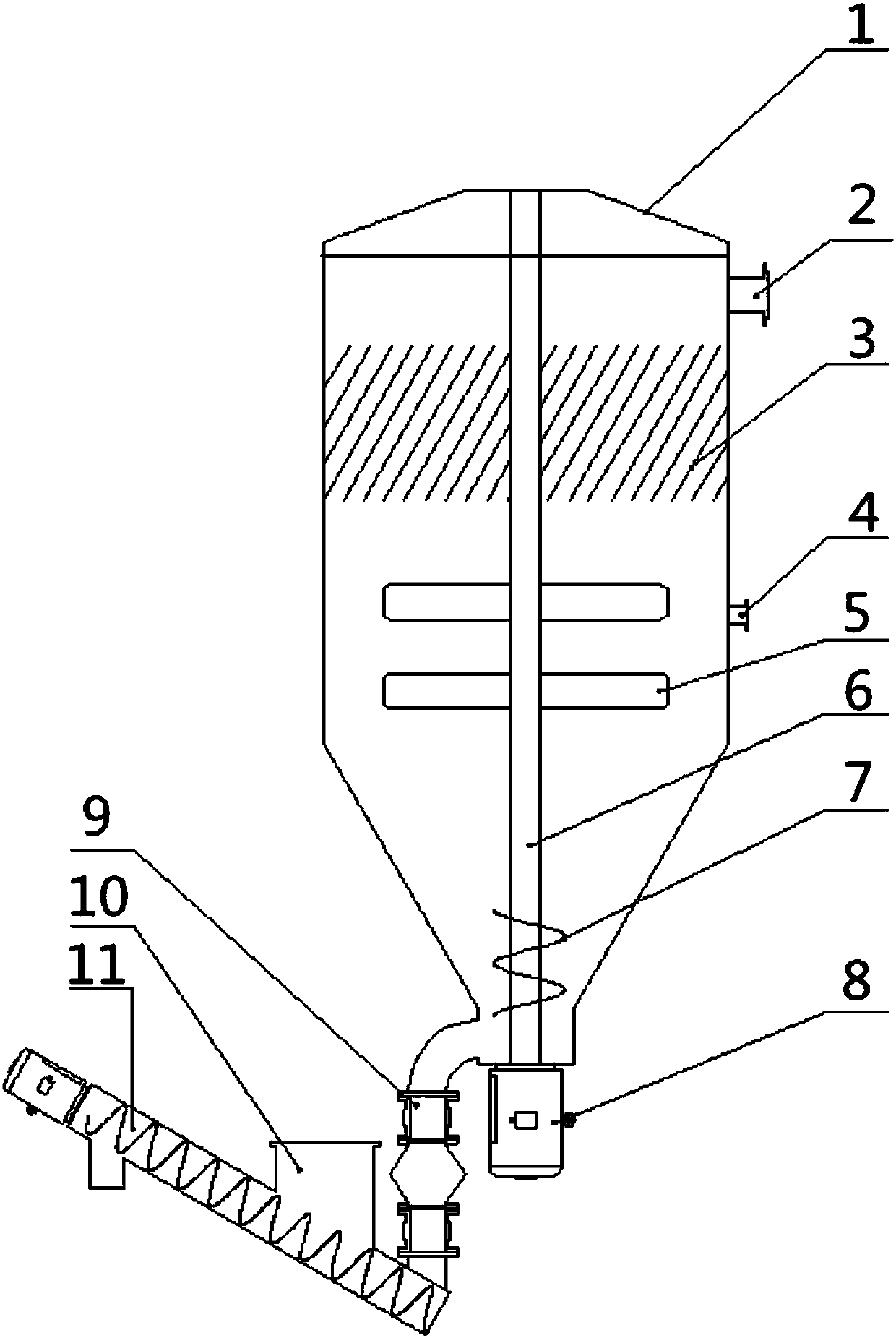

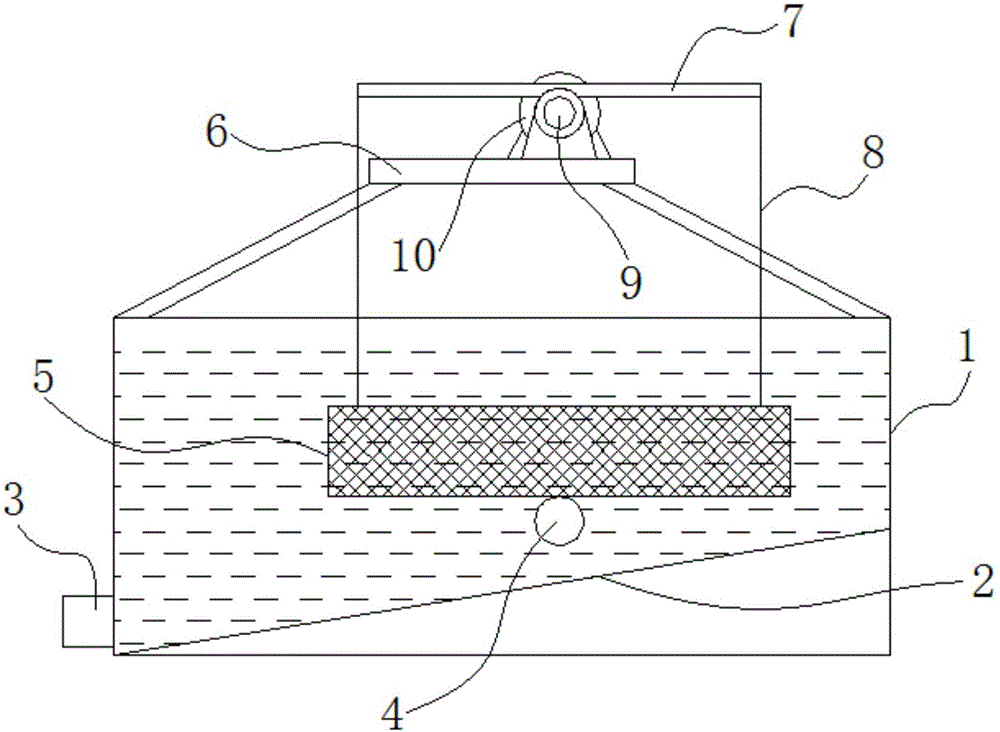

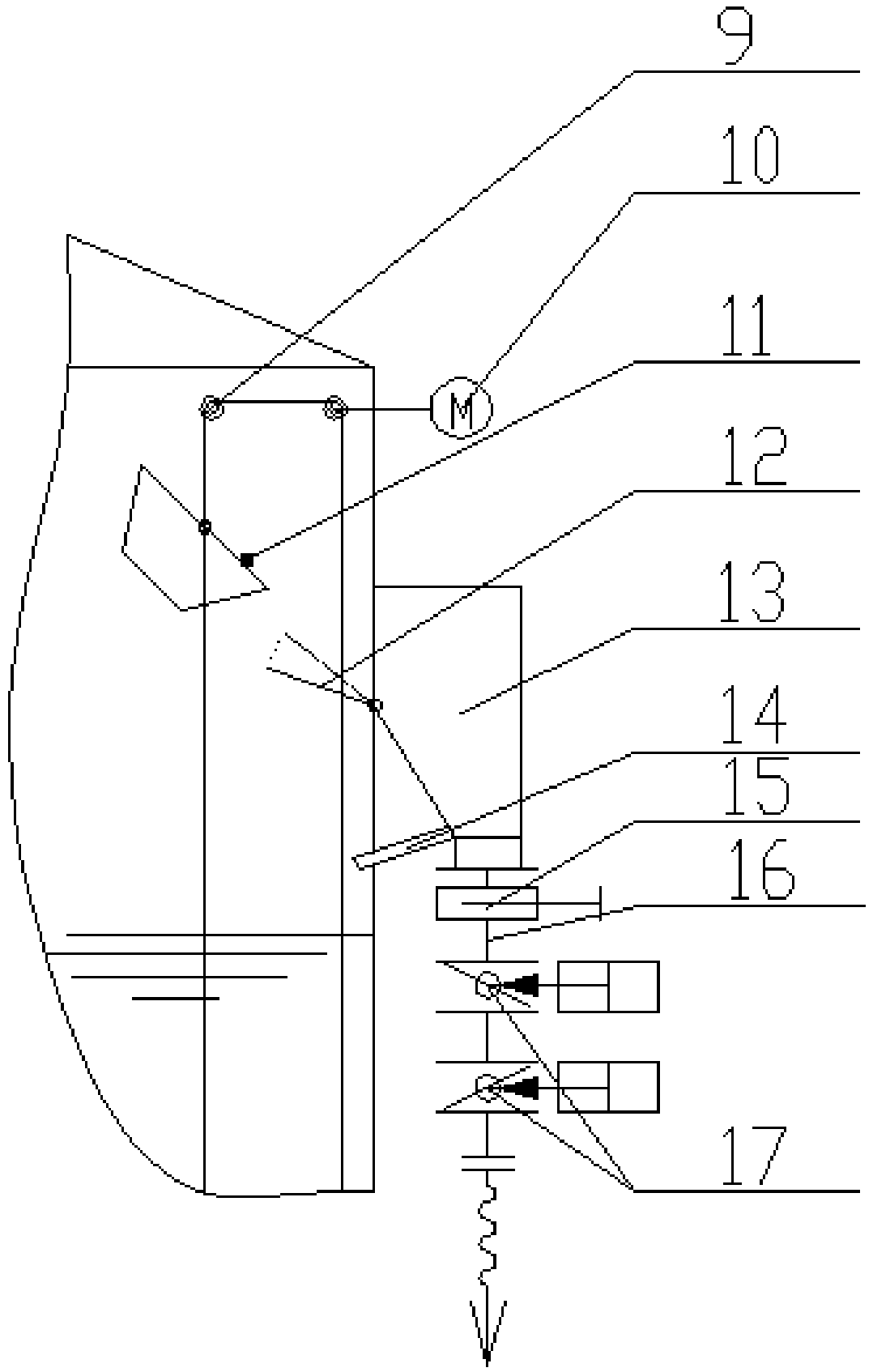

Combined efficient desander

InactiveCN110013706AImprove sand removal efficiencyLarge tank volumeFiltration circuitsSpecific gravityDesander

The invention discloses a combined efficient desander. The desander comprises a tank body, a liquid outlet pipe, an inclined sedimentation device, a liquid inlet pipe, rotary blades, a rotary shaft, arotary sand discharging device, a motor, a valve, a sand sedimentation box and a spiral conveying device. A stock solution enters the desander from a feeding opening along the tangential direction ofthe tank body; strong rotational movement occurs under the driving of the rotary blades; due to the fact that density of sand and water is different, water and fine solid particles with low density ascend under the combined action of centrifugal force, centripetal force and fluid drag force, secondary sedimentation is carried out through the inclined sedimentation device, and then the water and fine solid particles with low density are discharged from a water outlet; sand grains with large density enter the spiral conveying device through the valve at the bottom of the desander, third sedimentation is carried out by the sand sedimentation box, and finally the sand grains with large density are discharged from a sand outlet. The desander solves the problems that a conventional desander isdifficult for treating dirt with small specific gravity, is small in treatment amount and is low in desanding efficiency.

Owner:深圳龙澄高科技环保股份有限公司

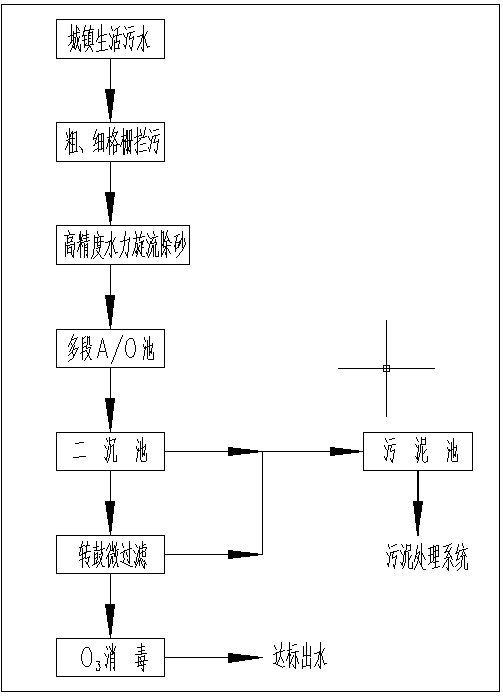

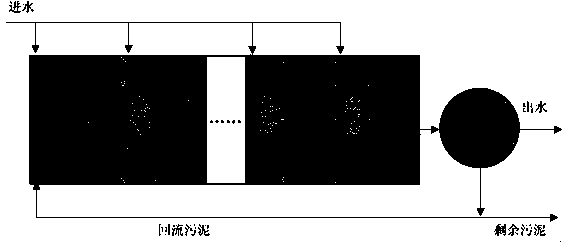

Urban sewage treatment process suitable for quasi IV-class water standards

PendingCN110922000AImprove denitrification efficiencyCarbon savingWater/sewage treatment by centrifugal separationWater contaminantsSludgeSewage treatment

The invention discloses an urban sewage treatment process suitable for quasi IV-class water standards. The urban sewage treatment process comprises a first-stage pretreatment system, a second-stage biochemical treatment system and a third-stage deep treatment system. High-precision hydraulic cyclone desanding is adopted in the first-stage pretreatment system. The second-stage biochemical system adopts a multi-stage multi-section A / O process; a biological tank is sequentially arranged into a first-stage anaerobic / aerobic zone and a multi-stage anoxic / aerobic zone, and internal reflux is avoided. Effluent of the biological tank enters a secondary sedimentation tank, part of sludge in the secondary sedimentation tank flows back to an anaerobic zone of the biological tank, and residual sludgeenters a sludge system for concentration and dehydration treatment. Effluent of the secondary sedimentation tank passes through a drum micro-filter, and finally effluent is disinfected, can be discharged outside after reaching the quasi IV-class water standards, and can also be used for reuse such as site washing, greening and the like. The sewage treatment process provided by the invention has good effects of removing organic matters and SS and removing nitrogen and phosphorus, and can stably realize the quasi IV-class effluent standards.

Owner:四川欧美华环境工程有限公司

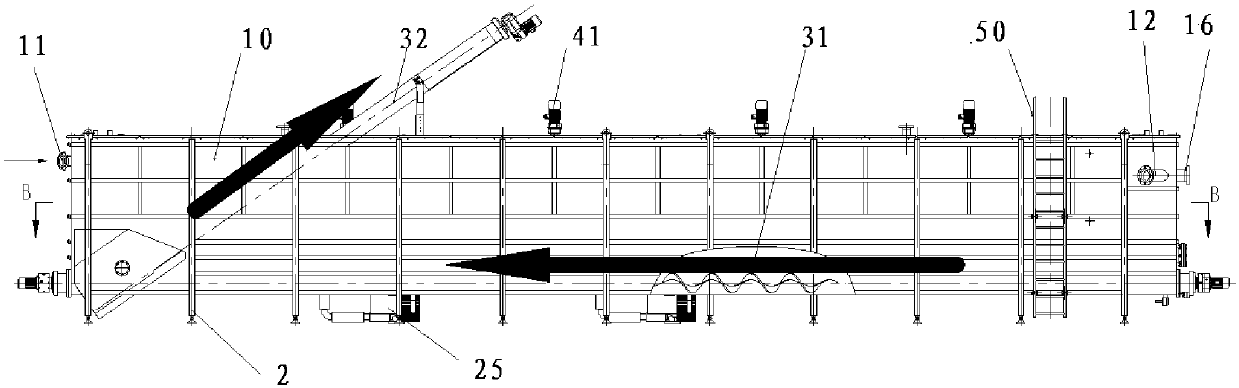

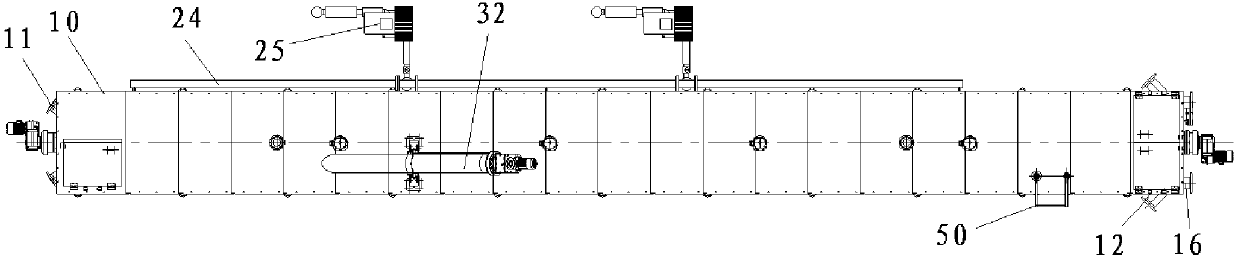

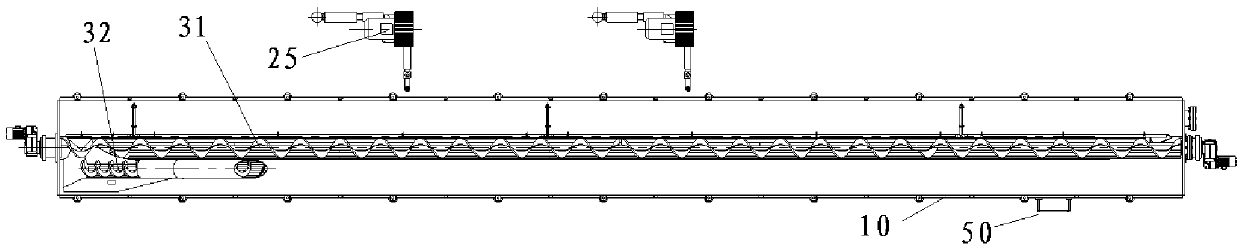

Mortar separating equipment for kitchen waste

ActiveCN107552252AWill not harmImprove sand removal efficiencyReversed direction vortexHigh intensitySlurry

The invention relates to the field of kitchen waste treatment and discloses mortar separating equipment for kitchen waste. The mortar separating equipment comprises a box body (10) for accommodating to-be-treated waste slurry, and an aerating apparatus (20) arranged in the box body (10), wherein the box body (10) comprises a feeding hole (11) and a discharging hole; the aerating apparatus (20) comprises an aeration pipeline (21) extending from the feeding hole (11) towards the discharging hole; and a plurality of aeration openings (22) are formed in the aeration pipeline (21) in a staggered angle manner to enable the to-be-treated waste slurry to flow spirally from the feeding hole (11) towards the discharging hole, so that the aeration action is utilized to separate sand and organic matter so as to improve the sand removing efficiency and carry out high-strength sand removing operation.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

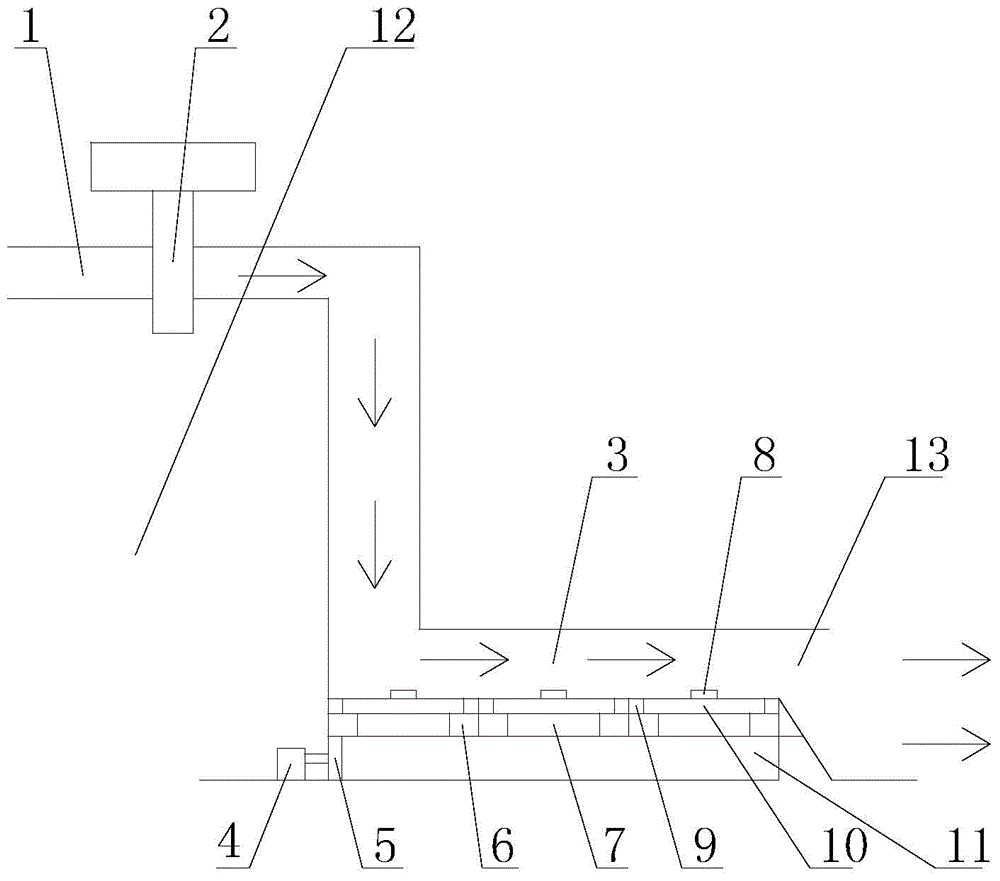

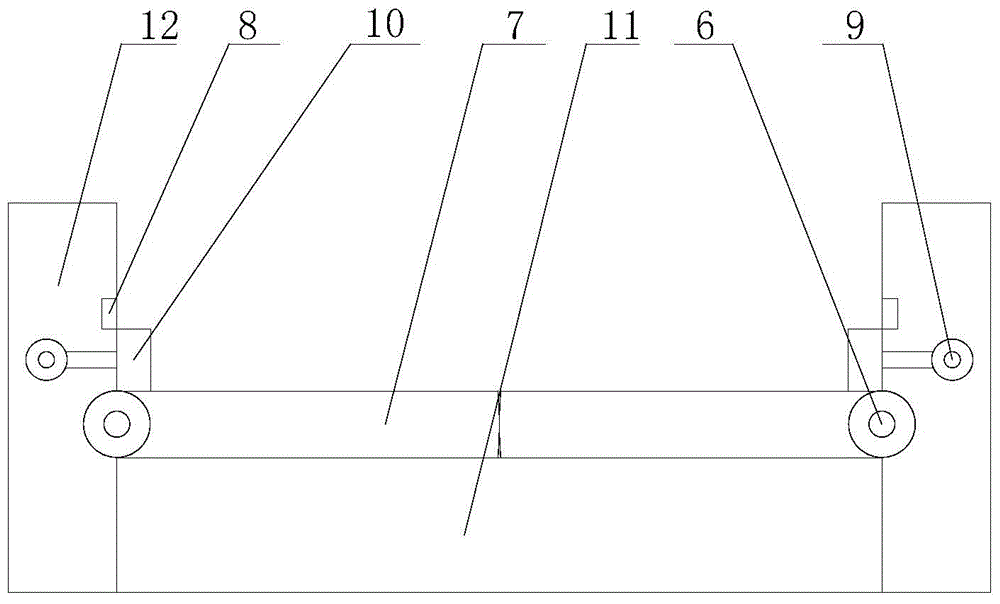

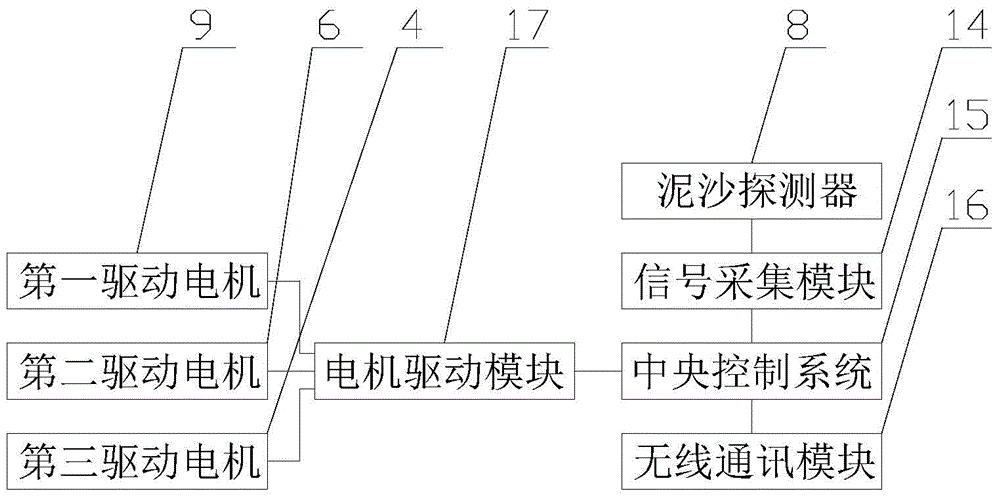

Environment-friendly system for water conservancy power generation

ActiveCN104790361AImprove sand removal efficiencyPlay an environmental roleWater-power plantsHydro energy generationDrive motorEnvironmental engineering

The invention relates to an environment-friendly system for water conservancy power generation. The environment-friendly system comprises a water inlet, a water conservancy power generator unit, a water outlet pipeline, sand removing mechanisms arranged in the water outlet pipeline, a water outlet, a dam and a central control device. The water inlet is communicated with the water outlet through the water outlet pipeline. The water conservancy power generator unit is arranged at the water inlet. The sand removing mechanisms include the multiple first sand removing mechanisms and the multiple second sand removing mechanisms. The first sand removing mechanisms are arranged in the water outlet pipeline, and the second sand removing mechanisms are located below the first sand removing mechanisms. Each first sand removing mechanism comprises a silt detector, a first drive motor, a first mud removing plate, a second drive motor and two deposition plates. By means of the environment-friendly system for water conservancy power generation, the first sand removing mechanisms are used for removing silt deposited in the water outlet pipeline, the silt is guided into the second sand removing mechanisms to be treated in a centralized mode, the sand removing efficiency is greatly improved, and a certain environment protection role is played on centralized processing of the silt.

Owner:SOUTHERN XINJIANG ELECTRICITY SUPPLY COMPANY OF STATE GRID XINJIANG ELECTRIC POWER

Cleaning and sand removing device for marine product

InactiveCN106540916AImprove sand removal efficiencyReduce manpower consumptionCleaning using liquidsShake upEngineering

The invention discloses a cleaning and sand removing device for marine products. The device comprises a cleaning box, a rotary shaft, a net cage, a bracket, an oscillating rod and a driving mechanism, wherein the bottom wall surface of the cleaning box is an inclined surface, and a drain outlet corresponding to the lowest end of the bottom wall surface of the cleaning box is formed in the cleaning box; the rotary shaft is arranged in the cleaning box in a rotatable manner; the middle part of the lower end of the net cage is fixed to the rotary shaft, and the net cage is located above the relatively high side of the bottom wall surface of the cleaning box; the bracket is erected above the cleaning box; the middle part of the oscillating rod is arranged on the bracket in a rotatable manner, and the two ends of the oscillating rod are connected to the net cage through pull ropes; and the driving mechanism is used for driving the oscillating rod to rotate. According to the device disclosed by the invention, when the oscillating rod rotates back and forth, the net cage can shake up and down through the pull ropes, so that silt in the marine products in the net cage falls into the cleaning box and flows to the lowest end of the bottom wall surface, waste of water can be reduced, and moreover, the sand removing efficiency for the marine product is high, and the manpower consumption is small.

Owner:防城港市海洋局

A kind of preparation method of sea cucumber intestinal oral liquid

ActiveCN103719926BEasy to synthesizeReduce consumptionNatural extract food ingredientsFood ingredient functionsBiotechnologyNeutral protease

The invention relates to a preparation method of sea cucumber sausage oral liquid, which uses fresh sea cucumber sausage as a raw material, grinds it into a slurry, heats and cools it, then adds neutral protease and flavor enzyme dual enzymes, and controls the enzymolysis conditions for enzymolysis treatment The enzymatic hydrolyzate of sea cucumber intestines is centrifuged once with a centrifuge, the supernatant is collected and then centrifuged twice, and the supernatant is collected and desalted repeatedly by nanofiltration separation technology to obtain sea cucumber intestinal juice; supplemented with wolfberry, astragalus, angelica and The natural plant extract and sweetener prepared from ginseng are formulated, filled and sterilized to prepare sea cucumber intestine oral liquid. The preparation method of the invention has reasonable technology, simple and convenient operation, strong operability, and is easy to realize industrialized production; the sea cucumber intestine oral liquid prepared by the method is not only rich in nutrition, clear and transparent, moderately sweet and sour, and natural in flavor, but also has the functions of nourishing blood, nourishing qi, strengthening body Strengthen the body, strengthen essence and marrow, eliminate fatigue and improve immunity and other health effects.

Owner:SHANDONG HOMEY AQUATIC DEV +1

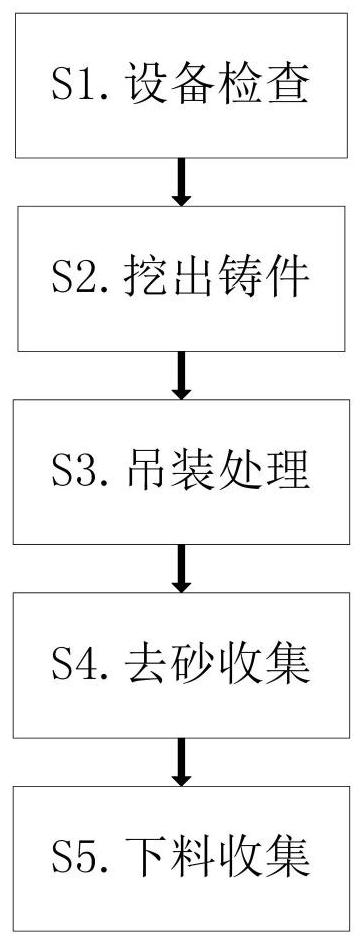

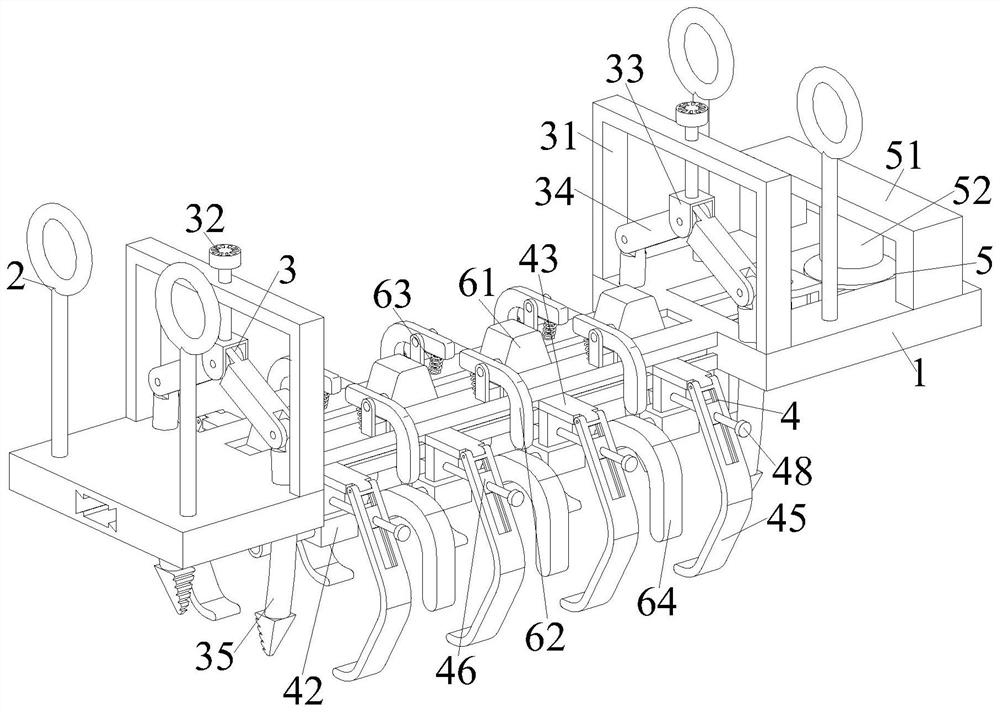

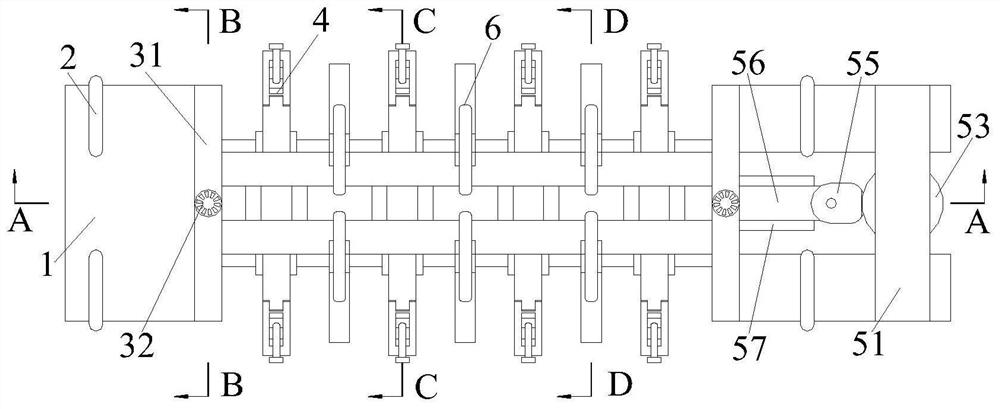

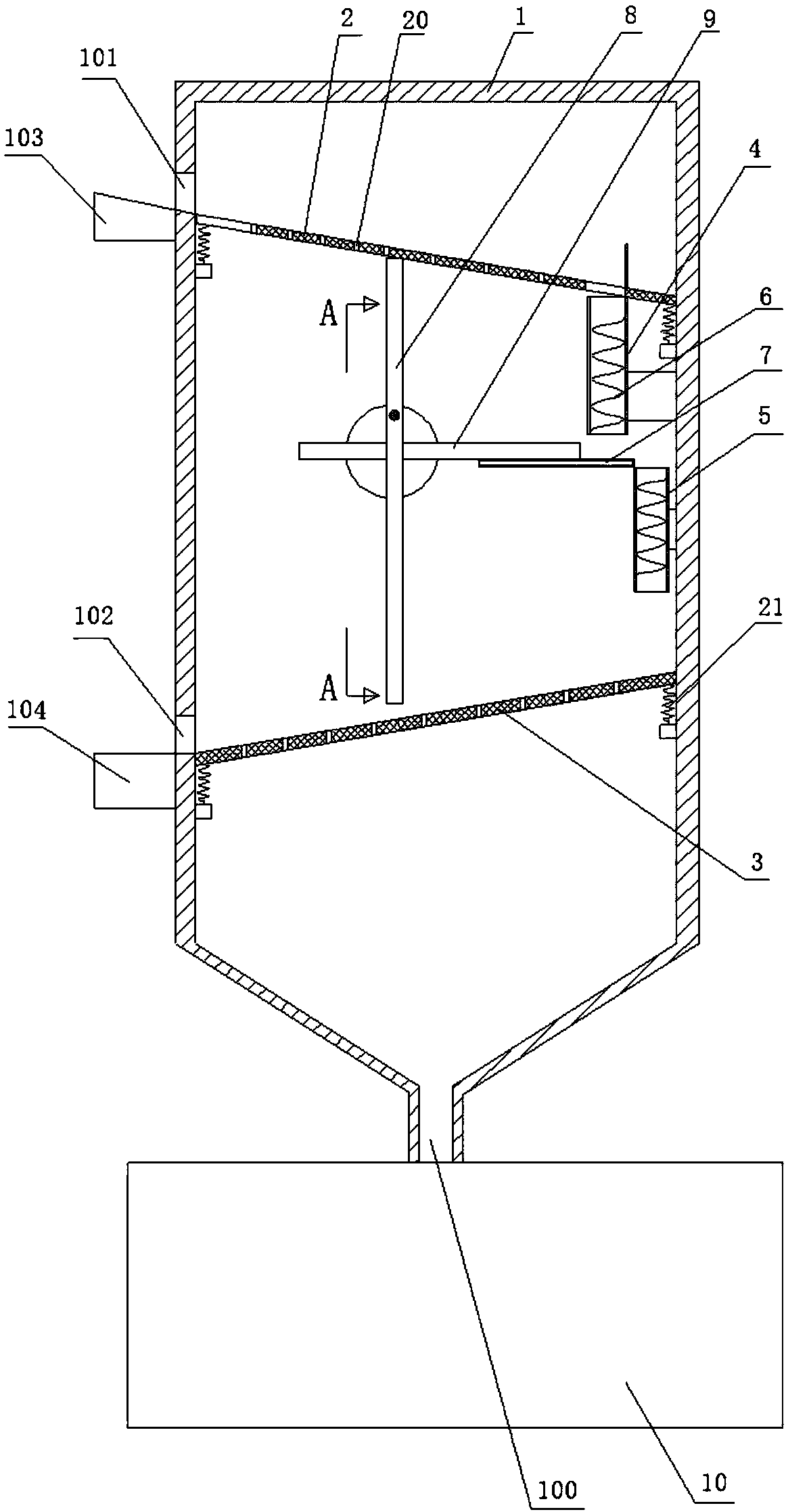

Precoated sand casting method for large castings

The invention relates to a precoated sand casting method for large castings. The large castings are hoisted and subjected to sand removal through the combined work of a hoisting plate, hoisting rings,digging devices, clamping devices, a driving device and knocking devices. According to the precoated sand casting method for the large castings, the problems that when an existing casting device forthe large castings is used for casting the large castings, the cast castings are usually directly hoisted out of a sand mold after being directly locked and fixed, the castings are likely to slide with a locking mechanism in the hoisting process, so that the castings fall off, then the situation of personnel injury is caused, meanwhile, after the castings are hoisted to a designated position, residual sand on the surfaces of the castings needs to be manually removed, due to the fact that the large castings are large in size and complex in shape, the manual sand removing efficiency is low, andthen the casting efficiency of the large castings is low are solved.

Owner:江西维海机械设备有限公司

Casting sand removing device

The invention belongs to the field of casting equipment, and particularly discloses a casting sand removing device. The casting sand removing device comprises a sand removing box; a horizontal first movable plate and a horizontal second movable plate are sequentially arranged in the sand removing box from top to bottom in a sliding manner; the first movable plate and the second movable plate are both inclined; the first movable plate and the second movable plate are inclined in opposite directions; sand through holes are formed in the first movable plate and the second movable plate; a first push rod is vertically connected between the first movable plate and the second movable plate in a sliding manner; the top end of the first push rod is propped against the first movable plate; the bottom end of the first push rod is propped against the second movable plate; a first passage is arranged at the low end of the first movable plate; a second passage is rotationally connected with the inner side wall of the sand removing box below the first passage; spiral bulges are arranged on the inner wall of the first passage and the inner wall of the second passage; bristles are densely distributed on the bulges; a receiving slot is arranged between the first passage and the second passage; and a second push rod is connected with the receiving slot in a sliding manner. The device can turn over automatically when used for sand removal of castings.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

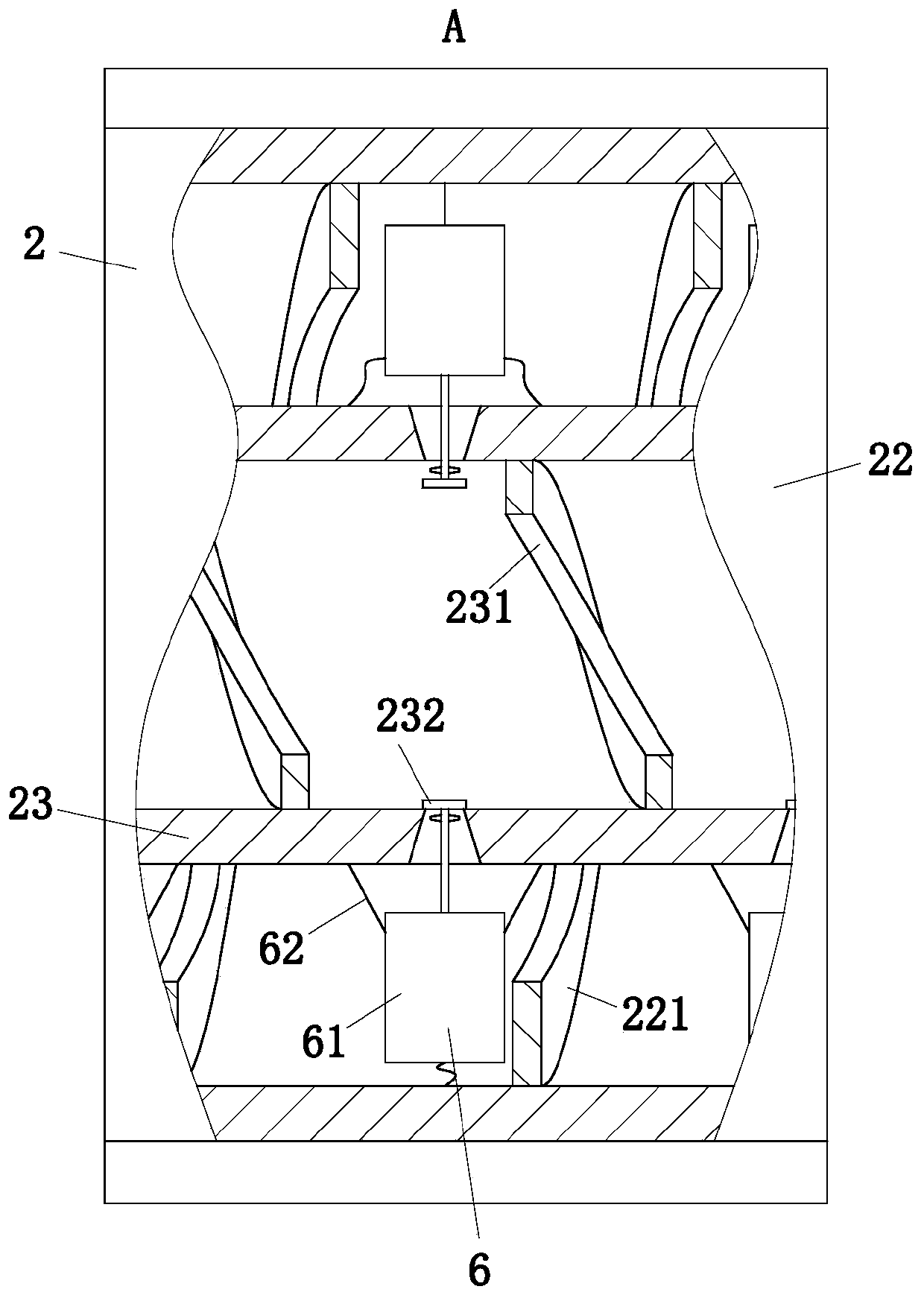

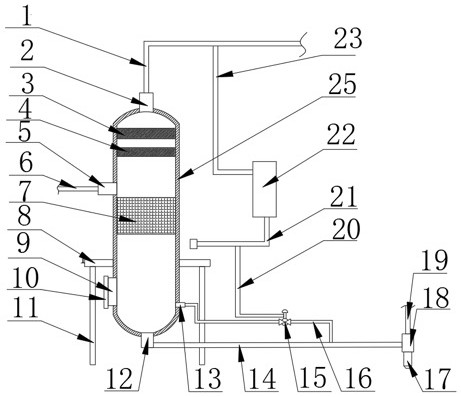

Natural gas wellhead shutdown-free desanding separation device

ActiveCN114293969AImprove sand removal efficiencyEnsure air qualityFluid removalDesanderMechanical engineering

The invention discloses a natural gas wellhead shutdown-free desanding separation device, and belongs to the technical field of natural gas extraction. Comprising a support, and a bottom plate is fixed to the upper end of the support; a cylinder body is fixed on the bottom plate; an upper cover is fixed at the upper end of the barrel, one side of the barrel is connected with an air inlet pipe, and a sand remover opposite to the air inlet pipe is mounted in the barrel; the upper cover is connected with an air outlet pipe; a pull rod penetrates through the center of the bottom plate; lifting devices are connected to the lower ends of the pull rods; the upper ends of the pull rods are connected with conical seats; the conical seat is connected with a sand gathering cylinder; the lower side of the conical seat is a sand gathering cavity; a pressurizing pipe and a pressure reducing valve which are communicated with the sand gathering cavity are mounted on the side wall of the barrel; a sand unloading hole is formed in the bottom plate, and a sand outlet pipe is connected below the sand unloading hole; a pressure plate is fixed on the pull rod; and a sealing column which is relatively matched with the sand unloading hole is fixed below the pressure plate. In the whole sand unloading process, the air inlet pipe does not stop air inlet, the whole machine continuously works, and the working efficiency is improved.

Owner:江苏华普泰克石油装备有限公司

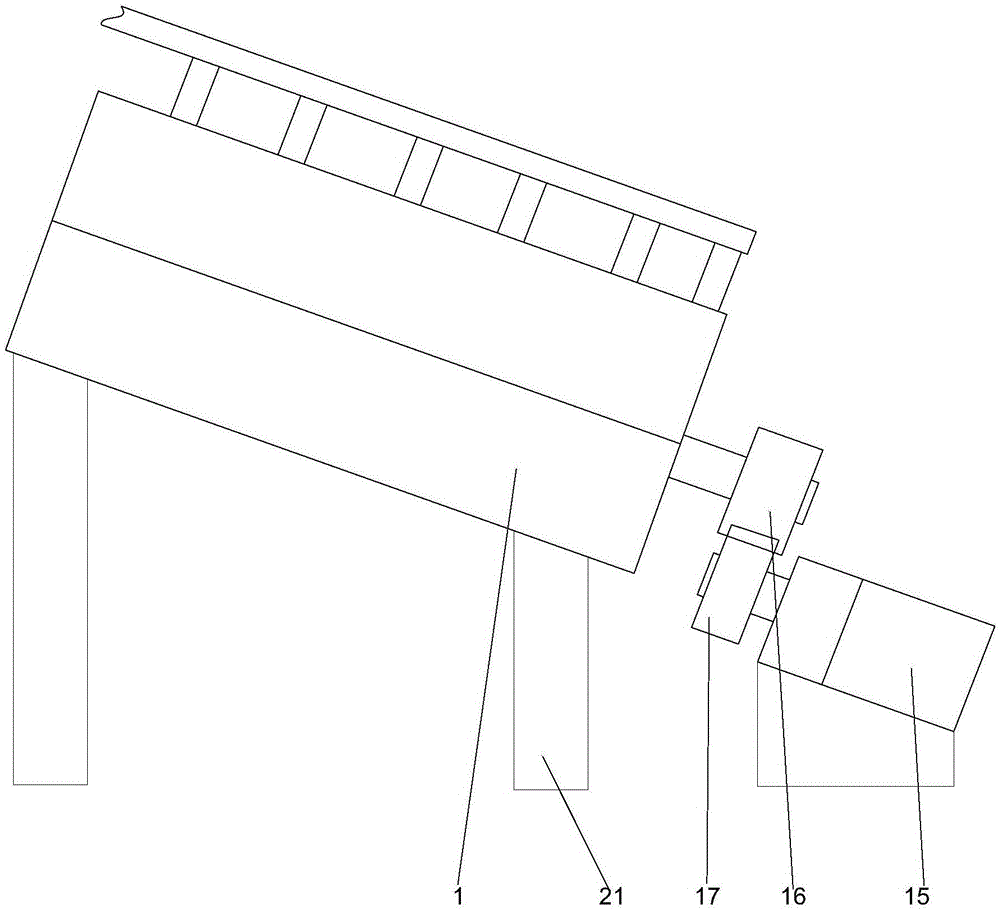

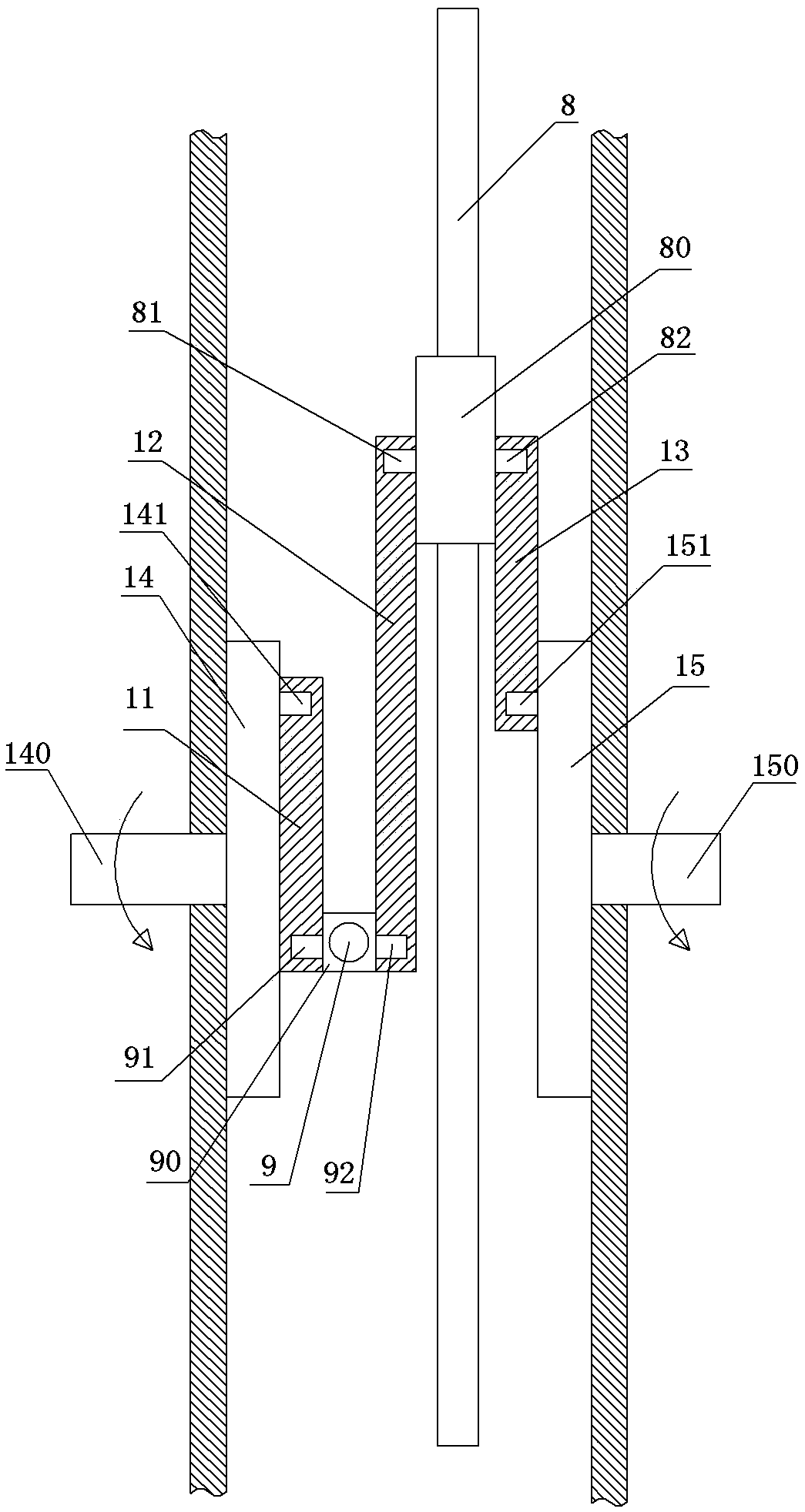

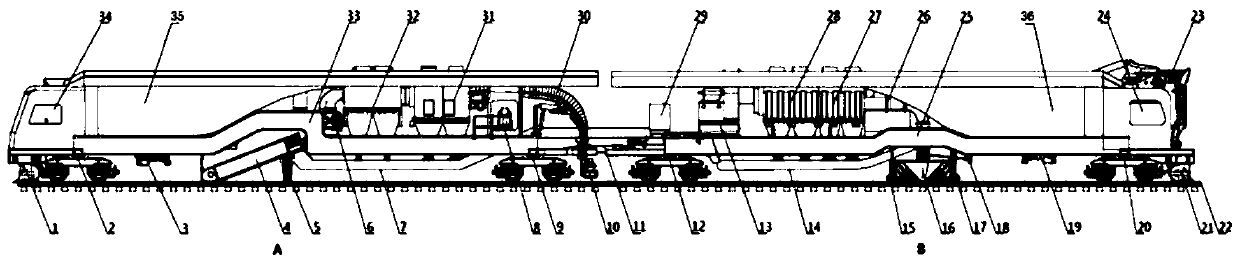

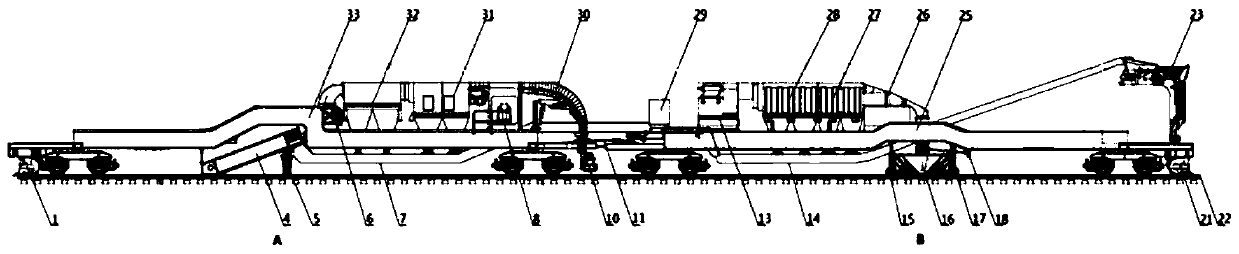

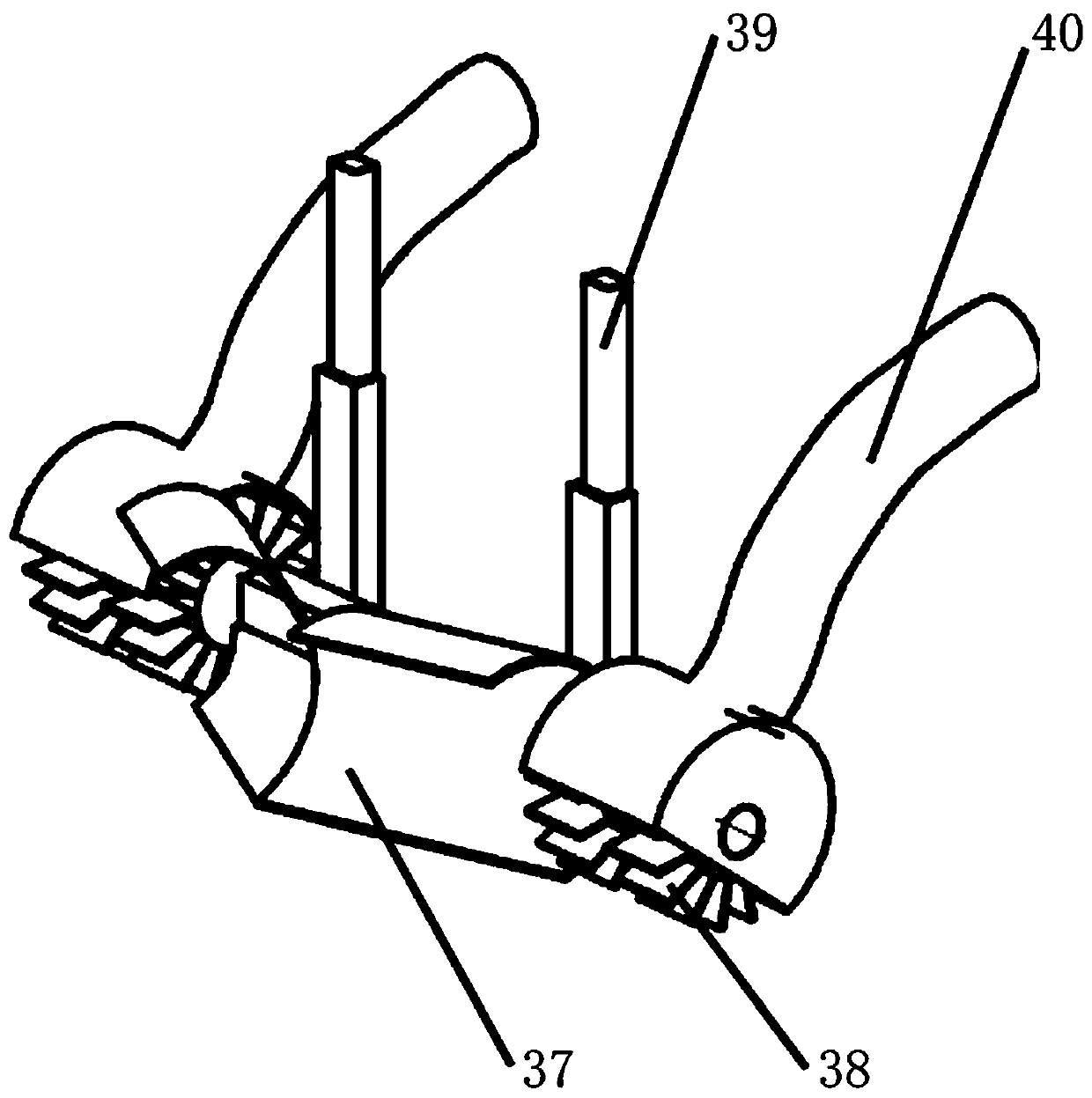

Rail ballast bed sand removal vehicle

The invention relates to a rail ballast bed sand removal vehicle, which comprises a vehicle body A and a vehicle body B. The vehicle body A and the vehicle body B are connected through a connecting beam (11), and the vehicle body A comprises a vehicle body A main vehicle frame (33), a vehicle body A front bogie (2) and a vehicle body A rear bogie (9); the front lower part and the rear lower part of the vehicle body A main vehicle frame (33) are provided with the vehicle body A front bogie (2) and the vehicle body A rear bogie (9) correspondingly; the front upper part of the vehicle body A mainvehicle frame (33) is provided with a vehicle body A driver cab (34), and a mechanical sand removal device is fixedly mounted in the middle of the vehicle body A main vehicle frame (33); and front-row sand ploughs (1) are mounted on the front part of the vehicle body A front bogie (2) and the lower part of the vehicle body A driver cab (34). Compared with the prior art, the rail ballast bed sandremoval vehicle has the beneficial effects that through the front-row sand ploughs and rear-row sand ploughs which are arranged at the two ends of the vehicle correspondingly, when a railway encounters a serious sand disaster and steel rails are buried, normal sand removal operation of the sand removal vehicle can be guaranteed; and by arranging a side suction sand removal device and a main suction working trolley, the sand removal efficiency, quality and effect are improved.

Owner:CRCC HIGH TECH EQUIP CORP LTD

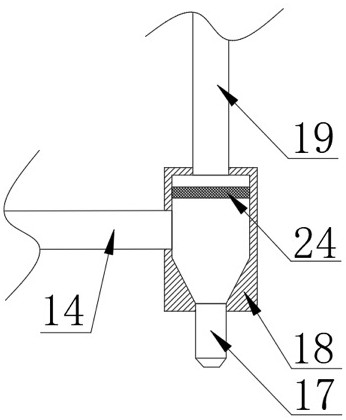

Sand fishing pipe column and sand fishing working method thereof

PendingCN110374535AAct as an upward suctionLarge amount of sandBorehole/well accessoriesAutomatic control for drillingEngineeringFishing

The invention discloses a sand fishing pipe column and a sand fishing working method thereof used in the petroleum industry. The pipe column comprises a suction pump, drill rods and a sand washing penpoint. The suction pump is connected with a rotational flow pipe, a sand settling pipe and the sand washing pen point sequentially from top to bottom through the drill rods, wherein a sand settling cavity is formed in the sand settling pipe, a rotational flow channel is formed in the rotational flow pipe, and at least one sand settling pipe is connected in the sand fishing pipe column. After thesand washing pen point in the sand fishing pipe column makes contact with the sand face, a pump is started on the ground to conduct direct cycle sand washing, at the moment the put-in drill rods beginto be counted, when the size of the drill rods put into washed sand is matched with the volume of the sand settling cavity / cavities in one or more sand settling pipes connected in the sand fishing pipe column, the pump is stopped on the ground, and sand is settled. The sand washing quantity of a sand washing well section can be calculated according to the depth of the sand washing well section, and thus the sand settling quantity of the sand settling pipe connected in the sand fishing pipe column is equal to the sand washing quantity of the sand washing well section. The sand cleaning effectis improved significantly, the construction period is shortened, the purpose of effective sand washing is achieved, and working cost is lowered effectively.

Owner:中石化石油工程技术服务有限公司 +2

Automatic liquid discharging and sand removing separator

InactiveCN113431549AImprove sand removal efficiencyRealize continuous sand discharge functionFluid removalProcess engineeringMechanical engineering

The invention discloses an automatic liquid discharging and sand removing separator. The automatic liquid discharging and sand removing separator comprises a shell, wherein a supporting plate is fixedly connected to the side wall of the shell; a plurality of supporting columns are fixedly connected to the bottom side wall of the supporting plate; a natural gas outlet, a feeding port, a mixture outlet and a pressure dividing port are formed in the side wall of the shell; a feeding pipe is fixedly connected to the feeding port; a cyclone, a coalescer and a mist catcher are sequentially arranged in the shell from bottom to top; an air outlet pipe is fixedly connected to the natural gas outlet; and a fifth connecting pipe is fixedly connected to the side wall of the air outlet pipe. The automatic liquid discharging and sand removing separator is high in sand removing efficiency, capable of achieving a continuous sand discharging function, simple to install, capable of achieving automatic liquid discharging after being installed and debugged to run normally, free of manual assistance and capable of saving working hours, and other equipment can be used only through cooperation of at least two sets of equipment.

Owner:北京中海沃邦能源投资有限公司

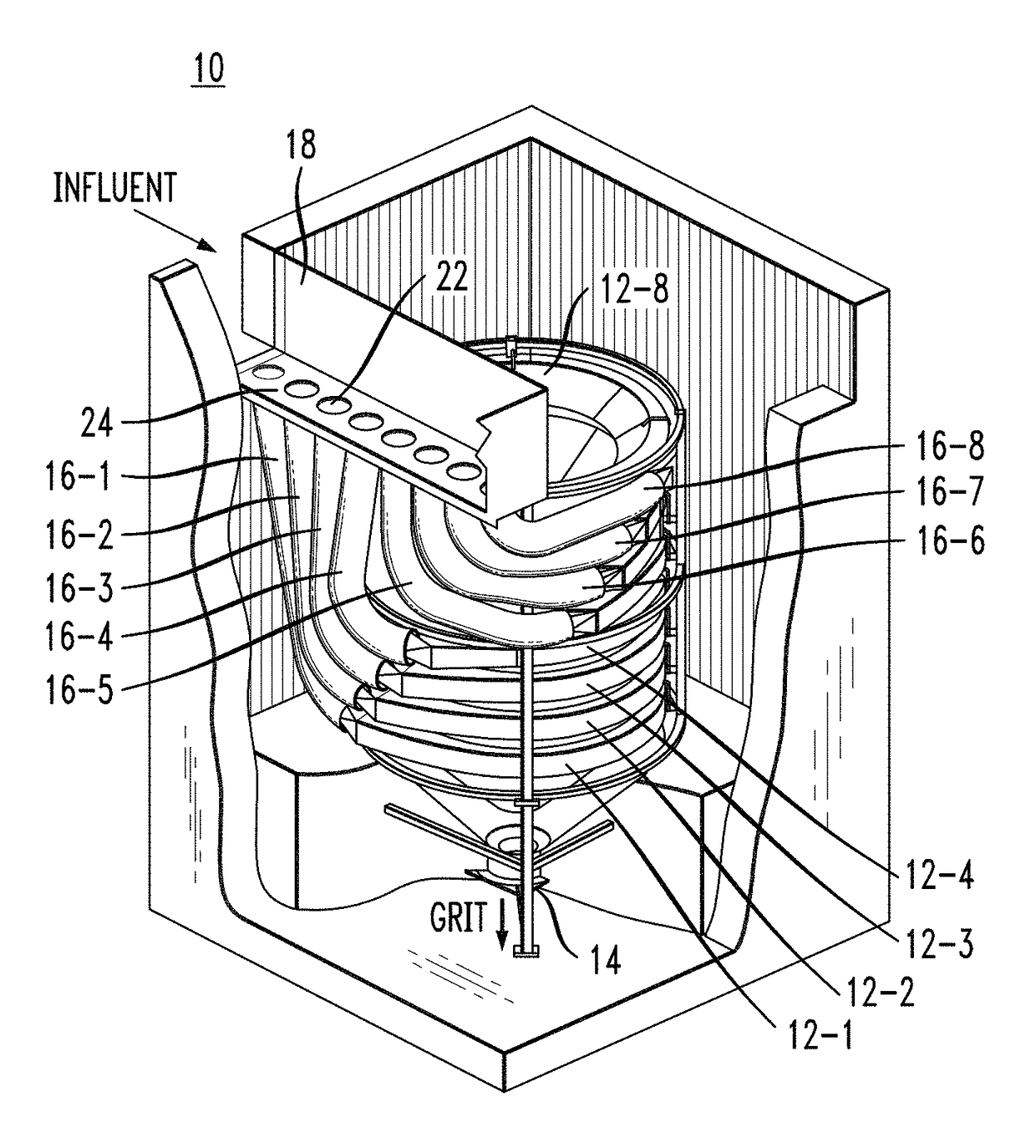

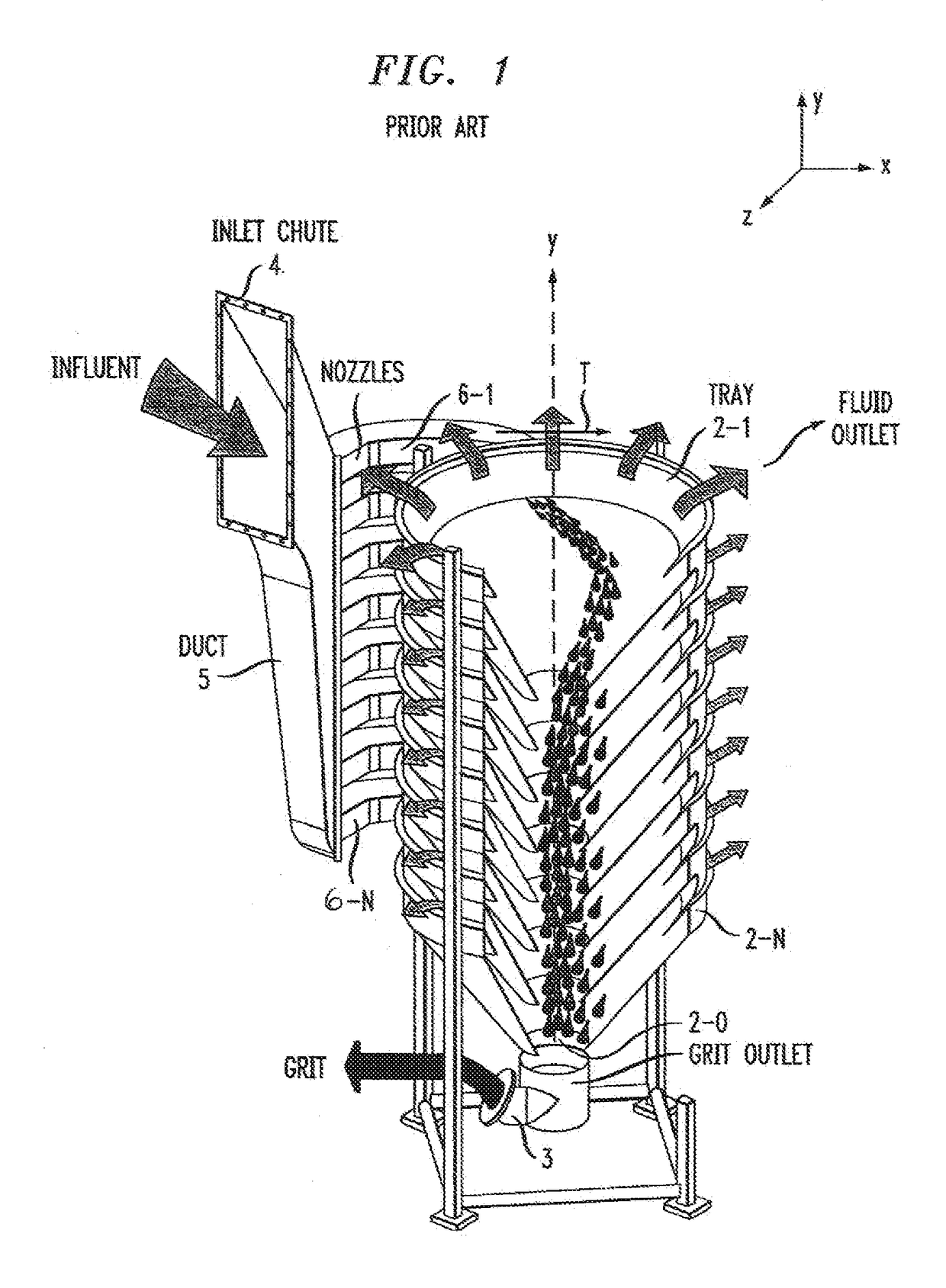

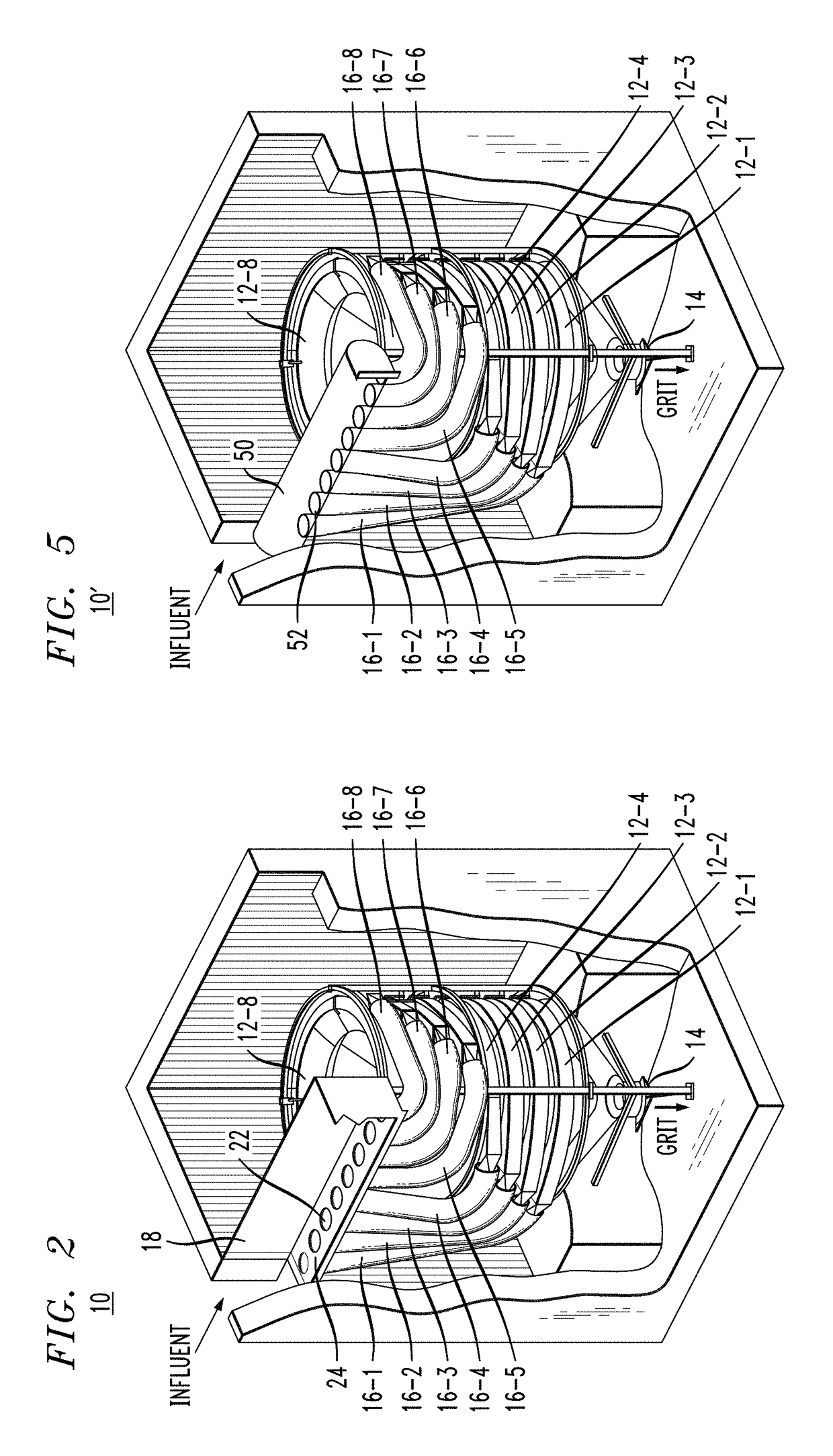

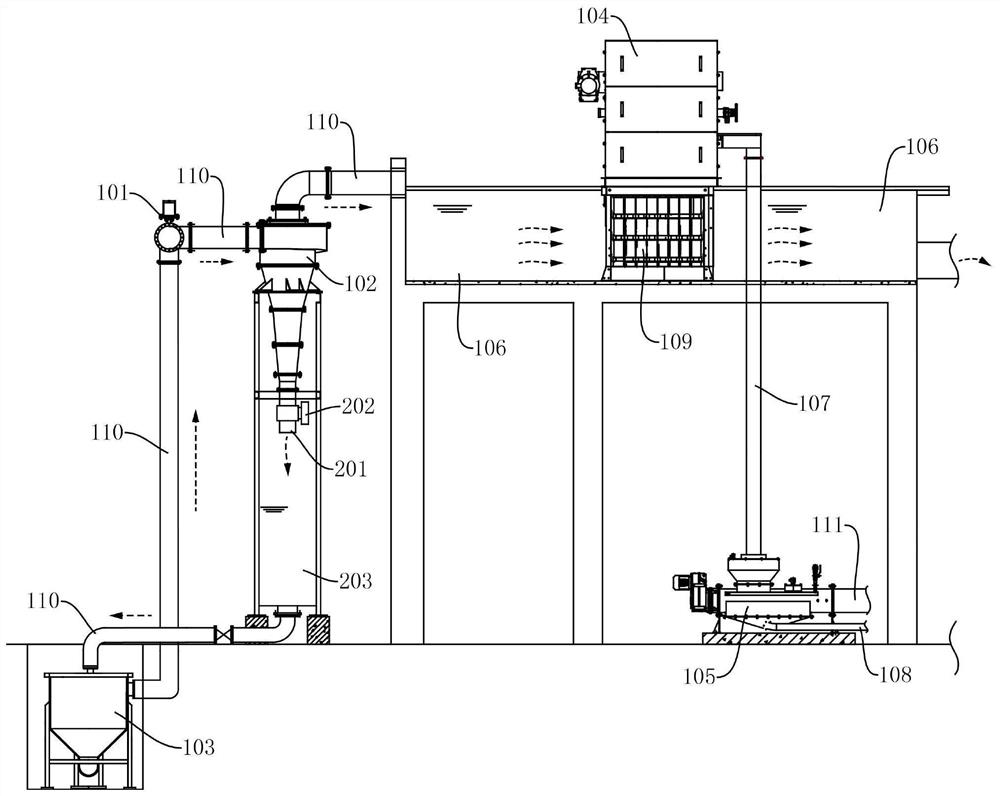

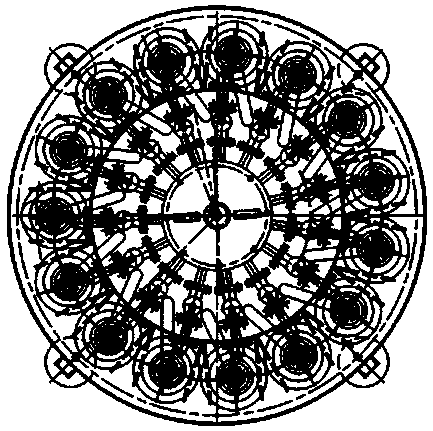

Low headloss feed devices and control methods for tray-type vortex grit removal systems

ActiveUS9770722B1Improve sand removal efficiencyReduce headlossWater/sewage treatment by centrifugal separationWater treatment parameter controlEngineering

An inlet arrangement for a tray-based grit removal system utilizes a set of separate inlet hoses to connect the vertical stack of trays to a horizontally-disposed inlet chute, thus eliminating the inlet duct utilized in prior art configurations. Each hose is configured to have about the same length and diameter, providing an essentially uniform influent pressure at the input to each tray. The hoses are directly connected between the trays and the inlet chute, where each tray may be formed to include a hose coupler of the same diameter as the hose. The inlet chute may take the form of a trough or tube (or other suitable geometry), with the plurality of hoses all terminating along a common, horizontal output face of the chute.

Owner:ENVIRODYNE SYST

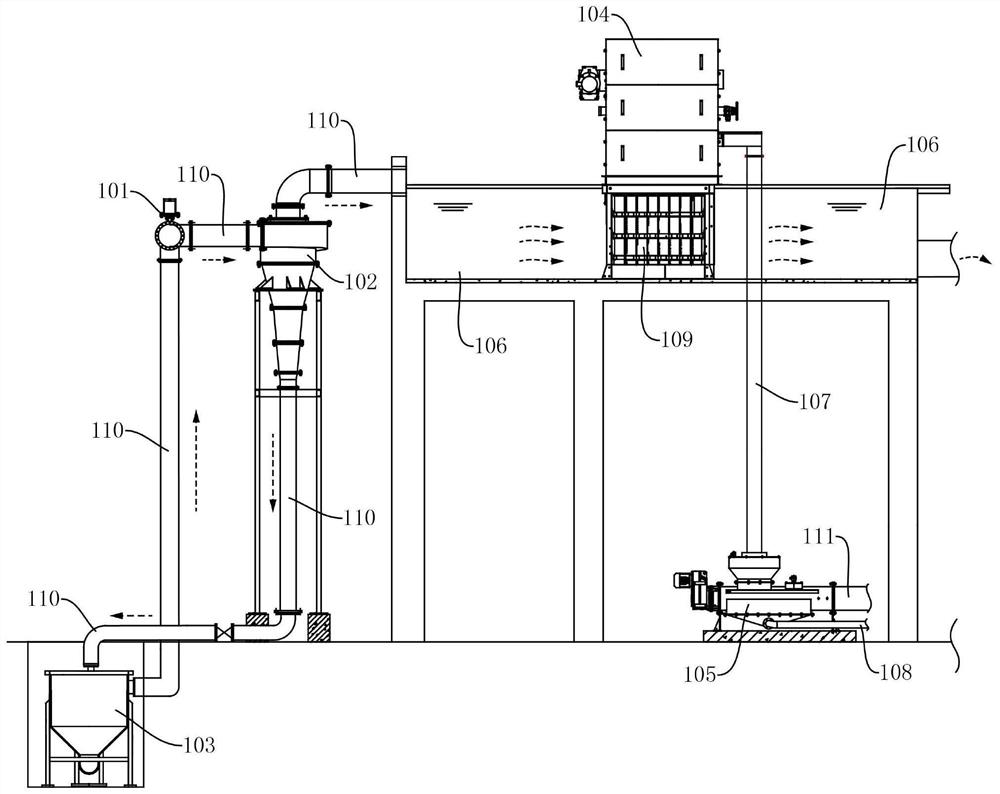

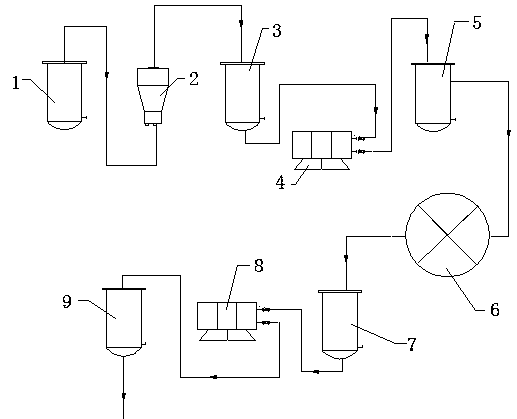

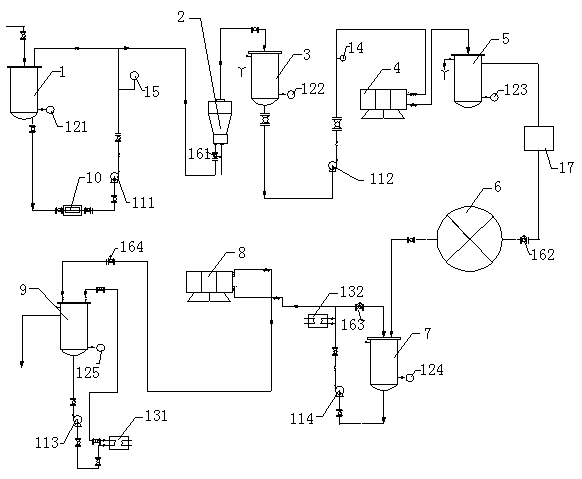

Sand-slag co-removal efficient pretreatment system and process

ActiveCN113144698AReduce wearHigh removal rateReversed direction vortexStationary filtering element filtersProcess equipmentSlag

The invention relates to a sand-slag co-removal efficient pretreatment system and process, the pretreatment system comprises a slag removal unit and a sand removal unit, the slag removal unit comprises a hydrocyclone, and the sand removal unit comprises pore plate grating equipment; an overflow port of the hydrocyclone is communicated with the water inlet end of the pore plate grating equipment, the hydrocyclone settles and separates sand grains and grating slag by utilizing centrifugal force, and the pore plate grating equipment is used for further intercepting the sand grains and the grating slag; according to the pretreatment system, municipal sewage pretreatment is carried out by adopting a mode of firstly removing sand and then removing slag, so that the sand removal efficiency can be remarkably improved, the removal rate of fine sand of more than 100 microns can reach 90%, and the fine sand can be effectively prevented from entering the subsequent treatment unit; therefore, abrasion of process equipment and pipelines can be effectively reduced, the problems that MLVSS / MLSS is reduced, the sludge yield is increased, and the follow-up sludge treatment difficulty is large are avoided, sand grains and grating slag in sewage can be further intercepted with high precision and high removal rate, and the slag / sand removal rate is increased.

Owner:SCIMEE TECH & SCI CO LTD

Sand removing process and system of waste glue

PendingCN108893804AReduce loadReduce maintenance timesArtificial filament recoveryTextile/flexible product manufactureCycloneViscose

The invention discloses a sand removing process and system of waste glue, and belongs to the technical field of viscose production. On the basis of an existing sand removing device, a multi-core cyclone desander is used for separation, a metal mesh board frame filter and a polypropylene felt board frame filter are additionally arranged at the front and back of a butterfly separator respectively, so that while the filtering effect is ensured, the problems are solved that thin glue contains a large number of impurities, has very high number of particles and is not conducive to repeated use, andthe butterfly separator is frequently repaired in the prior art.

Owner:YIBIN GRACE +1

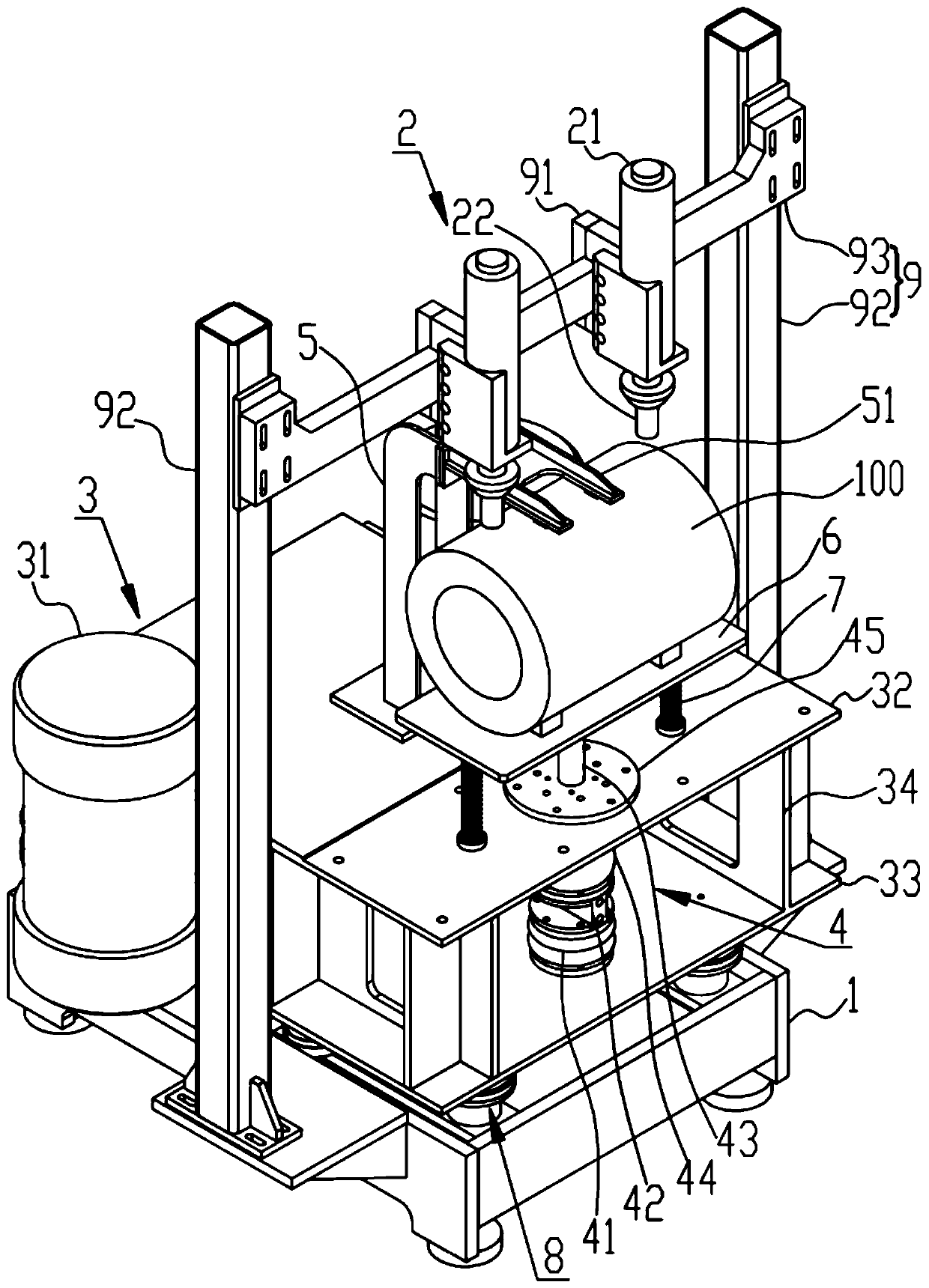

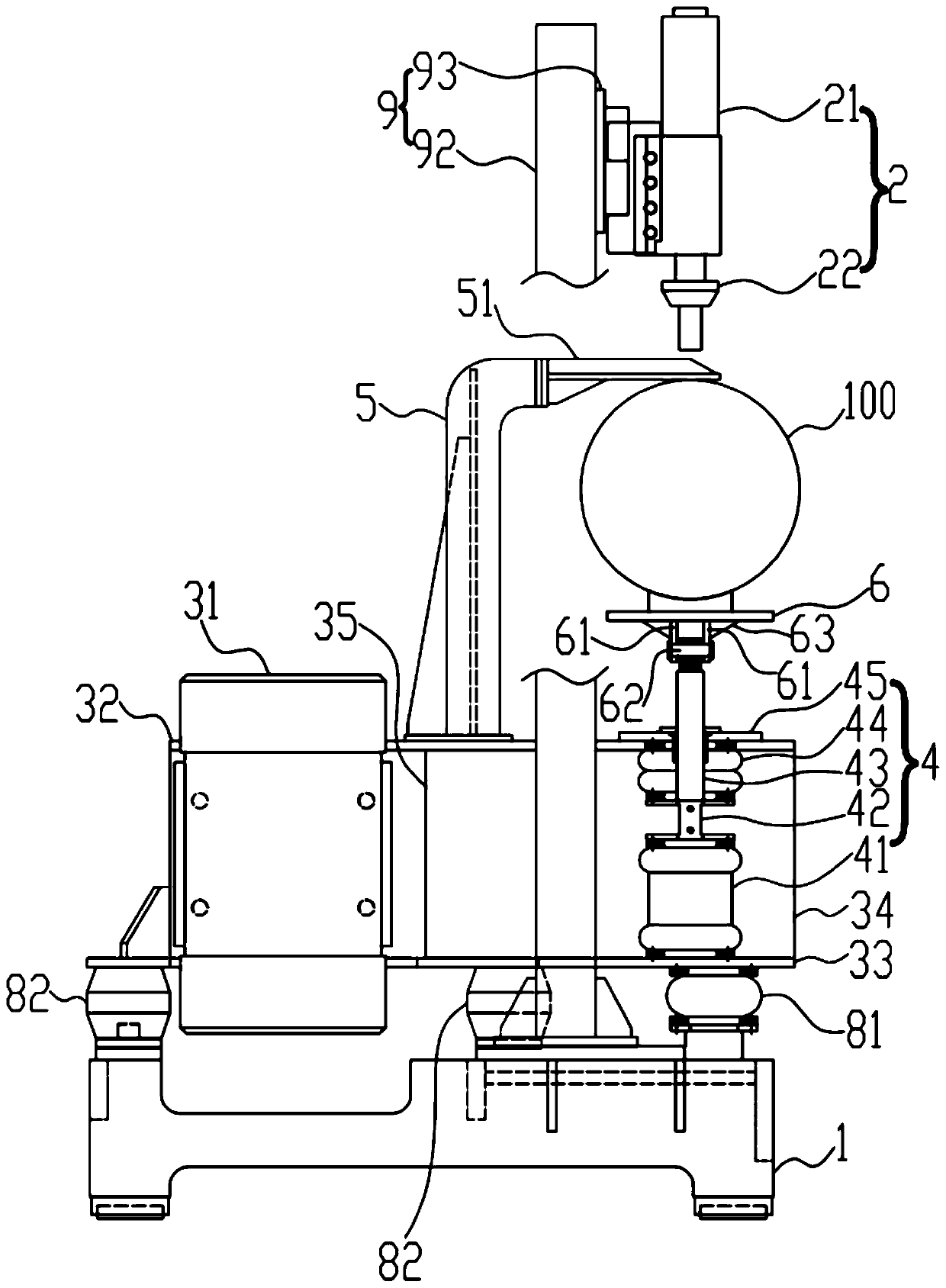

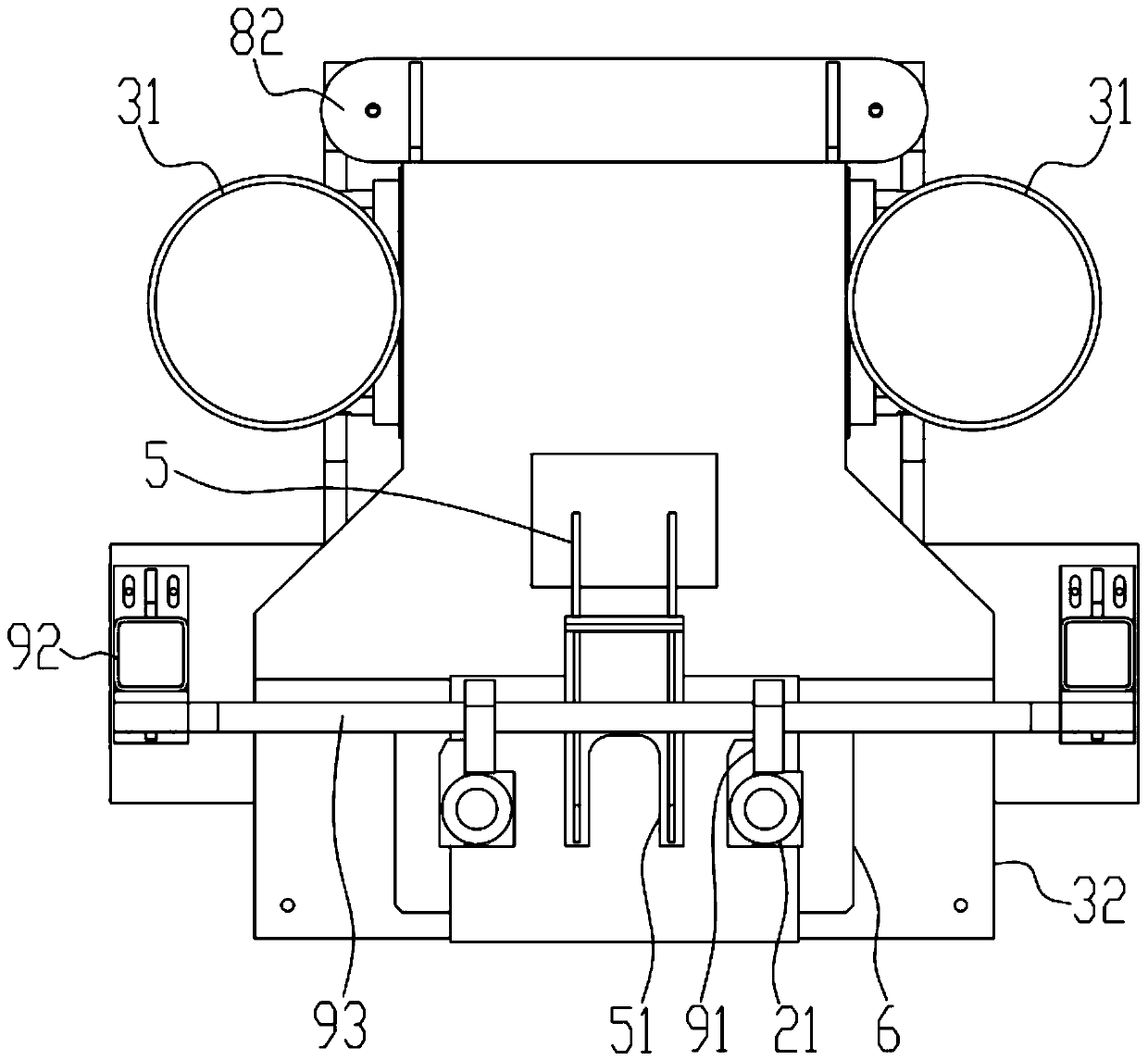

Vertical vibrating sand removal device

The invention discloses a vertical vibrating sand removal device. The vertical vibrating sand removal device comprises a base, hammering mechanisms, a vibrating mechanism, an air spring lifting mechanism and an upper clamping seat; the vibrating mechanism comprises vibrating motors, an upper bracket, a lower bracket and vertical plates; the upper bracket is connected with the lower bracket throughthe vertical plates; the vibrating motors are fixed to the side edges of the upper bracket and the lower bracket through a side plate; the air spring lifting mechanism comprises an air spring, a guide rod, a fixed spring and a fixed plate; the air spring is installed on the lower bracket; the guide rod is arranged on the air spring, and sequentially penetrates through the fixed spring, the upperbracket and the fixed plate vertically upwards; the fixed plate is connected with the upper bracket; the upper part of the guide rod is connected with a workbench; springs are arranged between the workbench and the upper bracket; the upper clamping seat is provided with clamping arms, and is installed on the upper bracket; the lower bracket is arranged above the base; buffering assemblies are arranged between the lower bracket and the base; and the hammering mechanisms are located above the workbench. A casting can be rapidly fixed, the casting is fixed firmly, and has a free space to shake inthe vibrating process, the base is stable, sand removal is complete, and the efficiency is high.

Owner:WUXI HUAZHU MACHINERY IND CO LTD

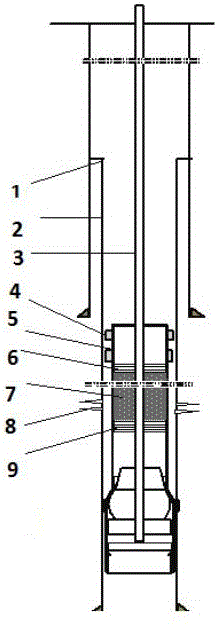

Expandable sand screen device capable of controlling sand removal granularity

The invention relates to an expandable sand screen device capable of controlling the sand removal granularity. An expandable mounting mechanism comprises a hanger, a casing pipe, a drill rod, an upper rubber ring, a perforated hole, an expandable head guide device, an intelligent expandable head, a lower fixed rubber ring, an expandable sealing rubber ring, an expandable sealing gasket, a bottom sealing gasket, a bottom sealing rubber ring, a steel ball and a base. An expandable sand screen filtering mechanism comprises an expandable pipe, end threads, a sand screen, a middle thread, an outer protection layer, a transverse seam layer (the section of the transverse seam layer is a local structure enlarged view of the local structure layer), an inner connecting layer (the section of the inner connecting layer is a local structure enlarged view of the inner connecting layer), inner connecting layer round holes, outer protection layer round holes, and sand screen transverse seams. According to the expandable sand screen device capable of controlling the sand removal granularity, the drainage area is enlarged through expanding, and the output of oil extraction is increased by half; the sand removal granularity range can be determined directly through calculation by a formula according to the physical dimension of the screen and the expansion rate, sand removal is stable, and sand removal efficiency is high; the expandable sand screen device is resistant to abrasion and corrosion by sulfuretted hydrogen, good in structural stiffness, not prone to distortion and long in service life; and installation and construction are easy, the expansion resistance is small, the process is stable, and sealing is reliable.

Owner:天津冠力博石油科技有限公司

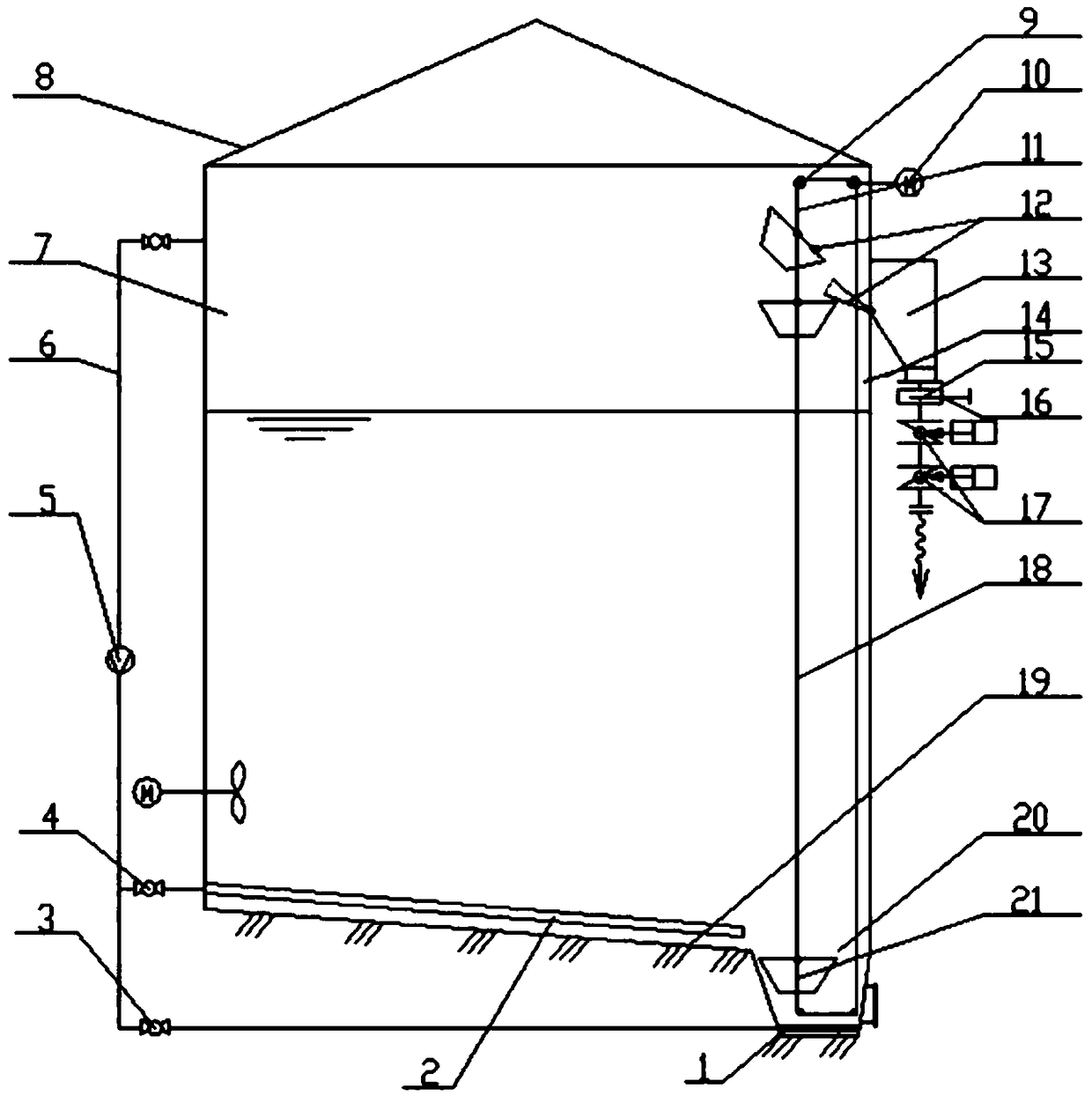

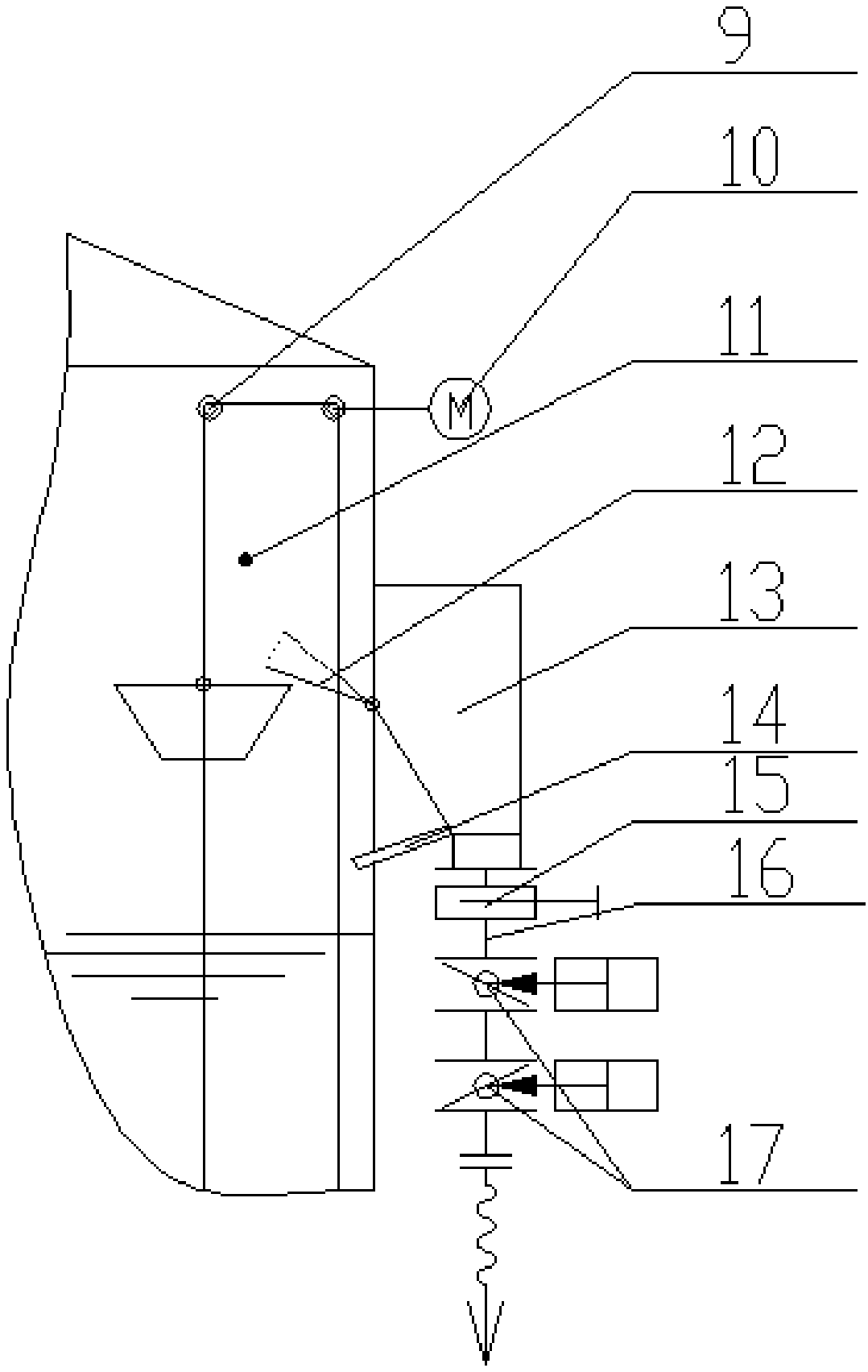

Anaerobic jar mechanical sand discharging device

PendingCN109504601AEliminates scattered retentionChange the path of the tankBioreactor/fermenter combinationsBiological substance pretreatmentsAir pumpSprocket

The invention relates to an anaerobic jar mechanical sand discharging device. The anaerobic jar mechanical sand discharging device comprises a bottom surface, a sand discharging collecting pit, a gasrelease pipe, a gas conveying pipe, a gas pump or a high-pressure fan, an inverted trapezoidal sand lifting bucket, a sand lifting bucket lifting chain, a chain supporting chain wheel, a chain wheel driving mechanism, a baffle, a sand storage bucket, a gate valve, a sand discharging pipe and a double-layer ash discharging valve, wherein the bottom surface is inclined in an anaerobic jar; the sanddischarging collecting pit is arranged at the lower position of the inclined bottom surface; the gas release pipe for stirring is arranged in the anaerobic jar and near the bottom surface and the bottom surface of the sand discharging collecting pit; the gas conveying pipe is communicated with the gas release pipe and an upper gas cavity in the anaerobic jar; the gas pump or the high-pressure fanis arranged on the gas conveying pipe; the inverted trapezoidal sand lifting bucket is arranged in the sand discharging collecting pit; the baffle is used for touching the sand lifting bucket to tiltand discharge sand; the sand storage bucket is arranged outside the anaerobic jar and is hermetically connected with the opening of the anaerobic jar; the gate valve is arranged at the lower end of the sand storage bucket; the sand discharging pipe is connected with the gate valve; the double-layer ash discharging valve is mounted on the sand discharging pipe. The anaerobic jar mechanical sand discharging device has the following positive effects: the method and the mechanical structure of inclining the jar bottom, stirring the lower part by gas to collect sand, gaining sand by using the lifting bucket and discharging sand by using the storage bucket are adopted, so that the phenomenon that the sand is dispersed and retained at the jar bottom is eliminated, a sand discharging route from the jar is changed, blockage is avoided, and the sand discharging workload is reduced.

Owner:CHANGCHUN POWER GENERATION EQUIP PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com