Anaerobic jar mechanical sand discharging device

An anaerobic tank and mechanical technology, applied in the field of anaerobic tank, can solve the problems such as the inability of continuous operation of the sand discharge pipeline, the inability to empty and handle the sediment, and the limited stirring force, so as to improve the efficiency of sand removal, maintenance and repair. Small workload, eliminating the effect of dispersion and retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

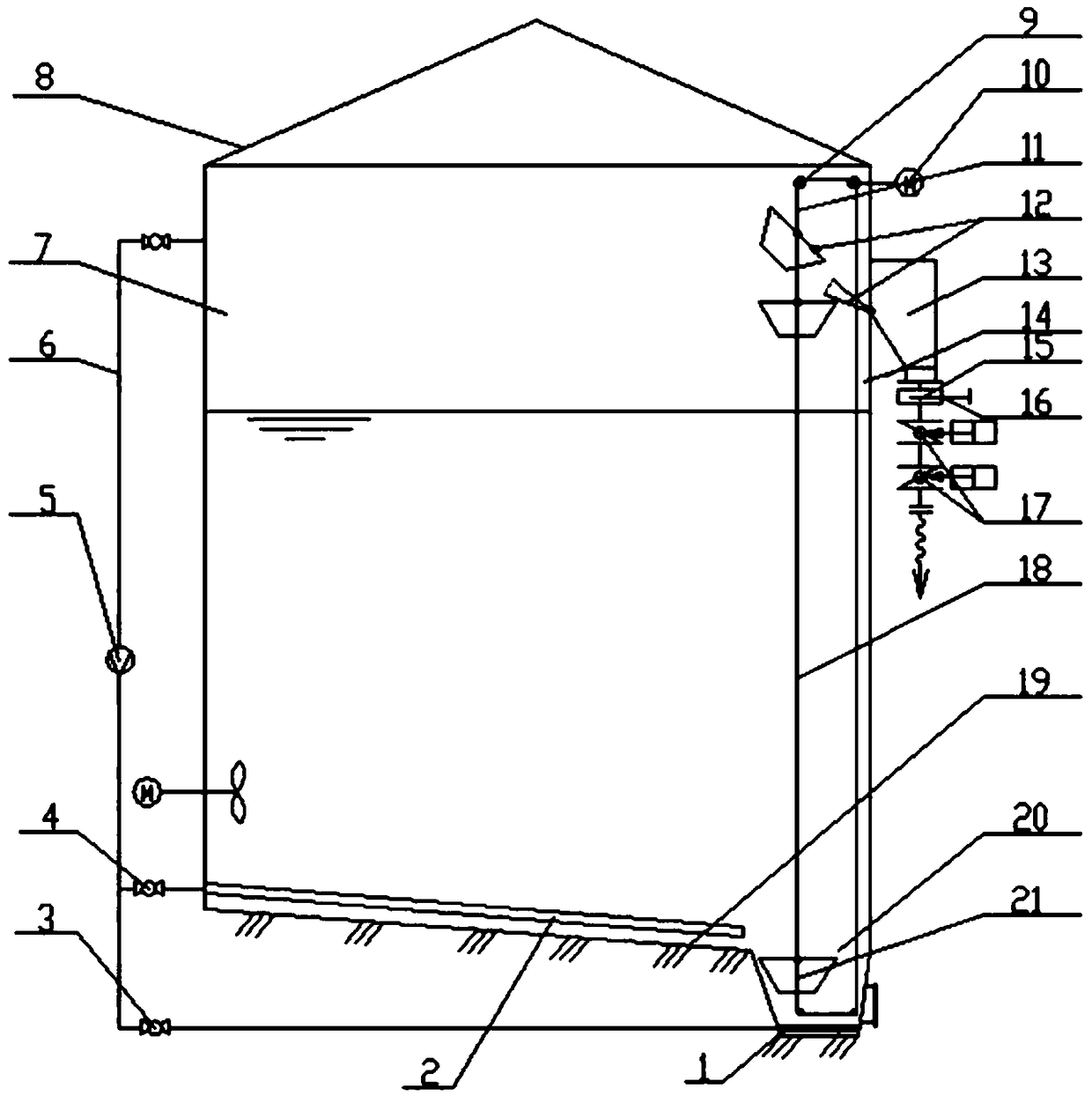

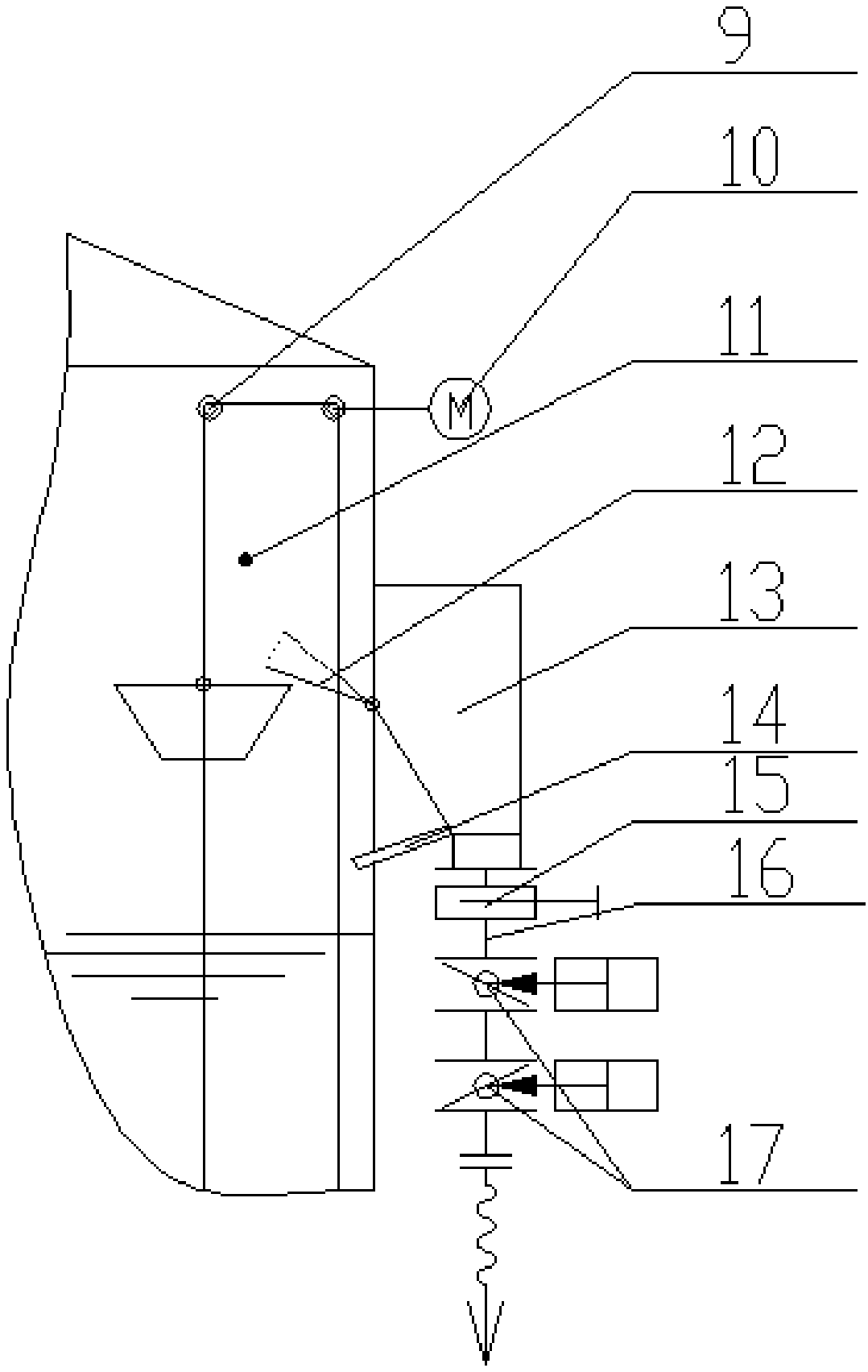

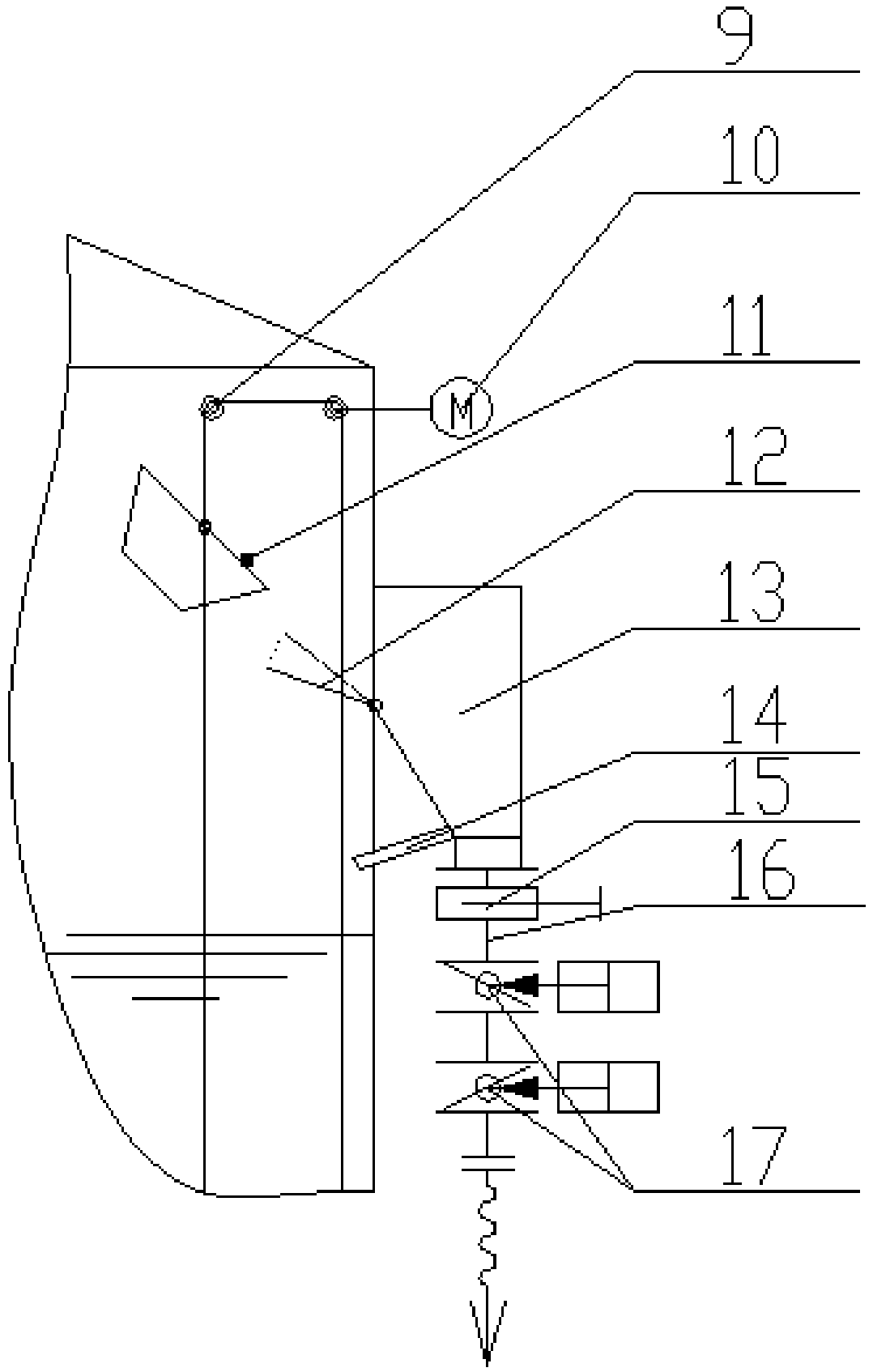

[0015] refer to figure 1 , The sand discharge device of the present invention comprises: the inclined bottom surface 19 in the anaerobic tank 8, the sand discharge collection pit 20 at the lowest point of the inclined tank bottom surface 19, the stirring gas release pipe arranged in the anaerobic tank 8 near the bottom surface to distribute the exhaust holes 2. The agitating gas release pipe 1 arranged in the sand discharge collection pit 20 near the bottom surface to distribute vent holes, the gas pipeline 6 connecting the agitating gas release pipes 1 and 2 with the upper air chamber (chamber) 7 in the anaerobic tank 8, and installing The Roots (brand) fan 5 on the gas pipeline 6, the inverted trapezoidal sand lifting bucket 21 that proposes the sedimentation of the sand collection pit, two lift chains 18 on both sides of the sand bucket 21, the chain support sprocket 9, The sprocket bracket fixed on the anaerobic tank, the sprocket drive motor and the worm gear reduction me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com