High-efficiency tilted plate sand-removal and water-intake device

A technology of water intake device and sloping plate, which is applied in the field of high-efficiency sloping plate sand removal and water intake device, can solve the problems of low sand removal efficiency, unsatisfactory fine sand removal effect, and difficulty in reaching the predetermined target, so as to achieve improved sand removal efficiency and structural Compactness and the effect of reducing water intake costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

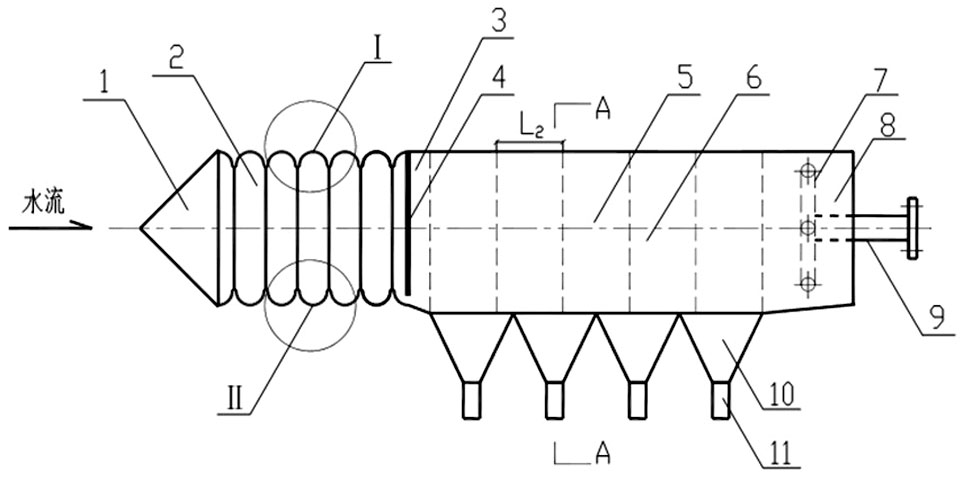

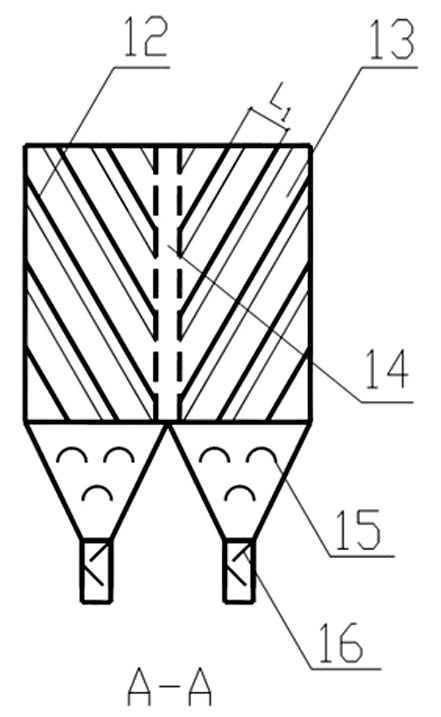

[0024] Such as figure 1 As shown, the high-efficiency inclined plate sand removal and water intake device is composed of three parts: the water inlet chamber 2, the sediment separation and self-cleaning chamber 5 and the water outlet chamber 8. The water inlet chamber 2 is located at the forefront of the water intake device, and its front portion is provided with a conical front cover 1 . The sediment separation and self-cleaning chamber 5 is located in the middle of the water intake device, the water outlet chamber 8 is connected to the rear end of the sediment separation and self-cleaning chamber 5, and the outlet pipe 9 is connected to the end of the water collecting pipe 7 .

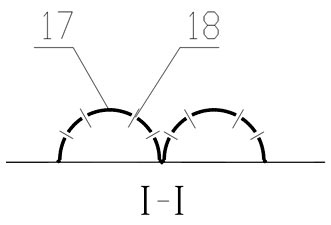

[0025] The water inlet chamber 2 is assembled into a tube with a rectangular cross section by using four corrugated folded plates 17, the direction of the corrugatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com