Combined efficient desander

A kind of sand remover and composite technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of low sand removal efficiency, poor sand removal effect, small size of sand remover, etc., to achieve sand removal. The effect of high efficiency, large tank volume and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is a clear and detailed description of the technical solutions in the embodiments of the present invention in combination with the accompanying drawings in the embodiments of the present invention:

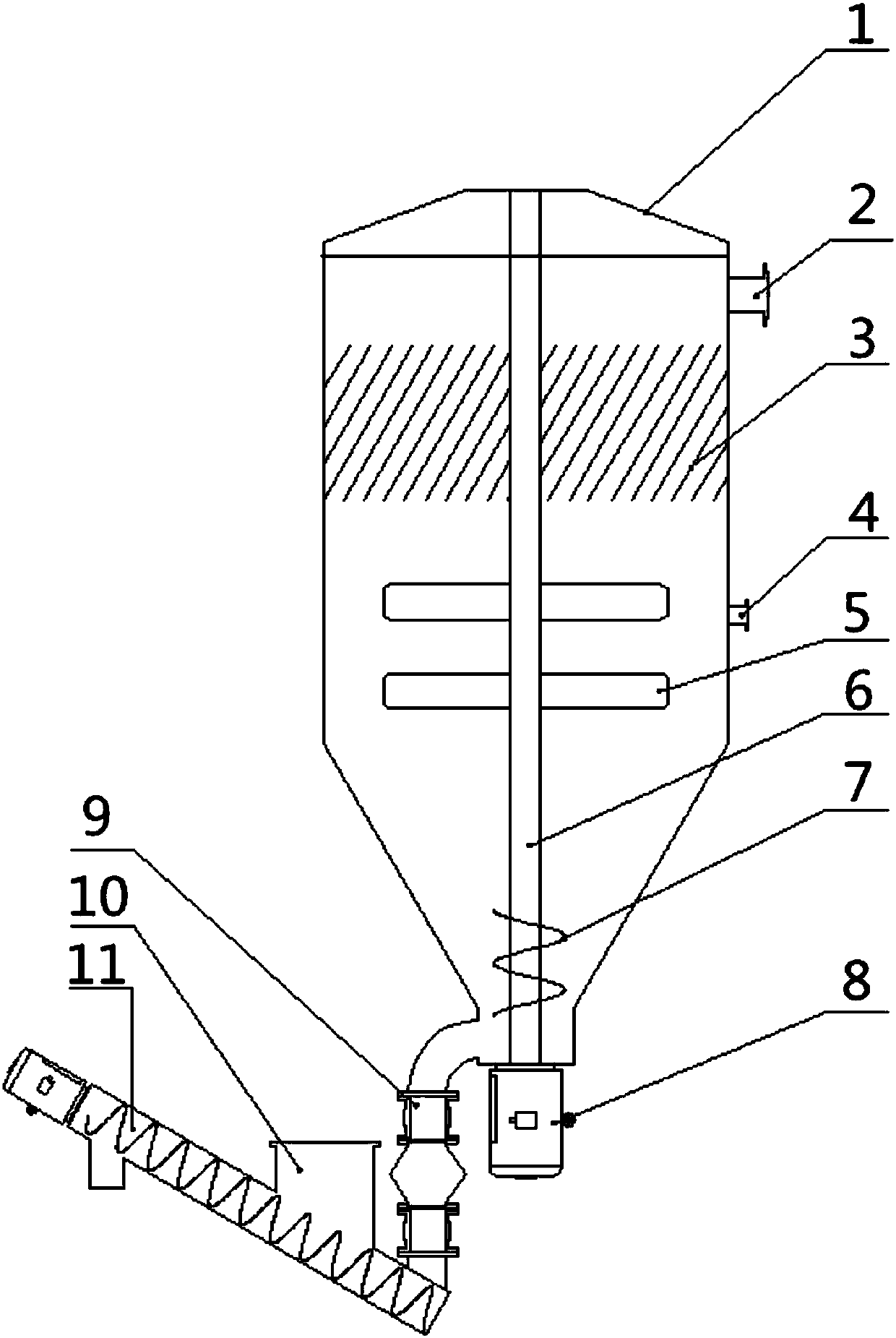

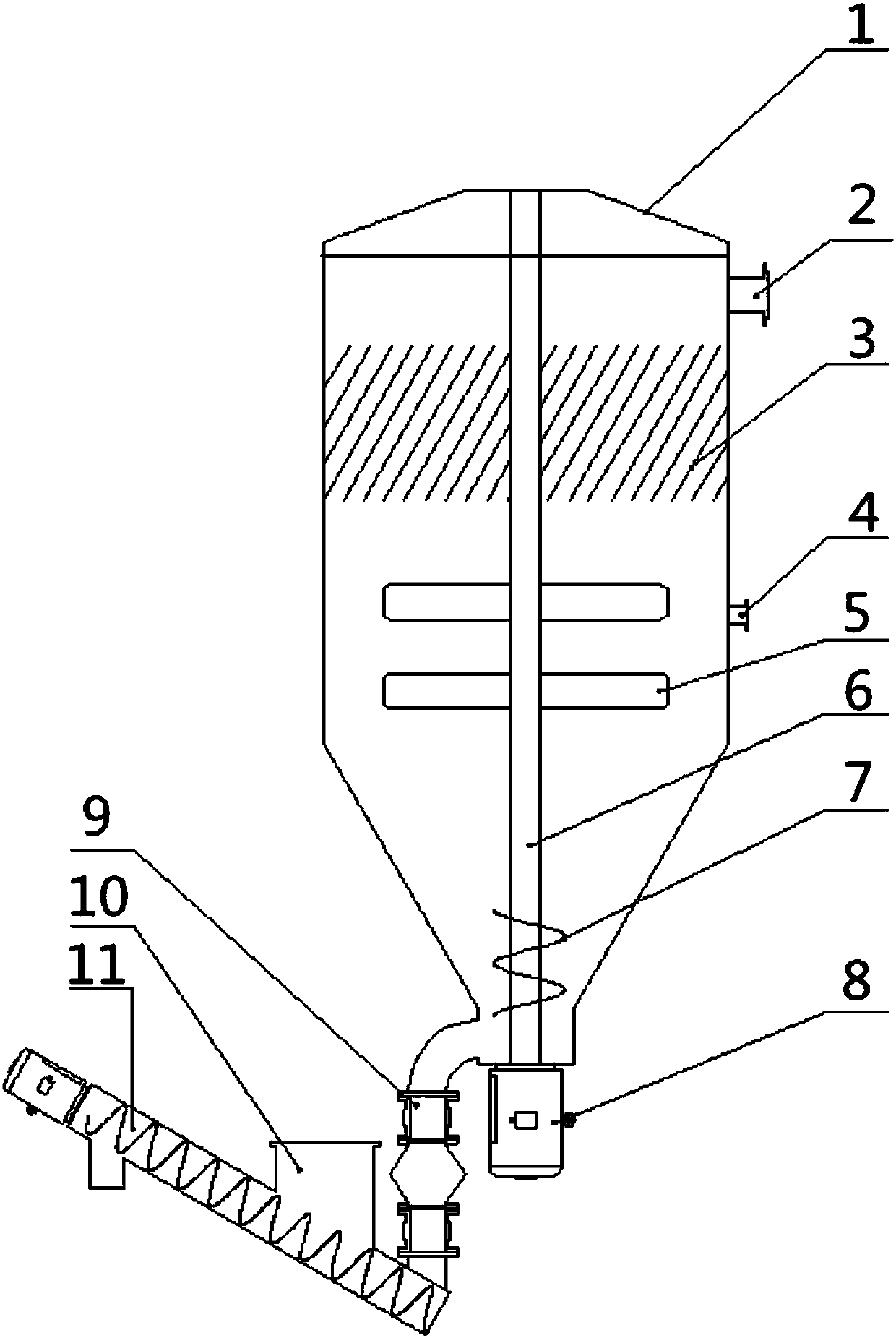

[0016] Such as figure 1 Provided is a composite high-efficiency desander, the tank (1) is composed of a top conical cylinder, a middle cylindrical cylinder and a bottom conical cylinder, the liquid inlet pipe (4) and the tank (1) are in the form of The tangential direction is connected to the middle part of the tank body (1), and the liquid outlet pipe (4) is located above the liquid outlet pipe (2), and is installed vertically to the tank body (1). The rotary blade (5), the rotary shaft (6), the rotary sand removal device (7), and the motor (8) form a centrifugal sand removal device. The rotating blade (5) is a double-layer flat paddle up and down, the rotating shaft (6) is connected with the extension shaft of the motor (8) through a shaft coupling, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com