Patents

Literature

150results about How to "No clogging problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

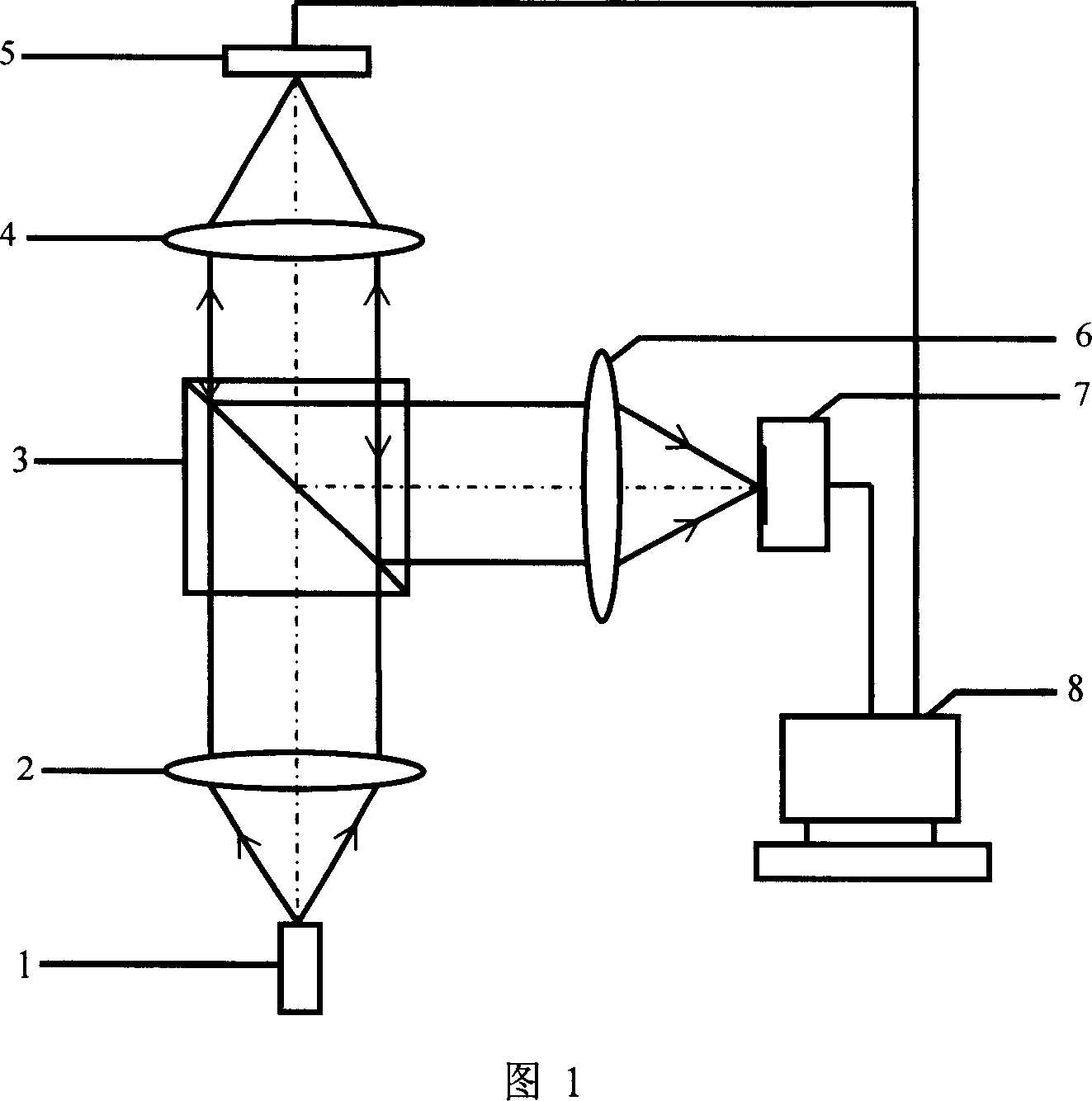

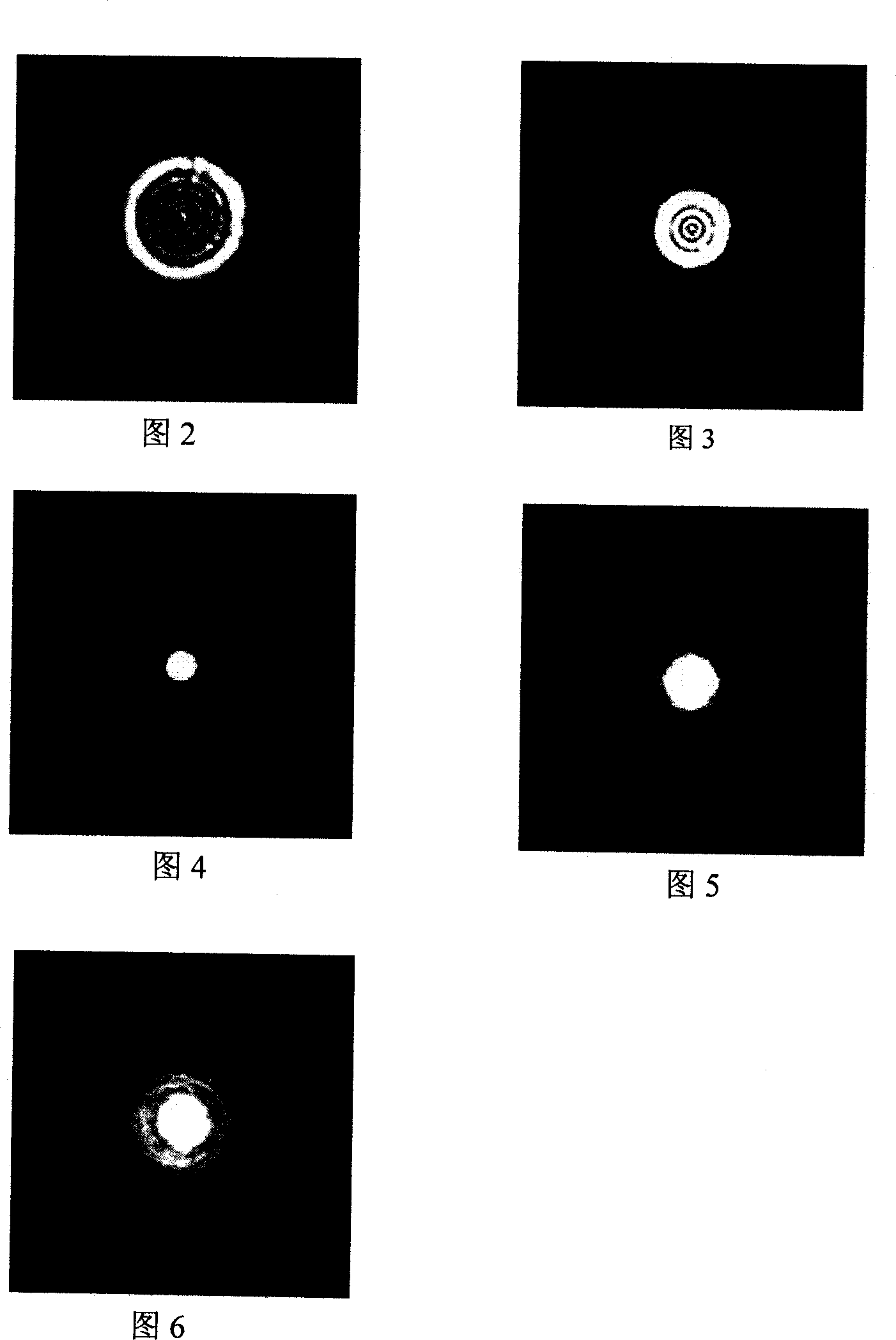

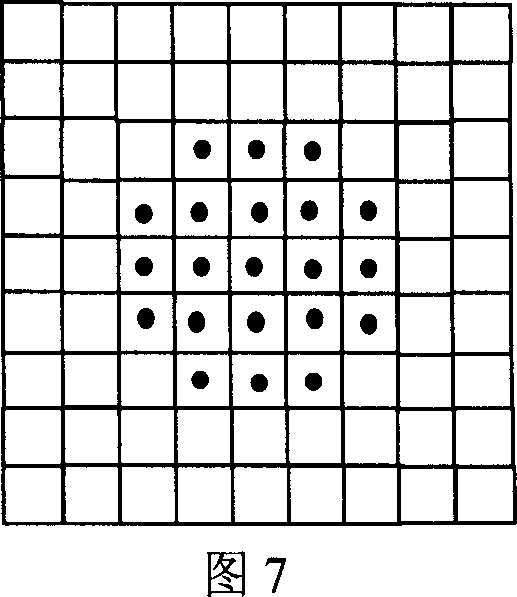

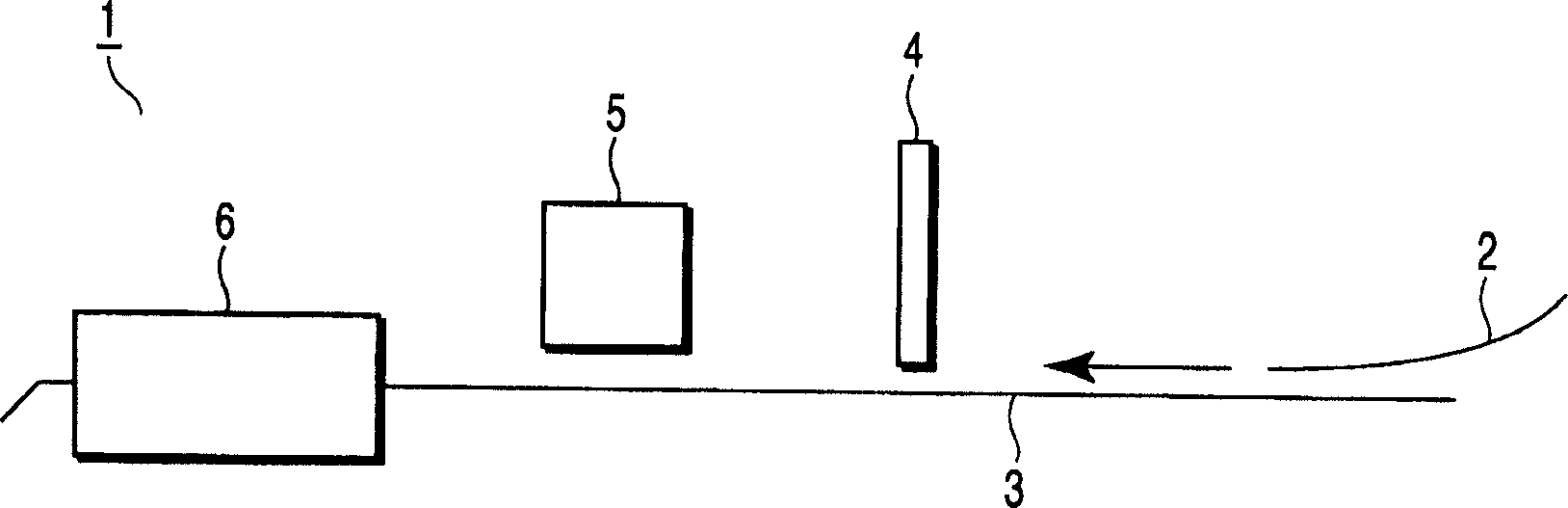

Confocal micro imaging system using dummy pinhole

The invention relates to a confocal imaging system in fields of optical microimaging, it is a confocal microscopic system which uses virtual confocal pinhole to make the system to obtain the longitudinal chromatography capability. It's widely used in the fluorescence microscopy, optical microscopy and so on which possess the microtechnique of three-dimensional imaging capability. The invention includes: light source, collimation lens, beam splitter, microscope objective, objective table, collective lens and CCD. It characterized in that the photosensitive surface of CCD is directly located at the focal plane of the collimation lens, the computer sets the virtual pinhole at the corresponding position of two-dimensional digital image collected by CCD based on the position of the focal point of collimation lens, the signal values of the pixels in the pinhole are accumulated as the signal intensity of current scanning point to eliminate the effect of stray light in non-focal plane to the image quality. The function of virtual confocal pinhole is significant with the physical confocal pinhole and the position, size can be controlled and adjusted by computer, and it possesses the advantages of convenient gauging adjustment.

Owner:NANKAI UNIV

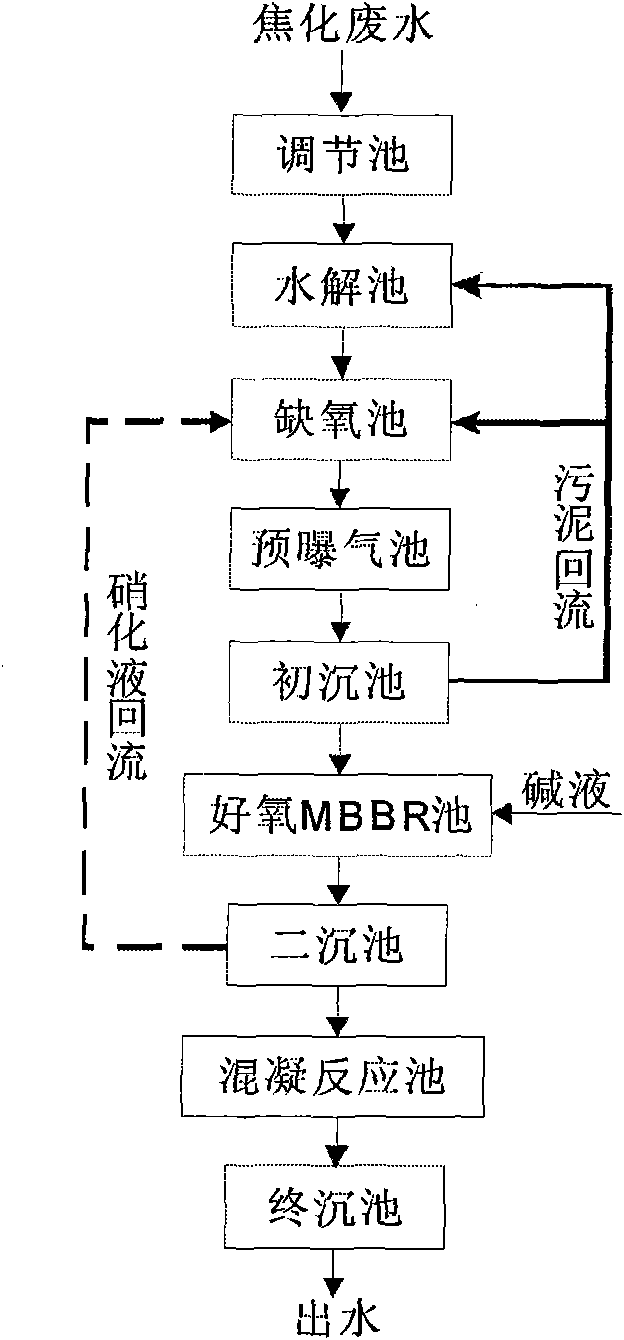

Method for treating coking wastewater

InactiveCN101602564AHigh activityNo reflow requiredTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationSludge

The invention discloses a method for treating coking wastewater, which belongs to the field of wastewater treatment. The method comprises the following steps that: wastewater of a coking plant enters a regulating reservoir for the adjustment of water quality and water amount, and orderly enters a hydrolytic tank, an anaerobic tank, a preaeration tank, a preliminary sedimentation tank, an aerobic tank, a secondary sedimentation tank and a coagulation reaction tank for treatment, wherein the hydrolytic tank and the preaeration tank are filled with a bio-cord filler; the sludge of the preliminary sedimentation tank refluxes into the hydrolytic tank and the anaerobic tank respectively; a clarifying solution of the secondary sedimentation tank refluxes into the anaerobic tank; and the aerobic tank adopts a moving bed bio-film reactor. The bio-cord filler adopted in the invention has short film formation time and high biomass, does not need repeated washing, and has strong shock resistance; and the moving bed bio-film reactor can fix a large amount of nitrobacteria with long generation time, and has no the problem of blocking. The method can remove high-concentration ammonia nitrogen and organic substances in the coking wastewater, and the COD and the ammonia nitrogen of treated effluent can synchronously achieve the primary standard of the national integrated wastewater discharge standard (GB9878-1996).

Owner:NANJING UNIV

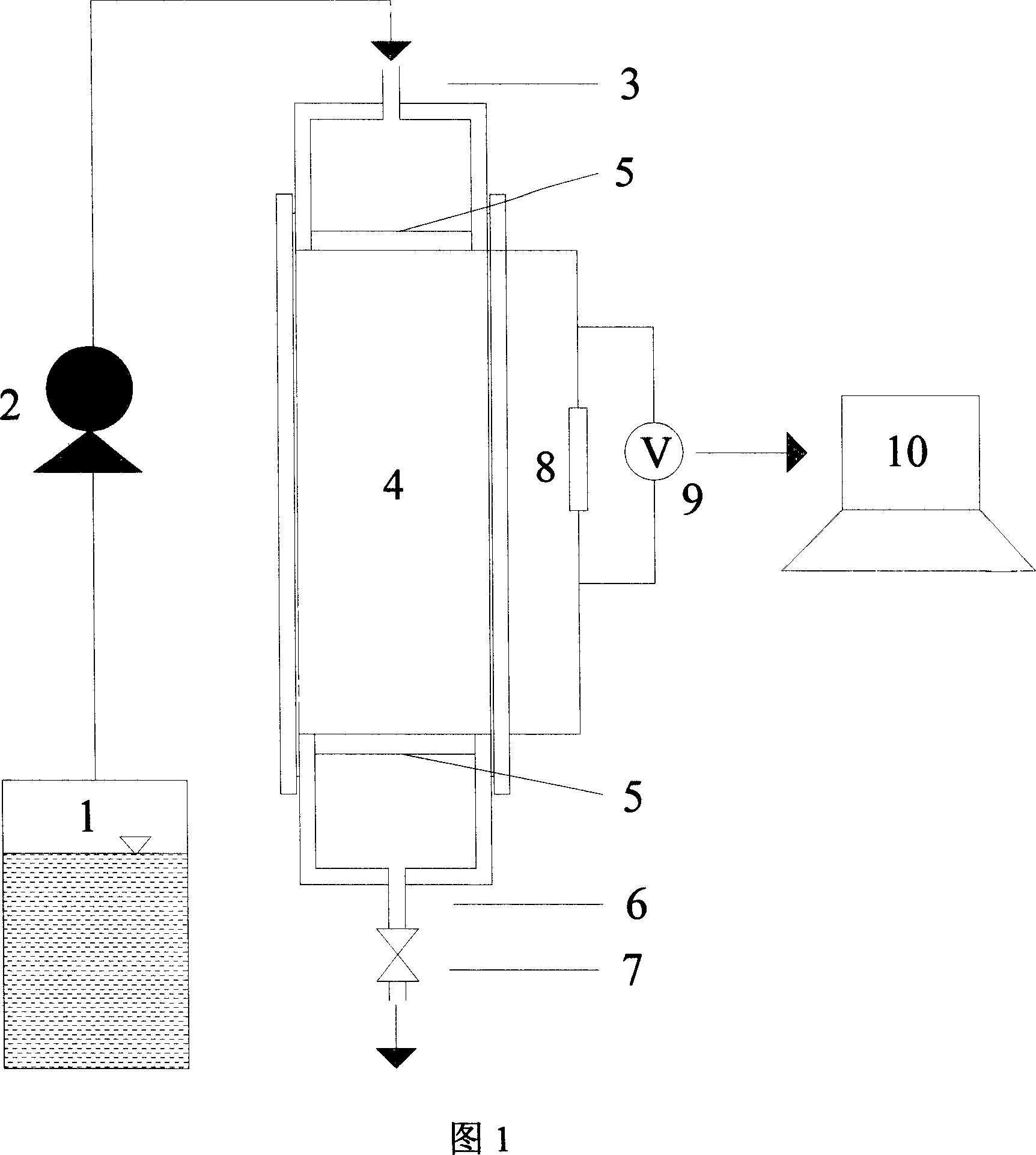

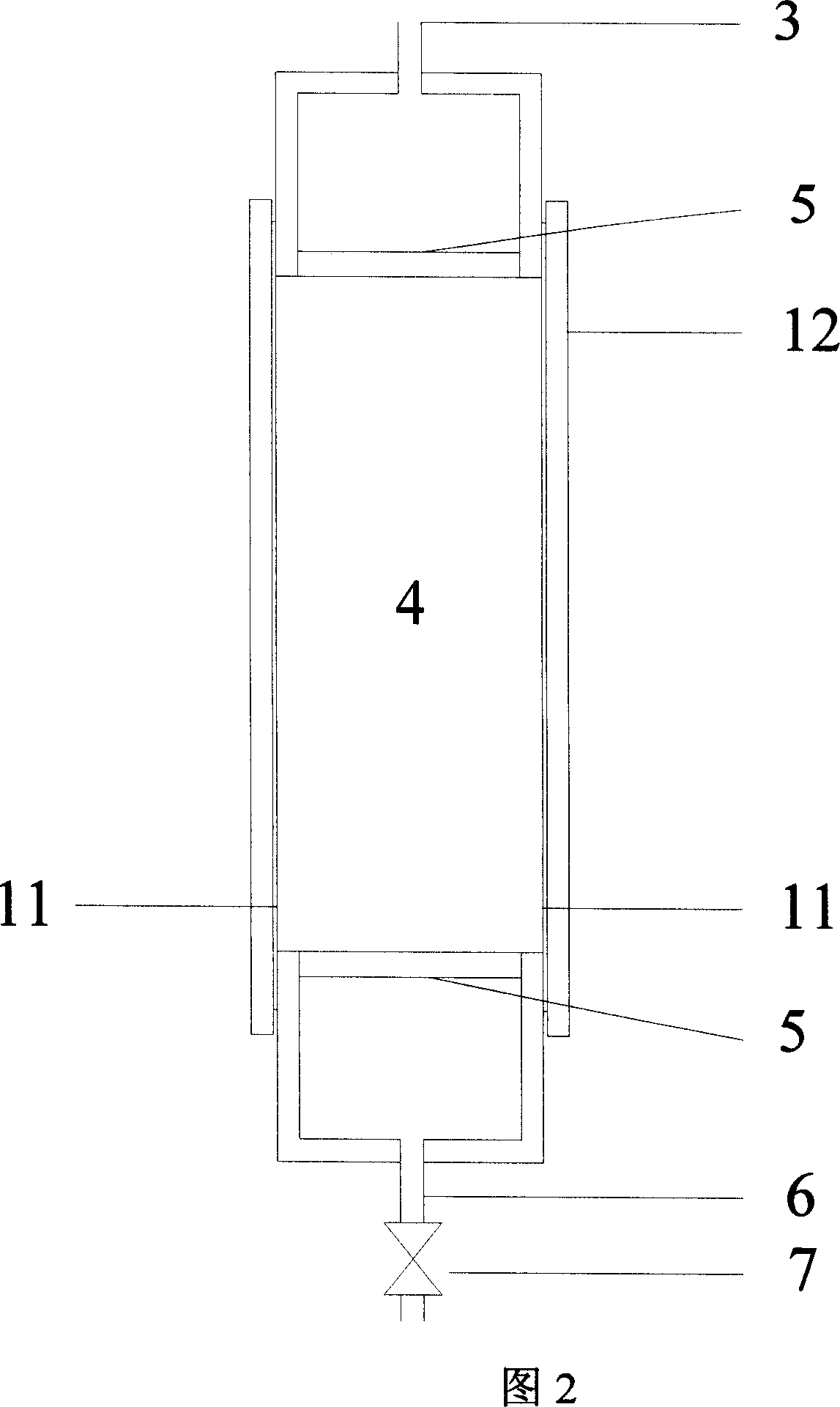

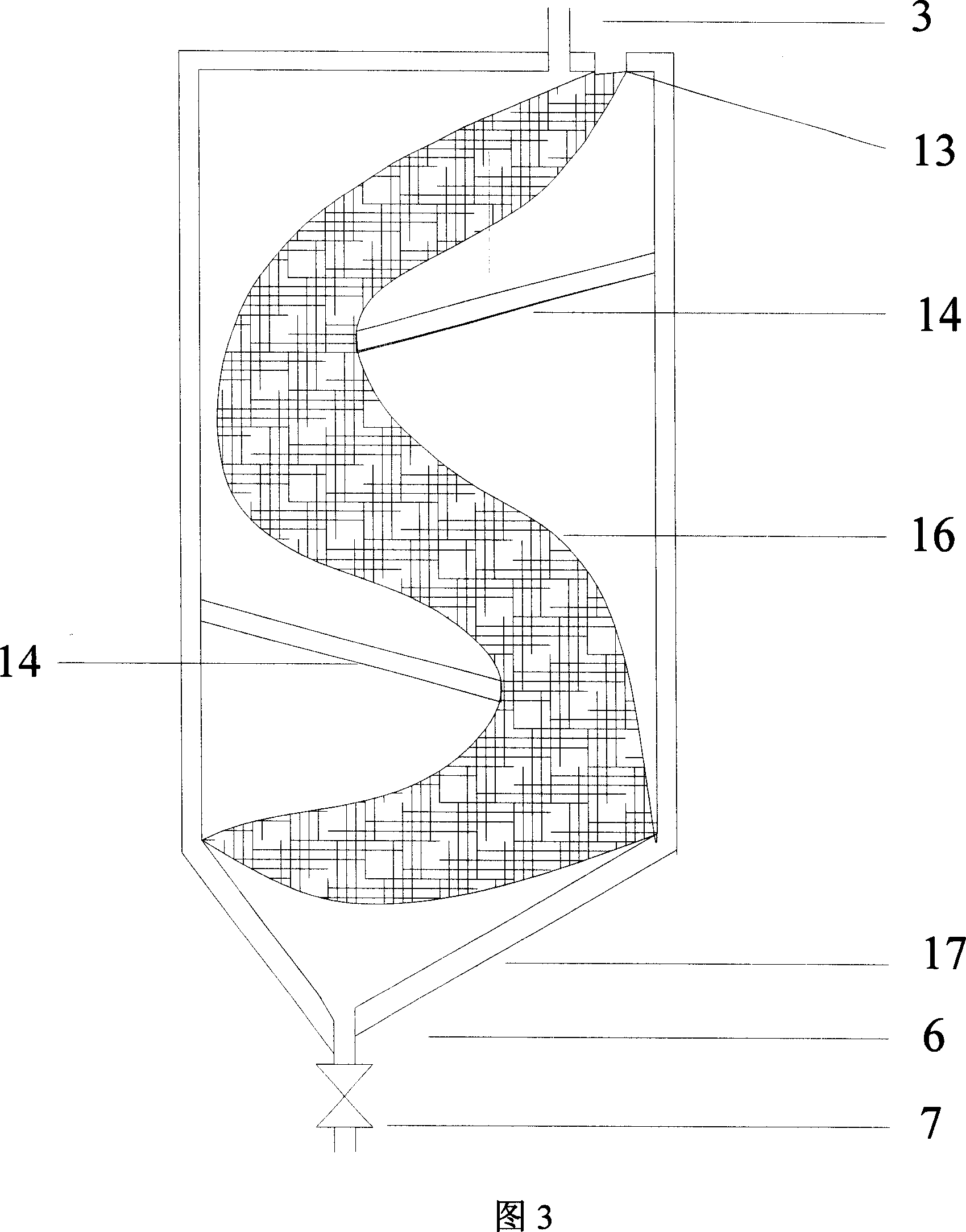

Stackable single cell microbe fuel battery

The invention discloses a pile type single room microbiological fuel cell; the battery is the sheet style structure, battery thickness is 5-30 centimeter, two groups of membrane electrodes altogether used an anode chamber, which is advantageous for composing the large-scale microbiological fuel cell heap, in order to output a greater voltage and electric current to satisfy the different current collector demand. The monomer battery uses the air type negative pole, does not need aeration, simultaneously does not need to add vector to the negative pole room, can greatly reduces the movement cost, and avoids the environmental pollution which creates by adding vector. In the anode chamber increases the carbon fiber to enhance the anode relative surface product, may enhance the monomer battery current density 3-10 times. The battery movement uses the method of upside feed-water, the base high and dry, reduced the backflow equipment demand, but also can save 50% -70% of the electrical energy. The invention is a clean advanced energy technology; and it has the broad application prospect in the municipal, industry, agricultural and spatial organic waste water processing.

Owner:BEIHANG UNIV

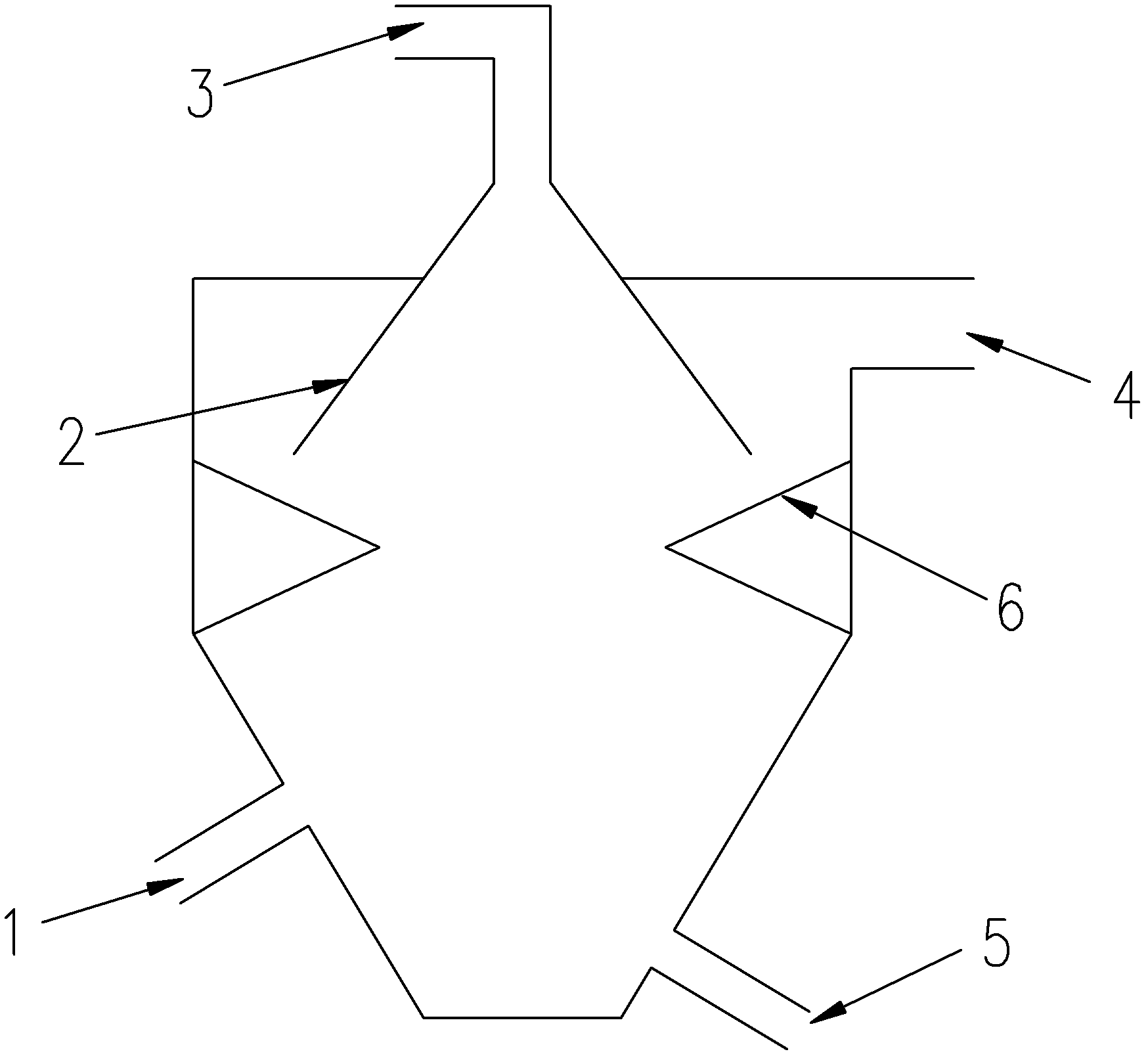

Treatment method for nitrogen oxide tail gas discharged from industrial production furnace, and apparatus thereof

ActiveCN102451610AImprove removal efficiencyNo clogging problemUsing liquid separation agentNitrogen oxidesLiquid cooling system

The present invention discloses a treatment method for nitrogen oxide tail gas discharged from an industrial production furnace, and an apparatus thereof. According to the present invention, gas generated from the furnace is connected to a self-sucking type gas-liquid mixing device through a pipeline to carry out a treatment on the furnace tail gas; the treated gas is discharged by using a gas exhaust tube with the pressure provided by the self-sucking type gas-liquid mixing device. The apparatus of the present invention comprises the self-sucking type gas-liquid mixing device, an absorption liquid cooling system and an absorption liquid settlement system. Compared to the prior art, with the method and the apparatus of the present invention, the nitrogen oxide tail gas discharged from the industrial production furnace can be effectively treated, the cost is low, the process is simple, and the operation can be stably performed for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

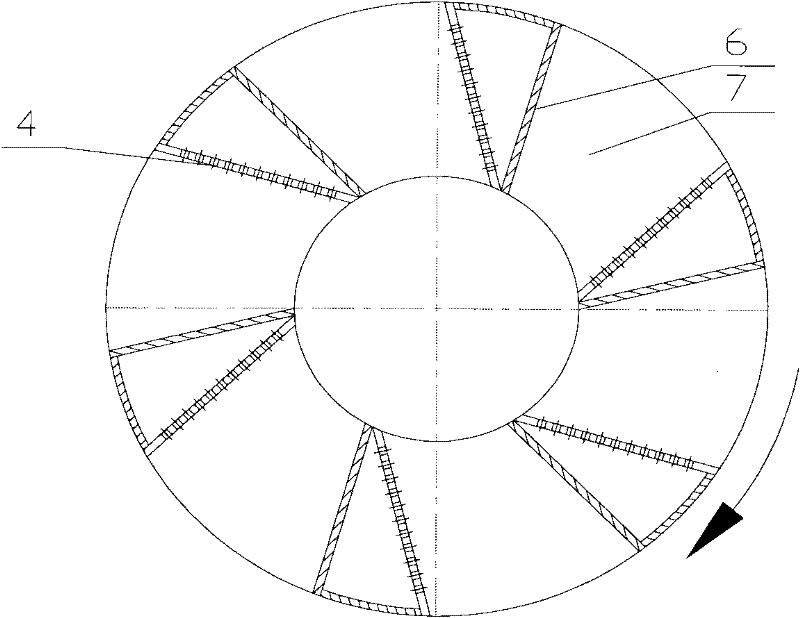

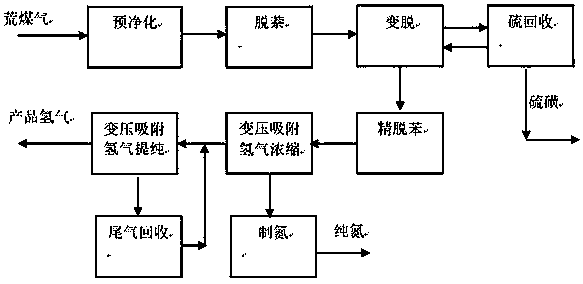

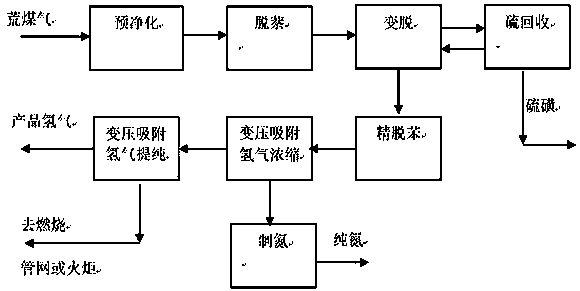

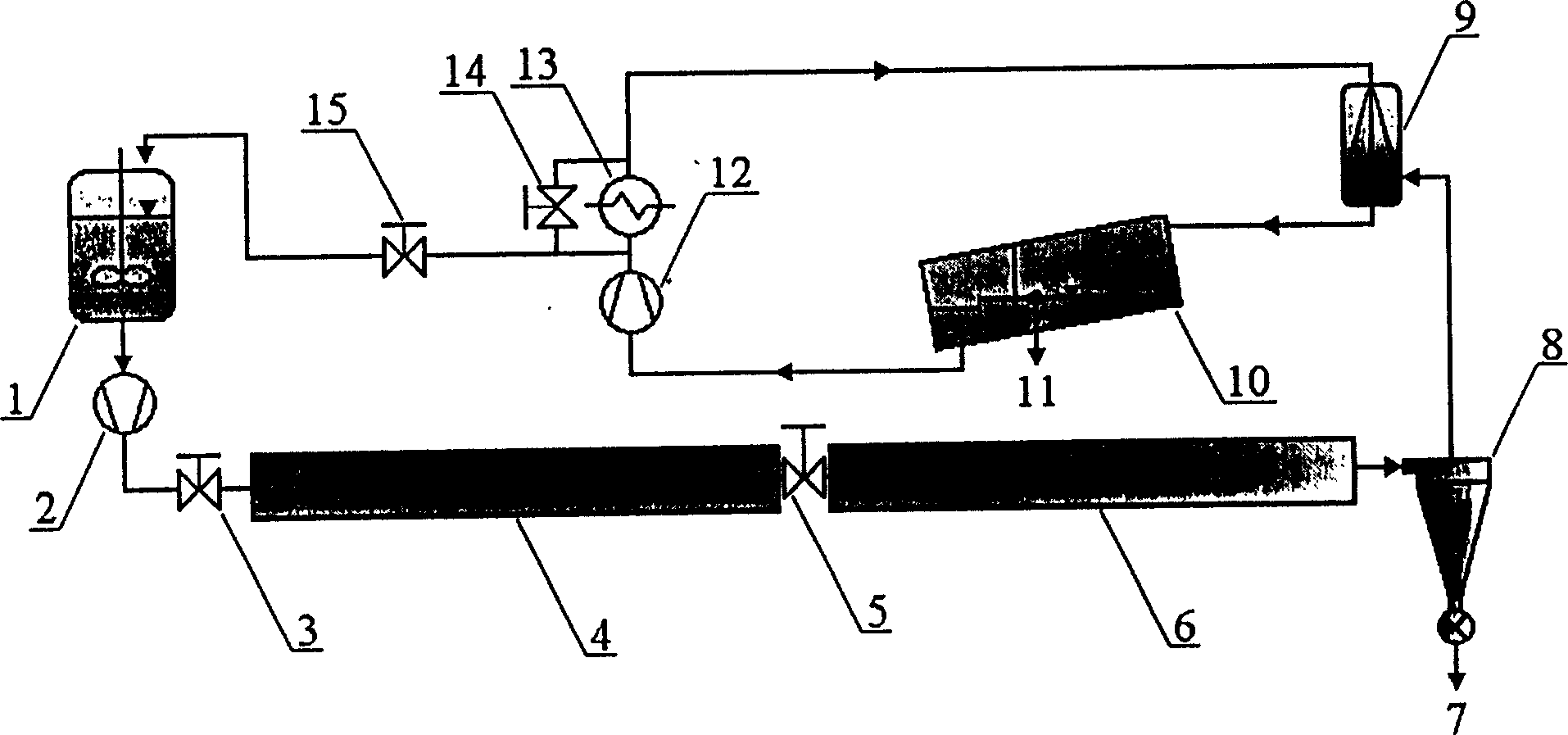

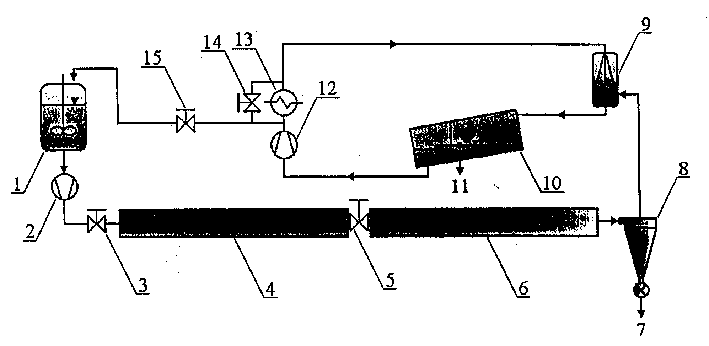

Low-energy-consumption high-yield method for preparing hydrogen from raw gas

InactiveCN107758615AReduce consumptionEmission reductionNitrogen purification/separationHydrogen separation using solid contactSulfurNitrogen

The invention discloses a low-energy-consumption high-yield method for preparing hydrogen from raw gas. The method comprises the following procedures: pre-cleaning; naphthalene removal; transformationand desulfurization; sulfur recovery; refined debenzolization; pressure swing adsorption for hydrogen production; recovery of tail gas; nitrogen production; etc. After pretreatment and naphthalene removal, raw gas is allowed to enter the procedure of transformation and desulfurization so as to obtain more hydrogen and increase the yield of hydrogen, and then desulfurization is carried out in a desulfurization tower; then pure hydrogen is prepared through the procedure of refined debenzolization and the procedure of pressure swing adsorption for hydrogen production; through the procedures of tail gas recovery and nitrogen production, effective hydrogen in desorbed gas is recovered, and hydrogen yield is further increased; and pure nitrogen with a purity of 99% or more is further prepared through a nitrogen production unit. The method provided by the invention substantially reduces the energy consumption of an apparatus for hydrogen production from raw gas, increases hydrogen yield, recovers almost all the effective hydrogen component in the desorbed gas, realizes recovery and graded utilization of each component in the raw gas while guaranteeing low energy consumption and high yield, and by-produces sulfur, pure nitrogen and the other products while preparing pure hydrogen.

Owner:SICHUAN TECHAIRS

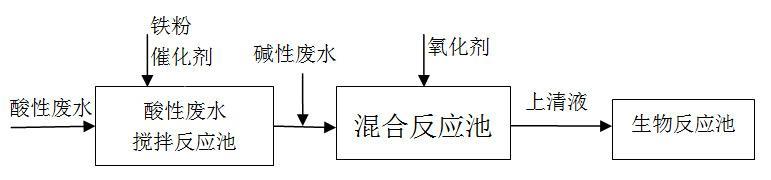

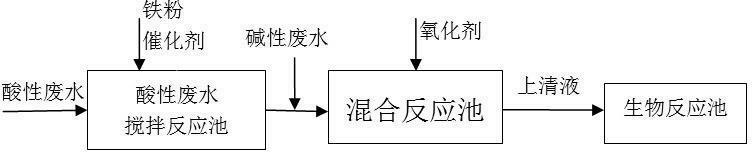

Method for pretreatment on industrial wastewater by nascent state ferrous iron reduction

ActiveCN102627360ARaise the pHSolve processing problemsMultistage water/sewage treatmentIndustrial waste waterPtru catalyst

The invention belongs to the technical field of environmental protection and especially relates to a method for pretreatment on industrial wastewater by nascent state ferrous iron reduction. The method is characterized in that acidic wastewater and zero-valent iron undergo a reaction in the presence of a catalyst to produce a large amount of high-activity nascent state ferrous iron and the acidity of the acidic wastewater is eliminated and a pH value of the acidic wastewater is improved; the high-activity nascent state ferrous iron and alkaline wastewater are mixed according to a certain ratio so that nascent state ferrous iron ions form a high-activity structural-state ferrous complex under alkaline conditions; through negative and positive ions and the catalyst in the wastewater, reduction performances of structural-state ferrous iron are improved; and through addition of a trace amount of an oxidizing agent, catalytic oxidation effects of residual ferrous iron are performed so that a ferrous iron structural form is changed and coagulating precipitation effects of ferrous iron are improved. The method realizes preparation of nascent state ferrous iron from acidic waste water, utilizes reduction effects of zero-valent iron and ferrous iron, realizes synchronous treatment on acidic wastewater and alkaline wastewater, realizes treatment of wastes with processes of wastes against one another and saves a treatment cost.

Owner:TONGJI UNIV

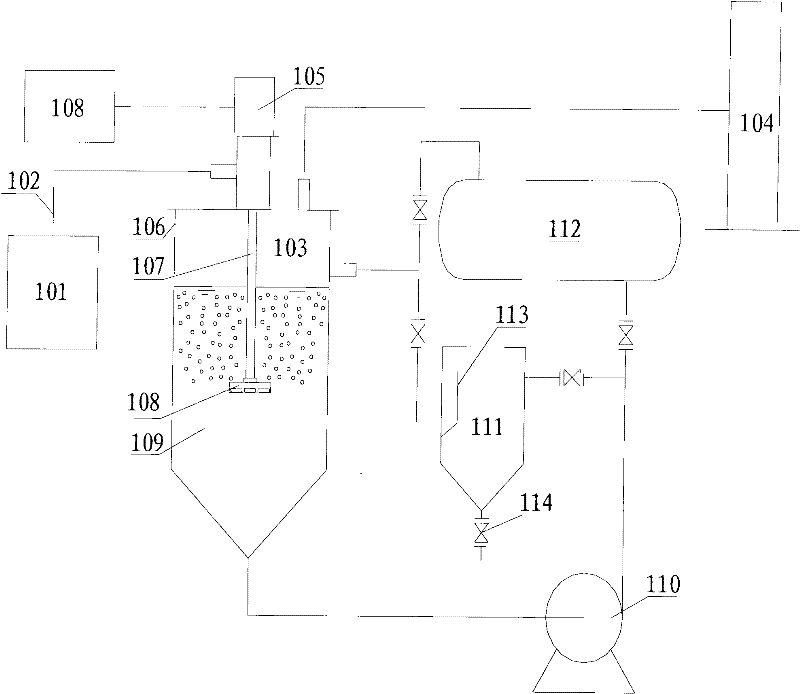

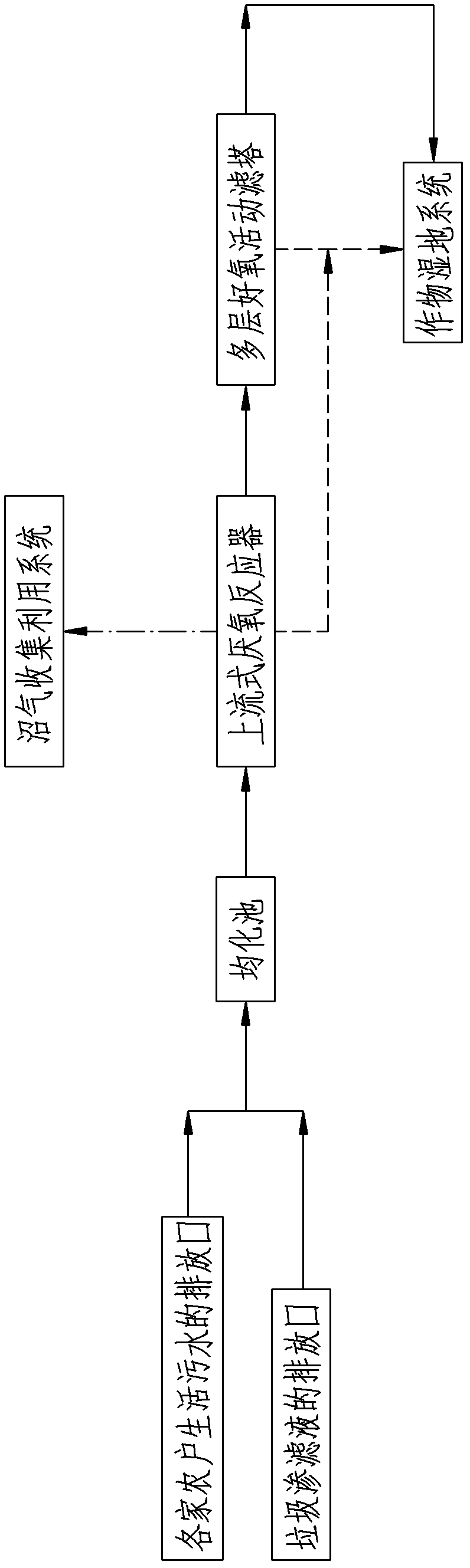

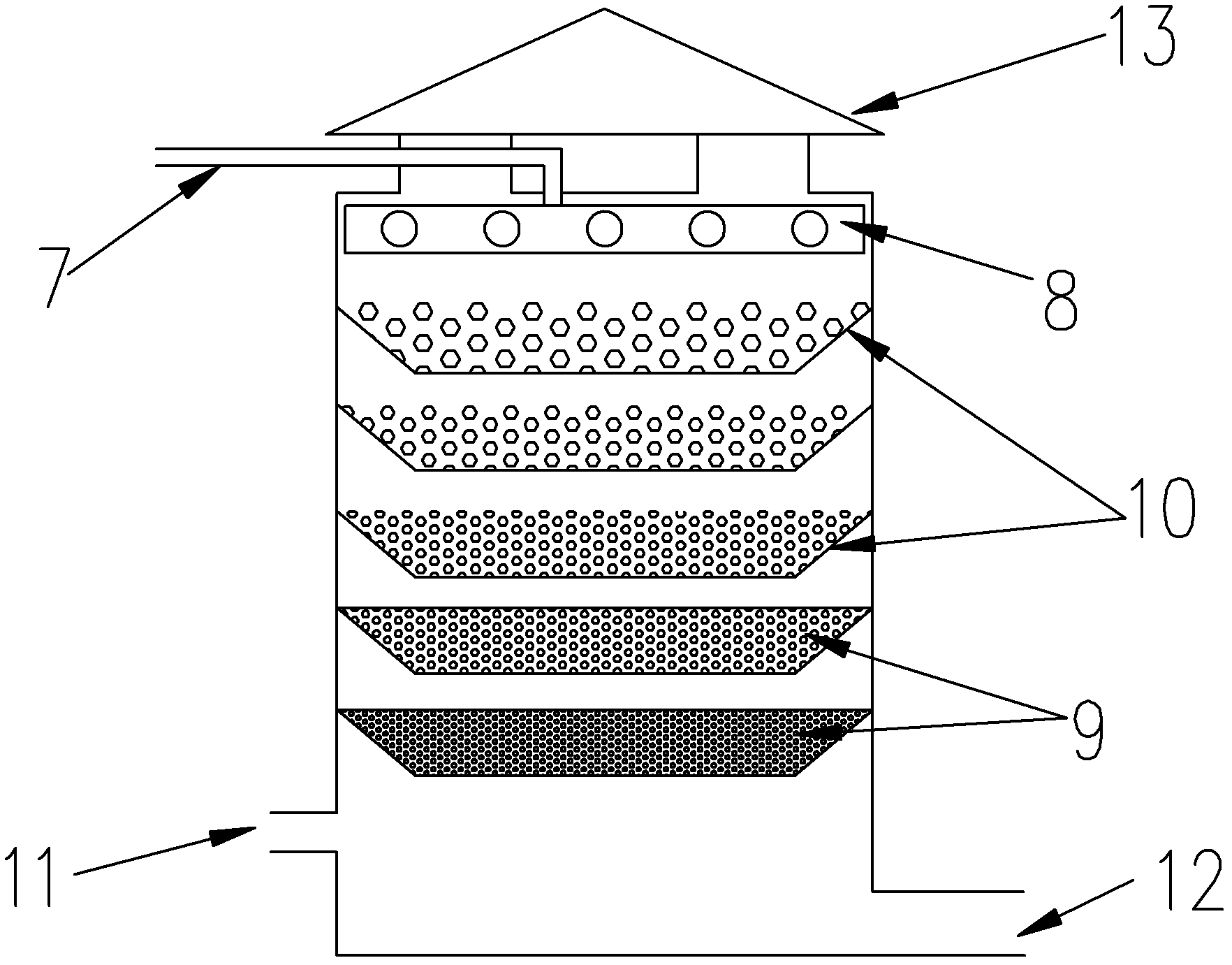

Centralized treatment system for sewage in rural area

InactiveCN102531293ASolve pollutionReduce the burden onMultistage water/sewage treatmentEnergy based wastewater treatmentRural areaAnaerobic reactor

The invention relates to a centralized treatment system for sewage in a rural area. The centralized treatment system comprises an equalizing basin, an upflow anaerobic reactor, a multi-layer aerobic movable filter tower, a crop wetland system and a methane collecting and utilizing system, wherein the equalizing basin is arranged underground; the heights of the upflow anaerobic reactor, the multi-layer aerobic movable filter tower and the crop wetland system gradually decreases; the equalizing basin is communicated with each sewage discharging hole by a sewage pipe; the equalizing basin is communicated with the upflow anaerobic reactor by the sewage pipe, and a water pump is arranged between the equalizing basin and the upflow anaerobic reactor; the upflow anaerobic reactor is communicatedwith the multi-layer aerobic movable filter tower by the sewage pipe; the multi-layer aerobic movable filter tower is communicated to the crop wetland system by the sewage pipe; the upflow anaerobic reactor and the multi-layer aerobic movable filter tower are communicated to the crop wetland system by a sludge pipe; and the upflow anaerobic reactor is communicated with the methane collecting and utilizing system by a methane pipe. According to the centralized treatment system provided by the invention, energy saving and environment protection are realized, and the production value of agriculture and forestry is increased; and the centralized treatment system is simple in structure and convenient to mount and operate and is capable of reducing the burden of farmers, decreasing the occupiedarea and solving the problem on the pollution caused by the sewage in the rural area.

Owner:CHINA CONSTR ENG DESIGN GROUP

Method for removing nutrient salt in water

InactiveCN1603251AShorten the timeGovernance is deepSustainable biological treatmentBiological water/sewage treatmentMicroorganismEutrophication

The invention relates to a method to remove nutrition salt in water body. Its including the following steps: first, building biology island according to the square and depth of the water body needs to be handle; second, using nylon, plastic or stainless steel to construct flexible or steel frame of floating island; third, filling light, suspending, porous and absorbing base material into the floating island; finally, putting the floating island into ultrophication water body, and microorganism can grow and form organic membrane on the light carrier. The invention can reduce nutrition salt consistency from 40% to 80% and lasting for 2 years to 3 years. Moreover, it has advantage of improving water quality, easy to maintain and long term effect.

Owner:WUHAN UNIV

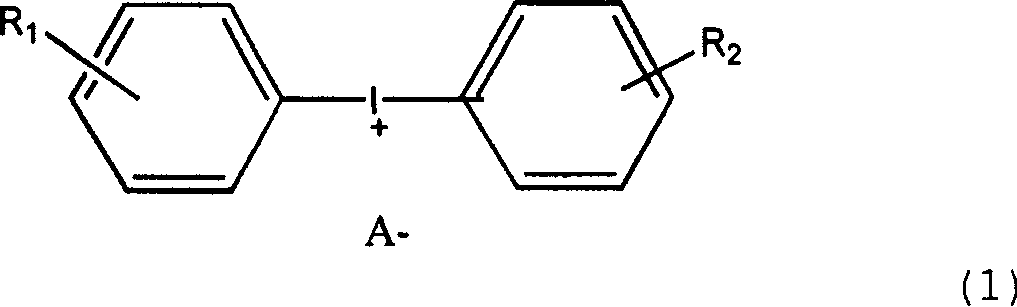

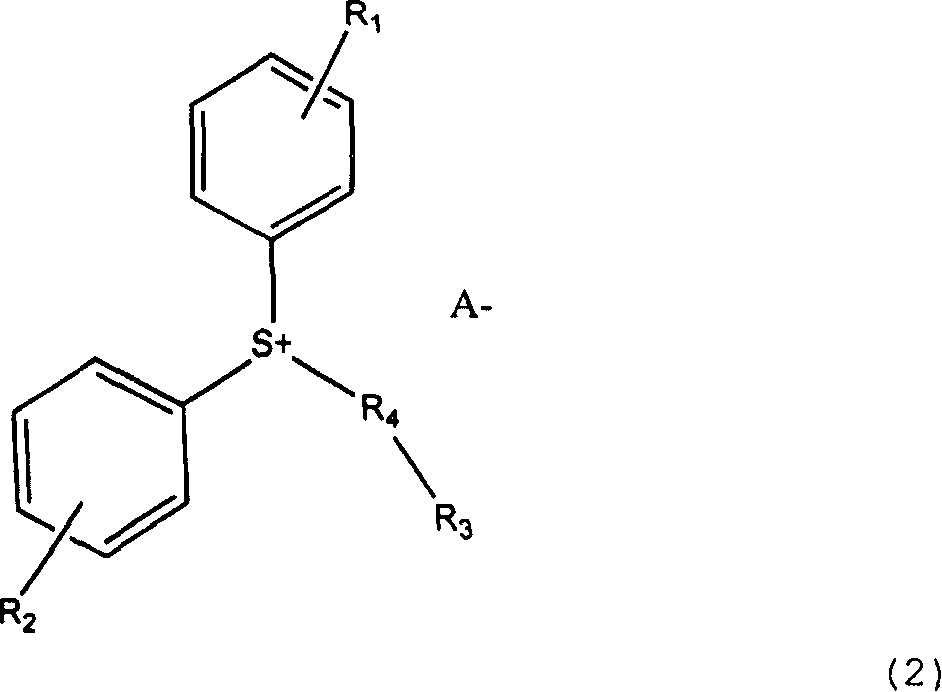

Inkjet ink composition and printed matters created using inkjet ink composition

There is proposed an inkjet ink composition comprising a pigment component to which a resin having a basic terminal is adsorbed, a photo-acid generating agent containing an onium salt, and at least one kind of solvent which can be polymerized under the presence of an acid. The content of multivalent salt included in the onium salt is not more than 20% by weight based on a total weight of onium salt, and the content of the pigment component is confined within the range of 3 to 41% by weight based on the ink composition.

Owner:TOSHIBA TEC KK

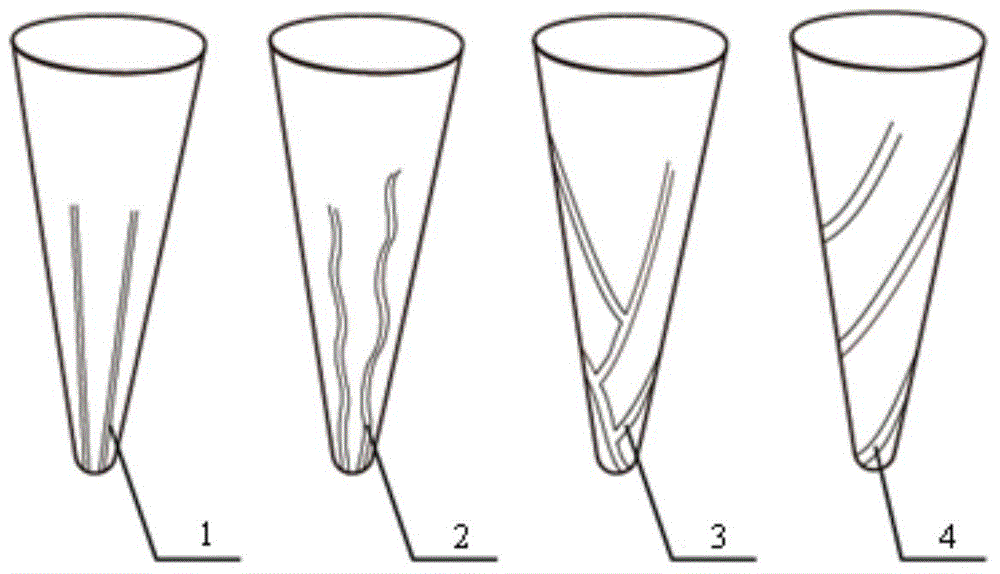

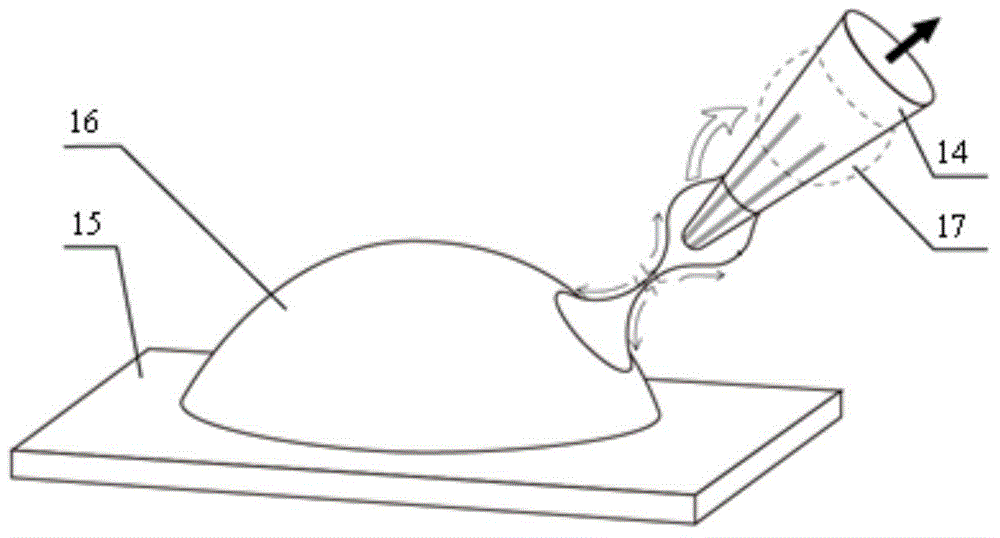

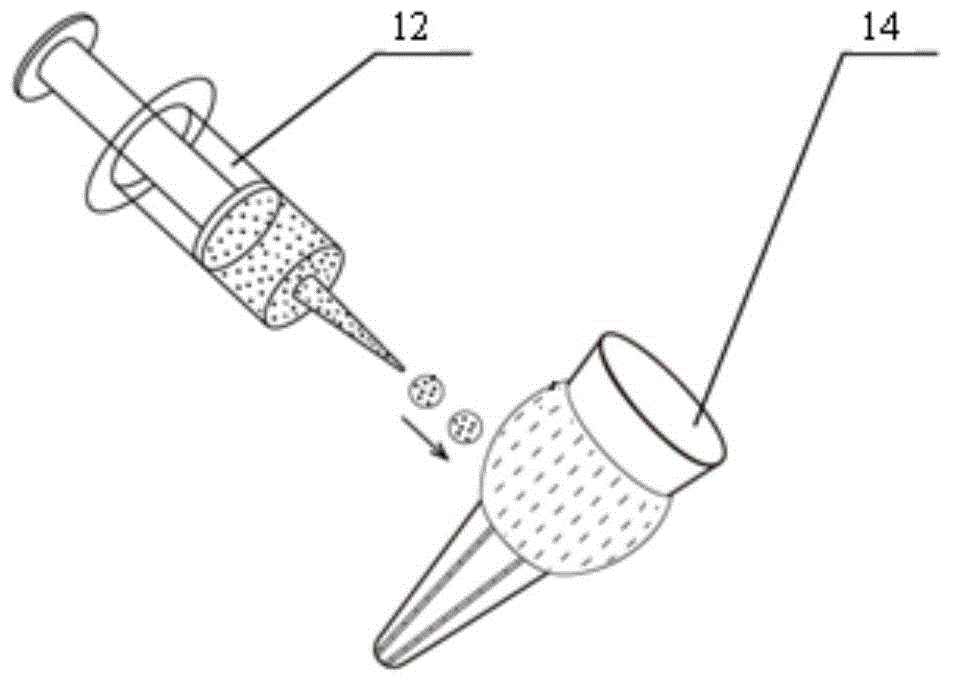

Micro needle tip with orientation structure and method thereof for continuously conveying liquid

ActiveCN105036052AContinuous deliveryAchieve precision manufacturingSemi-permeable membranesFixed microstructural devicesMicro nanoImage resolution

The invention discloses a micro needle tip with an orientation structure and a method thereof for continuously conveying liquid, belonging to the technical field of micro-nano manufacture. The tapered micro needle tip has a thin tip and a thick root. An oriented micro-nano groove-shaped structure is manufactured on the surface of the micro needle tip. Liquid drops are put on or supplemented to the micro needle tip with the micro-nano groove-shaped structure. Under the action of surface tension, the liquid drops automatically move to a liquid storage position of the micro needle tip. Under the control of a mobile device, the micro needle tip with the liquid drops moves to a target position. Under the action of capillary force of the micro-nano groove-shaped structure on the surface of the micro needle tip, liquid drops flow downward along the micro needle tip to a substrate of the target position. The liquid drops are solidified and stacked on the substrate of the target position so as to form a pattern or a stereostructure. The micro needle tip can be manufactured precisely from bottom to top. Compared with the prior art, the micro needle tip has the advantages of good continuity, controllable size, simple device, high resolution, and broad application range.

Owner:SHENZHEN TSIMEC CO LTD

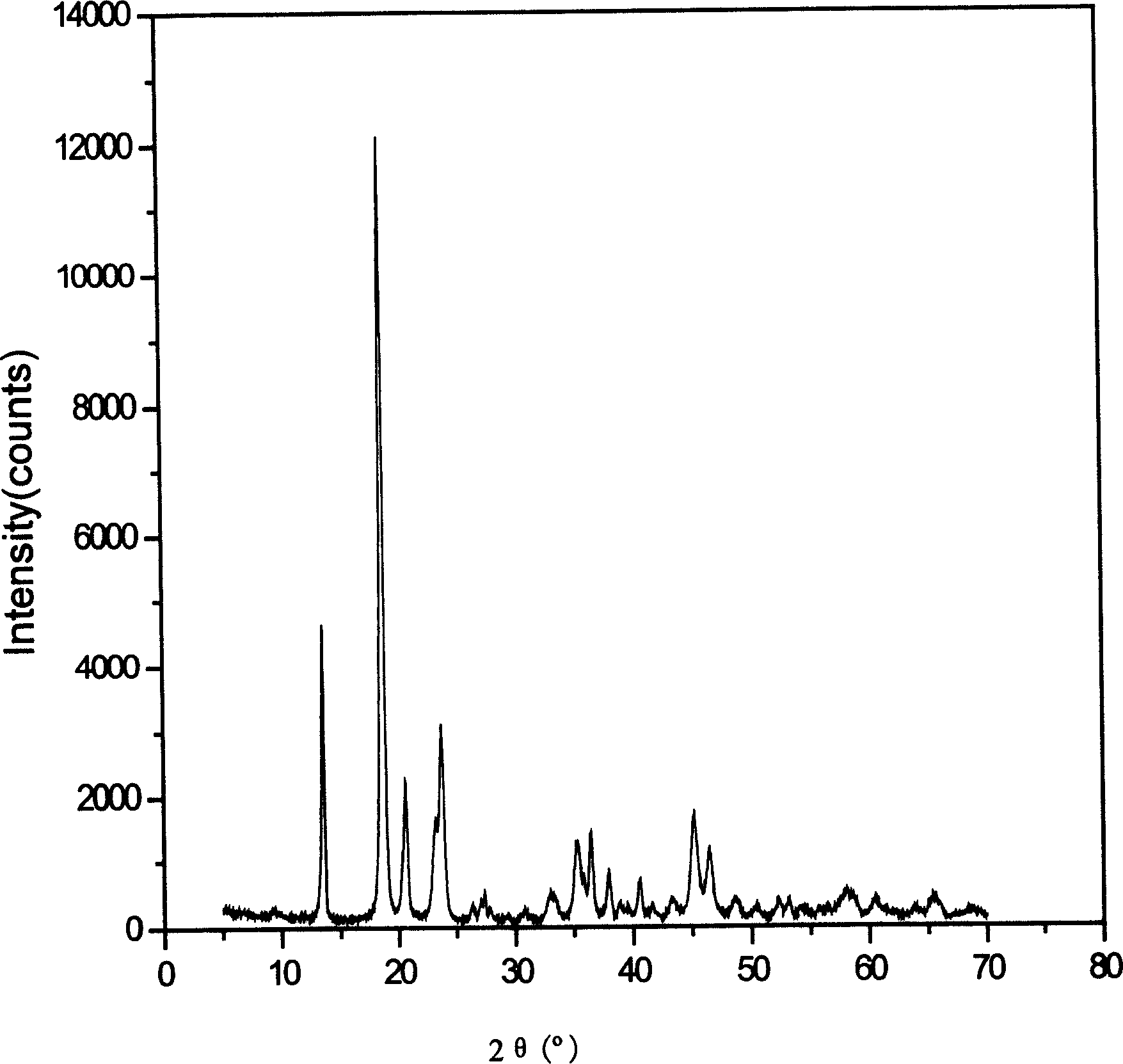

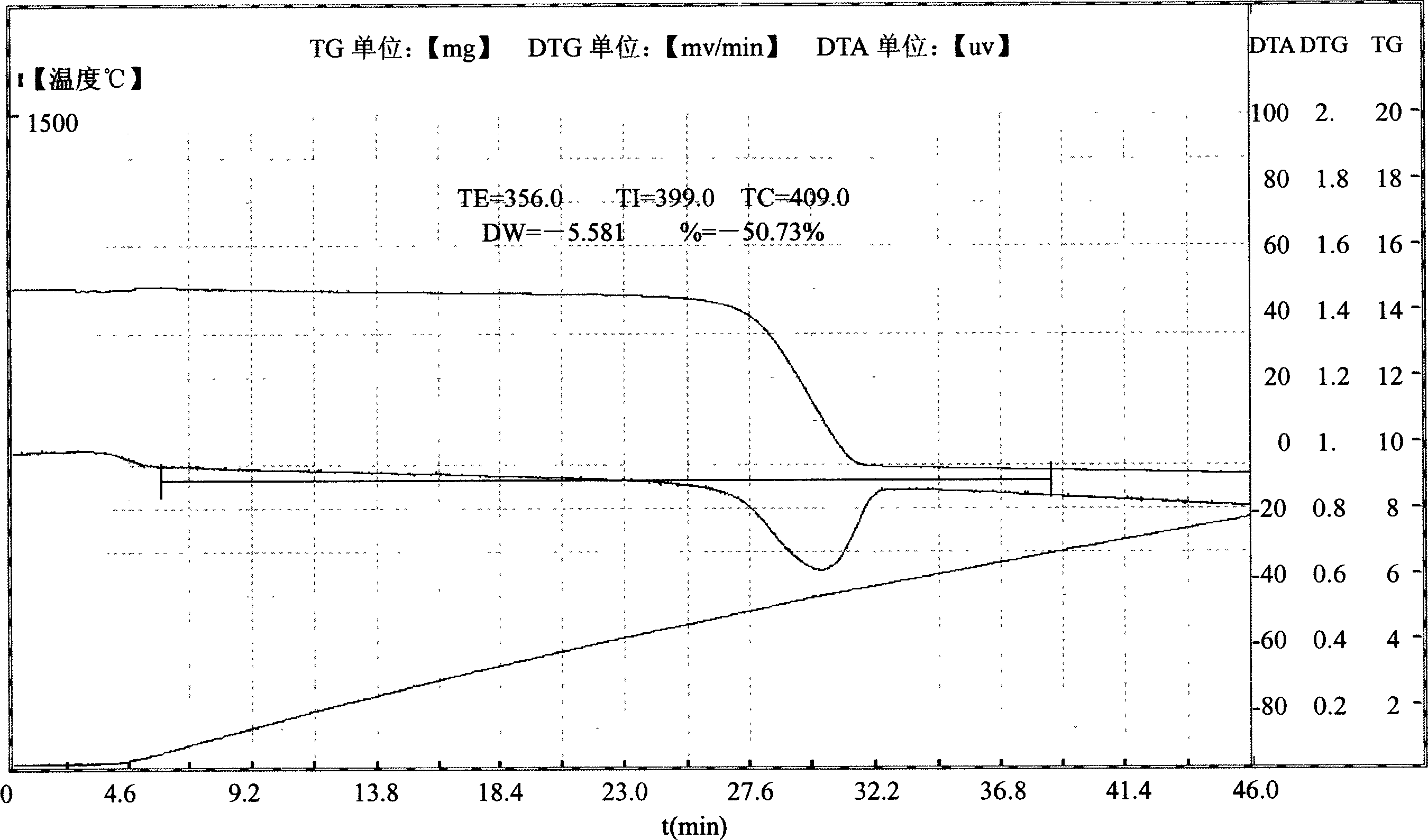

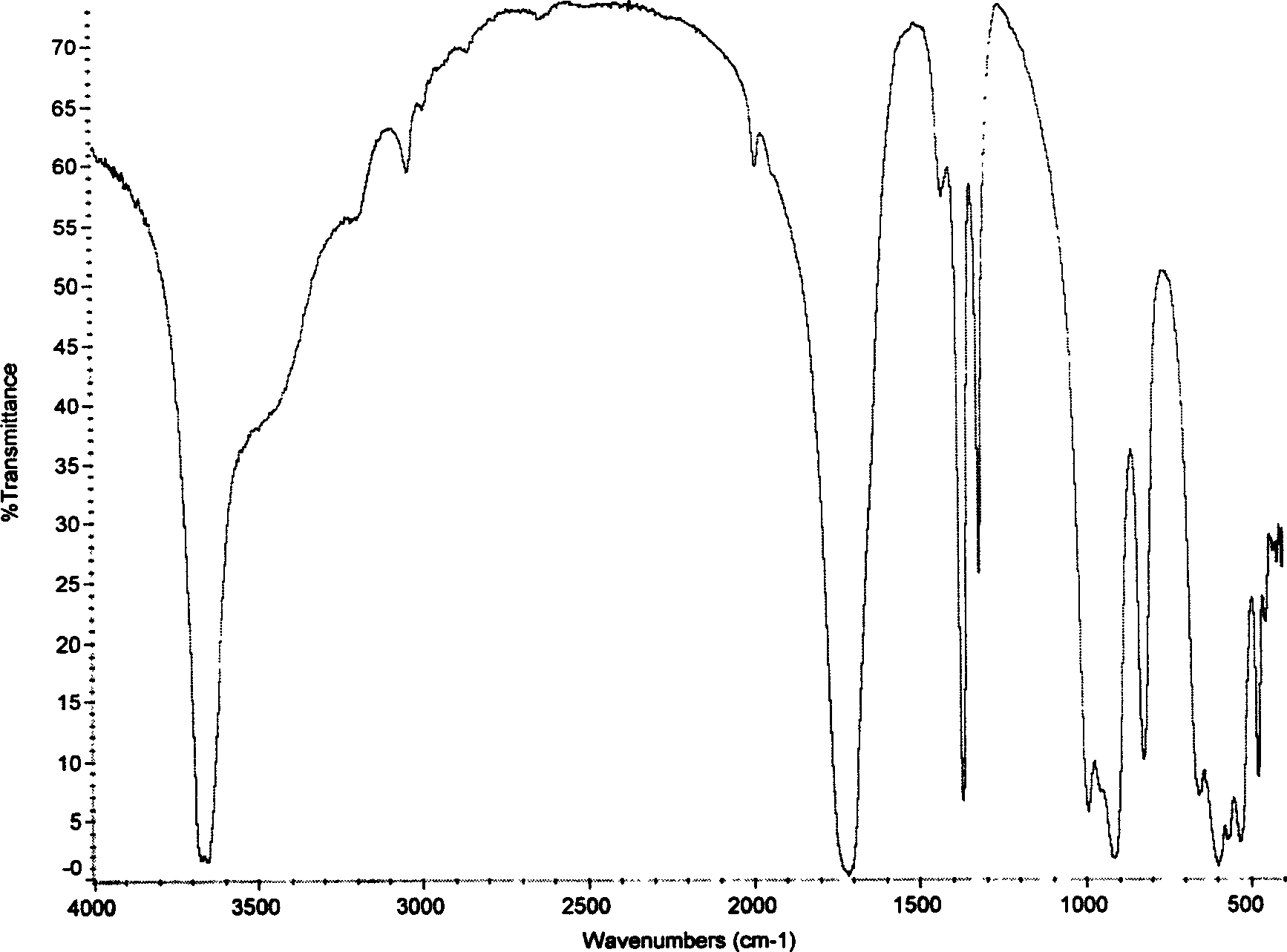

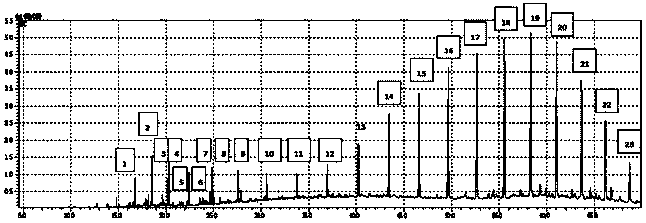

Hydroxy aluminium oxalate, and its preparing method and hydroxy aluminium oxalate as fire retardant

InactiveCN1640865ASimple structureEasy to operateCarboxylic acid salt preparationThermoplasticDecomposition

The present invention is the aluminum hydroxyoxalate and its preparation process. Aluminum hydroxyoxalate is used as fire retardant, and has molecular expression of Al2(C2O4)(OH)4, and X-ray diffraction spectrum with strong diffraction peaks at D values one 6.5149, 4.7263 and 4.2957 angstrom. Aluminum hydroxyoxalate is prepared through carbonization and decomposition and modification treatment, and through further crystal form controlling treatment, aluminum hydroxyoxalate with high dispersivity and complete crystal form may be obtained. Aluminum hydroxyoxalate has minimum one-dimensional size controlled in 40 nanometers to several microns, extrapolation onset weight-loss temperature higher than 340 deg.c, and weight-loss rate before 500 deg.c up to 51 %. As one kind of green fire retardant, aluminum hydroxyoxalate may be used in thermoplastic plastic and other polymer material with processing temperature over 210 deg.c.

Owner:BEIJING UNIV OF CHEM TECH

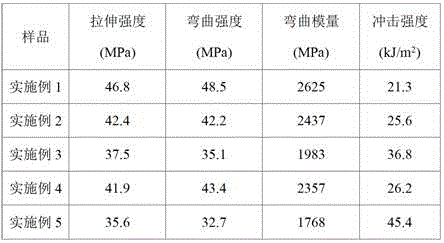

3D printing wire rod with pearl effect and preparation method thereof

ActiveCN106633723AWith self-pearl effectImprove toughnessAdditive manufacturing apparatusWire rodPolymer science

The invention discloses a 3D printing wire rod with a pearl effect and a preparation method thereof. A 3D printing material with the pearl effect is prepared by using transparency and refractive index differences among different materials according to a pearl effect generating principle. According to the technical scheme, the 3D printing wire rod is prepared from the following raw materials in percentage by weight: 5 to 90 percent of PLA, 5 to 90 percent of high-refractive-index transparent resin, 0 to 10 percent of compatilizer, 0.05 to 2 parts of antioxidant and 0.05 to 1.5 percent of white oil. The preparation method comprises the following steps: (1) drying; (2) weighing the materials; (3) mixing; (4) extruding and granulating; (5) molding a wire rod; (6) cooling and performing traction; (7) coiling. The obtained 3D printing wire rod has a self-pearl effect and excellent toughness, a printed product has high gloss, light resistance and stability, and the problem of plugging in a printing process is solved.

Owner:FUJIAN NORMAL UNIV

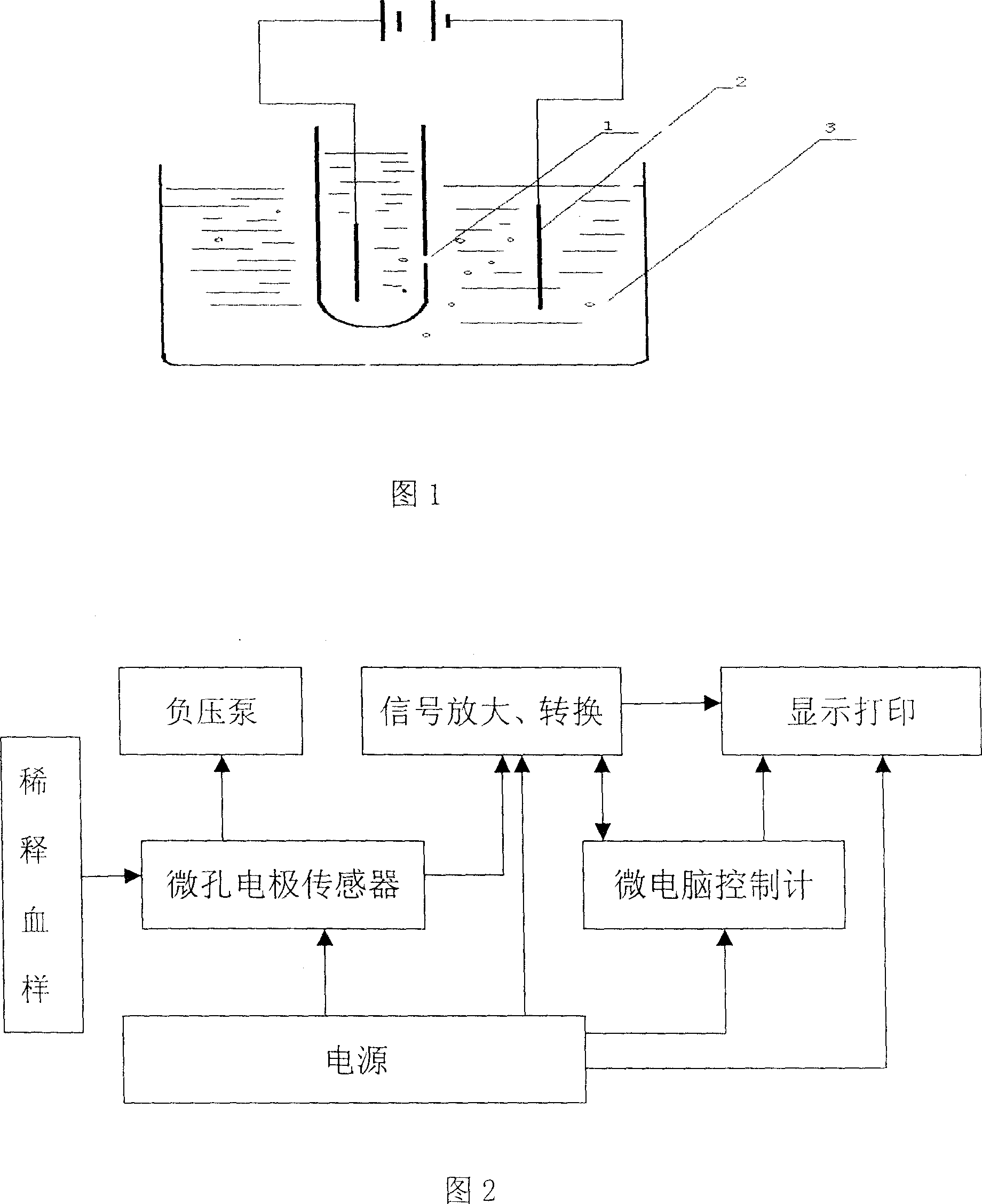

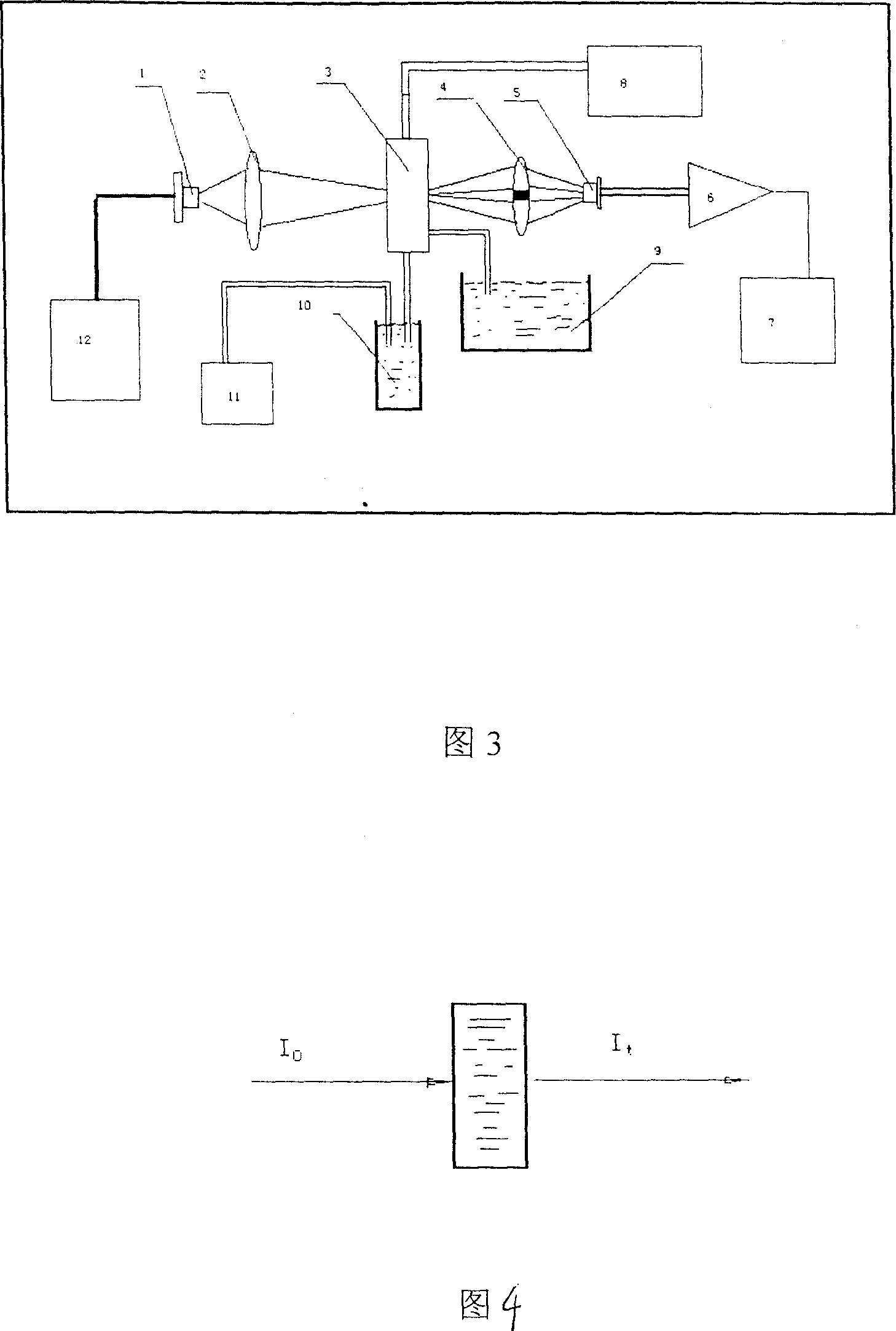

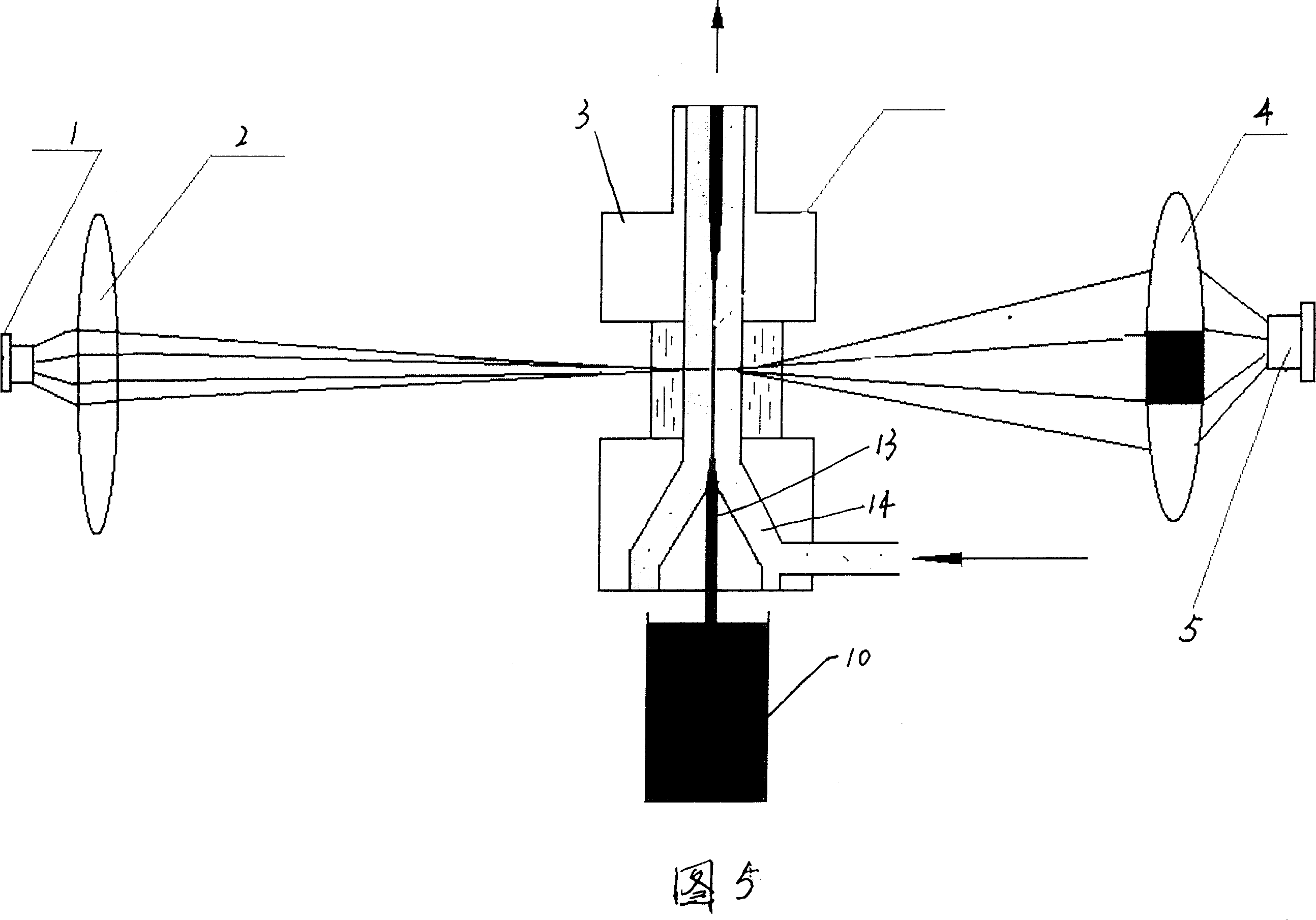

Laser blood cell counter

InactiveCN101025414ANo clogging problemImprove analysis accuracyMaterial analysis by optical meansBiological testingPhysicsOptical path

The invention relates to a laser haematimeter count instrument, the count instrument includes electronic circuit and in turn lasers, condenser lens group, sheath flow record boxes, receive convex lens, photoelectric tubes, laser light source, axis of condenser lens Group, the translucidus hole of sheath flow record boxes, axis of receive the convex lens, receive light head of photoelectric tube set on the same optical axis line, bloodshot mouth on the bottom of sheath flow record box connect sample cup of diluting blood with lay tube of diluting blood, the draft tube of sheath flow record box connect with sheath fluid balance Cup, the sheath flow exports at the top of the mouth above the sheath flow record box connect negative pressure suction means with pipeline, the center line of bloodshot mouth and sheath flow exports across the core line of the above light path, the cross point lie in concourse light spot of the condenser lens group. In the absence of micropore electrodes, the air-logged problem does not exist; This equipment is no need for the special dilution of expensive reagents, general saline can satisfy requirements.

Owner:JINGKE ANALYTICAL INSTR ZHENGZHOUCITY

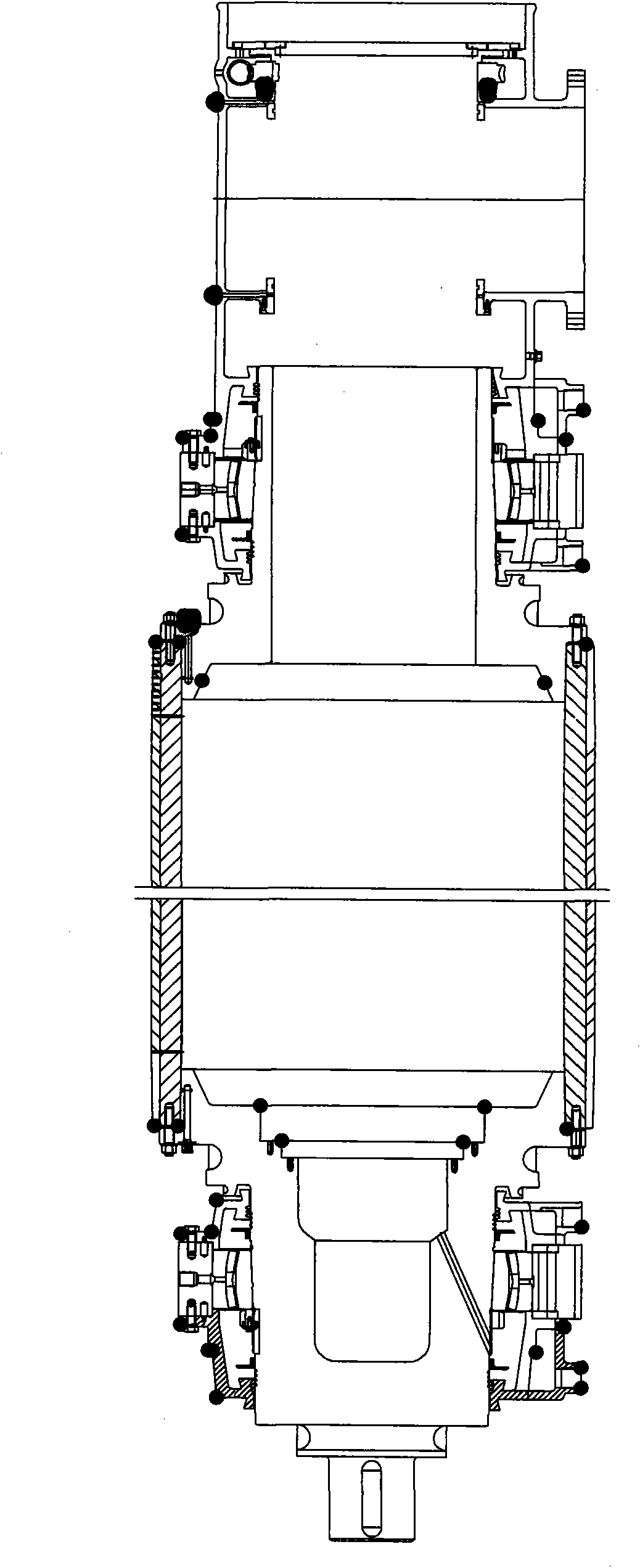

Thin oil lubrication sealing device for vacuum roller liner bearing

The invention discloses a thin oil lubrication sealing device for a vacuum roller liner bearing. The bearing is arranged between a liner and a transmission-side shaft head, and a bearing seat is fixed on the transmission-side shaft head; the bearing is fixedly sleeved on a shaft sleeve which is tightly fixed to a liner shaft and tightly fixed by locking nuts; the bearing is arranged in the bearing seat, a bearing cover is fixed on one end surface of the bearing seat and can close one end of a liner shaft; and one end surface of the inner bearing cover is fixed on the other end surface of the bearing seat. The invention realizes the thin oil lubrication sealing of the bearing by mechanical seal in a flaring chamber, oil seal, labyrinth seal and grease seal, is easy to add oil, hardly leaks thin oil, is suitable for the vacuum roller bearing of a papermaking machine at medium and high speeds and prolongs the service life of the bearing.

Owner:JIANGSU HUADONG PAPER MACHINERY

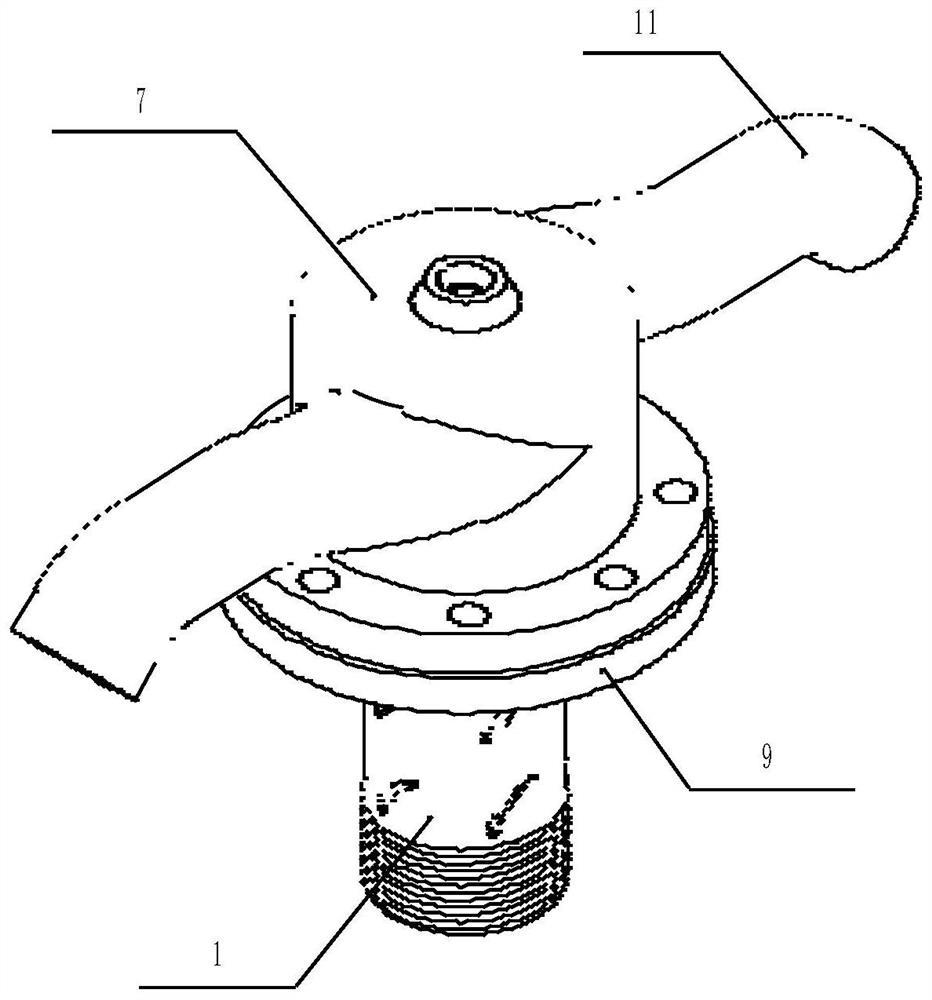

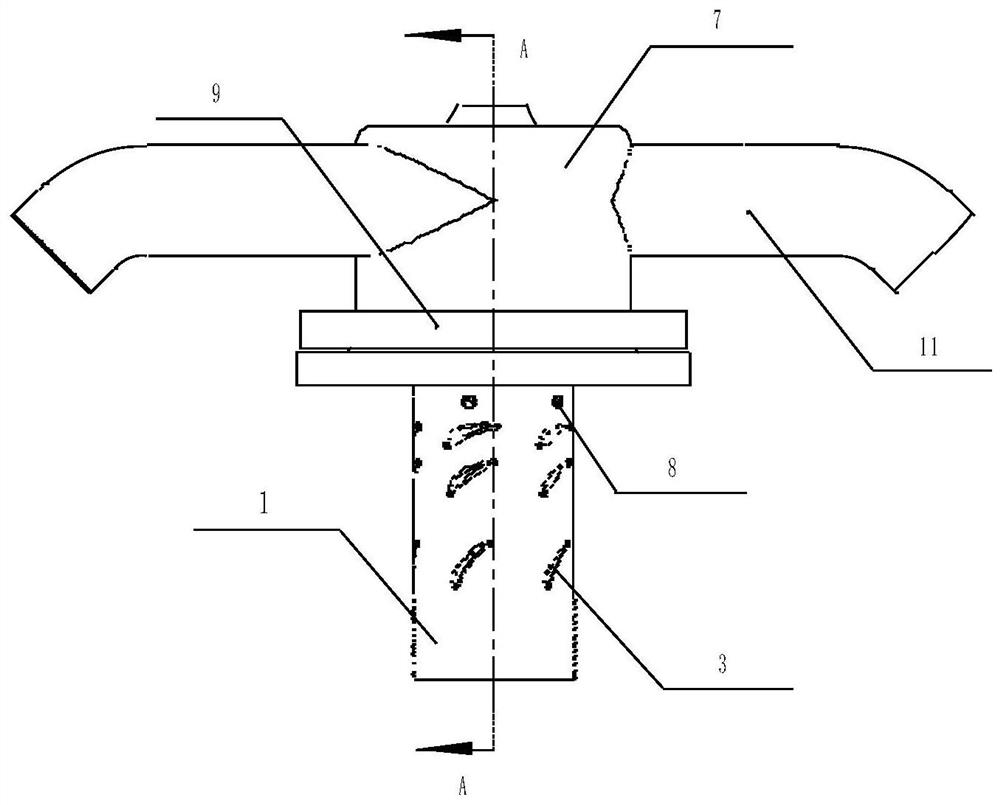

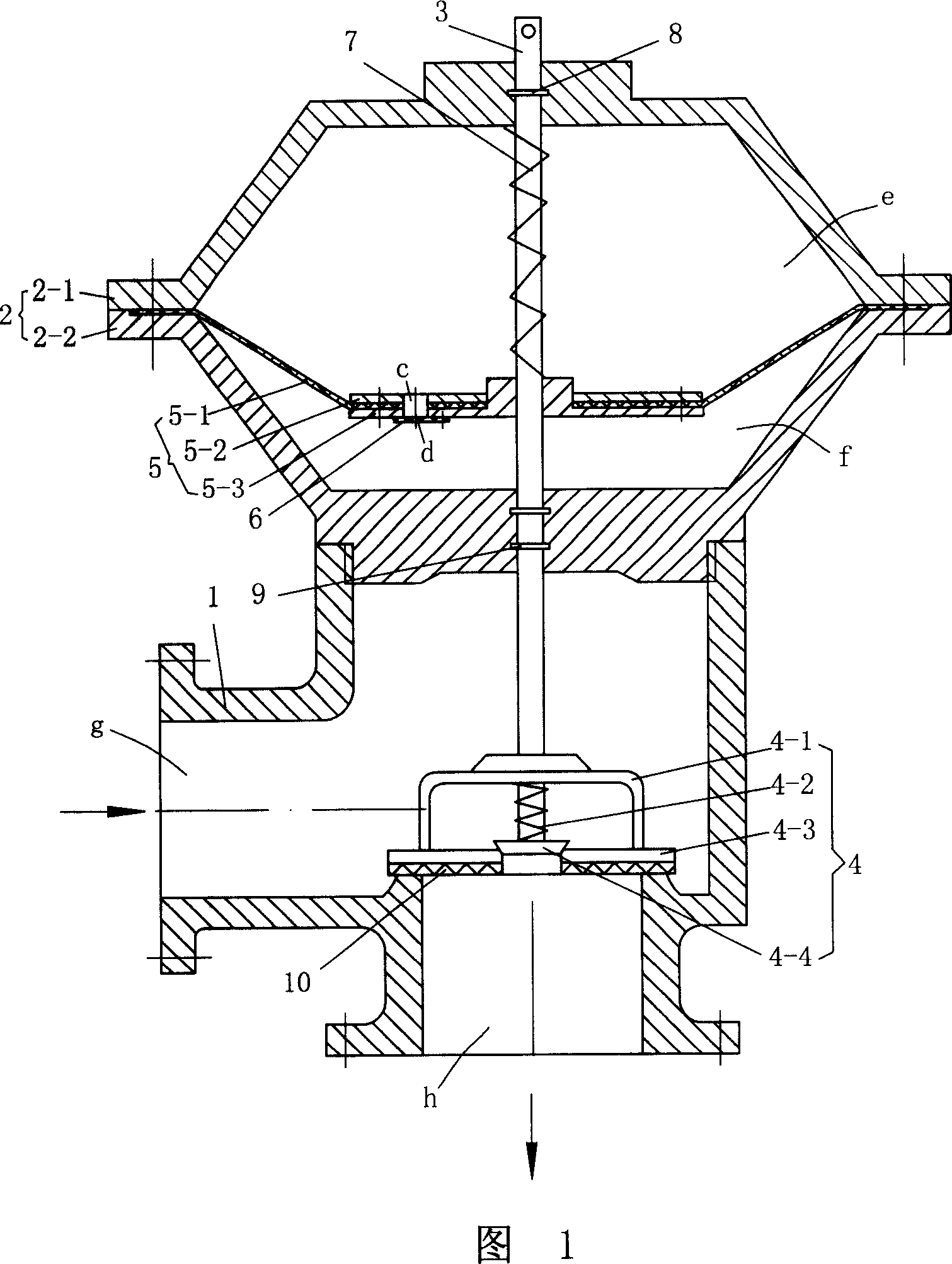

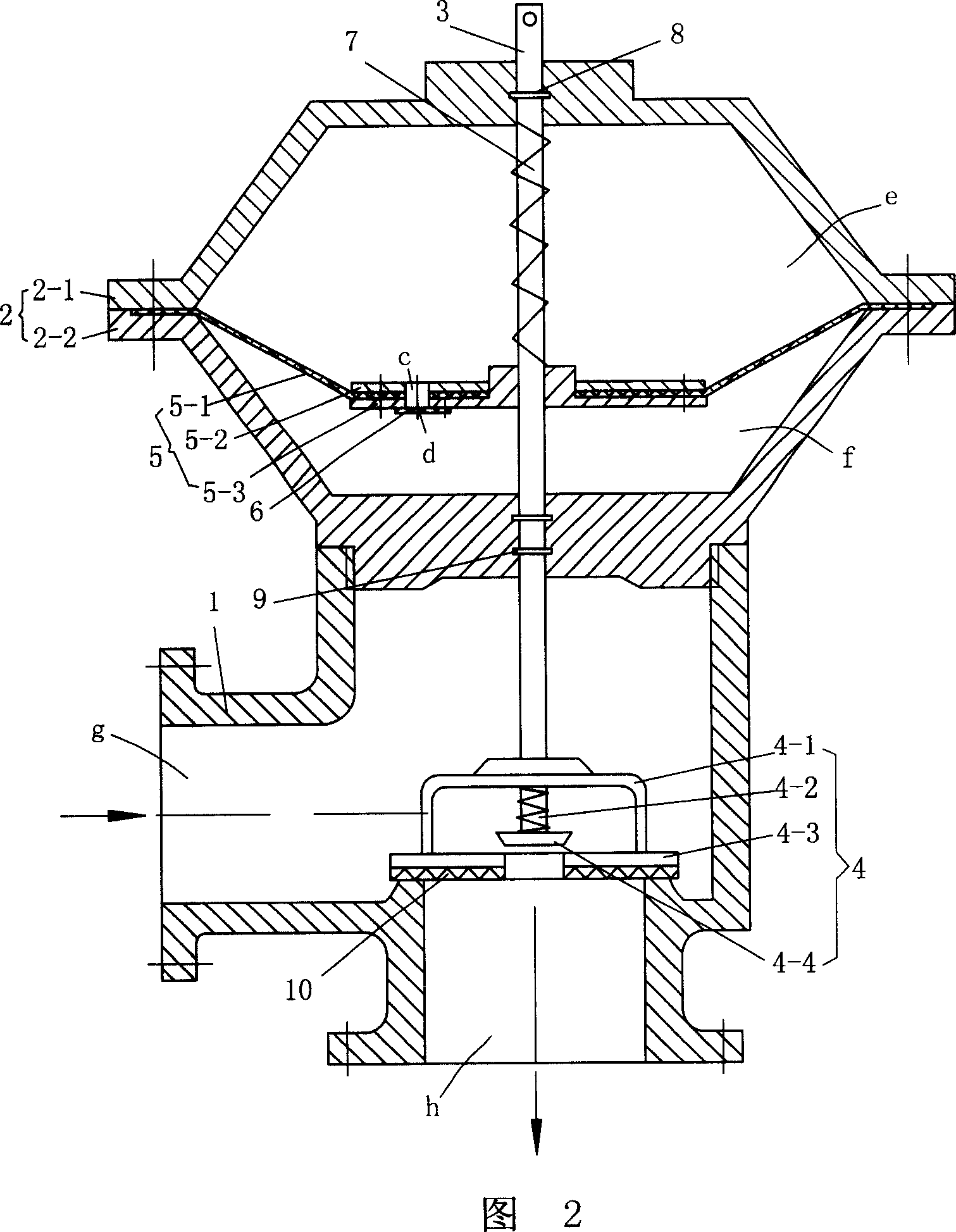

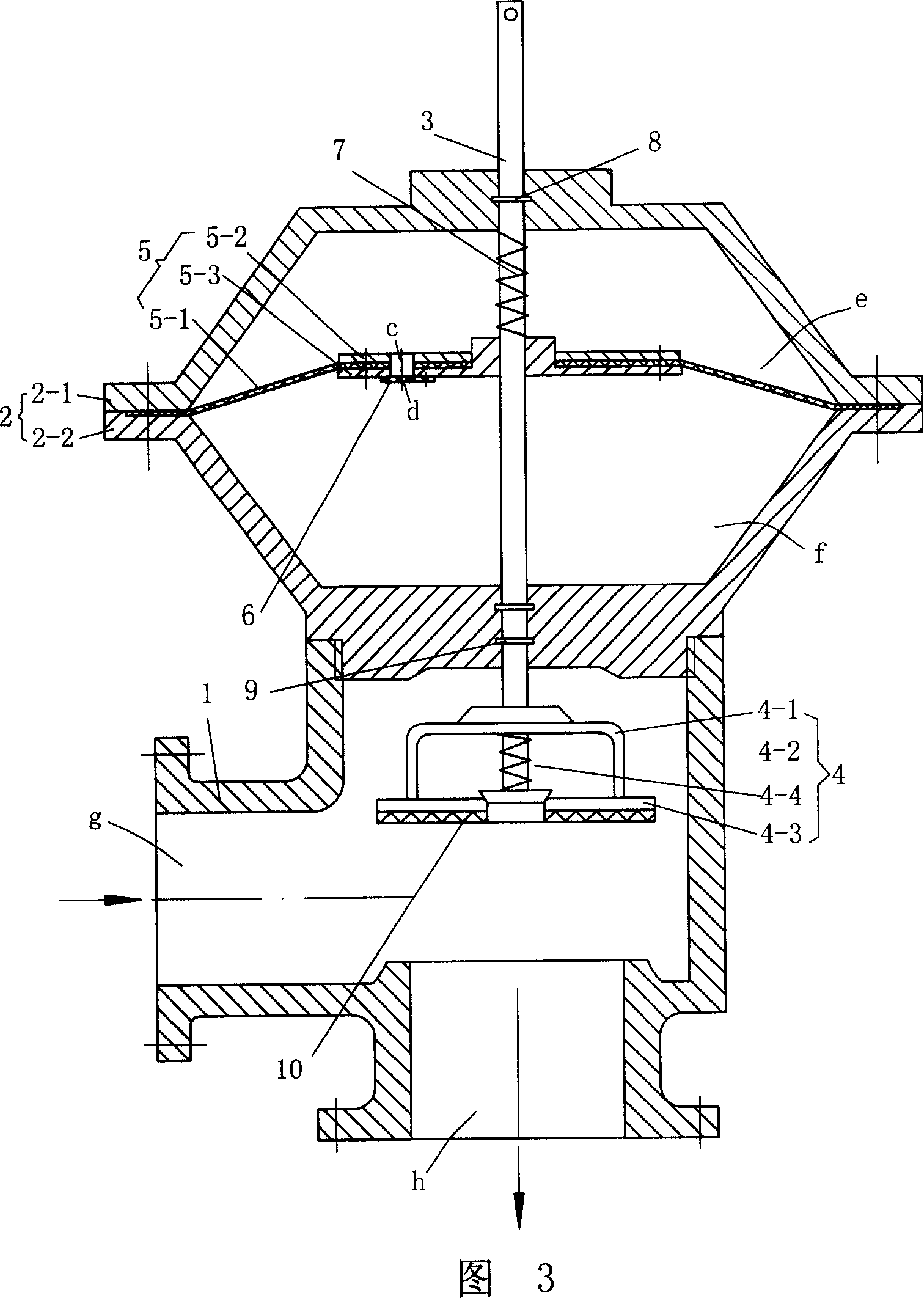

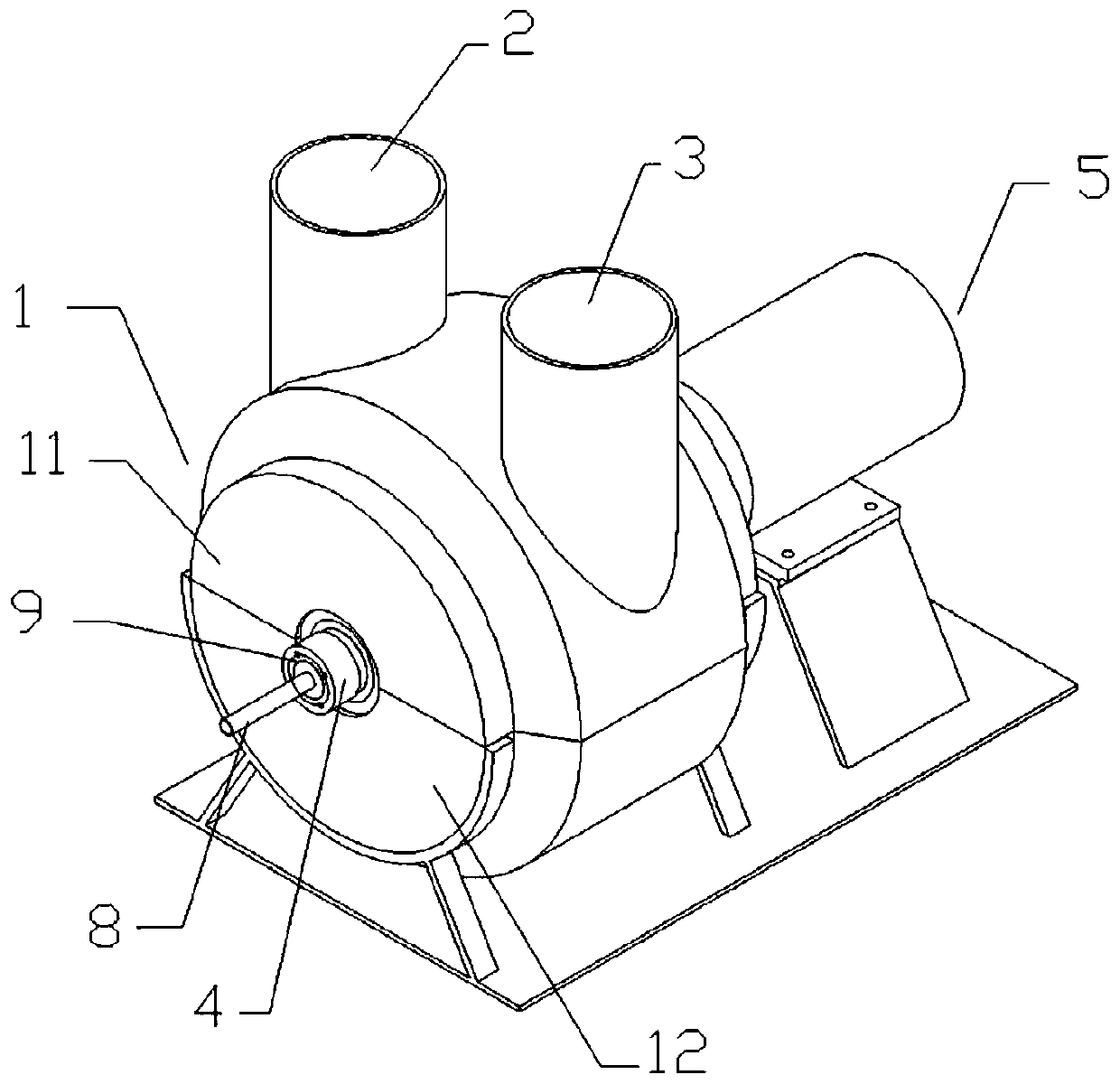

Spiral-flow type micro-nano bubble generator and generation method thereof

PendingCN112408584AMeet needsHigh spinning efficiencyTreatment using aerobic processesBiological treatment apparatusMicro nanoWater flow

The invention discloses a spiral-flow type micro-nano bubble generator and a generation method thereof.The spiral-flow type micro-nano bubble generator is mainly characterized in that two spiral-flowstarting cylinders are evenly distributed on the outer wall of a volute in the circumferential direction and communicated with the volute, a flange plate is arranged at the bottom of the volute, a through hole is formed in the center of the volute, and an outer cylinder is installed in a center hole of an installation disc; a plurality of grades of blades are arranged on a blade shaft, an air inlet throat pipe is installed at the top end of a sleeve, the bottom of the sleeve is installed at the top end of a cavitator through a positioning pin, a tooth-shaped gasket is installed between the bottom face of the sleeve and the top face of the cavitator, and the cavitator is installed in a positioning hole in the top end of the blade shaft. A static multi-stage cascade is adopted, the last stage is of a hollow blade structure, water flow is converted into rotational flow from horizontal flow through the cascade, the lift provided by the water pump is efficiently converted into high-speed circumferential water flow speed in a short process through the change of the installation angle of the multi-stage cascade, and micro-nano bubbles are generated by shearing gas through rotating water flow. The generator is reliable in operation and less susceptible to clogging.

Owner:陕西超微环境科技有限公司

Method for constructing inorganic artificial article floating island

InactiveCN1850659AChemically stableWide variety of sourcesSustainable biological treatmentBiological water/sewage treatmentPhosphateAdhesive

The invention discloses an inorganic man-made biological floating island, comprising the steps of: blending light inorganic material with inorganic adhesive (silicate, phosphate, borate or their combination, such as cement or clay, etc) and water; filling the mixture in a mould; curing, drying and moulding and then drawing it; placing in polluted water body, singly or after growing plants; purifying the polluted water body by growth of microbes and plants on the floating island. And the invention adopts inorganic materials, and has stable chemical property and friendly environment, and has no secondary pollution, and purifies the water body by coaction of plant and microbe membranes.

Owner:WUHAN UNIV

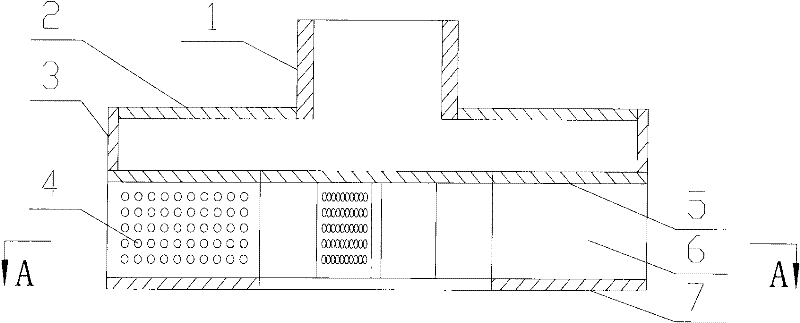

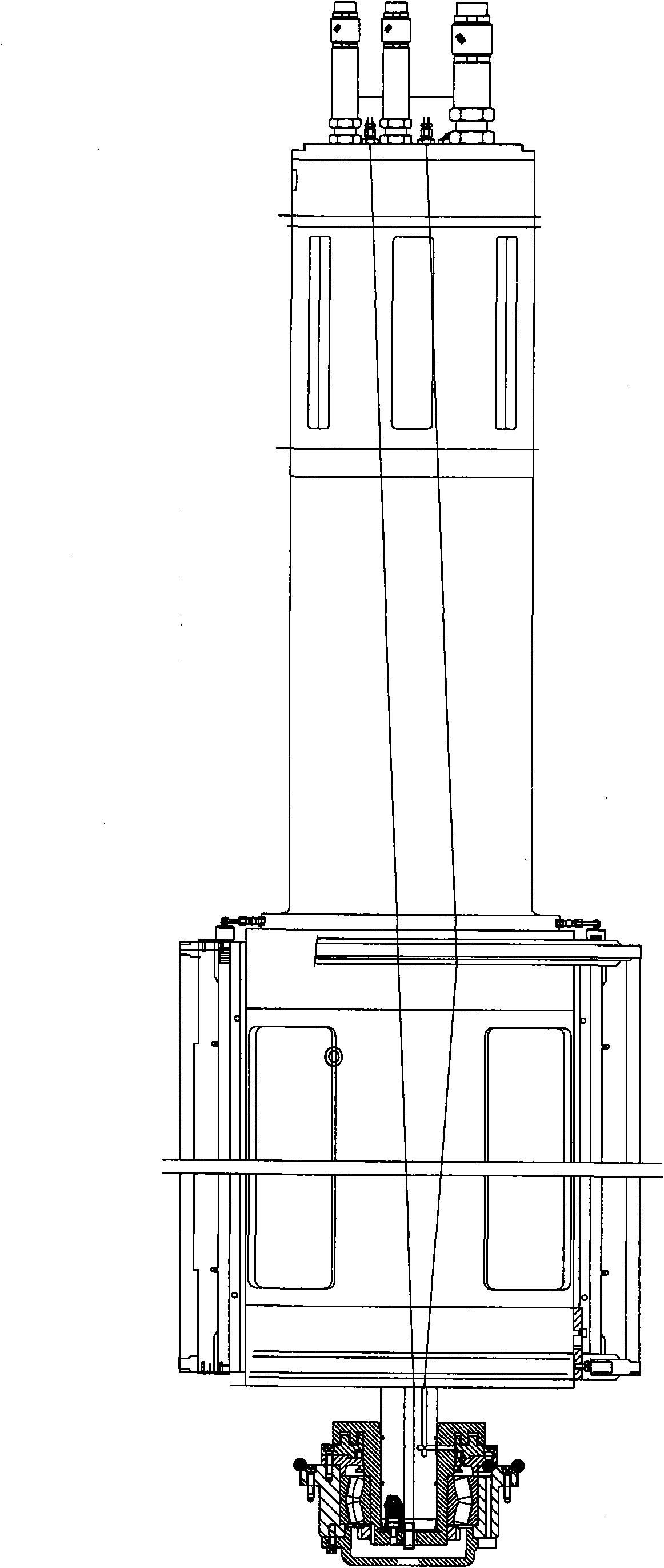

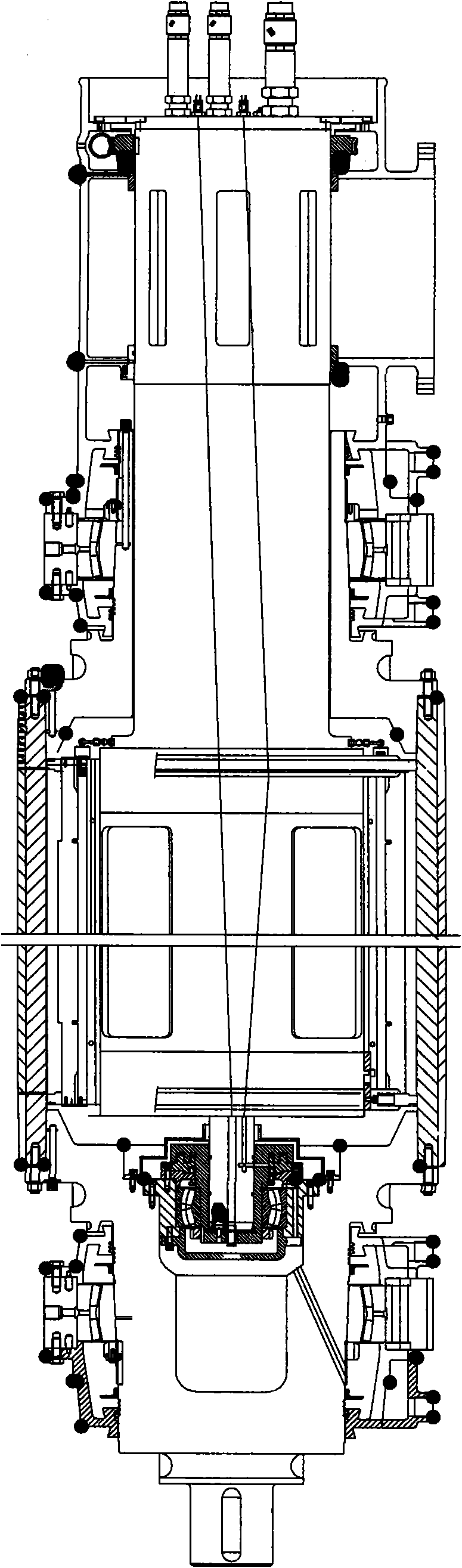

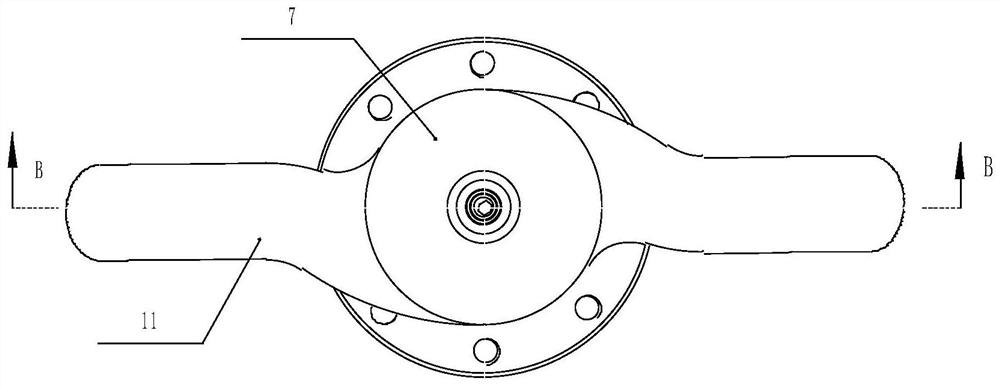

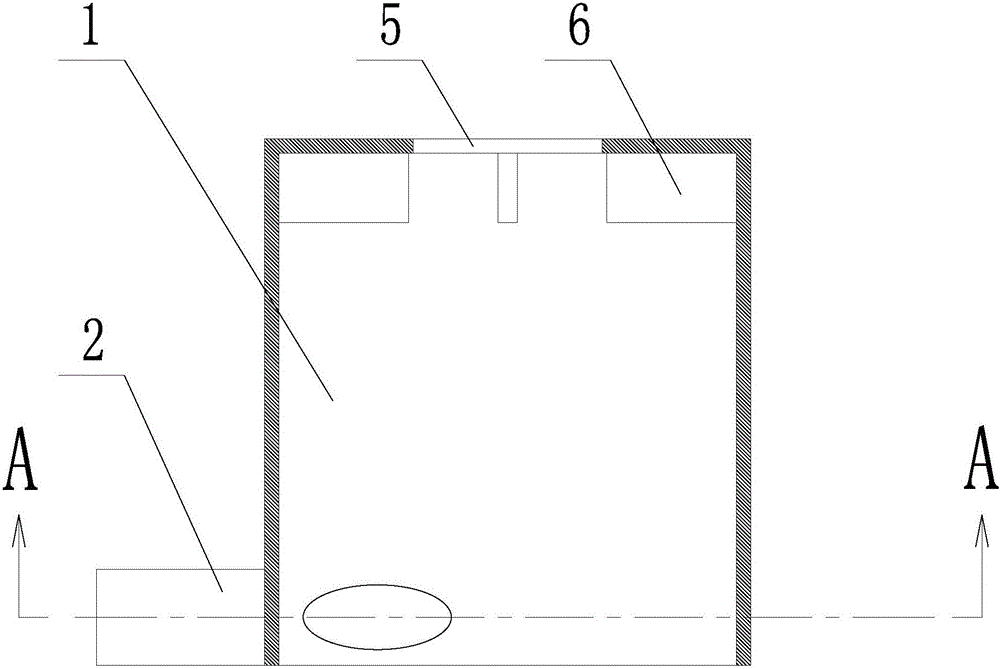

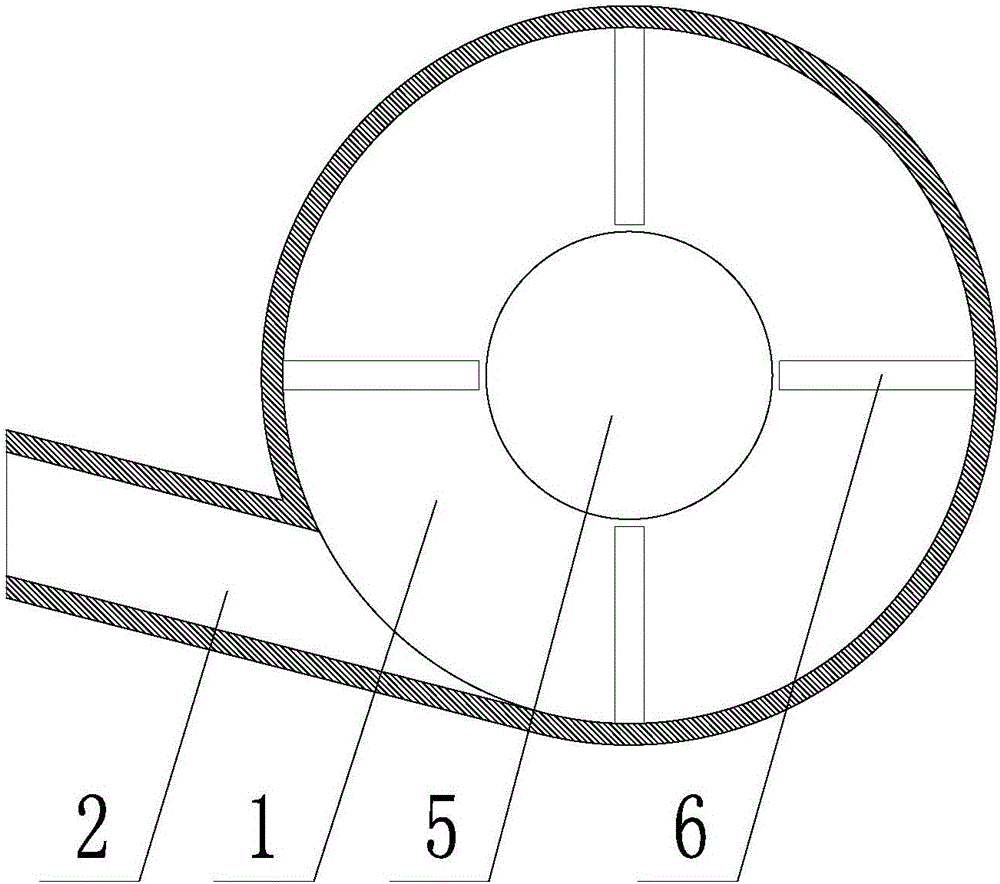

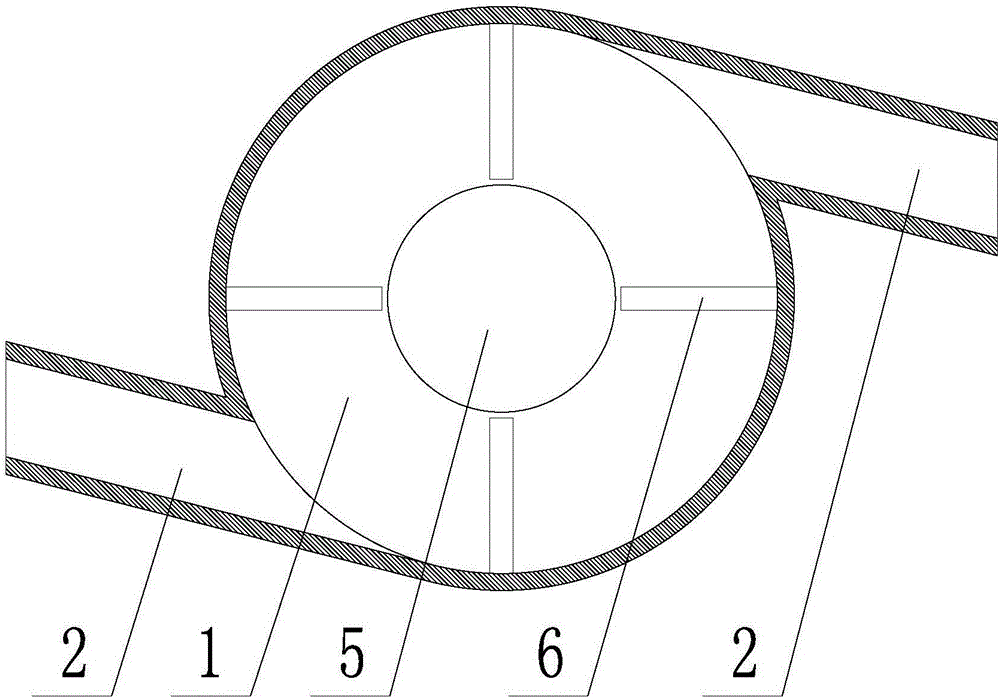

Nozzle flow rotating generation device and nozzle flow rotating continuous casting method

The invention discloses a nozzle flow rotating generation device and a nozzle flow rotating continuous casting method. The device comprises a cylinder type flow rotating generator and a cylinder type flow rotating tundish; the cylinder type flow rotating generator is mounted in a traditional continuous casting tundish, and an inner cavity of the traditional continuous casting tundish is communicated with an immersion type nozzle through the cylinder type flow rotating generator; the cylinder type flow rotating tundish has two mounting modes; according to the first mode, the cylinder type flow rotating tundish and the traditional continuous casting tundish are used in a cooperated manner, the cylinder type flow rotating tundish is mounted on the outer portion of the traditional continuous casting tundish, and the traditional continuous casting tundish is communicated with the immersion type nozzle through the cylinder type flow rotating tundish; and according to the second mode, the cylinder type flow rotating tundish is independently used, and a nozzle of a steel ladle is communicated with the immersion type nozzle directly through the cylinder type flow rotating tundish. The method comprises the steps that before continuous casting, according to the continuous casting technology, the nozzle flow rotating generation device is selected, then, the device and the traditional continuous casting tundish are assembled, during continuous casting, under the effects of molten steel gravity and tangent line entrances, molten steel generates rotating flowing, and molten steel in the immersing type nozzle generates rotary flowing.

Owner:NORTHEASTERN UNIV

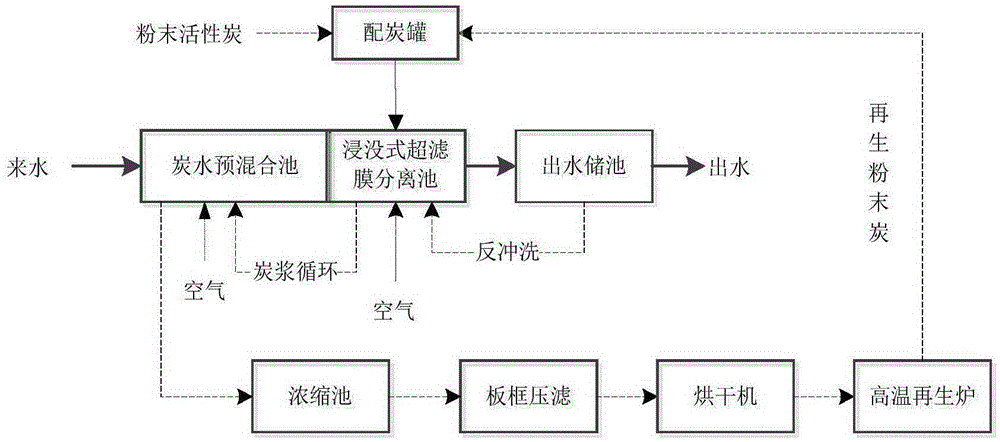

Method for performing water purification plant advanced treatment by using submerged ultrafiltration membrane

InactiveCN105293743AImprove utilization efficiencyStrong impact buffering abilityWater contaminantsMultistage water/sewage treatmentActivated carbonFiltration

The invention discloses a method for performing water purification plant advanced treatment by using a submerged ultrafiltration membrane. The method comprises five steps of adding powdered activated carbon, performing carbon-water premixing, performing activated carbon adsorption and carbon-water separation, performing carbon slurry settling concentration for dehydration and regenerating the powdered activated carbon. The fed water of waterworks is pumped into a carbon-water premixing tank and is uniformly and fully mixed with carbon slurry refluxed out of a submerged ultrafiltration membrane separation tank; then the mixture is put into the submerged ultrafiltration membrane separation tank for performing membrane separation of carbon and water, and a small part of outlet water is reused and is subjected to membrane back flushing; and the carbon slurry in a carbon-water premixing tank is discharged into a concentration tank for concentration, and then is delivered into pressure filtration equipment for dehydration and recovery, and the recovered activated carbon is treated by a baking regeneration activation process for recycling. According to the method disclosed by the invention, the adsorbing effect of the powdered activated carbon on micromolecular organic matters is well combined with a sieving effect of the ultrafiltration membrane on pathogenic microorganism including macromolecular organic matters and bacteria, so that the removal rate of the organic matters is greatly improved, and meanwhile, the powdered activated carbon can be reused after regeneration.

Owner:HUBEI JUNJI WATER TREATMENT

Delay self-closing water-saving valve

The invention is a delay self-closing water-saving valve, having valve body, valve cap, valve rod and valve core, where water inlet and outlet are arranged in the valve body, the valve cap is composed of upper and lower valve cap parts, the space the upper and lower valve form is equipped with elastic diaphragm dividing it into upper and lower air cavities, the valve rod runs through the upper valve cap, diaphragm and lower valve cap into the valve body, and the lower end of the valve rod is connected with the valve core, the position on the valve rod and between the upper valve cap and diaphragm is equipped with first spring, the valve rod is in sealing and sliding mode connected with the upper and lower valve caps, fixed with the diaphragm, and the center of the diaphragm is made with air hole, one way valve is arranged corresponding to the air hole and equipped with orifice connected with the air hole. And it adopts mutually separate air cavity and water cavity, and controls valve delay self-closing by air flowing in the two cavities, thus avoiding the orifice jam problem and assuring its quality.

Owner:CHANGZHOU TEXTILE GARMENT INST

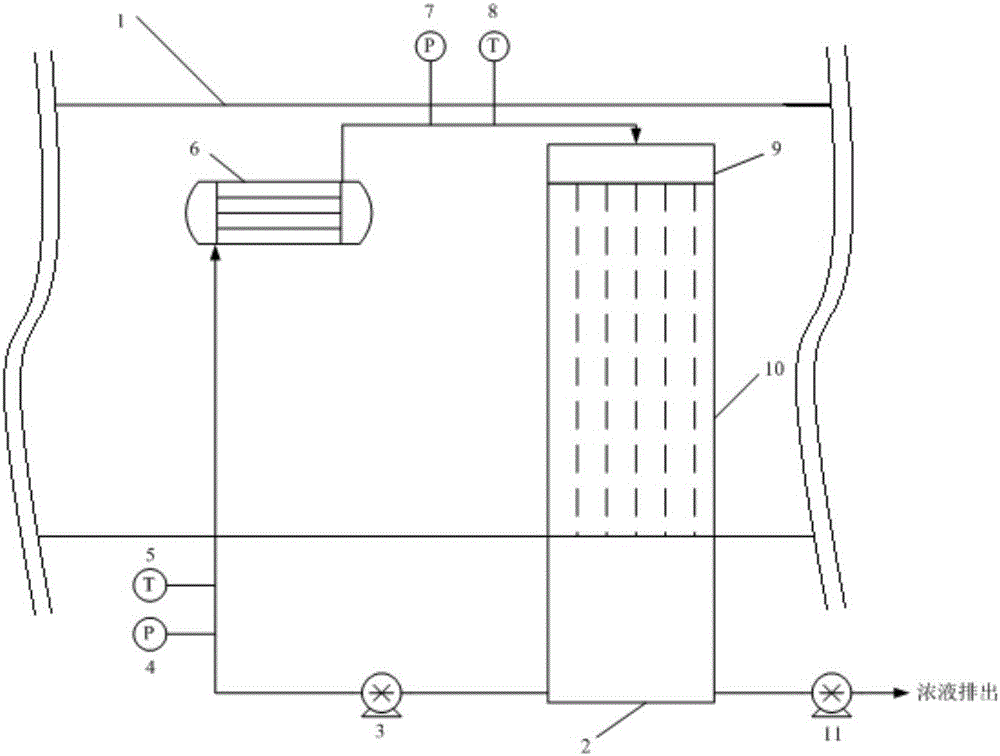

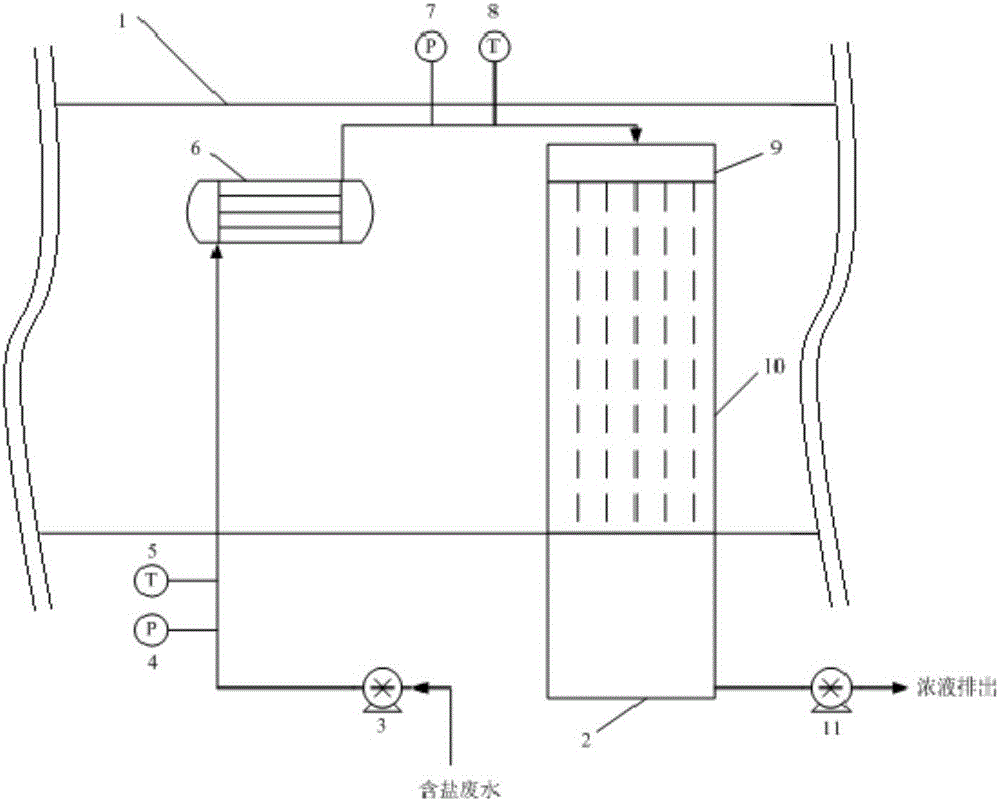

System and technology for utilizing low-temperature smoke to enhance concentration of brine wastewater

ActiveCN106669208AImprove evaporation efficiencyImprove energy saving and reduce consumptionWater/sewage treatmentEvaporationFlueEvaporator

The invention discloses a system and a technology for utilizing low-temperature smoke to enhance concentration of brine wastewater. The system comprises a flue, a first water pump, a wastewater pressurizing pre-heater, a water distributing device, a falling film flash evaporator and a water collecting tank, wherein the water distributing device is arranged at the upper end of the falling film flash evaporator; the water collecting tank is arranged at the bottom of the falling film flash evaporator; the water distributing device and the falling film flash evaporator are both arranged in the flue; the first water pump is used for conveying the pressurized brine wastewater to the wastewater pressurizing pre-heater; the low-temperature smoke in the flue can heat the brine wastewater pressurized in the wastewater pressurizing pre-heater so as to acquire high-temperature high-pressure brine wastewater; the high-temperature high-pressure brine wastewater is uniformly distributed by the water distributing device and then the pressure is reduced and a layer of uniform water film is formed on the falling film flash evaporator; and the water film is in direct contact with the low-temperature smoke in the flue and is evaporated, so that the brine wastewater can be concentrated. According to the invention, the low-grade waste heat energy is utilized to realize the evaporation and concentration of the brine wastewater, so that the wastewater treatment cost is lowered. A new method is supplied for performing low-cost treatment of the brine wastewater.

Owner:SHANDONG UNIV +1

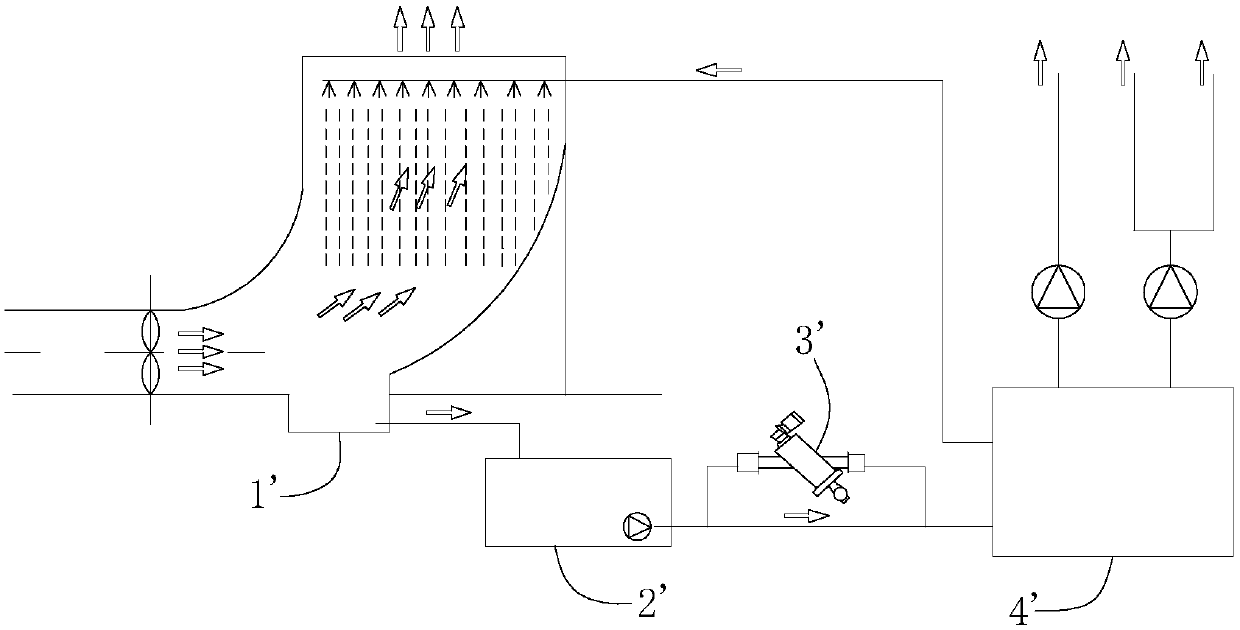

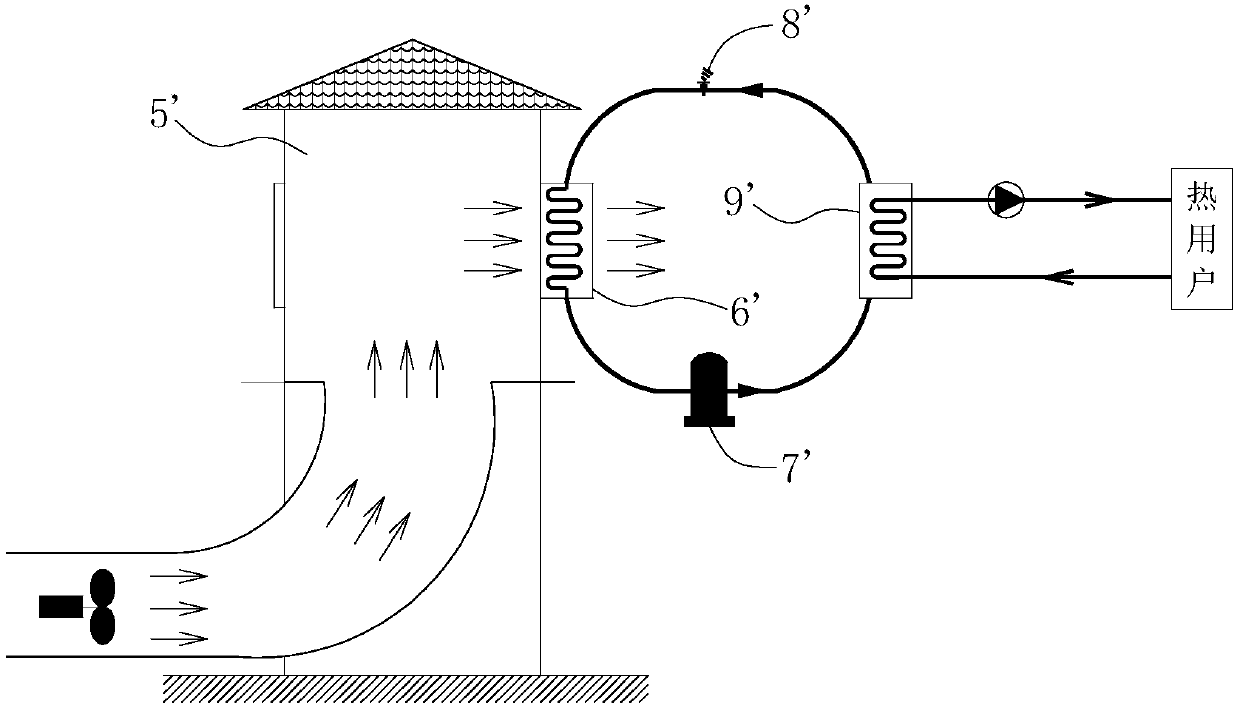

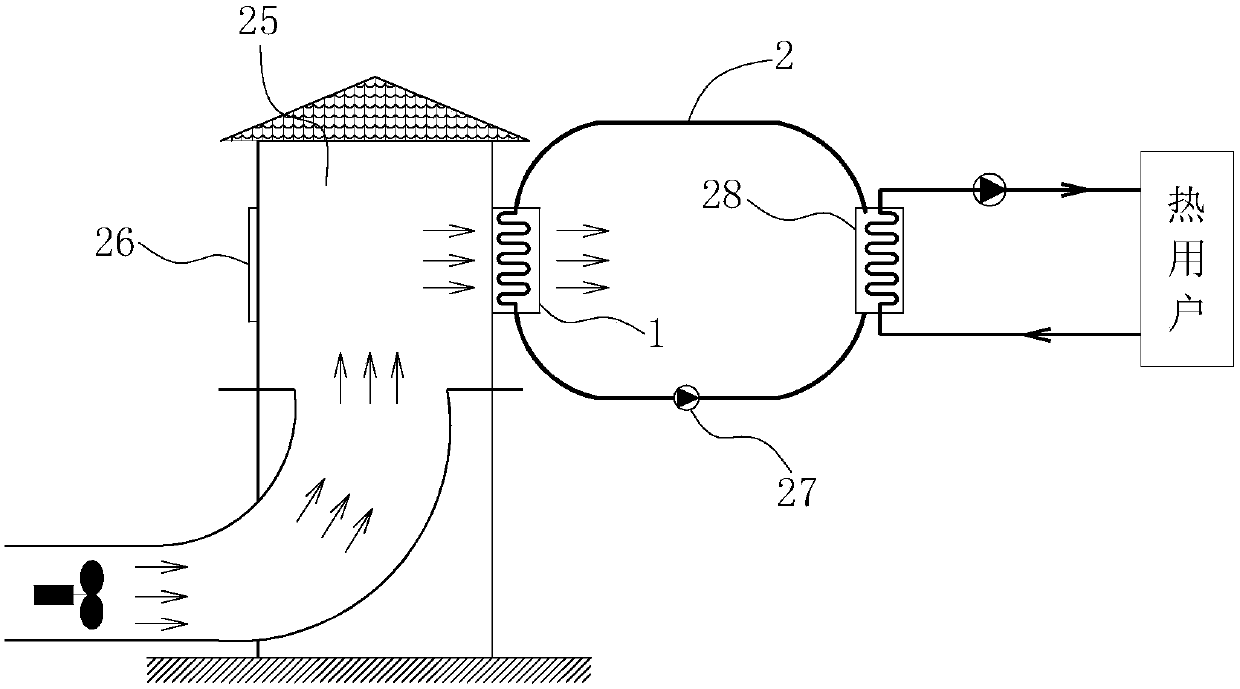

Direct-cooling deep-enthalpy heat-extracting coal mine gas heat pump system

PendingCN107940805ALittle impact on lifespanRelative location flexibilityMechanical apparatusHeat pumpsCoalSolution flow

The invention discloses a direct-cooling deep-enthalpy heat-extracting coal mine gas heat pump system. The direct-cooling deep-enthalpy heat-extracting coal mine gas heat pump system comprises a coalmine gas heat extracting chamber. At least one coal mine gas heat extracting box is arranged on the coal mine gas heat extracting chamber and communicates with an evaporator of a heat pump unit. An anti-freezing solution flows through an anti-freezing solution pipeline. A circulating pump is installed on the anti-freezing solution pipeline. The anti-freezing solution absorbs heat in coal mine gaswhile flowing through the coal mine gas heat extracting box and transmits the heat absorbed from the coal mine gas to a refrigerant in the heat pump unit while flowing through the evaporator. A condenser in the heat pump unit is used for heat exchange with hot water for users. The direct-cooling deep-enthalpy heat-extracting coal mine gas heat pump system is simple in structure and high in coal mine gas waste heat recovery efficiency.

Owner:BEIJING ZHONGKUANG BONENG ENERGY SAVING SCI &TECH

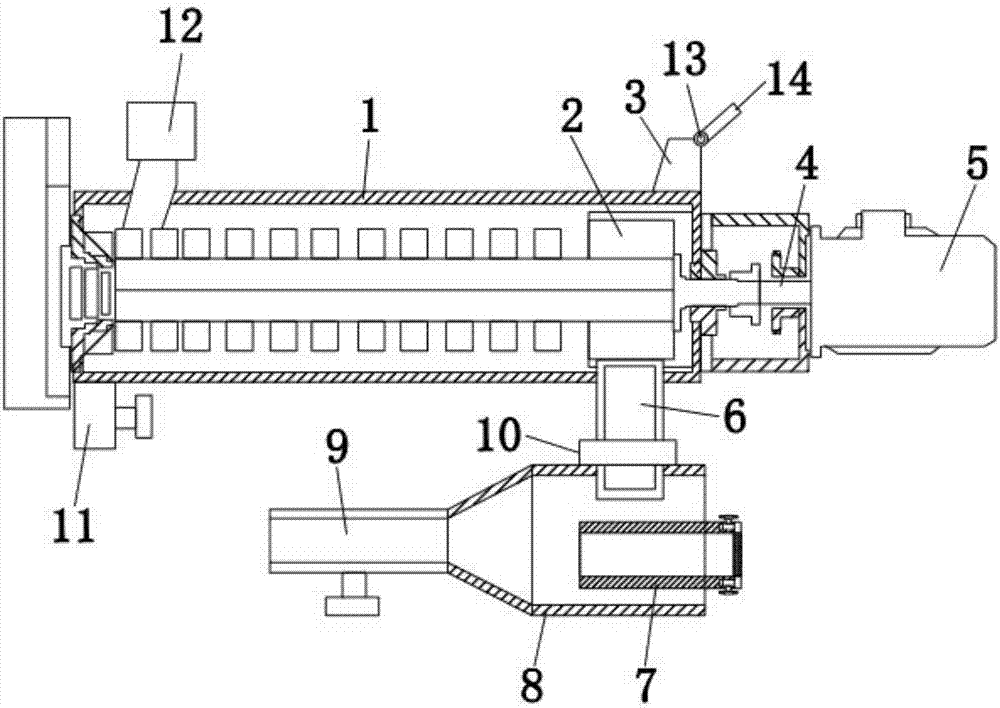

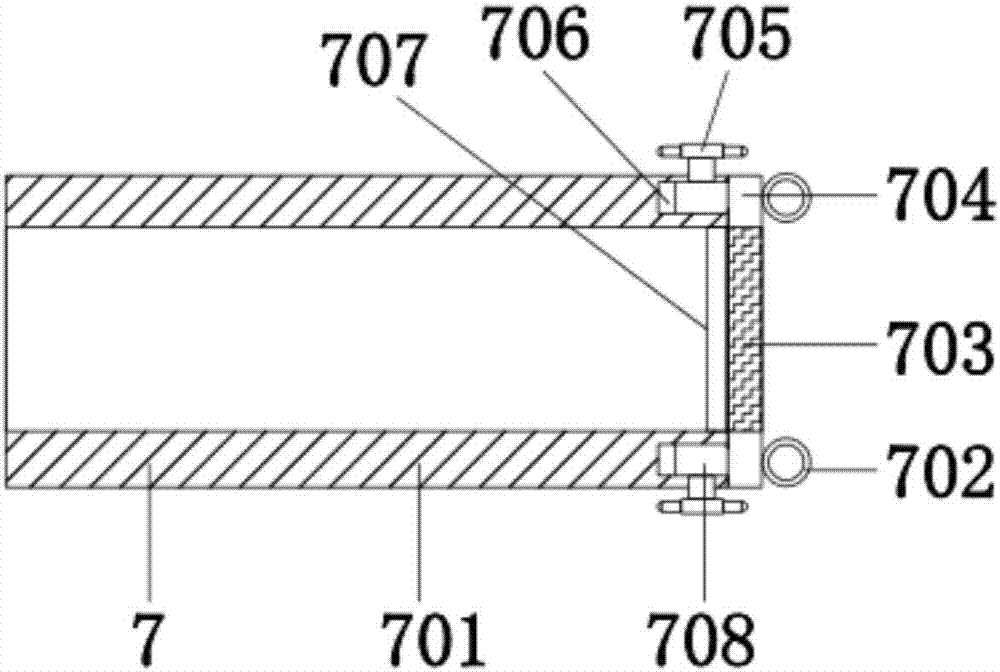

Pollution soil steam treatment method and apparatus

InactiveCN1448046ANo clogging problemExtend the desorption timeContaminated soil reclamationSteam soil sterilisationCooling towerPollution soil

The present invention relates to steam treatment method and apparatus for pollutant soil. The apparatus consists of container, pump, flow rate valve, high pressure reactor, throttle, low pressure reactor, vortex separator, condensator, liquid-liquid separator, cooling tower, return flow valve and other parts. The slurry from the container and containing cycloarene and other pollutants is pumpedinto the high pressure reactor for heating, desorbed to make cycloarene and other pollutants into steam and separated in the separator. While the clean soil is exhausted, cycloarene and other pollutants and steam are condensed, liquid-liquid separated and exhausted.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

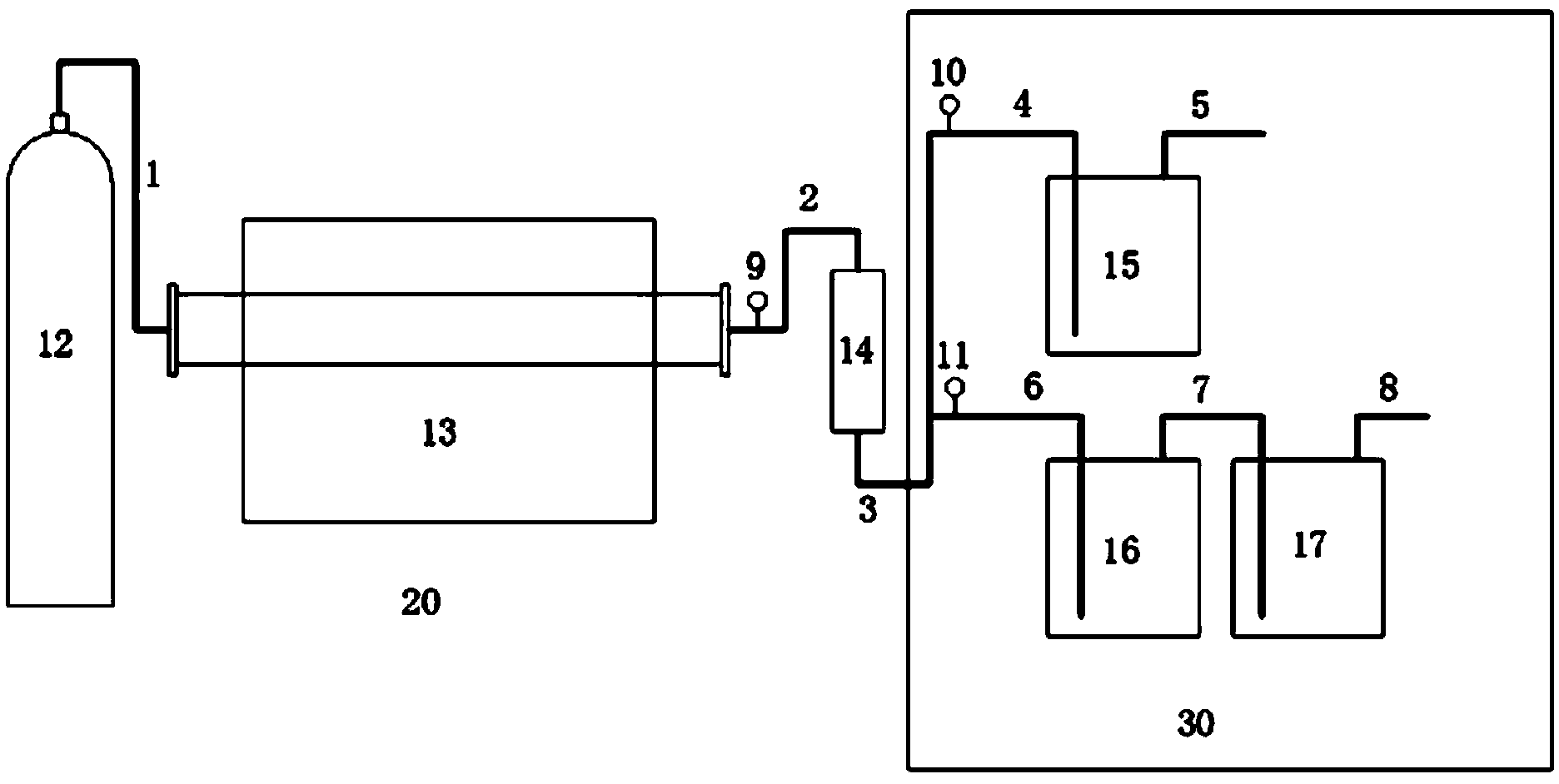

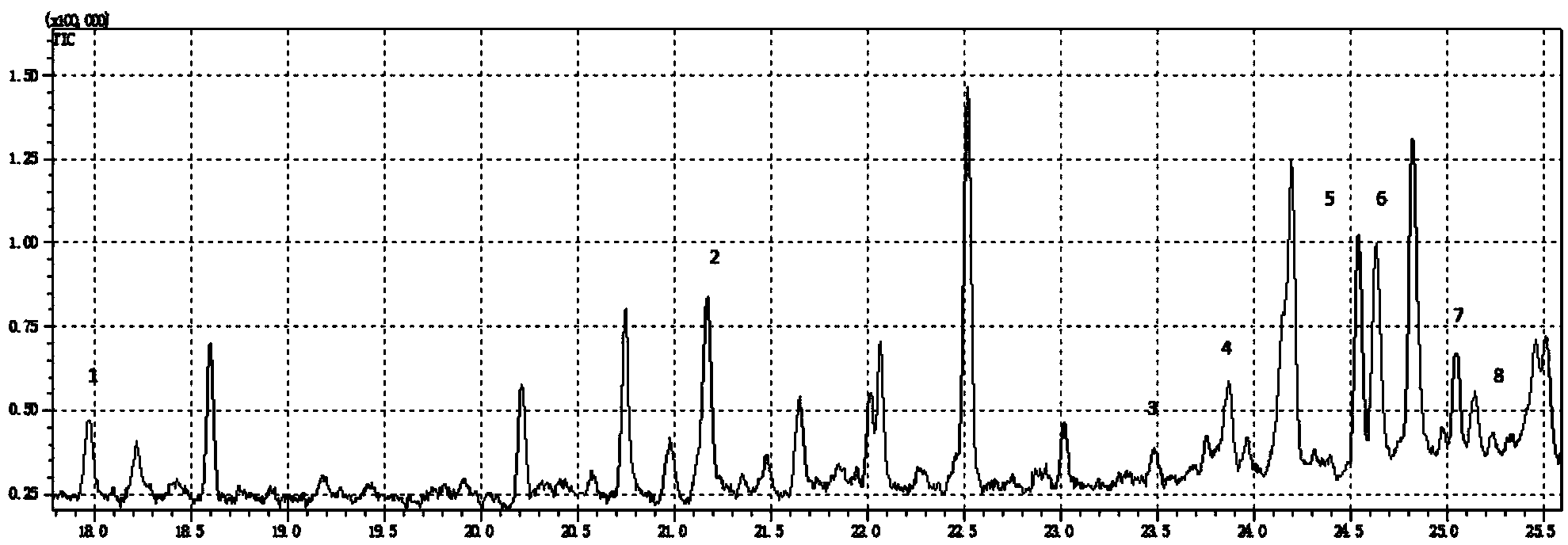

Method for collecting gas-state organic pollutants and implementation device thereof

InactiveCN103868763AEasy to separateEfficient and accurate determinationWithdrawing sample devicesSolid massFlue gas

The invention belongs to the technical field of resources and environments and relates to a method for separating and collecting gas-state organic pollutants and an implementation device thereof. The method comprises the following steps: (1) heating materials in a heating device, and preserving the temperature, wherein in the heating process, carrier gas is introduced, the gas-state organic pollutants released by the heated materials escape along with the carrier gas, are collected through a pipeline and are output to a condenser pipe for condensation, the condensed gas-state organic pollutant flue gas is divided into two paths which are respectively introduced into a first absorption system and a second absorption system, and characteristic gas-state organic pollutants are separated from the flue gas; and (2) enriching and separating the collected absorption liquid of the gas-state pollutant, and detecting the liquid in a detection system. The method can serve as an operating method for researching a release rule of the gas-state organic pollutants in the process of heating multiple materials such as sludge, tobaccos and industrial production solid wastes.

Owner:TONGJI UNIV

Centrifugal dehydrator for high-purity strontium hydroxide

InactiveCN107990640AReduce stressIncrease air volumeDispersed particle filtrationDrying solid materials without heatAir volumeSprocket

The invention discloses a centrifugal dehydrator for high-purity strontium hydroxide. The centrifugal dehydrator comprises a centrifugal dehydrator body, a transmission chain wheel, a motor, a drainage pipe and a feeding pipeline, wherein the left side of the motor is provided with the transmission chain wheel, the left side of the transmission chain wheel is provided with the centrifugal dehydrator body, and the left side of the top end of the centrifugal dehydrator body is provided with the feeding pipeline. According to the centrifugal dehydrator for the high-purity strontium hydroxide, during working, hot air is injected through an air inlet pipeline so that the pressure can be eliminated, and the air volume can be increased; in the process of rotating of the centrifugal dehydrator body, materials are conveyed into a centrifugal drying pipe through a first pipeline and an output pipeline, water vapor can be discharged through an gas discharge pipe, the materials can be discharged out through a discharging pipeline; spin-dry is carried out with strong air in the dewatering process, so that the problem of blockage of a flow channel is avoided, and emission of the materials is very labor-saving; and therefore the working efficiency is improved, meanwhile, the water vapor in the materials can be removed in time.

Owner:重庆新玉峡精细化工有限公司

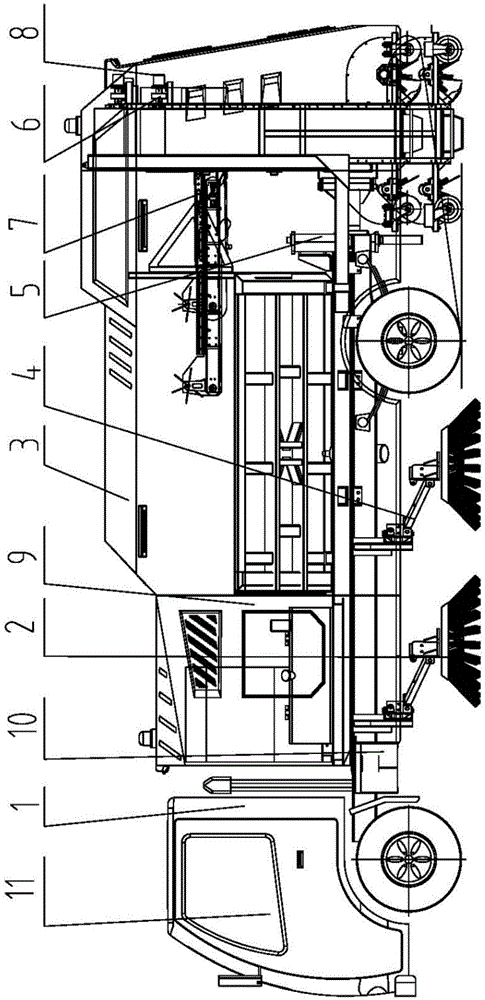

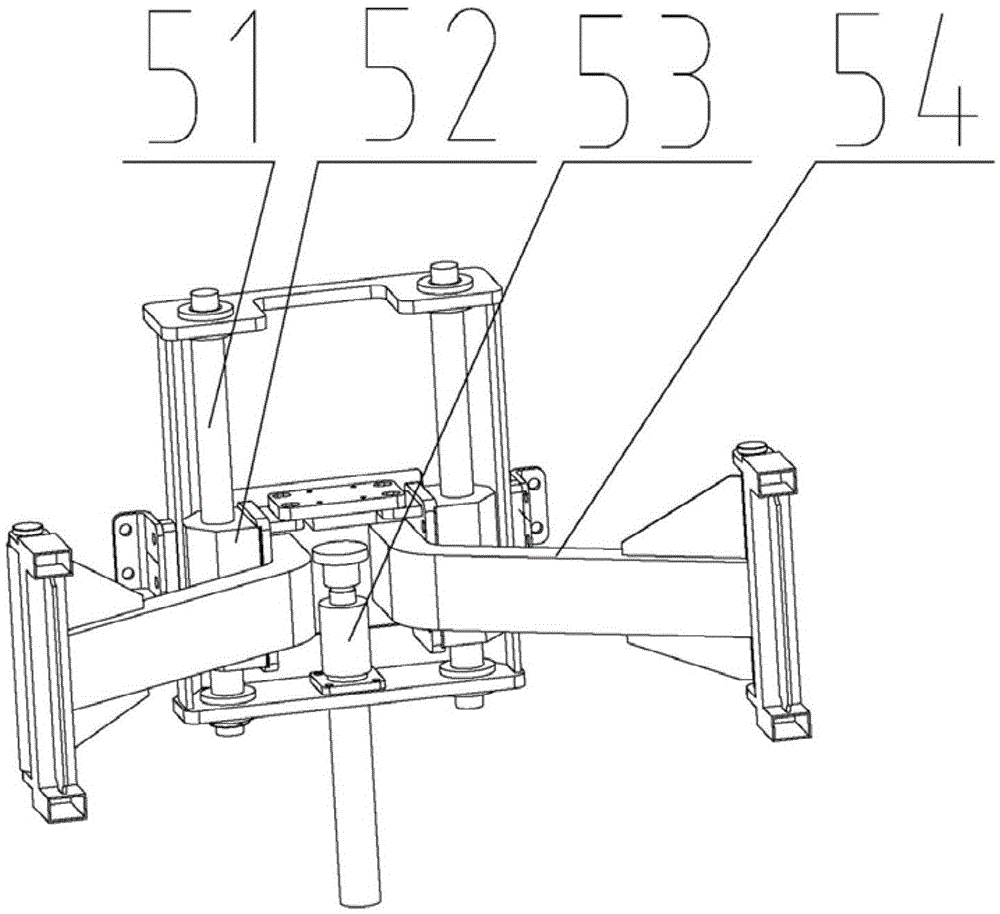

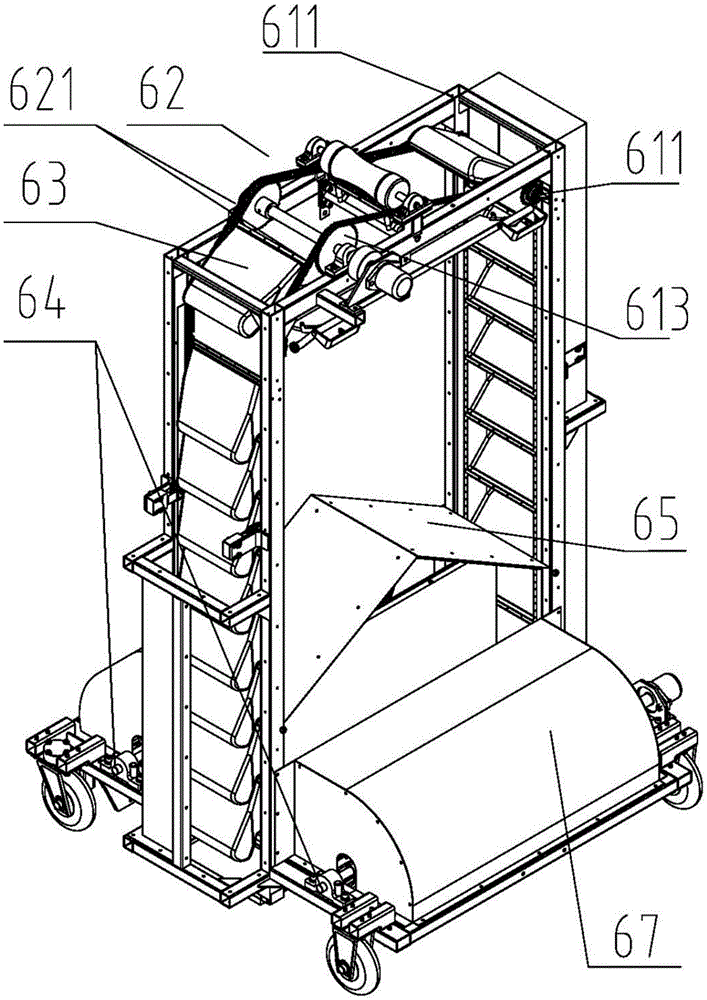

Sweeping mechanism of road sweeping vehicle, road sweeping vehicle and road sweeping method

The invention provides a sweeping mechanism of a road sweeping vehicle, the road sweeping vehicle and a road sweeping method. The sweeping mechanism comprises a base and an annular rail frame arranged on the base and extending in the vertical direction. An annular conveyor belt is arranged on the rail frame. The sweeping mechanism further comprises a drive mechanism and hoppers used for conveying garbage to the high positions from the low positions. The drive mechanism drives the annular conveyor belt to rotate around the horizontal axis. The hoppers fixed to the annular conveyor belt are provided with openings. The openings face the inner surface of the annular conveyor belt all the time, so that when the annular conveyor belt rotates around the horizontal axis, the openings of the hoppers in the low positions face upwards, and the openings of the hoppers operated to the high positions face downwards.

Owner:ZHONGLULIAN TECH CO LTD

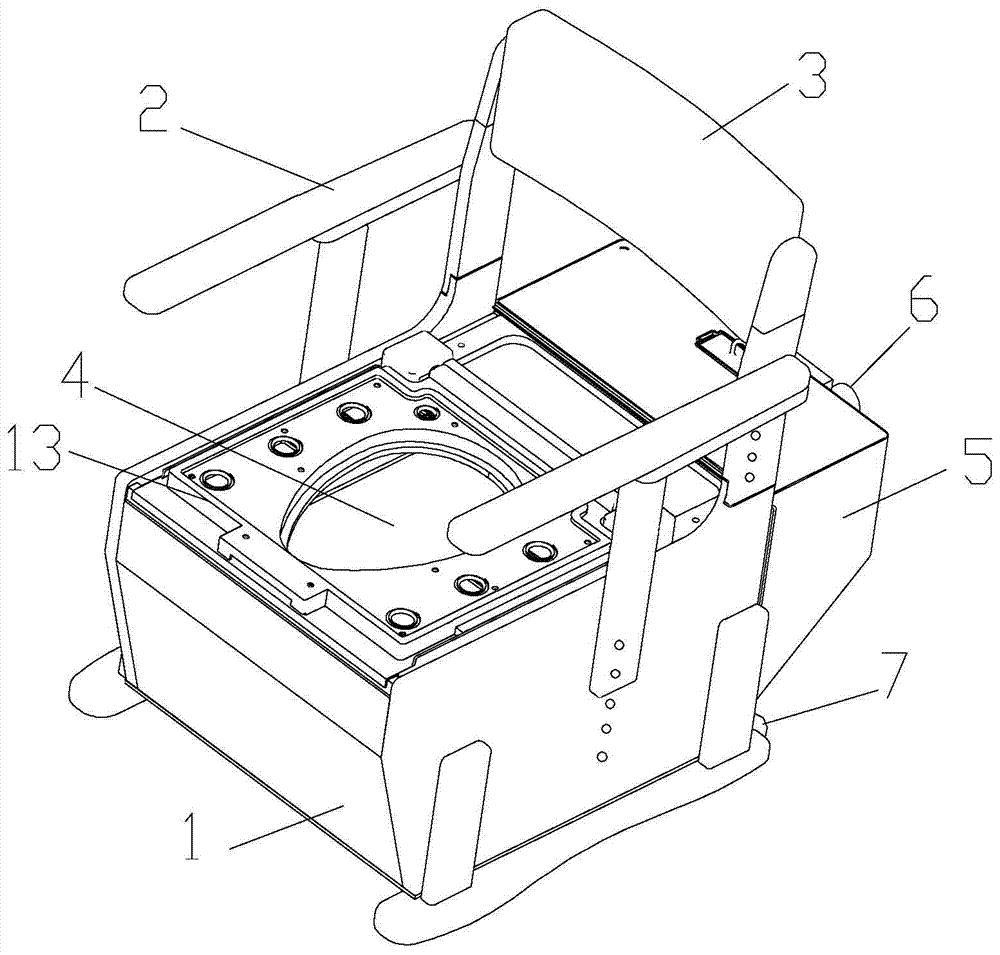

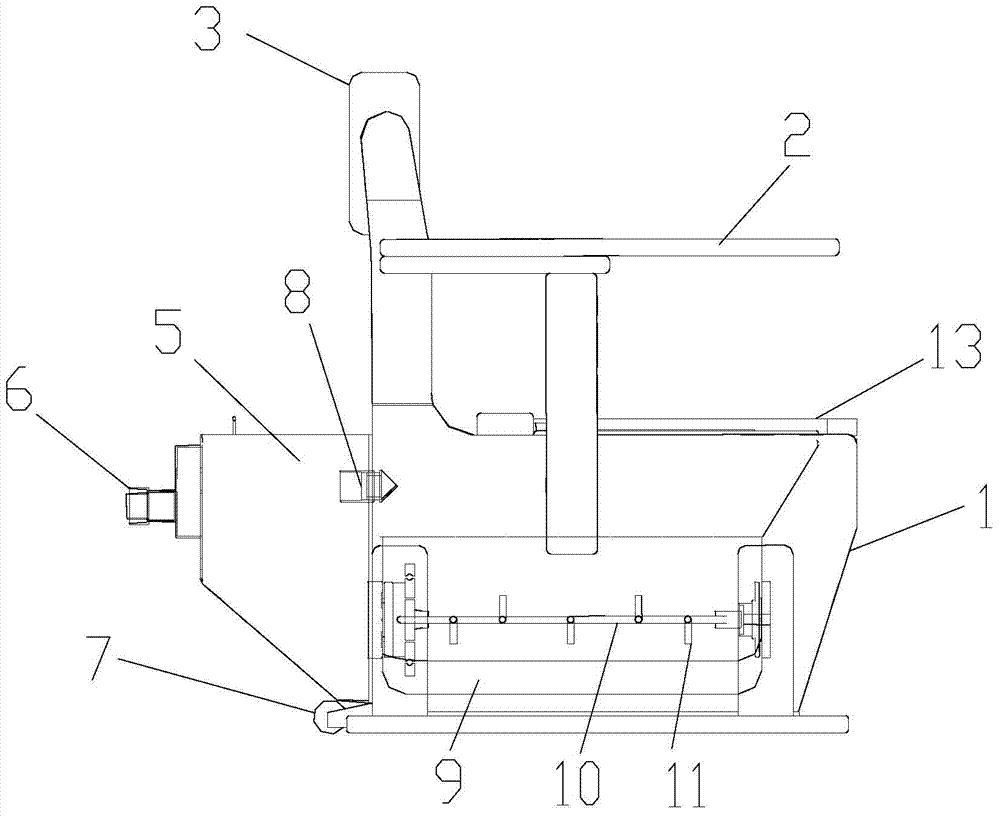

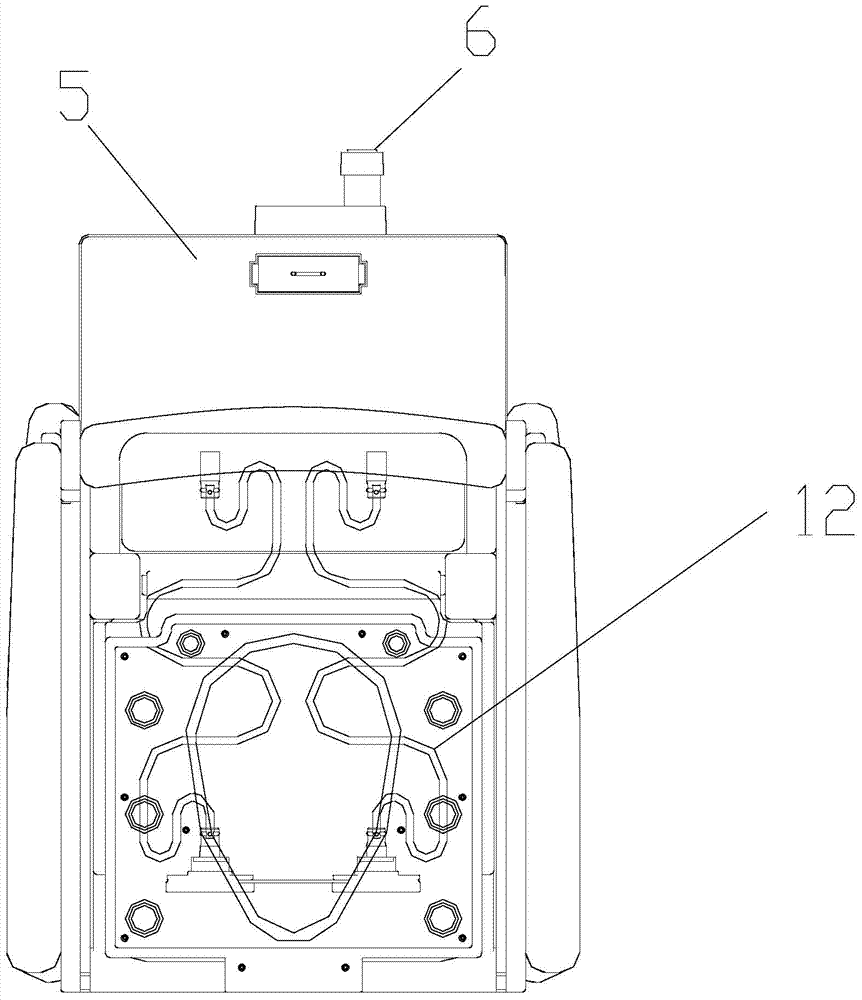

Automatic decomposition toilet

InactiveCN104739307AAutomatic decompositionNo smellBathroom coversAgainst vector-borne diseasesDecompositionWater resources

The invention provides an automatic decomposition toilet. The automatic decomposition toilet comprises a seat portion. The seat portion comprises a base, armrests and a backrest. A treatment chamber is arranged in the base. The upper portion of the treatment chamber is provided with a blocking plate with a toilet opening. The base is provided with a seat lid. A control box is arranged on the rear side of the base. At least one stirring unit is arranged in the treatment chamber and driven by a motor arranged in the control box. The bottom of the treatment chamber is provided with a compartment. A heating unit is arranged in the compartment. The automatic decomposition toilet is provided with an excrement decomposition material in the treatment chamber for automatically decomposing excrement for saving water resources, can be moved freely for facilitating the use of patients the elderly and children who are unable to move freely at any time and is attractive in appearance to be used as an ordinary chair in the room without affecting the appearance of the room.

Owner:DALIAN GOLDEN TRUST PRECISION MOLD ENG

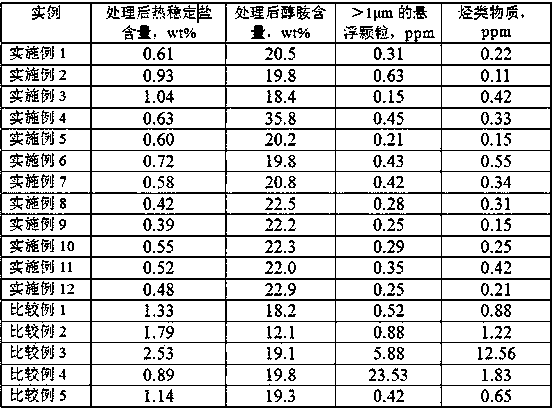

Method for purifying thermally stable salt in desulfurization amine solution

ActiveCN111097224AEasy accessHigh removal rateTreatment involving filtrationWaste water treatment from gaseous effluentsActivated carbonSuspended particles

The invention relates to a method for purifying a thermally stable salt in a desulfurization amine solution. The method comprises the following steps: filtering the desulfurization amine solution to remove solid suspended particles, regenerating the desulfurization amine solution, carrying out activated carbon adsorption, and finally carrying out electric adsorption treatment on an obtained aminesolution, wherein an electrode material for electric adsorption is a metal Zn-loaded activated carbon electrode material. According to the method disclosed by the invention, the removal rate of the thermally stable salt in the desulfurization amine solution is improved by strengthening anion adsorption effect, and efficient purification of the thermally stable salt is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Horizontal rotary multi-disc atomization device

PendingCN111305932ACompact structureSmall footprintExhaust apparatusSilencing apparatusCircular discParticulates

The invention discloses a horizontal rotary multi-disc atomization device. The device comprises a barrel, a rotary shaft arranged in the barrel and a power device, wherein the rotary shaft is transversely arranged, an air inlet and an air outlet are formed in the barrel, and a liquid outlet is formed in the lower end of the barrel; the rotary shaft is a hollow rotary shaft, and the rotary shaft istransversely arranged; and the power device is in rigid connection with the rotating shaft, the rotating shaft is sleeved with a rotating disc device, and the rotating shaft is provided with an opening. The horizontal rotary multi-disc atomization device is compact in structure and small in occupied space, tail gas is purified through a super-gravity device, the gas-liquid mixing capacity is enhanced, mass transfer is enhanced, and the purification capacity is excellent; and the rotating disc type supergravity device is adopted, the tail gas purifying capacity is excellent, PM particles in tail gas are thrown to the inner wall of the device by centrifugal force after absorbing moisture and are discharged from the liquid outlet to be removed after sliding down, the problem of particle blockage does not exist, and mounting, dismounting and cleaning are convenient.

Owner:NANTONG UNIVERSITY

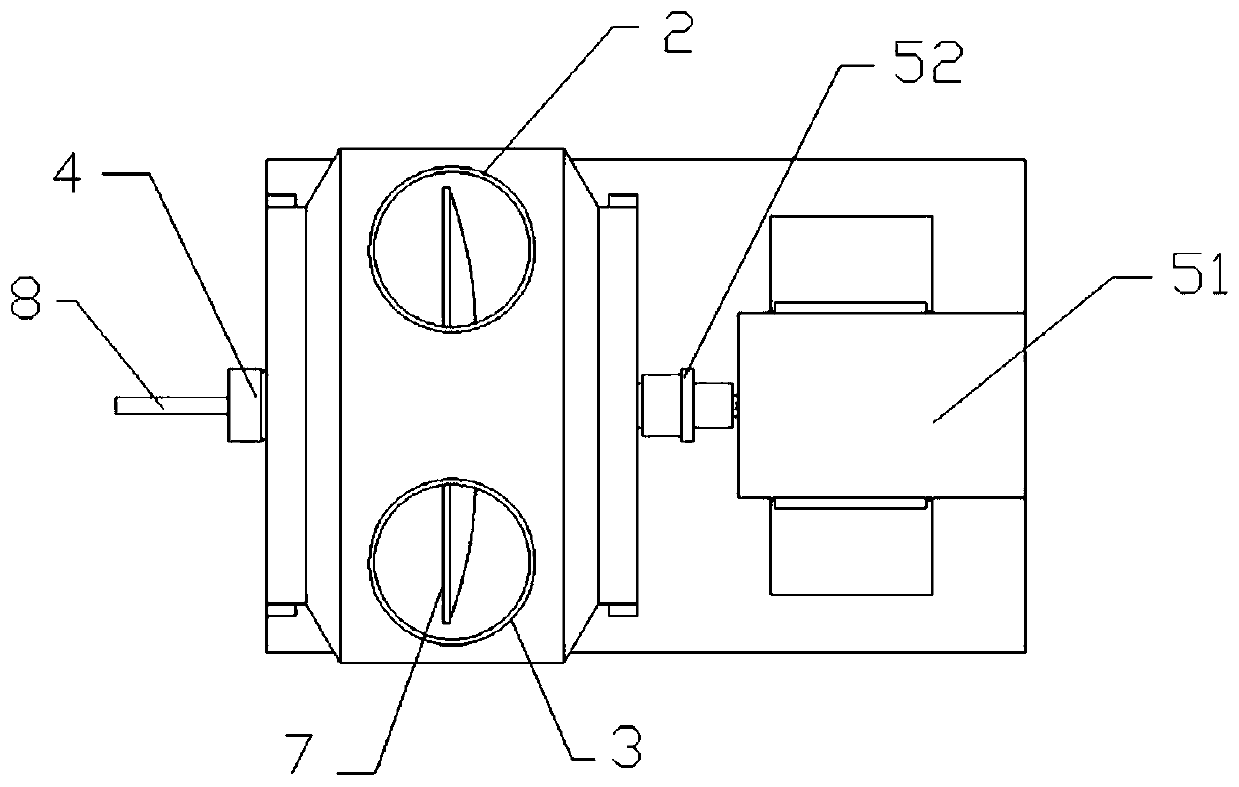

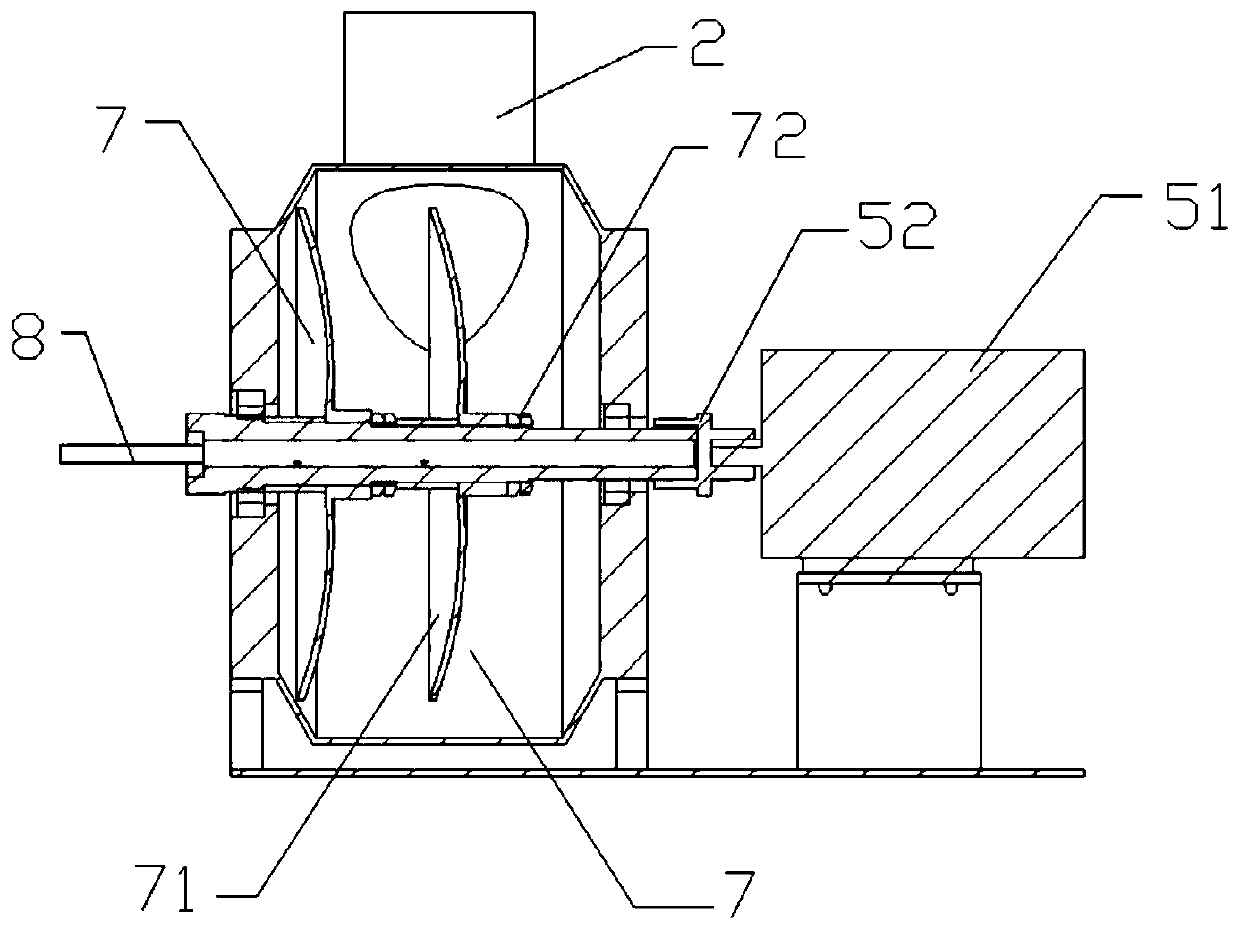

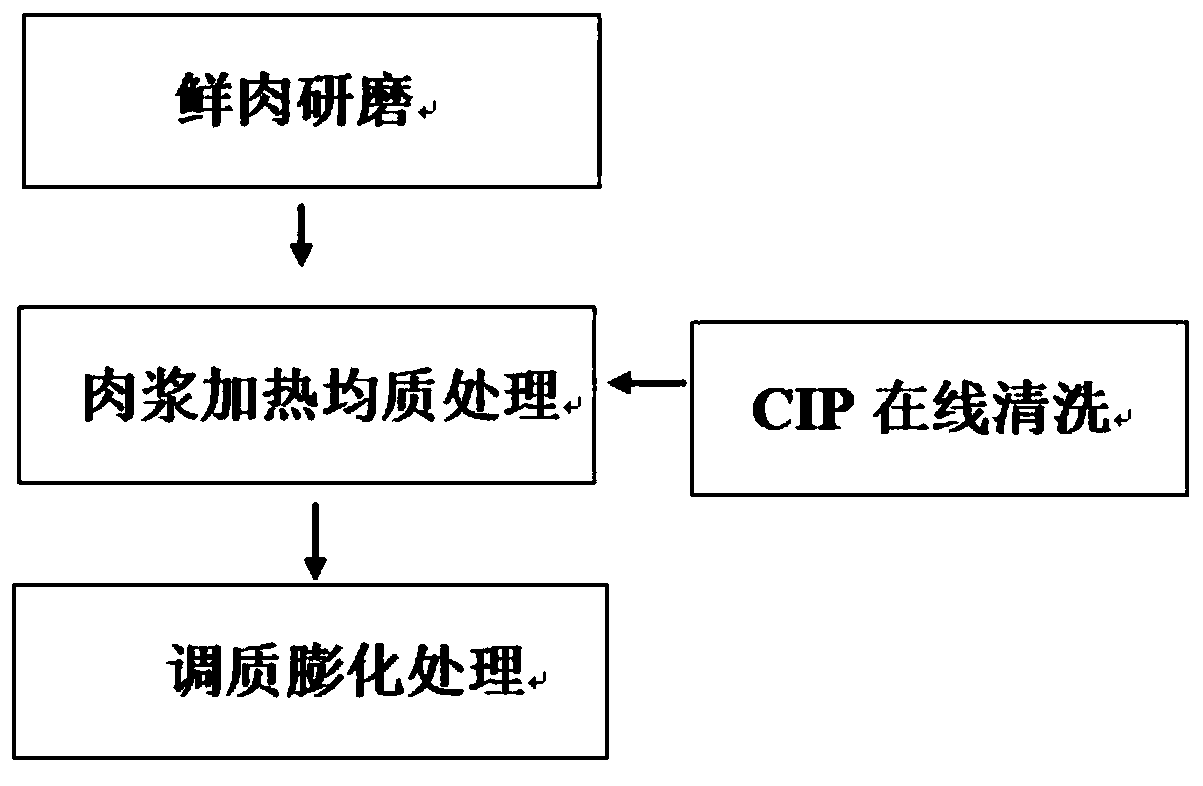

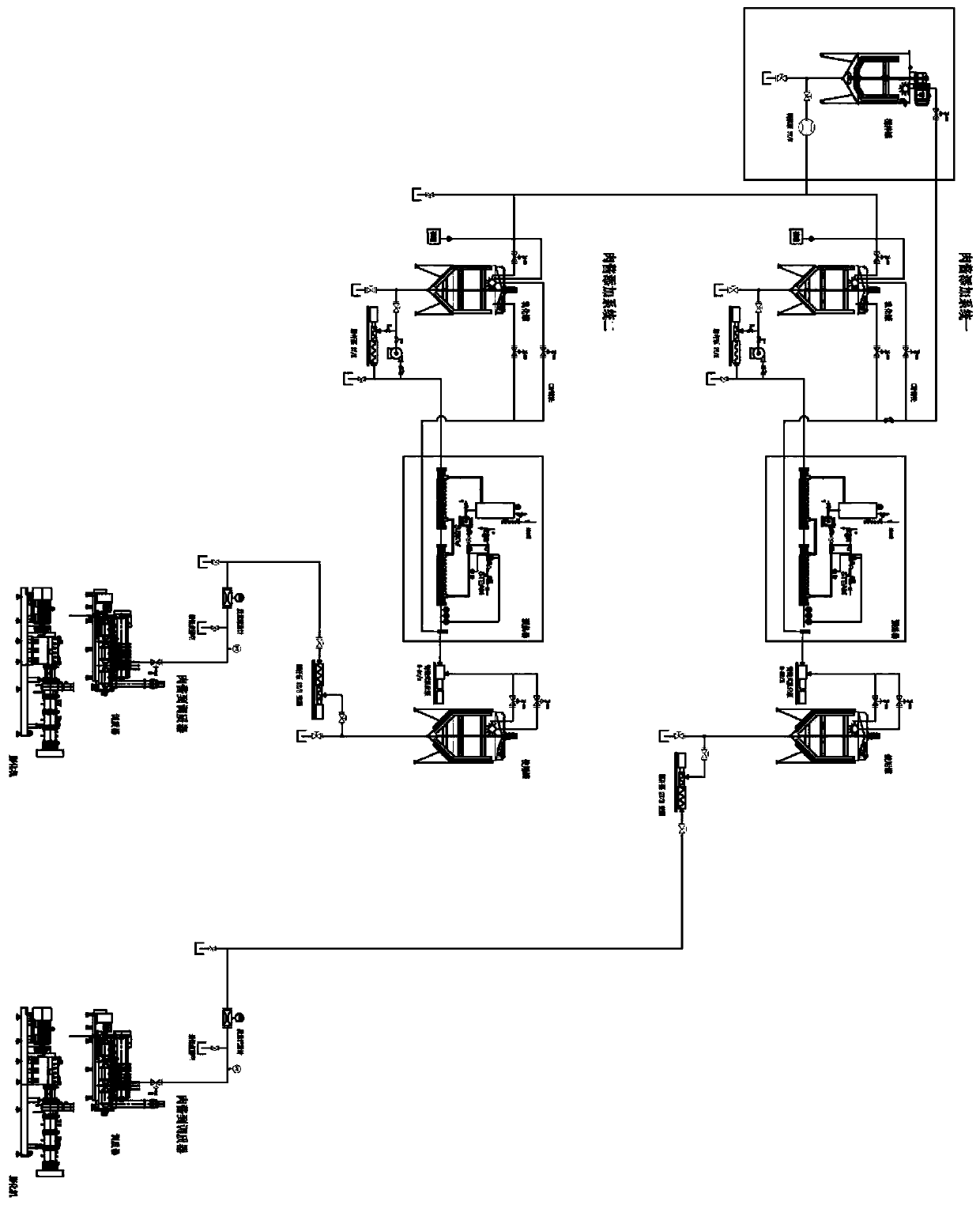

Process for producing pet food by utilizing fresh meat grouting technology

PendingCN111184241AGuaranteed liquidityFast heatingFeeding-stuffMeat processing devicesColloid millProcess engineering

The invention discloses a process for producing pet food by utilizing a fresh meat grouting technology. The process comprises the following steps: S1, grinding fresh meat, controlling unfreezing temperature and combining a slicing machine, a meat grinder and a colloid mill so as to ensure the fineness of meat pulp from the first step; S2, performing heating and homogenization treatment on the fresh meat pulp, performing pipeline-type circulating self-control heating, and generating strong shearing force in high-speed rotation through a pipeline-type emulsifying pump and precise combination ofa rotor and a stator so as to achieve the purpose of homogenizing and emulsifying the meat pulp; S3, cleaning a meat pulp system by using a CIP online cleaning system so as to solve the technical problems that: in traditional technologies, only pure water is adopted for flushing, incomplete cleaning is likely to be caused, bacterial pollution is caused, and products go bad; and S4, enabling the meat pulp to enter a conditioner for conditioning treatment, and then enabling the meat pulp to enter a double-screw bulking machine so as to complete a bulking process. According to the process disclosed by the invention, the loss rate of proteins and vitamins in the meat raw material in multiple processing processes is reduced by utilizing the fresh meat grouting technology, and the natural freshfragrance of meat, fishes and shrimps is reserved.

Owner:蛙牌宠物(湖北)股份有限公司

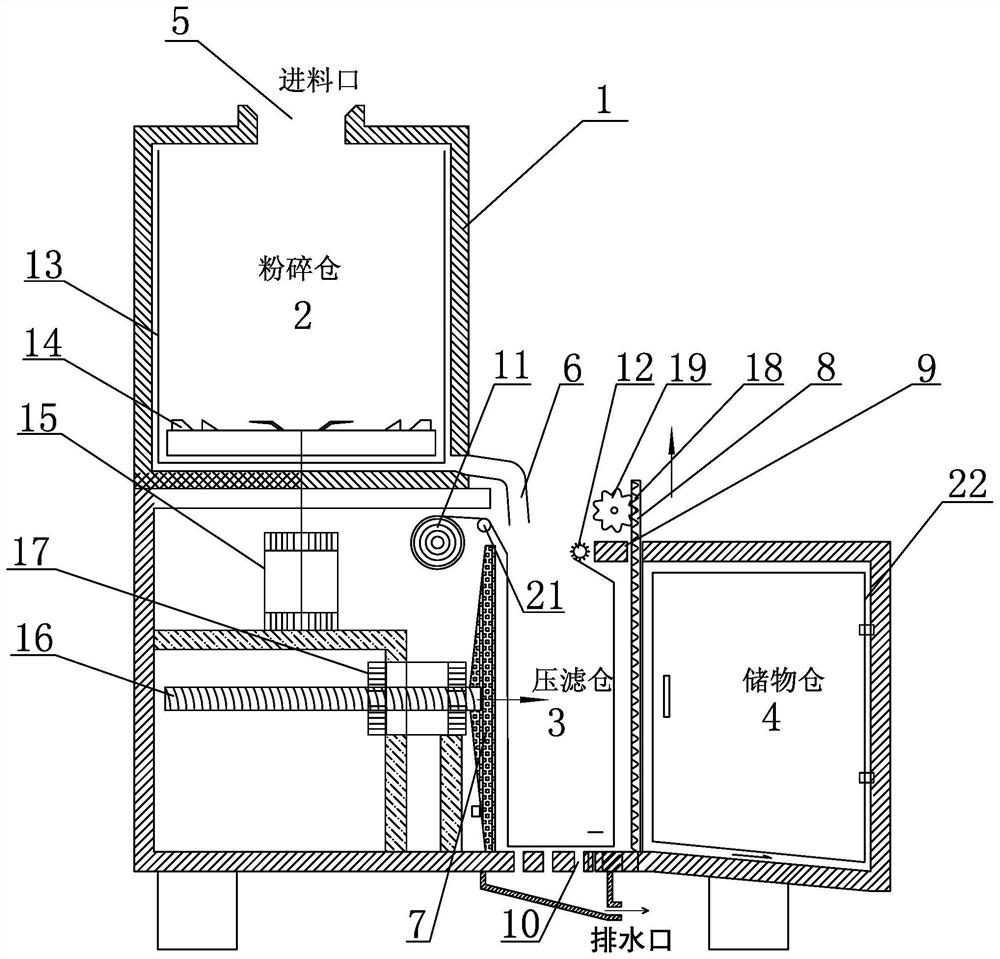

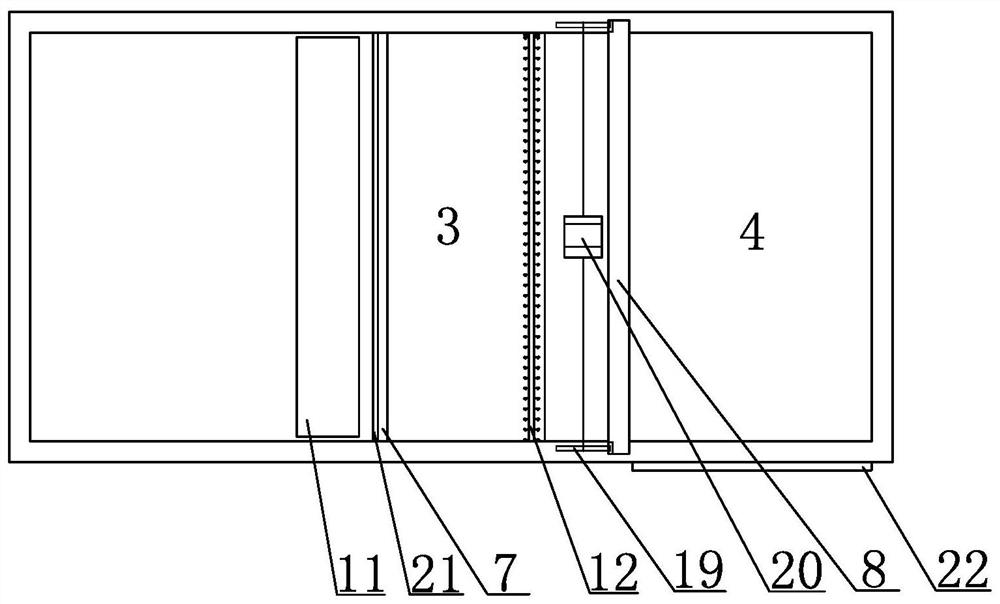

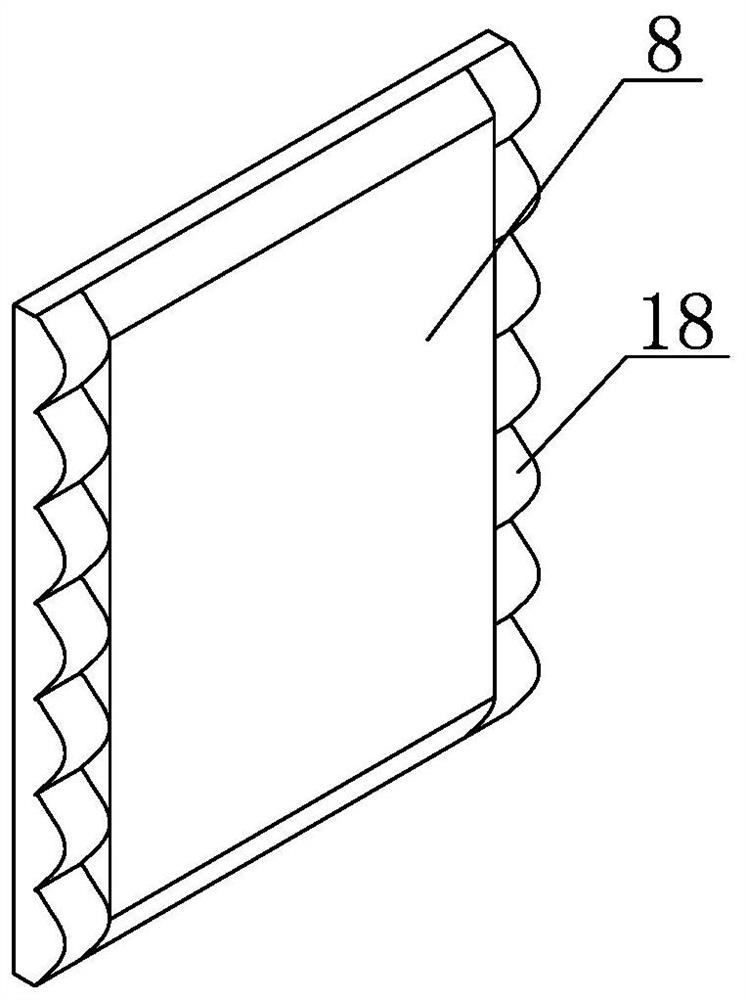

Kitchen garbage crushing and dewatering integrated treatment device and method

ActiveCN112792090ACompact structureImprove the efficiency of press dehydrationSolid waste disposalFiltration separationWater filterProcess engineering

The invention discloses a kitchen garbage crushing and dewatering integrated treatment device and method. The device is characterized in that a crushing bin, a filter pressing bin and a storage bin are arranged on the upper part in a shell, a feeding port is arranged in the top of the crushing bin, and a discharge tube used for feeding garbage to be dewatered into the filter pressing bin is arranged at the bottom of the side wall of the crushing bin; a horizontally movable filter pressing plate is arranged at one side of the filter pressing bin, a longitudinally movable pressure-bearing baffle is arranged at the other side of the filter pressing bin, a filter pressing bin top plate is arranged at the side, close to the pressure-bearing baffle, of the top of the filter pressing bin, water filtering holes are arranged in the bottom of the filter pressing bin, and a filter cloth cylinder is horizontally arranged outside the filter pressing bin and located obliquely above the filter pressing plate; and a barbed roller is horizontally arranged at an opening in the top of the filter pressing bin, the free end of filter cloth on the filter cloth cylinder is fixedly connected to the barbed roller, the pressure-bearing baffle moves upwards, and the filter pressing plate continuously moves horizontally until the dewatered garbage is pushed into the storage bin. According to the device and the method, kitchen garbage crushing, dewatering and temporary storage are integrally designed, the structure is compact and the filter cloth squeezing dewatering efficiency is high.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com