Spiral-flow type micro-nano bubble generator and generation method thereof

A technology of nano-bubbles and generators, applied in chemical instruments and methods, biological treatment devices, sustainable biological treatment, etc., to achieve the effects of increasing absolute speed, shortening gas path, processing difficulty and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of the structure, change of the proportional relationship or adjustment of the size shall still fall within the scope of the technical content disclosed in the present invention without affecting the effect and the purpose of the present invention. within the scope covered.

[0036] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the...

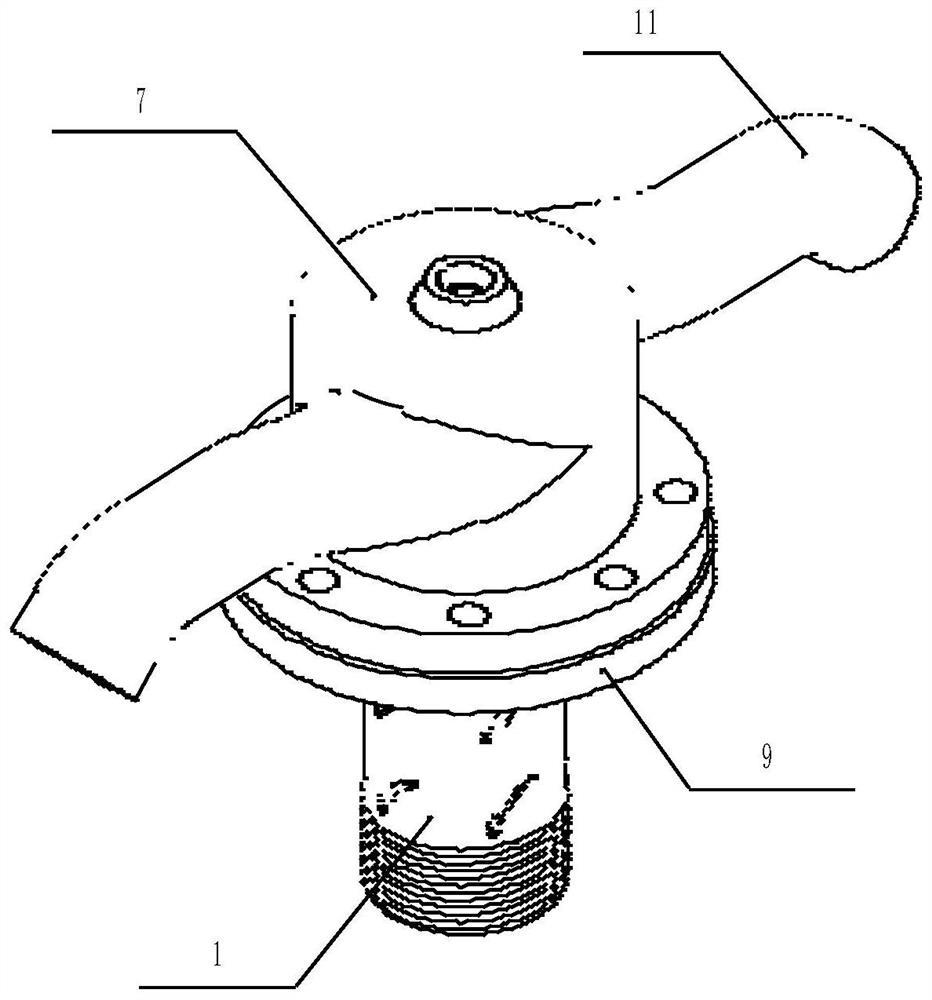

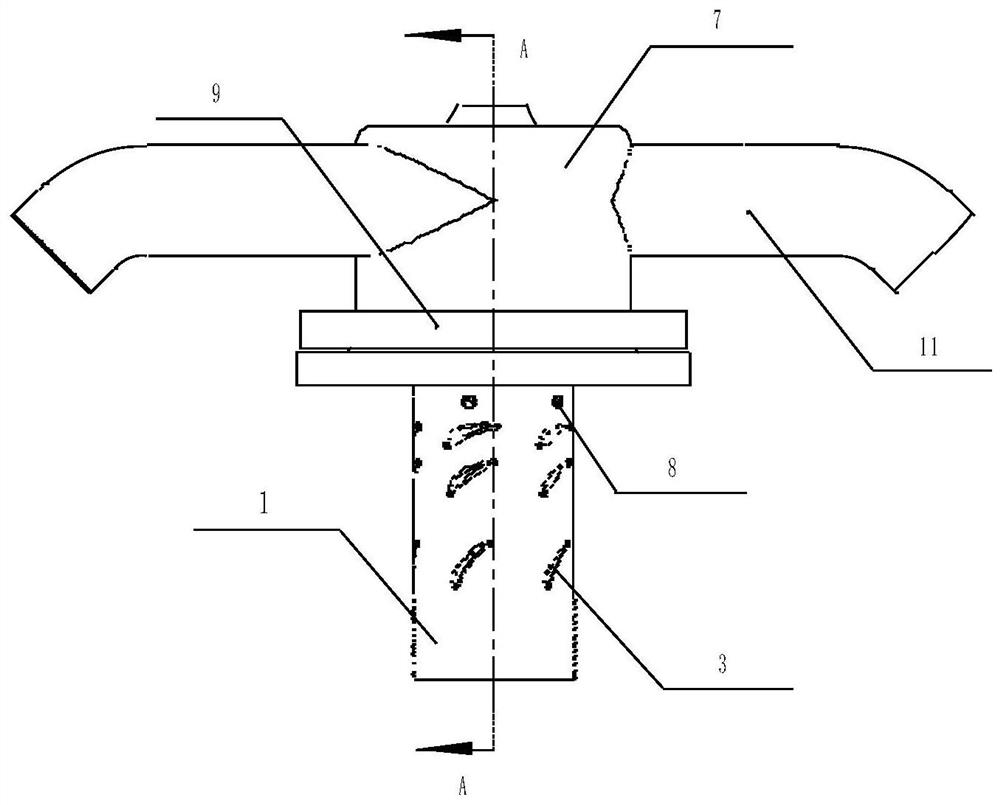

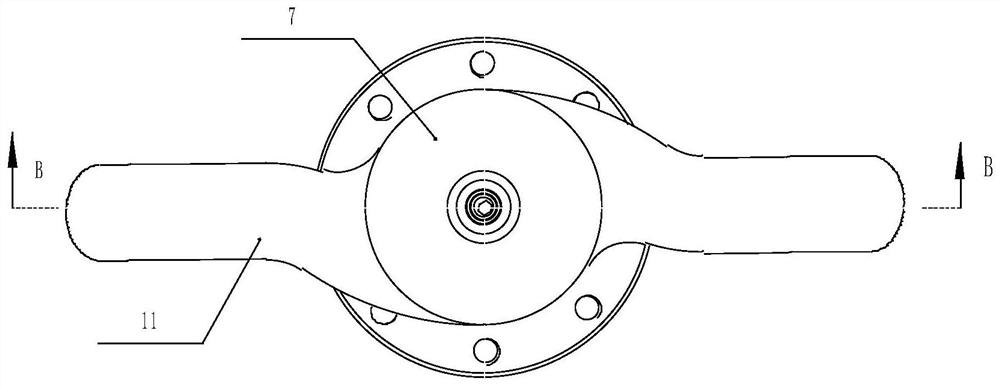

Embodiment 1

[0038] Such as Figure 1 to Figure 7 As shown, it shows a specific embodiment of the present invention. As shown in the figure, a swirl type micro-nano bubble generator disclosed by the present invention includes an outer cylinder 1, a blade shaft 2, a blade 3, a sealing ring 4, Sleeve 5, intake throat pipe 6, volute 7, top wire 8, mounting plate 9, cavitator 10, spinning cylinder 11, positioning pin 12, connecting screw 13 and toothed gasket 14, the volute 7. Two spinning cylinders 11 are evenly distributed along the circumferential direction on the outer wall, and the spinning cylinders 11 are connected to the volute 7. The bottom of the volute 7 is provided with a flange and the center of the volute 7 is provided with a through hole. An annular groove is arranged on the bottom surface of the flange at the bottom of the volute 7 and a sealing ring 4 is installed in the annular groove. The mounting plate 9 is fixed on the flange at the bottom of the volute 7 by screws and the...

Embodiment 2

[0047] A method for generating a swirling micro-nano bubble generator, characterized in that it comprises the following steps:

[0048] Step 1: Fix the swirl-type micro-nano bubble generator on the bearing platform in the sewage tank, and ensure that the outlet of the spinning cylinder 11 is located near the sewage water surface, and the top of the air inlet pipe 6 is located above the sewage water surface;

[0049] Step 2: Connect the outlet of the sewage pump to the bottom of the outer cylinder 1 through a pipeline. The sewage pump pumps sewage through multiple sets of blades 3 between the blade shaft 2 and the outer cylinder 1 to generate rotating water flow, and forms a negative flow after the final blade 3. The air is sucked in by pressure, and the air enters the sleeve 5 through the inlet throat 6, the air in the sleeve 5 enters the cavitator 10 through the air intake slot, and all the air exits through the airfoil-shaped hollow blade on the cavitator 10. The slit is she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com