Patents

Literature

89results about How to "Solve the above problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

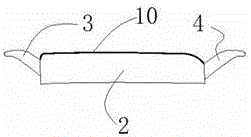

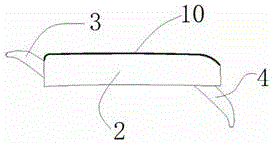

Positive electrode of lithium-sulfur battery with multifunctional elastic protection layer

InactiveCN105322132AThere is no effect on the charging and discharging processImprove stabilityNon-aqueous electrolyte accumulator electrodesCapacity lossLithium–sulfur battery

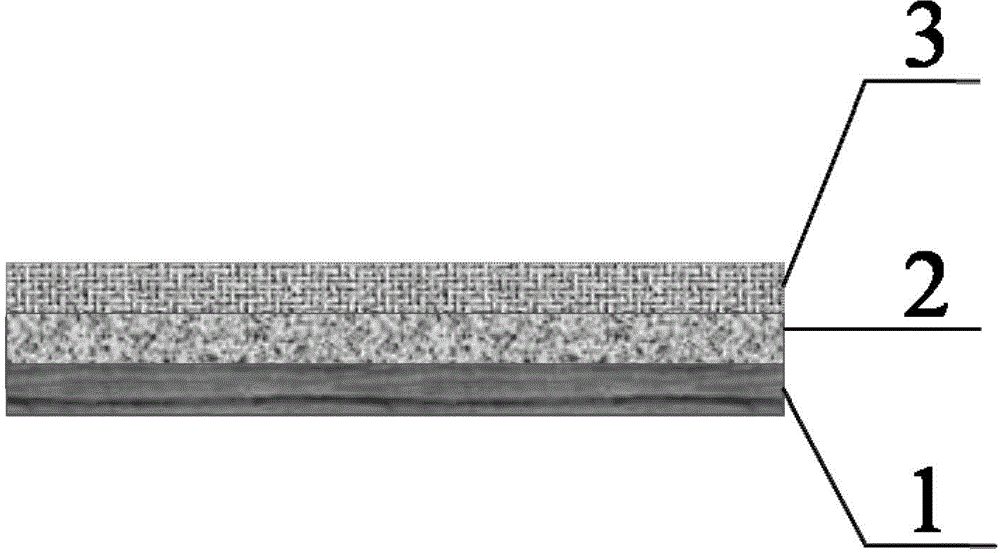

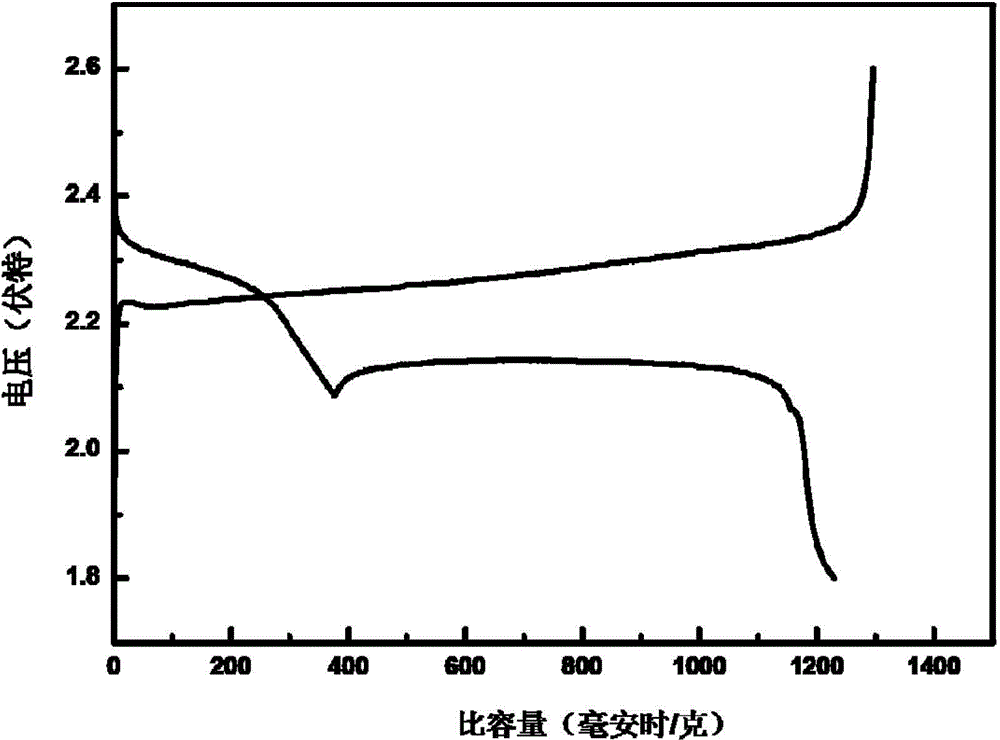

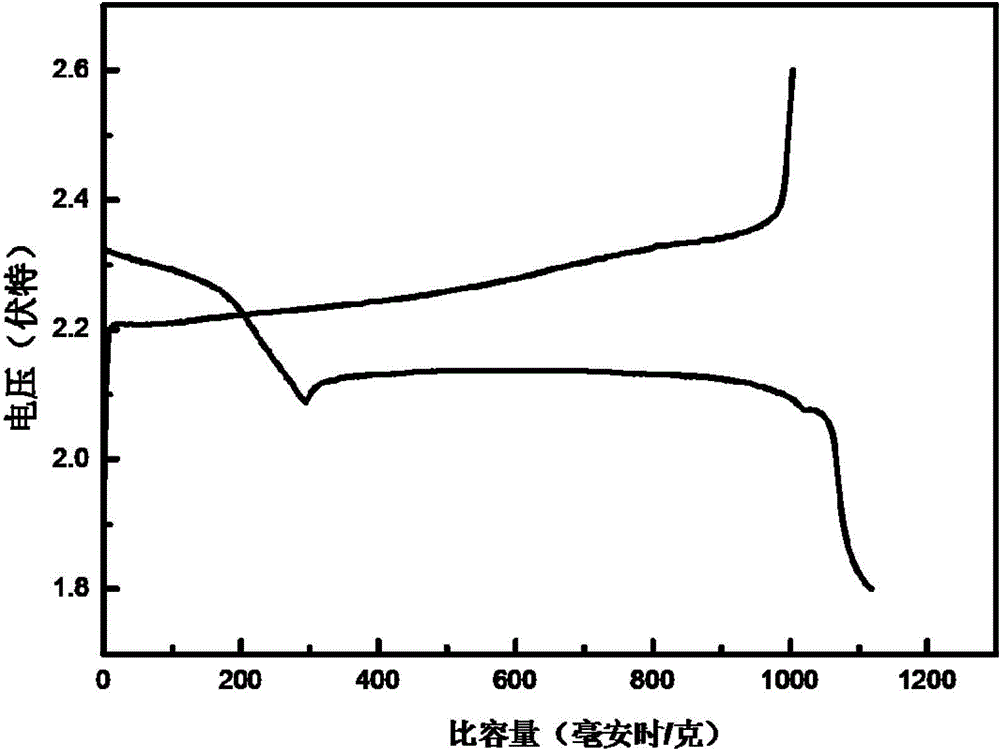

The invention relates to a positive electrode of a lithium-sulfur battery with a multifunctional elastic protection layer. The positive electrode of the lithium-sulfur battery comprises a positive material layer and the multifunctional elastic protection layer, wherein the multifunctional elastic protection layer is formed on the surface of the positive material layer and comprises a polymer and / or a conductive carbon material; and the thickness of the multifunctional elastic protection layer is 0.1-50 microns. The multifunctional elastic protection layer is introduced to the surface of the positive material layer of the lithium-sulfur battery; the multifunctional elastic protection layer has elasticity and conductivity; and has no influence on charge and discharge processes of the positive electrode of the lithium-sulfur battery; compared with the positive electrode of the lithium-sulfur battery without protection from a multifunctional elastic layer structure, the prepared positive electrode of the lithium-sulfur battery with the protection of the multifunctional elastic layer structure has good stability; a structural damage to the positive electrode caused by the volume effect in a charge-discharge cycle process of the battery can be relieved; and meanwhile, the added multifunctional elastic layer structure can ensure that an active material in the positive electrode is not greatly dissolved into an electrolyte to cause the capacity loss.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

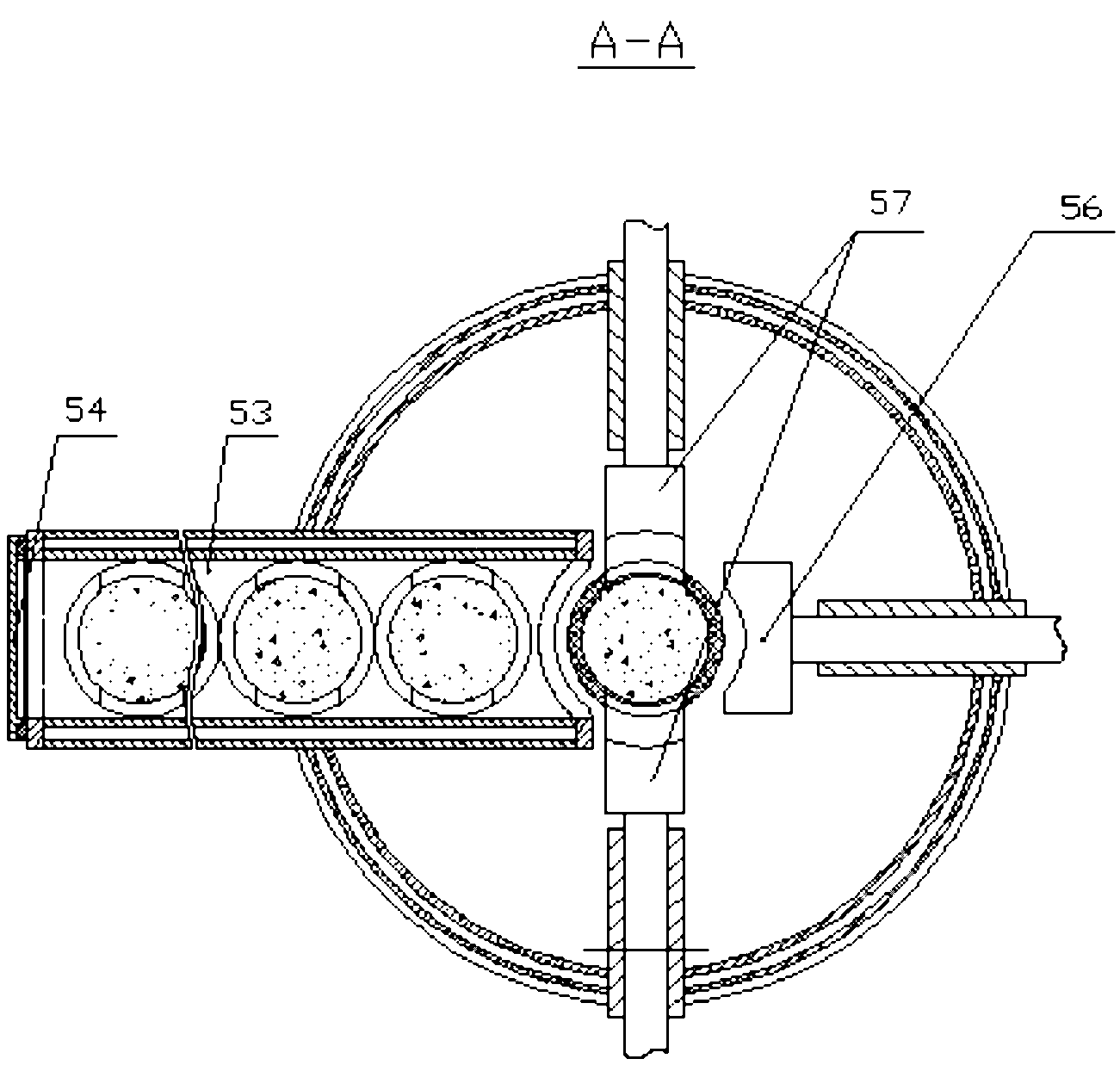

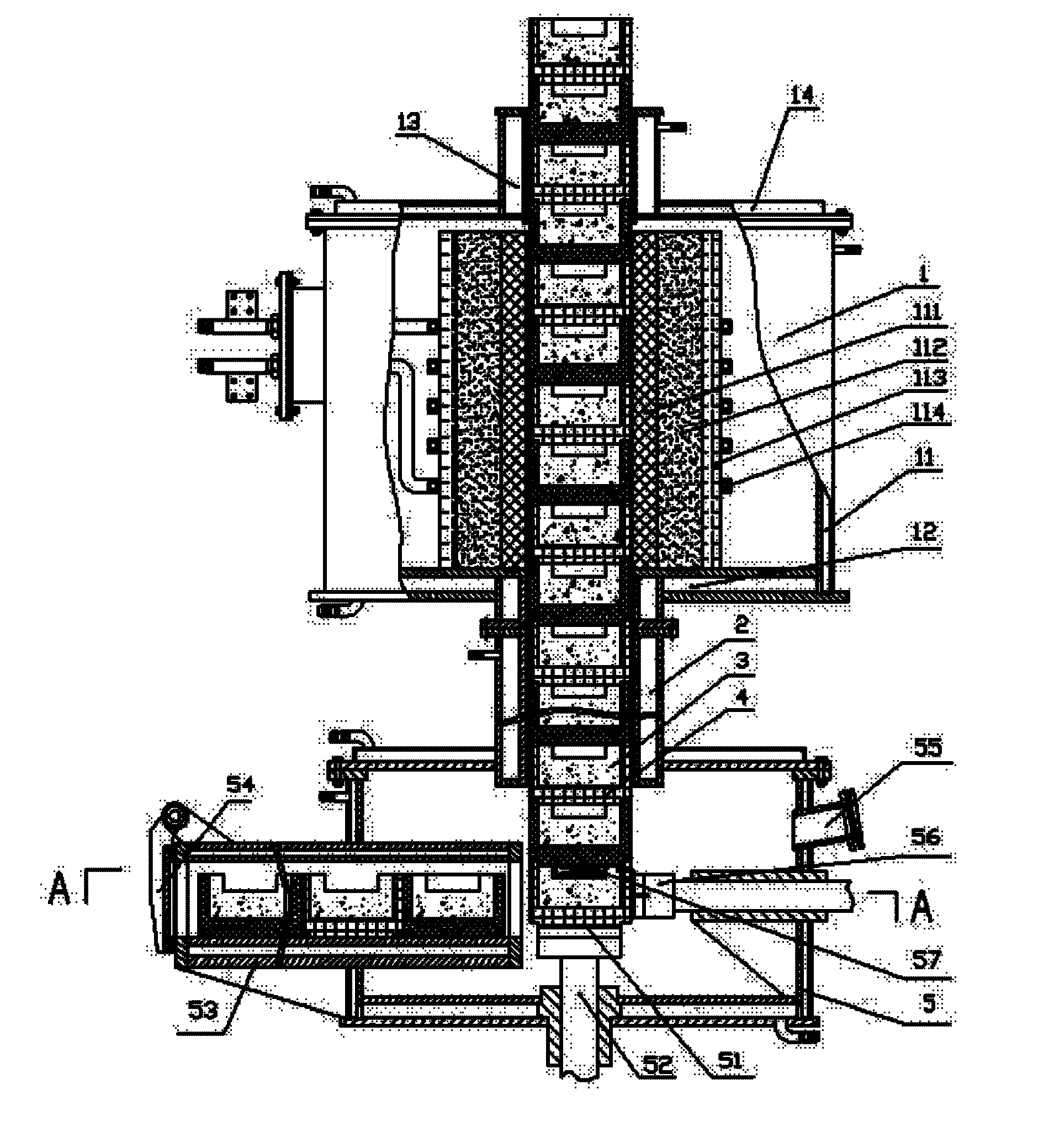

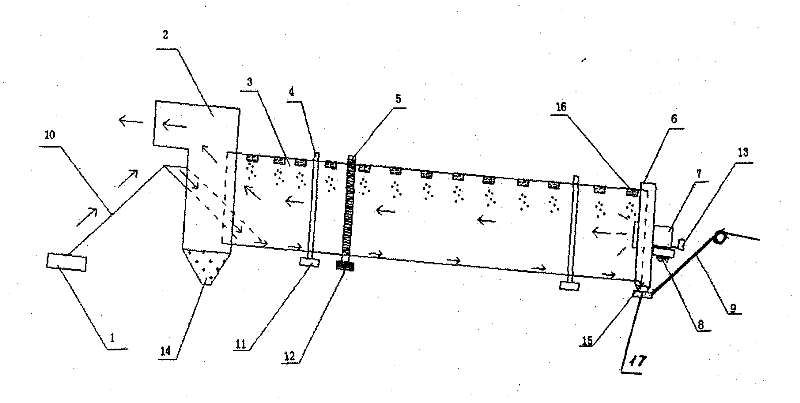

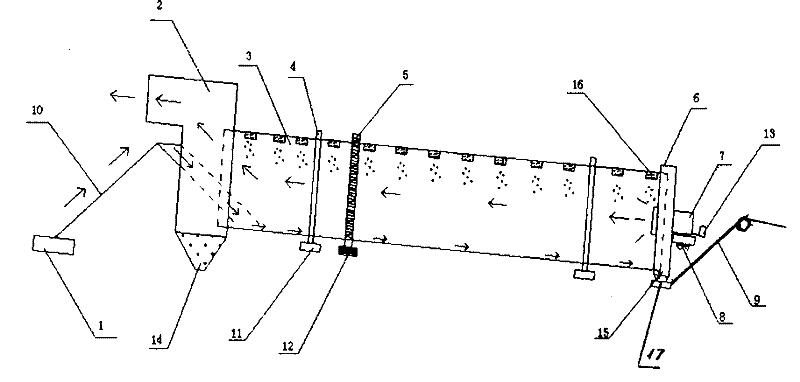

Induction heating ultra-temperature continuous carbonization furnace

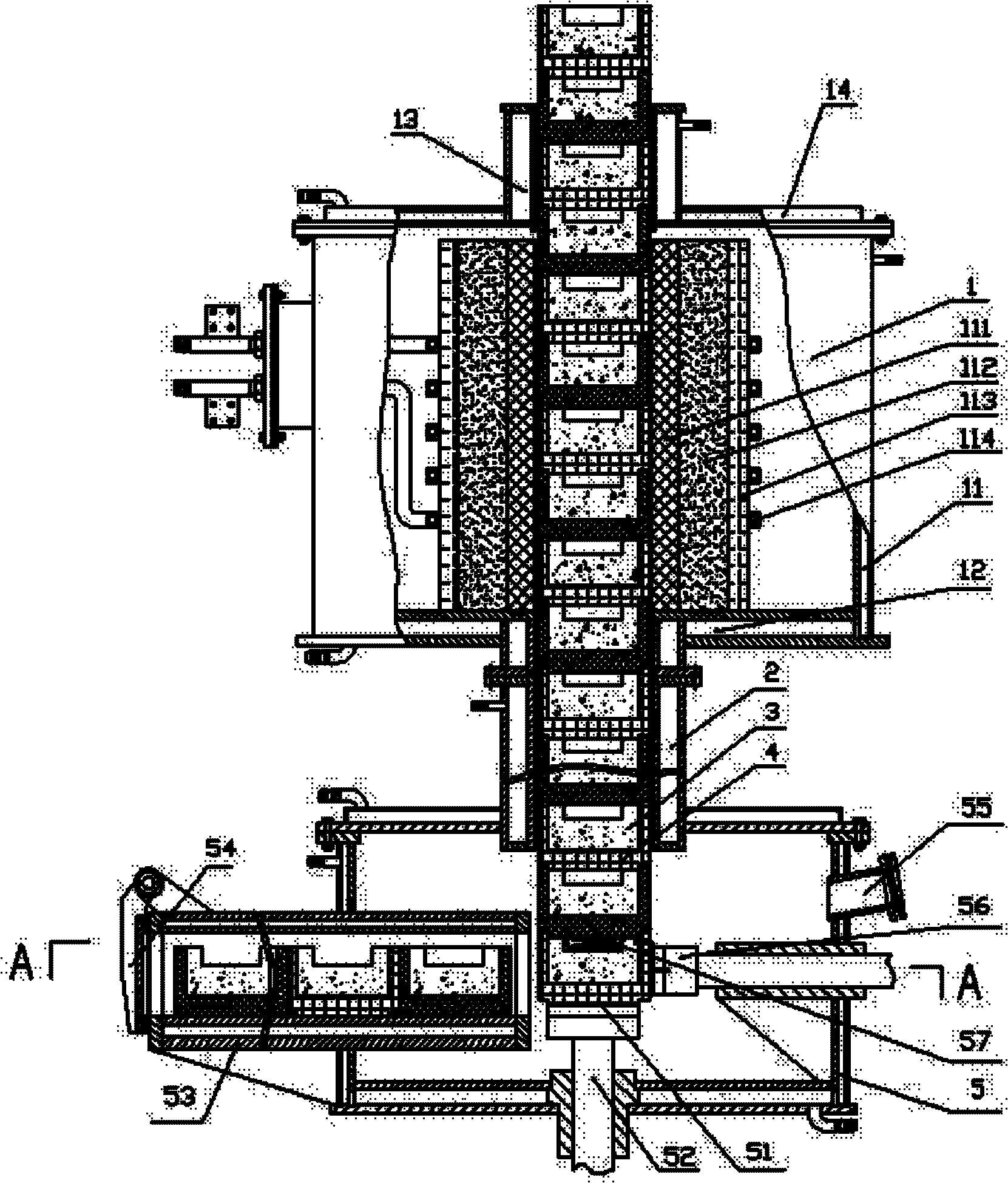

ActiveCN101788227ASolve the above problemsInnovative designFurnace typesCarbonizationVertical channel

The invention relates to an induction heating ultra-temperature continuous carbonization furnace which comprises an upper furnace body, a middle water-cooling connecting sleeve and a lower furnace body to from a vertical channel and a horizontal channel, wherein the upper furnace body and the lower furnace body are communicated through the middle water-cooling connecting sleeve, the upper furnace body is mainly used for heating and the like, the middle water-cooling connecting sleeve is a cooling region part of the vertical channel; the lower furnace body is mainly used for cooling, discharging and the like; boats loaded with materials are sequentially overlapped and stepped to enter the vertical channel of the furnace body, and the boats loaded with carbonized materials are pushed into the horizontal channel through a manipulator and are stepped into and discharged out of the furnace body. Vertical heating, continuous carbonization, horizontal cooling and discharging are adopted, a high-temperature hearth needs not to support the weight of the boats and the materials; and the invention has high cooling speed, high yield and good product quality, and can better solve the problems of a horizontal continuous furnace and a vertical intermittent furnace.

Owner:湖南弗拉德连续高温科技有限公司

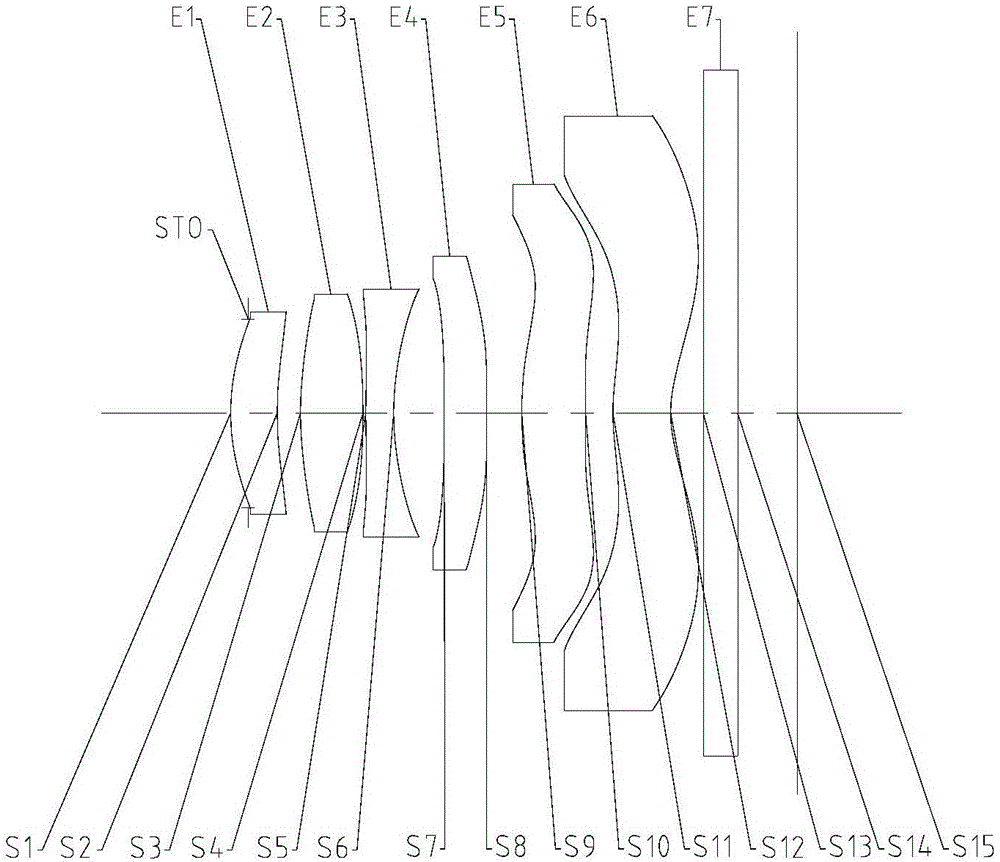

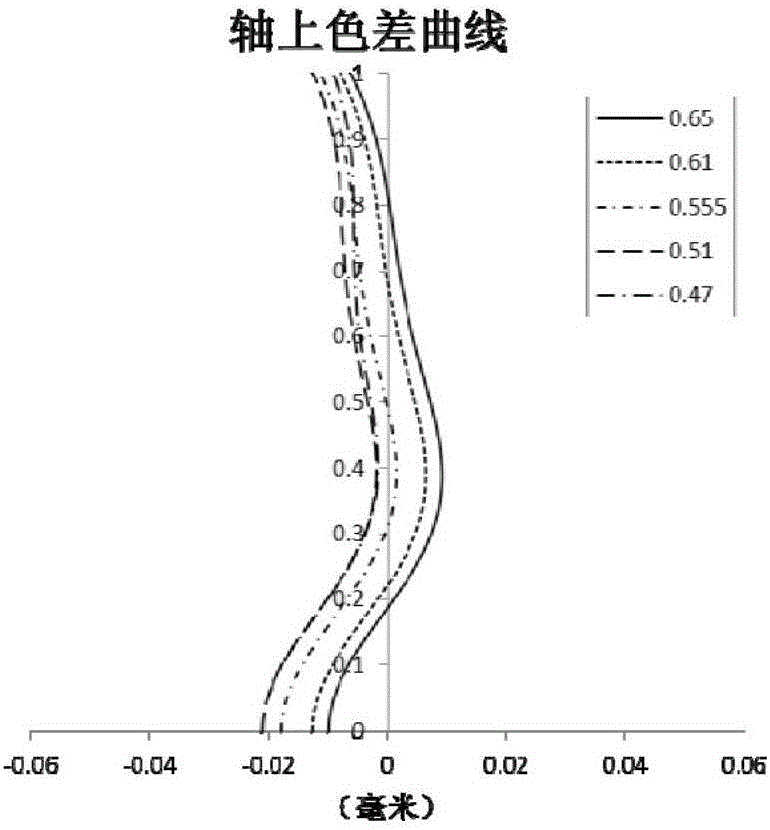

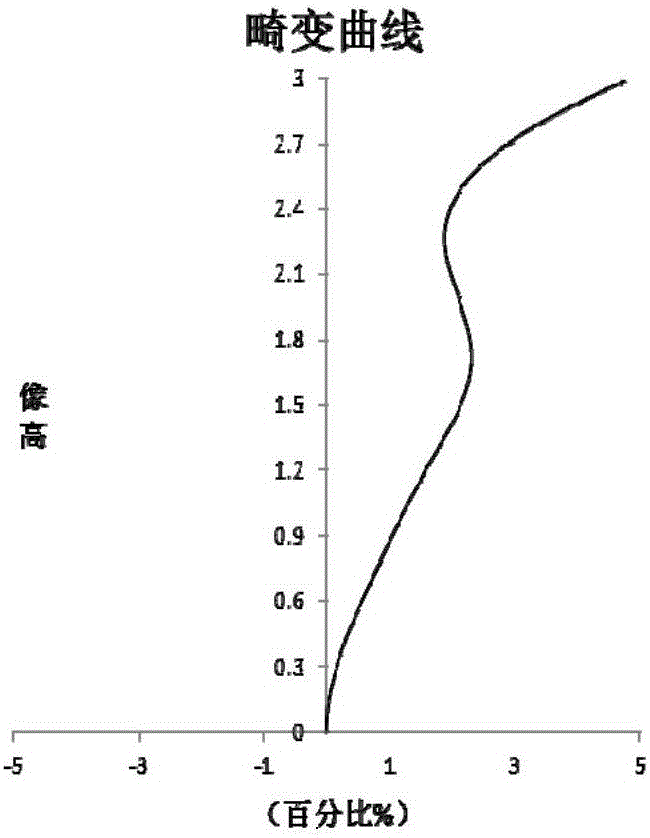

Shooting lens and camera device assembled with shooting lens

ActiveCN106338815AConducive to production and processingSolve the above problemsOptical elementsPhysicsCamera lens

The invention discloses a shooting lens and a camera device assembled with the shooting lens. The shooting lens comprises a first lens, a second lens, a third lens and multiple subsequent lenses; the first lens, the second lens, the third lens and the multiple subsequent lenses are arranged from the object side to the image side successively along the optical axis, and form a total effective focal length f; and the shooting lens is characterized in that a combined focal length f12 of the first and second lenses and a focal length f3 of the third lens satisfy that -0.7<f12 / f3<0.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

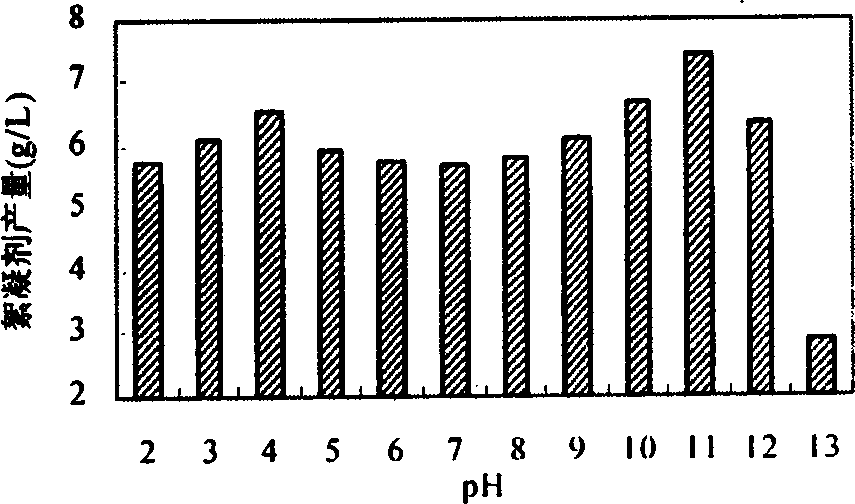

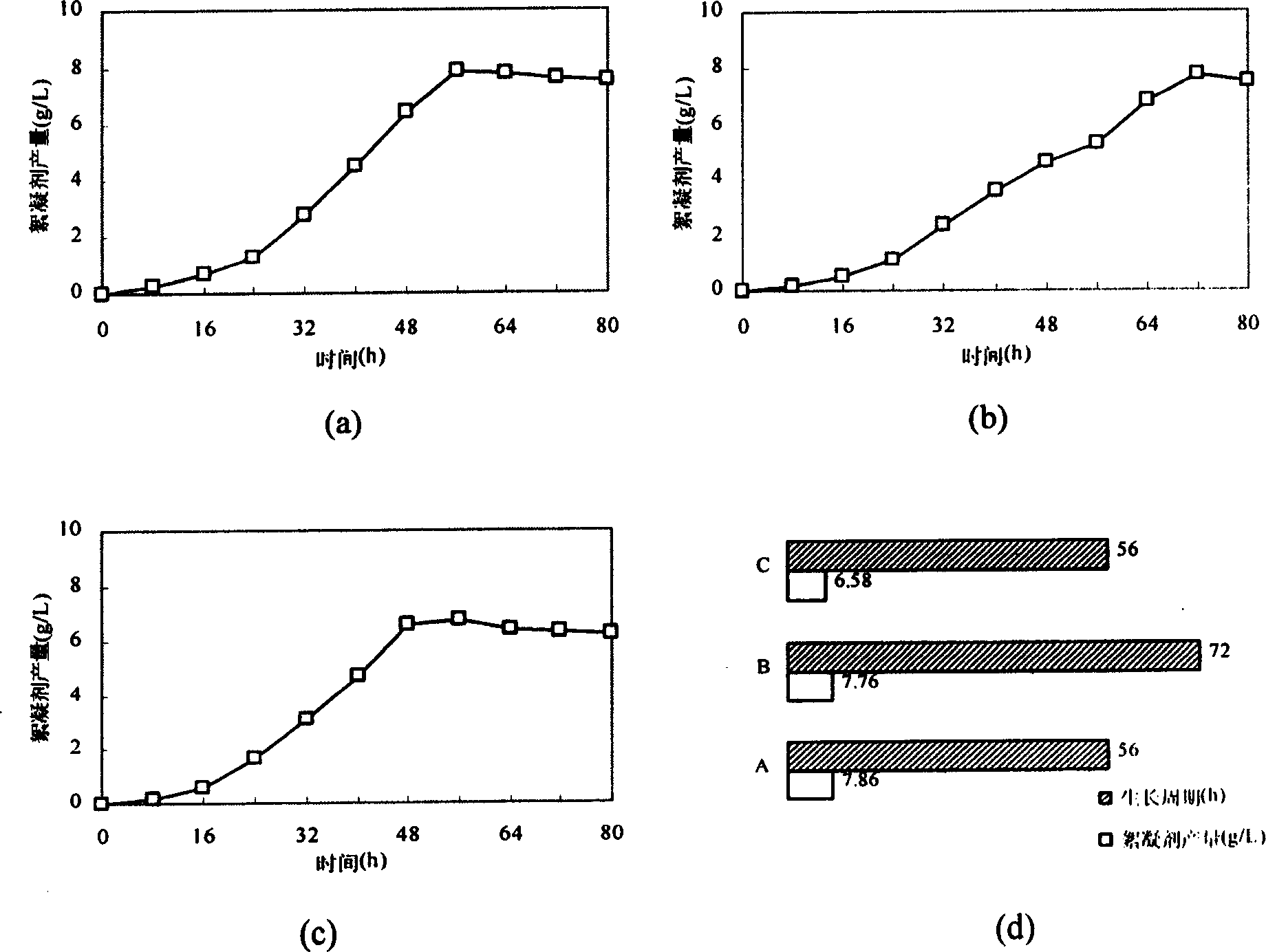

Microorganism flocculant producing strain by using bean dregs and process for producing same

InactiveCN1844360ASolve the above problemsSolve the above problems in productionBacteriaMicroorganism based processesMicroorganismLate stage

This invention relates to a microbial flocculating agent. The invention isolates a high-yield bioflocculation microorganism-Paenibacilluspolymyxa GA1 CCTCC M 206017, and utilizes bean dregs as the substituted culture medium to synthesize the flocculating agent. The culture process comprises: processing the bean dregs at pH11.0 by boiling at high temperature and pressure, adjusting the pH to pH6.0-8.0, inoculating with 0.5-2% seed solution, applying two-stage fermentation process, wherein: at the early state of 24 hours, the culture temperature is 30deg C and the shaker speed is 150r / min; and at the late stage of 32 hours, the culture temperature is 25deg C and the shaker speed is 100r / min. By applying the two-stage fermentation process, the bacteria can make use of nutrients to synthesize the flocculating agent at a maximu rate, with the yield increaed to 7.86g / L and culture cycle decreased to 56h. By using the bean dregs and the two-stage fermentation process, it can lower the cost for producing the microbial flocculating agent, improve the yield, and realize the massive industrial production of microbial flocculating agent.

Owner:HUNAN UNIV

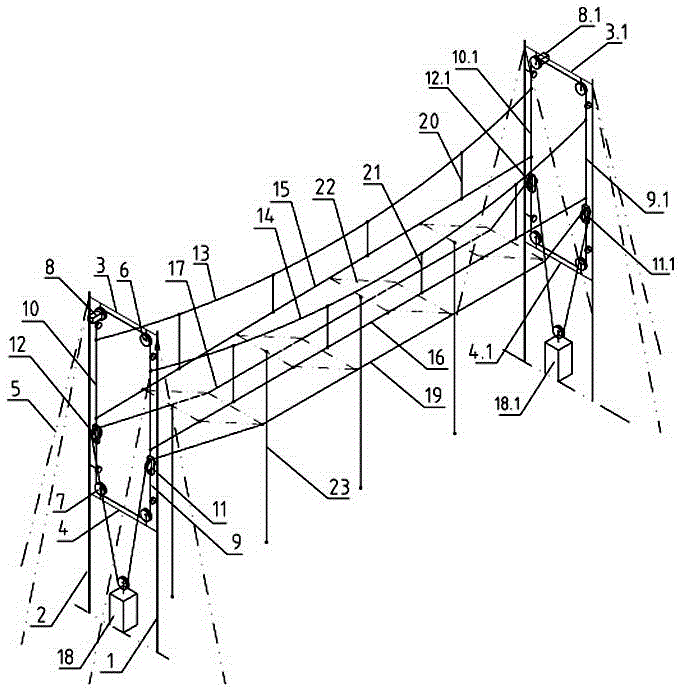

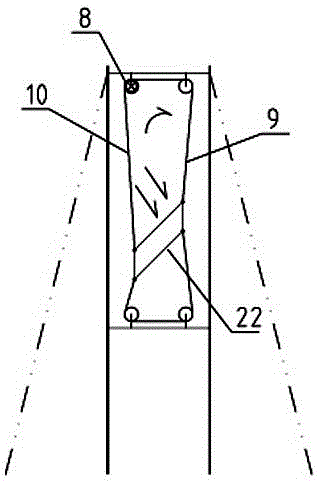

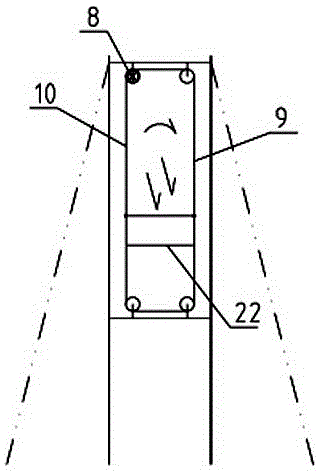

Dual-axis tracking type photovoltaic or photo-thermal support

ActiveCN106406364ASolve the above problemsSmall footprintControl using feedbackPhotovoltaic energy generationDual axisFlexible cable

The invention discloses a dual-axis tracking type photovoltaic or photo-thermal support. The support includes left and right bearing frame arranged at two ends of a longitudinal direction, a flexible cable rack is arranged between corresponding flexible cable rotation units on the left and right bearing frames, the flexible cable rack includes sag cables, first horizontal load cables and second horizontal load cables which are arranged on the front and rear side vertical cable bodies of corresponding rectangular flexible cable frames of the left and right bearing frames from top to bottom; two ends of the sag cables and the first horizontal load cables are fixed to the front and rear side vertical cable bodies of the corresponding rectangular flexible cable frames, and two ends of the second horizontal load cables bypass lifting fixed pulleys on the front and rear side vertical cable bodies of the corresponding rectangular flexible cable frames to be connected with a corresponding lifting driving device; and a plurality of droppers are arranged between the sag cables located on the front and rear side vertical cable bodies of the rectangular flexible cable frames and the first horizontal load cables at intervals along a longitudinal direction. The dual-axis tracking type photovoltaic or photo-thermal support provided by the invention is simple and stable in overall structure, low in cost, and simple and accurate to adjust, and is suitable for engineering popularization and application.

Owner:杨大楼

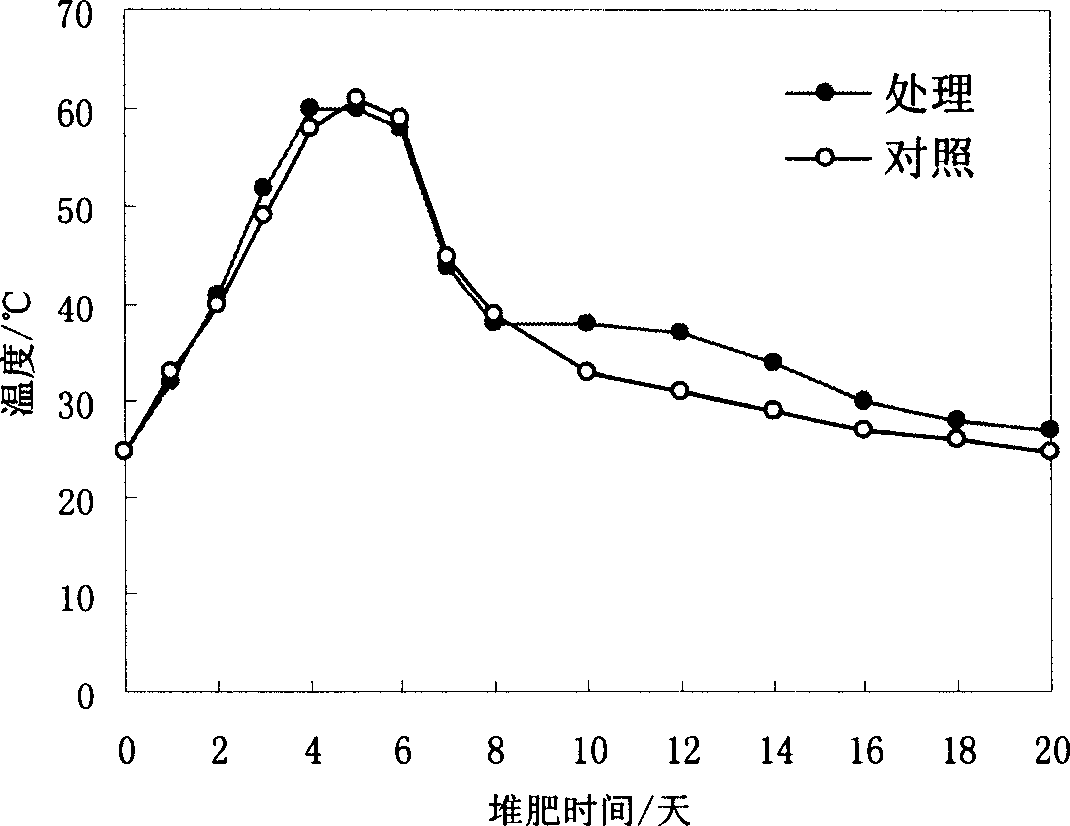

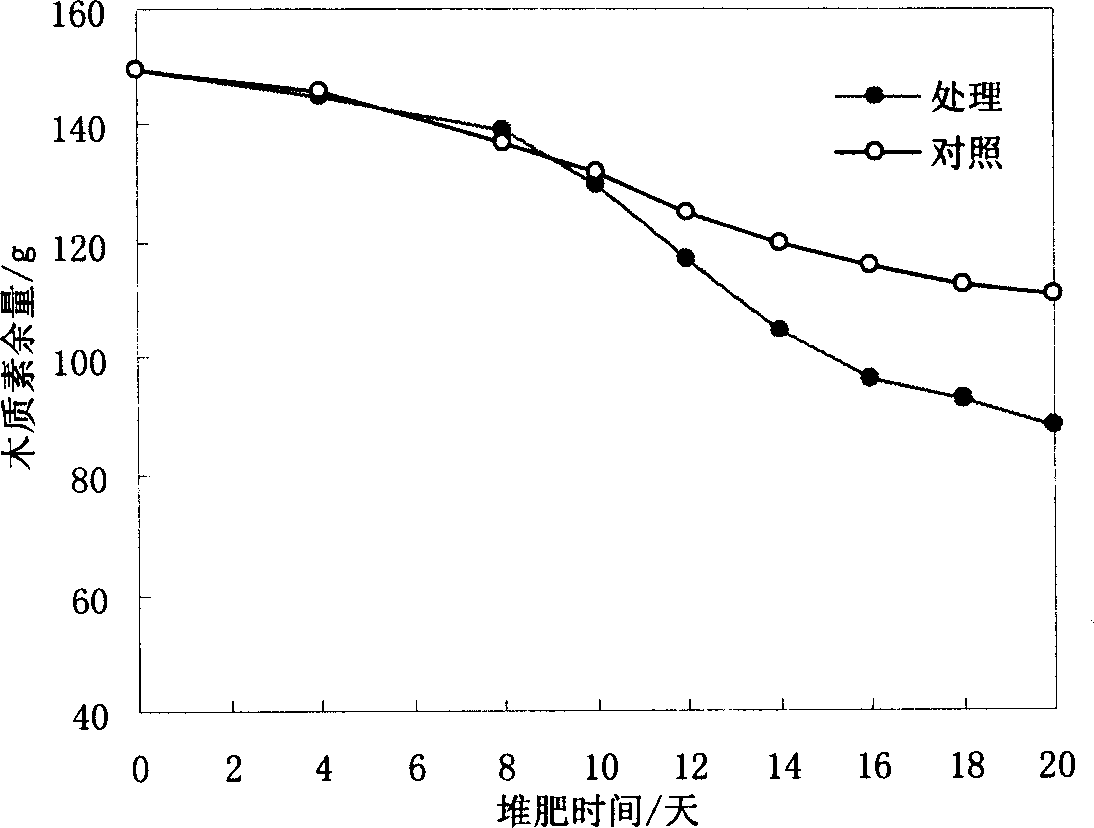

Immobilized white-rot fungus and its application for composting garbage

InactiveCN1654644ASolve the above problemsBio-organic fraction processingOrganic fertiliser preparationDecompositionBiology

The present invention relates to the utilization of microbial immobilizing technology in treating city domestic garbage. Immobilized microbial preparation is prepared with corn cob as carrier to immobilize whiterot fungus, immobilized whiterot fungus is then inoculated activity raising culture medium for culturing of 4-6 days and immobilized fungal preparation is prepared via filtering to eliminate culture liquid. The immobilized fungal preparation is used in treating garbage via inoculation while the compost material has its temperature lowered to 40 deg.c or so, regulating the water content in compost, controlling the ventilation rate and turning the compost timely for thorough decomposition. By utilizing whiterot fungus with high lignin degrading enzyme yield and high heavy metal adsorbing and fixing ability and the immobilizing technology to reduce heavy metal in compost, the present invention can raise the quality of compost greatly.

Owner:HUNAN UNIV

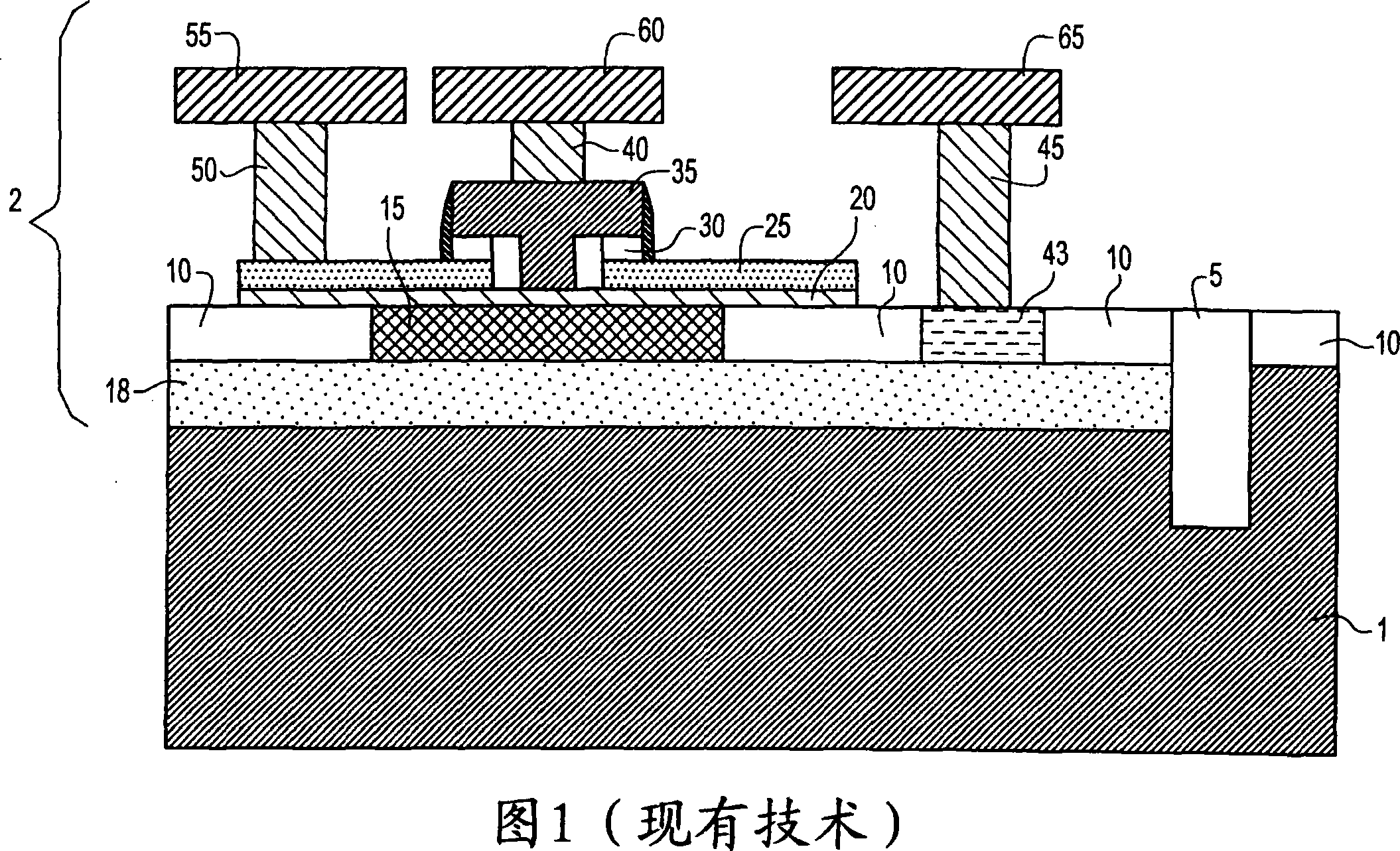

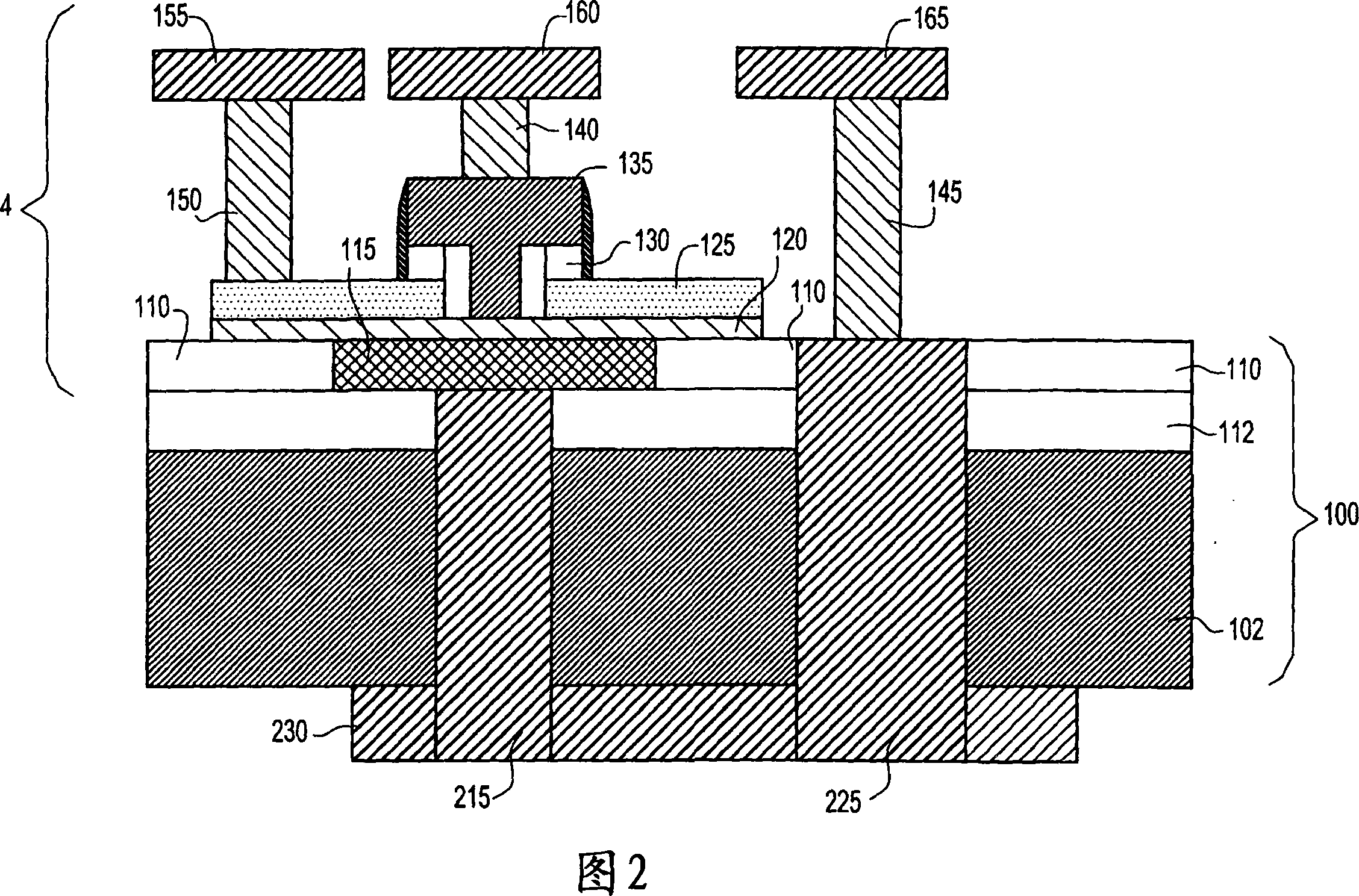

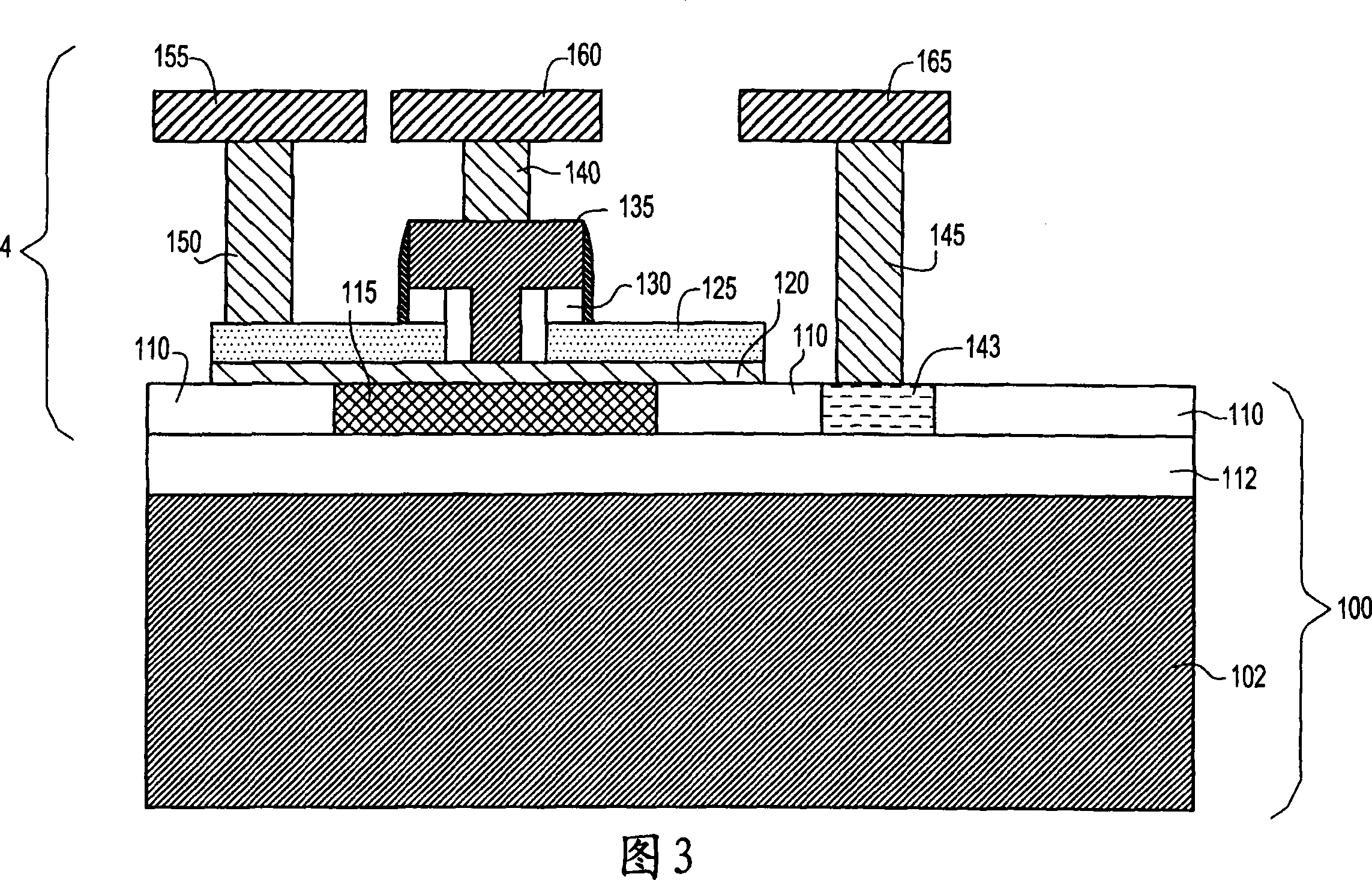

Semiconductor device and its forming method

ActiveCN101079441ASpeed up distributionImprove performanceTransistorSemiconductor/solid-state device detailsLithographic artistEtching

The present invention relates to a device structure that comprises a substrate with front and back surfaces, and at least one semiconductor device with a first conductive structure located in the substrate and a second conductive structure located thereover. A first conductive contact is located over the front surface of the substrate and laterally offset from the first conductive structure. The first conductive contact is electrically connected to the first conductive structure by a conductive path that extends: (1) from the first conductive structure through the substrate to the back surface, (2) across the back surface, and (3) from the back surface through the substrate to the first conductive contact on the front surface. Further, a second conductive contact is located over the front surface and is electrically connected to the second conductive structure. The conductive path can be formed by lithography and etching followed by metal deposition.

Owner:INT BUSINESS MASCH CORP

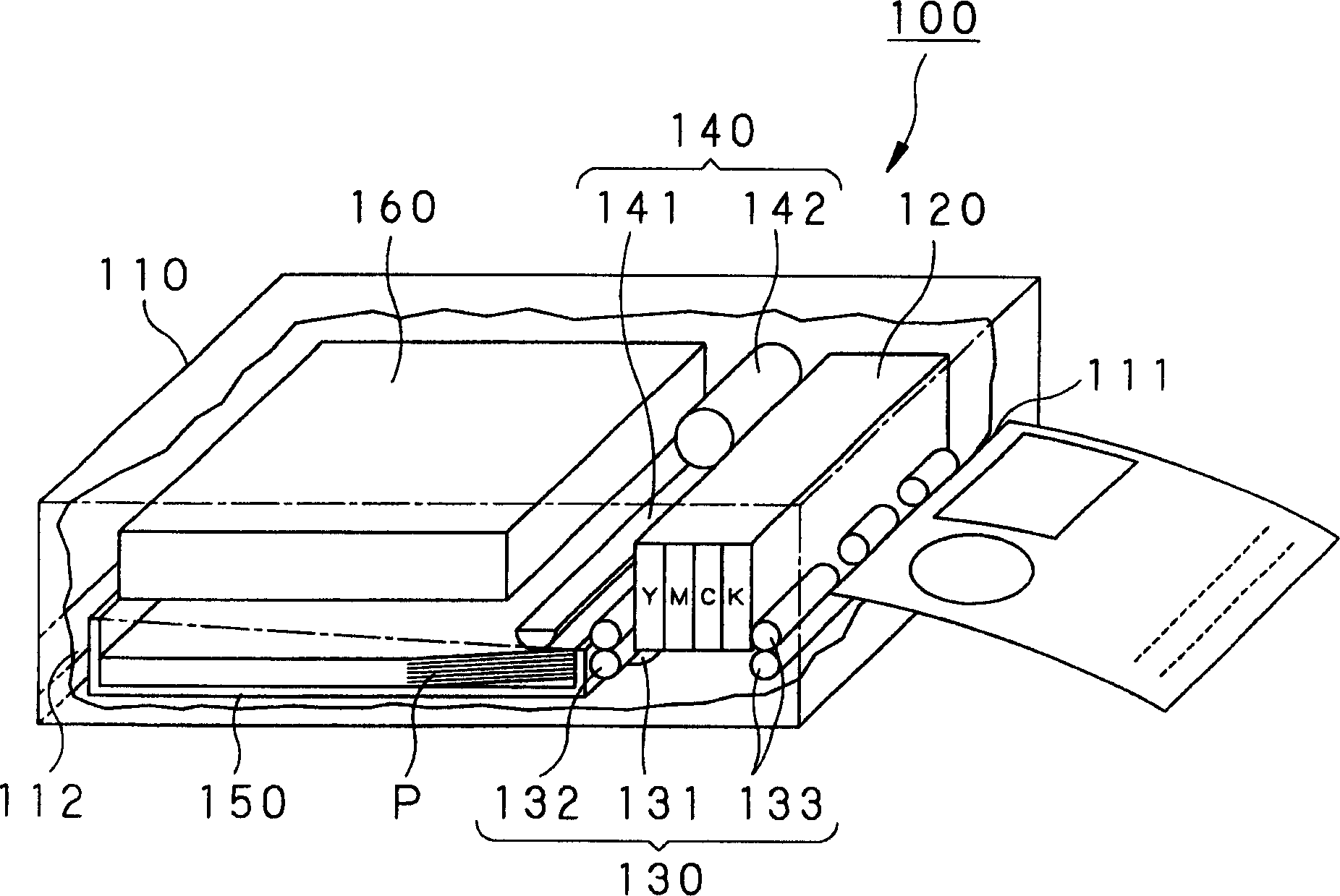

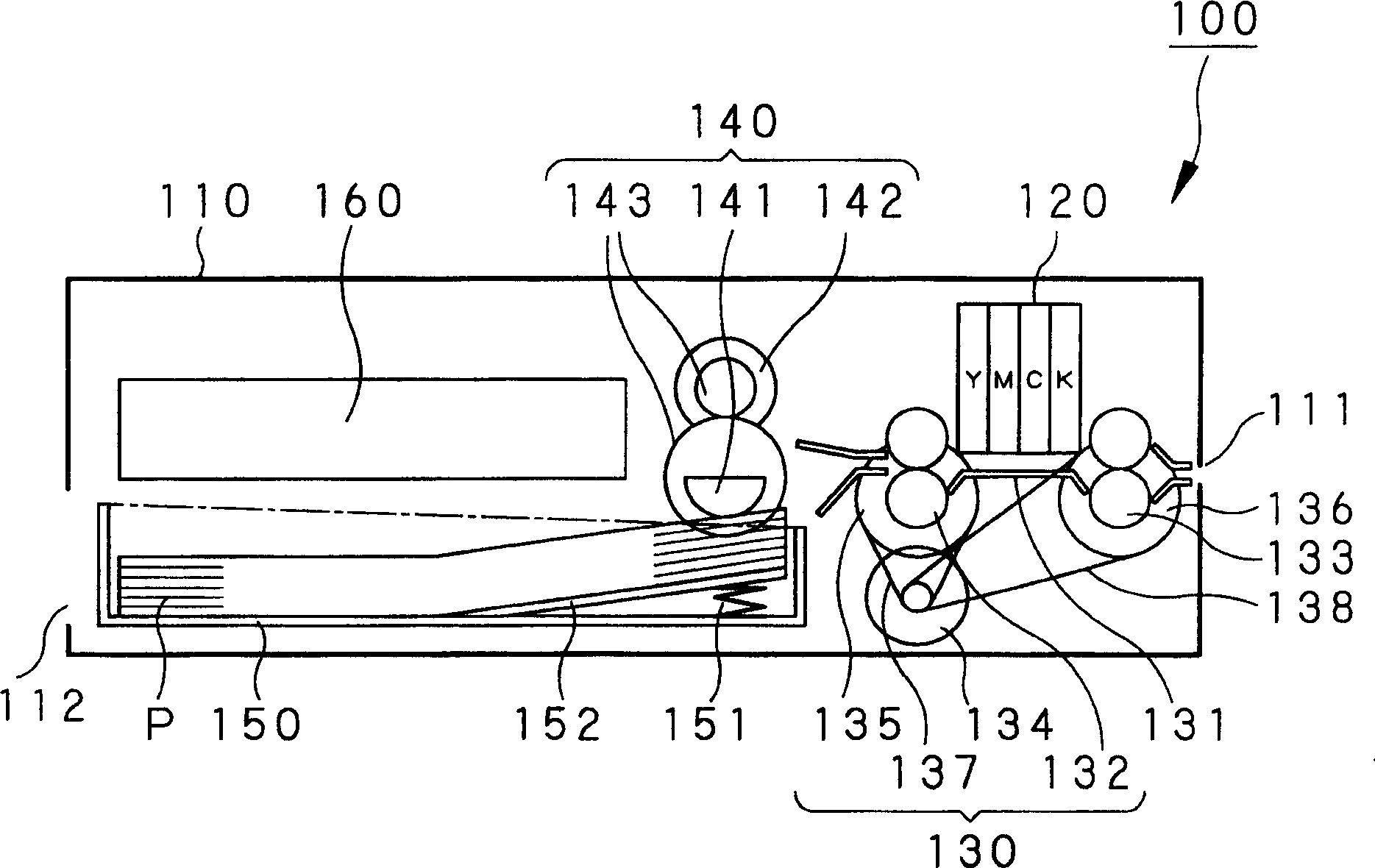

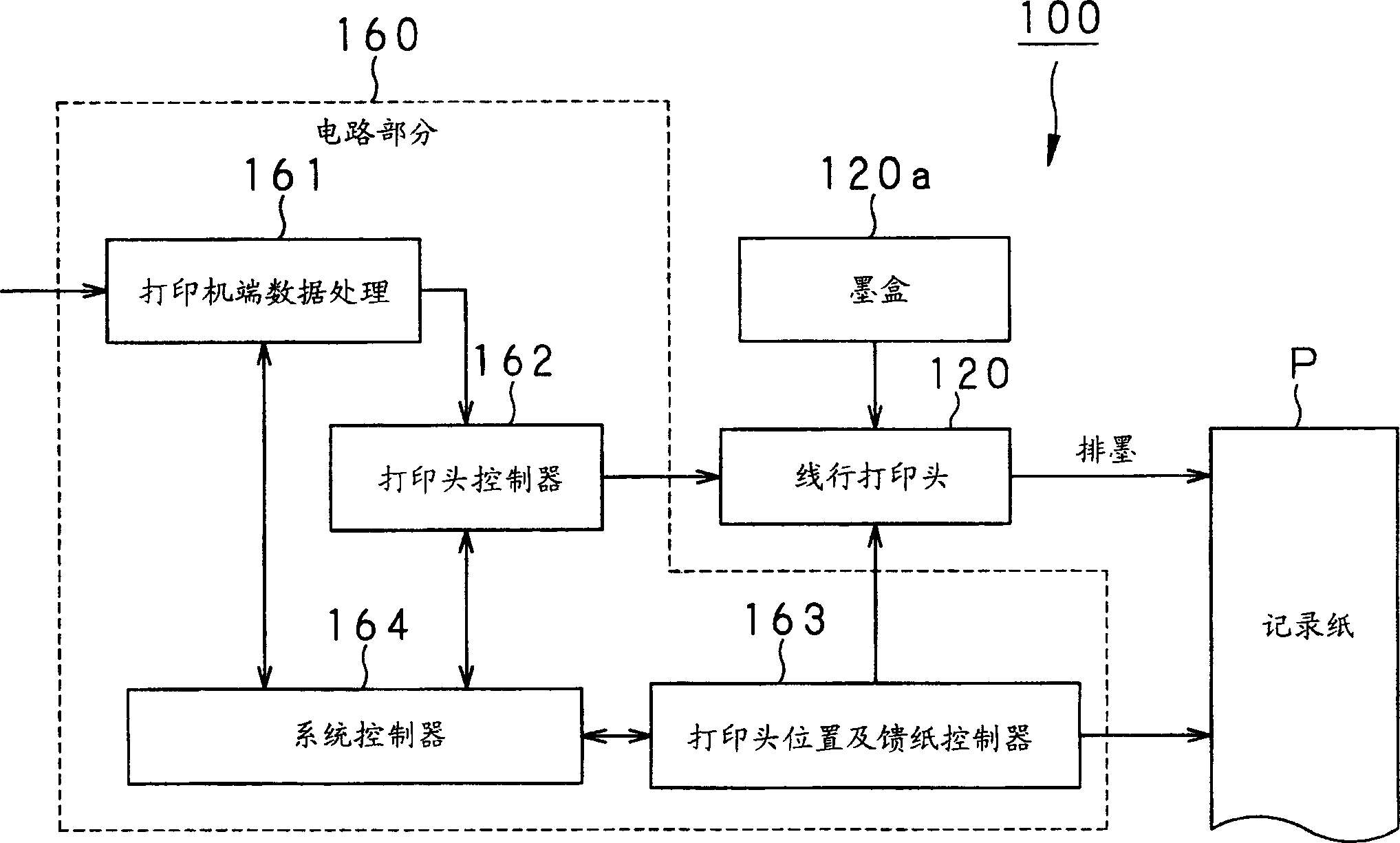

Liquid discharging device and liquid discharging method

InactiveCN1491161ASolve the above problemsNot easy to seeInking apparatusElectrical and Electronics engineeringLiquid drop

A liquid discharge apparatus includes a liquid discharge head (120) having ink discharge nozzles (203) for discharging droplets of inks, and a head controller (162) for controlling the liquid discharge head to discharge droplet from liquid discharge units onto the surface of recording paper (P), wherein the liquid discharge head includes the plural liquid discharge heads in a direction perpendicular to movement direction of recording paper where the recording paper is relatively moved with respect to the liquid discharge head. The head controller serves to allow discharge timings of droplets in movement direction of the recording paper to be different every one pixel in movement direction of the recording paper to eliminate stripes apt to take place when a portion or the entirety of image is printed by one scanning operation to obtain image having less defect.

Owner:SONY GRP CORP

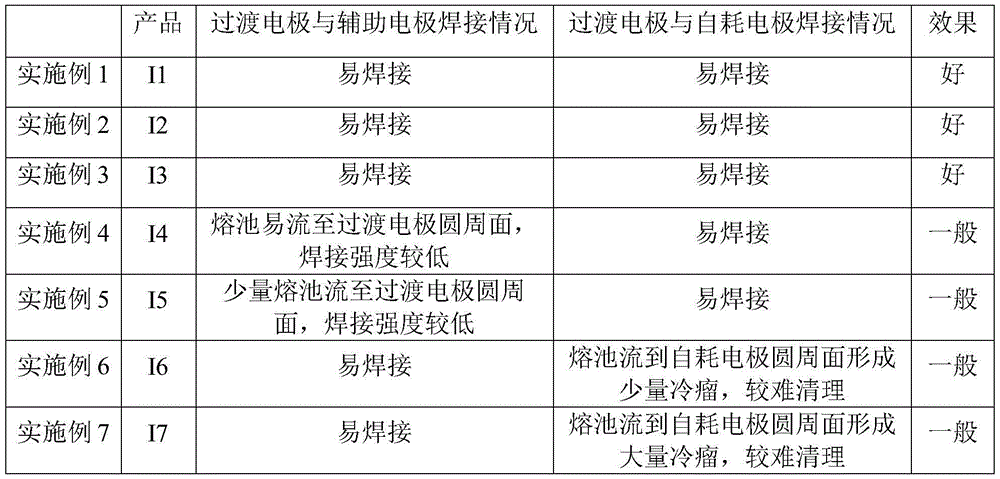

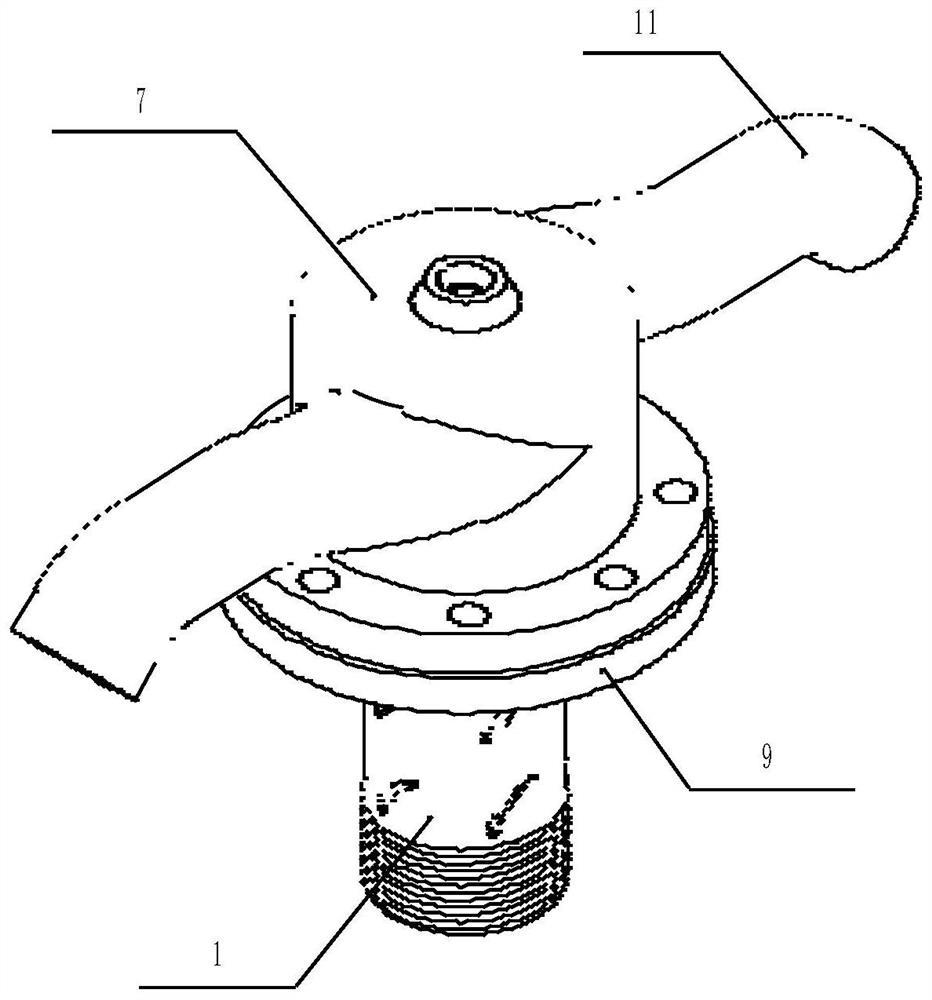

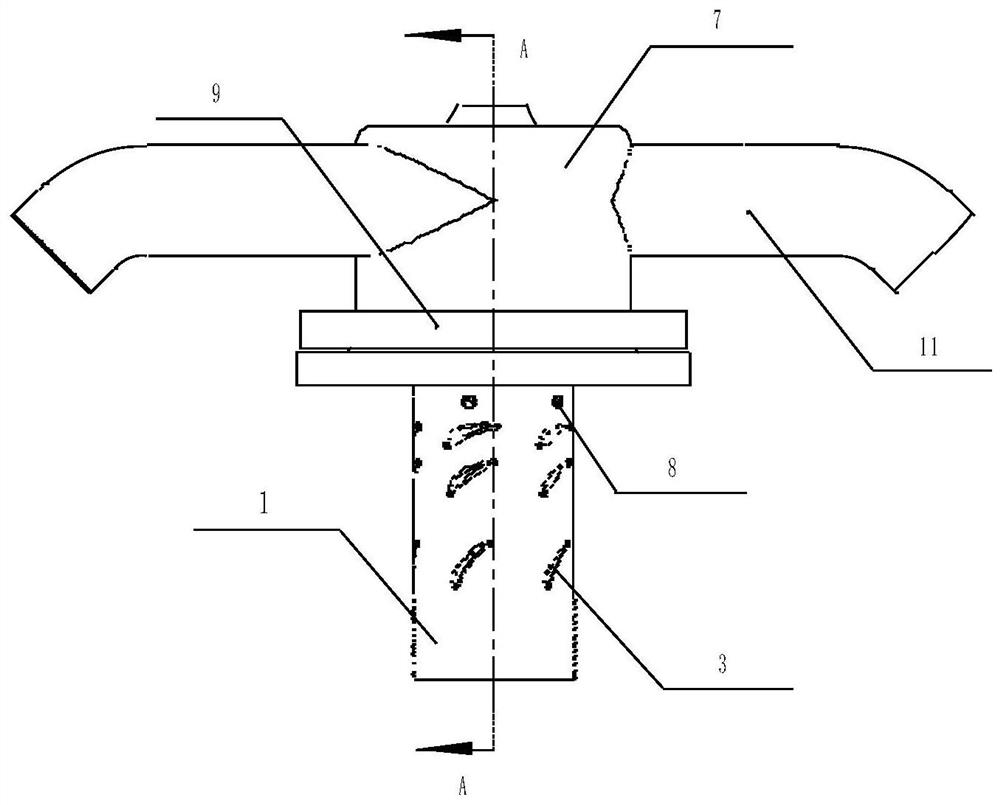

Electrode for vacuum self-consuming furnace and welding method thereof and vacuum self-consuming melting feeding method

ActiveCN105611663AReduce consumptionLow costElectric discharge heatingNonferrous metalAuxiliary electrode

The invention relates to the field of nonferrous metal melting, and specifically relates to an electrode for a vacuum self-consuming furnace, a welding method of the electrode and a vacuum self-consuming melting feeding method using the electrode. The electrode for a vacuum self-consuming furnace comprises a self-consuming electrode and an auxiliary electrode and is characterized in that a transition electrode is further connected between the self-consuming electrode and the auxiliary electrode. The electrode for a vacuum self-consuming furnace can effectively reduce the operating cost, improve the ingot yield and improve the quality of an ingot feeding end face.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

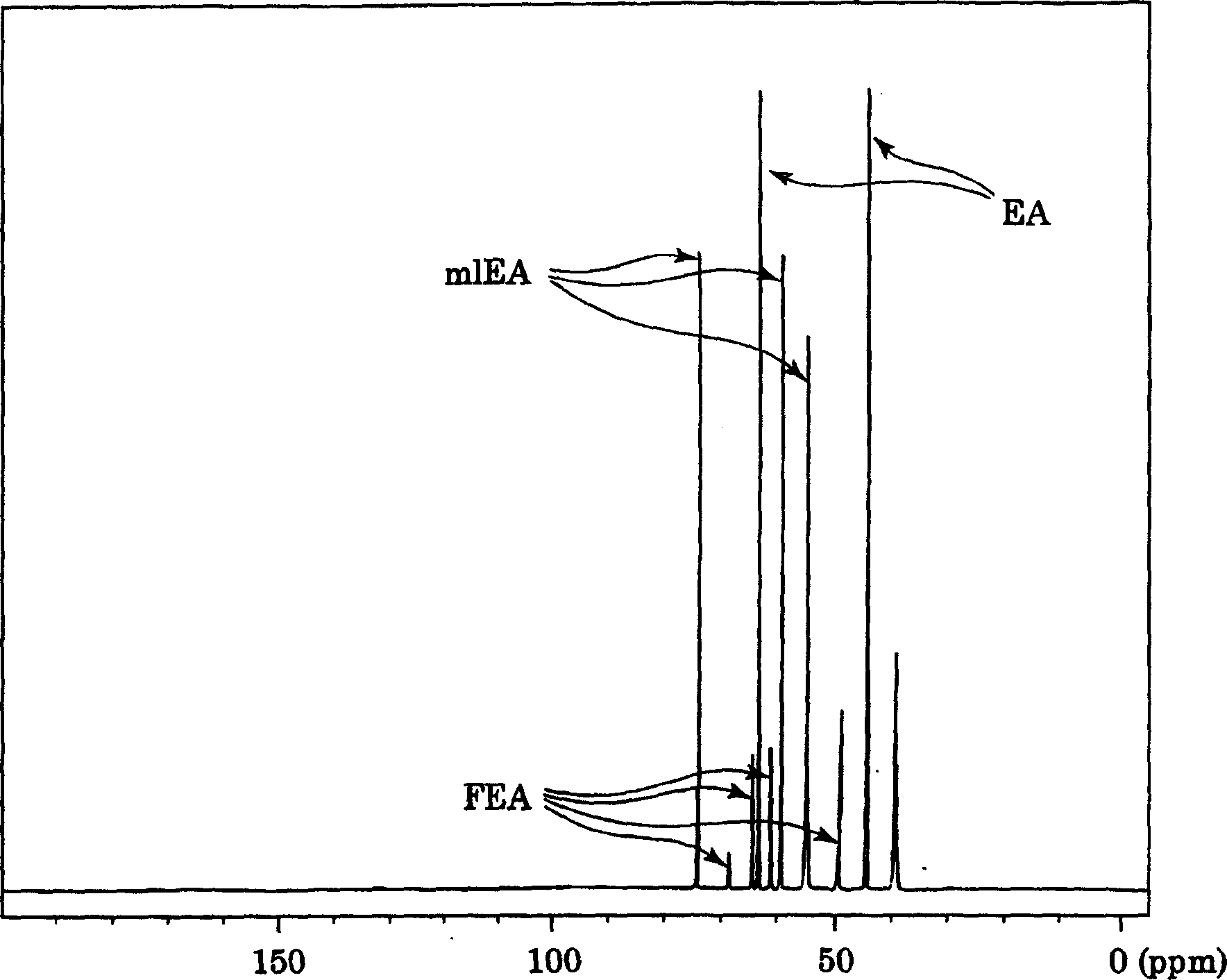

Dephotoresist agent

ActiveCN1517803ASolve the above problemsDoes not reduce photoresist removal efficiencySugar derivativesOrganic compound preparationResistPhotoresist

The photoresist stripping agent of the present invention contains a reaction product that is produced by the reaction of formaldehyde and an alkanol amine in a molar ratio of 0.8 or less. The photoresist stripping agent easily removes, at low temperatures in a short period of time, photoresist layers applied on substrates, photoresist layers remaining after etching and photoresist residues after ashing subsequent to etching. The photoresist stripping agent also removes the photoresist layers and photoresist residues without corroding substrates, wiring materials, insulating layers, etc. to enable the fine processing and provide high precision circuits.

Owner:MITSUBISHI GAS CHEM CO INC

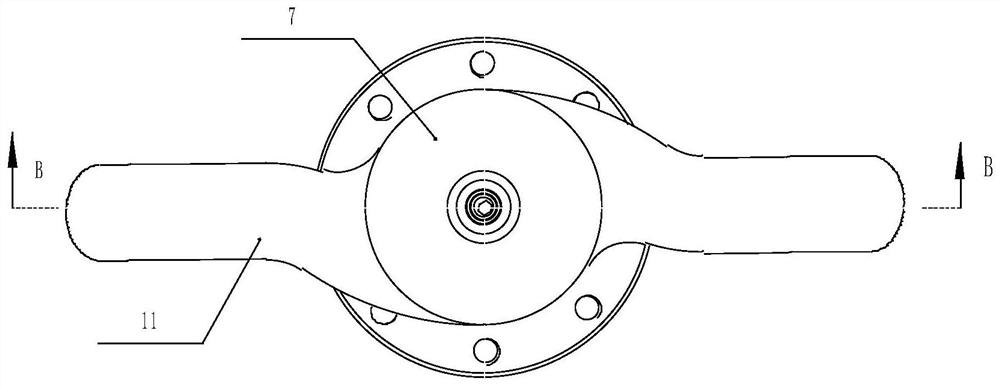

Spiral-flow type micro-nano bubble generator and generation method thereof

PendingCN112408584AMeet needsHigh spinning efficiencyTreatment using aerobic processesBiological treatment apparatusMicro nanoWater flow

The invention discloses a spiral-flow type micro-nano bubble generator and a generation method thereof.The spiral-flow type micro-nano bubble generator is mainly characterized in that two spiral-flowstarting cylinders are evenly distributed on the outer wall of a volute in the circumferential direction and communicated with the volute, a flange plate is arranged at the bottom of the volute, a through hole is formed in the center of the volute, and an outer cylinder is installed in a center hole of an installation disc; a plurality of grades of blades are arranged on a blade shaft, an air inlet throat pipe is installed at the top end of a sleeve, the bottom of the sleeve is installed at the top end of a cavitator through a positioning pin, a tooth-shaped gasket is installed between the bottom face of the sleeve and the top face of the cavitator, and the cavitator is installed in a positioning hole in the top end of the blade shaft. A static multi-stage cascade is adopted, the last stage is of a hollow blade structure, water flow is converted into rotational flow from horizontal flow through the cascade, the lift provided by the water pump is efficiently converted into high-speed circumferential water flow speed in a short process through the change of the installation angle of the multi-stage cascade, and micro-nano bubbles are generated by shearing gas through rotating water flow. The generator is reliable in operation and less susceptible to clogging.

Owner:陕西超微环境科技有限公司

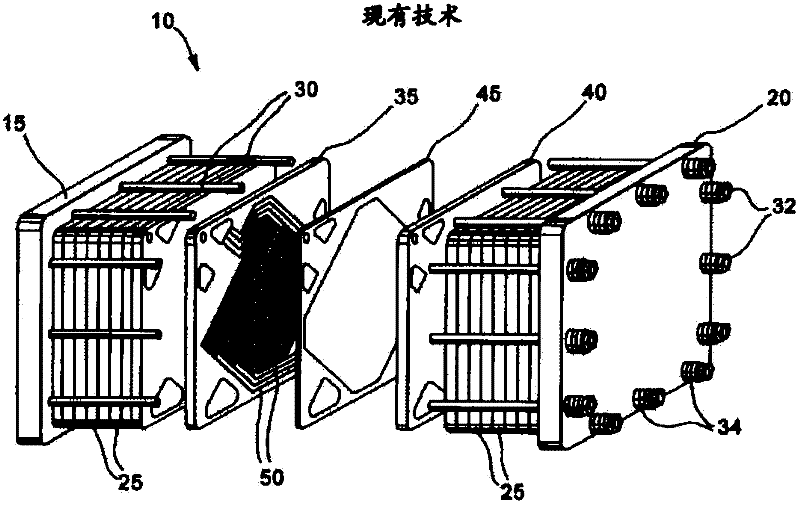

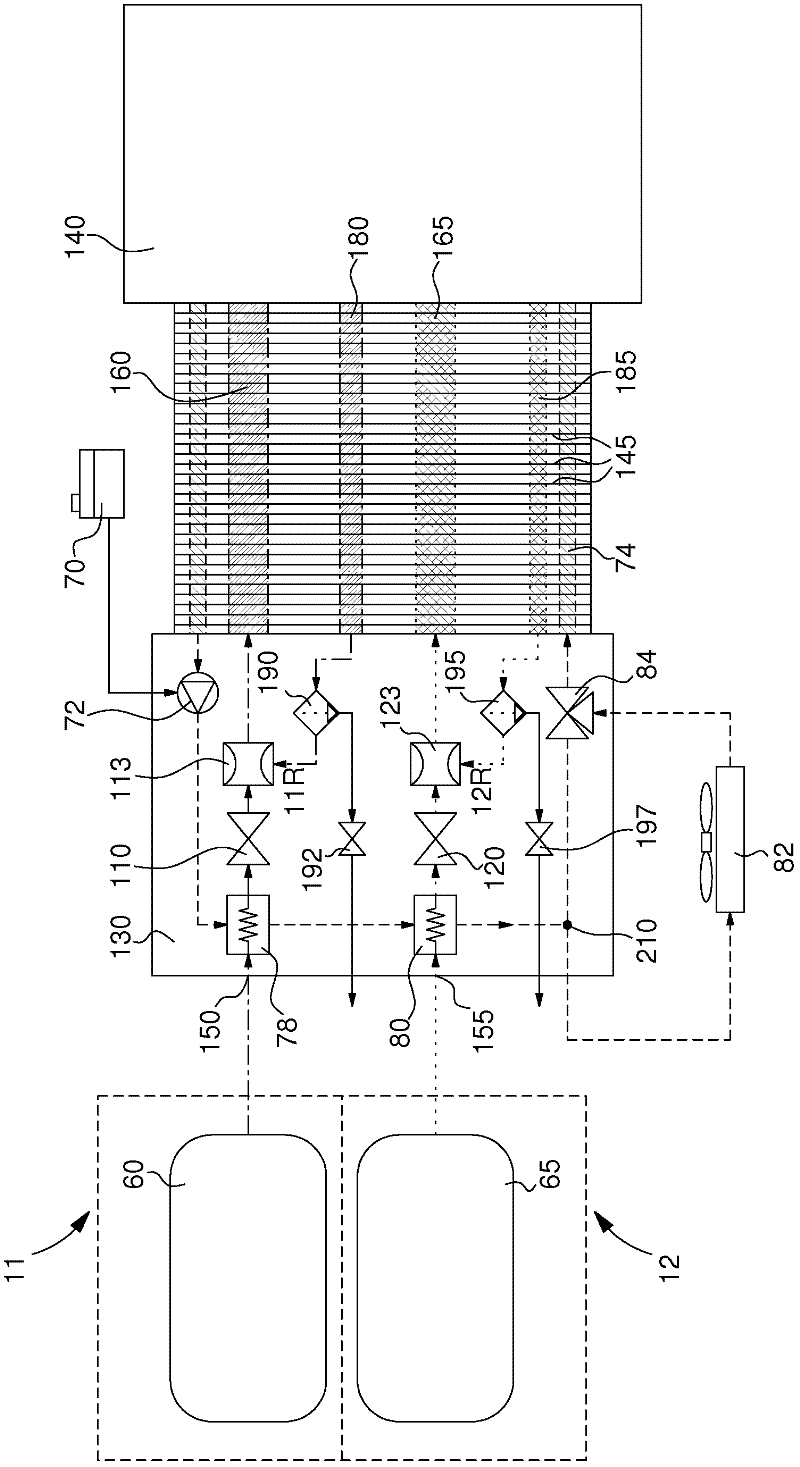

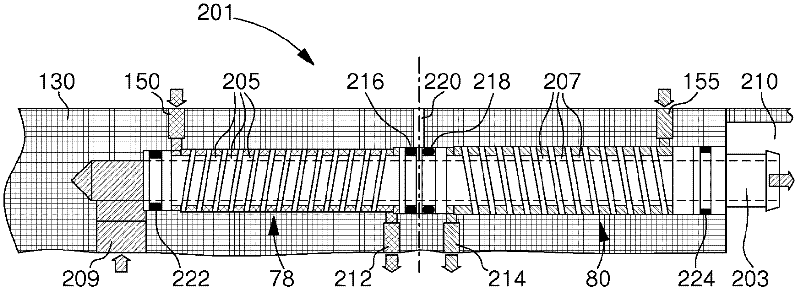

Fuel cell system including heat exchanger

ActiveCN102272995ASolve the above problemsReactant parameters controlFuel cell detailsFuel cellsCirculator pump

A fuel cell system including: a fuel cell stack including plural fuel cells sandwiched between two end plates; a fuel supply system supplying a stream of fuel gas to the fuel cell stack; an oxidizer supply system supplying a stream of oxidizer gas to the fuel cell stack; a closed loop coolant circulation system driving a cooling liquid through the fuel cell stack so that the cooling liquid enters the fuel cell stack, absorbs heat from the fuel cells, and exits the fuel cell stack. The coolant circulation system includes a circulation pump driving the cooling liquid, a heat exchanger removing heat from the cooling liquid and for at least partially transferring the heat to the stream of fuel gas and / or the stream of oxidizer gas. The heat exchanger includes a tube made from a heat-conducting material and inserted into a bore in one of the end plates, the tube and the bore defining at least a first fluid channel inside the tube and a second fluid channel in a space existing between the tube and the sides of the bore in the end plate, one of the first and second fluid channels being for the cooling liquid, and the other fluid channel being for the fuel or the oxidizer gas.

Owner:BELENOS CLEAN POWER HLDG

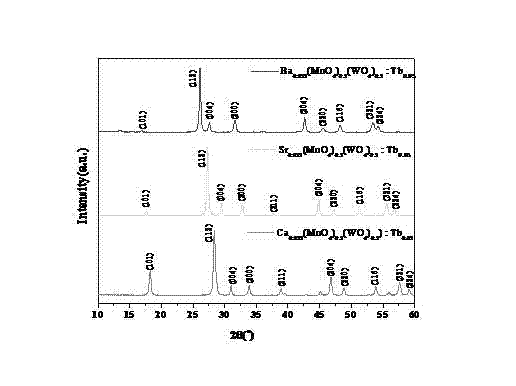

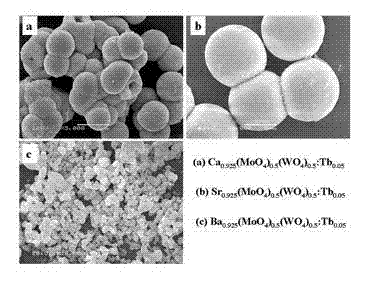

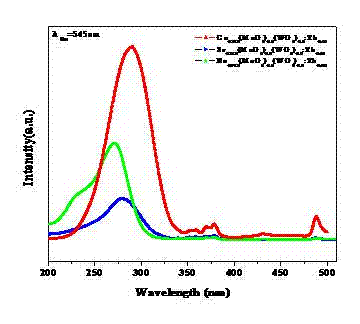

Preparation method of chemical solution of terbium-doped tungsten molybdate green fluorescent microcrystalline

InactiveCN102382643APracticalSolve the above problemsLuminescent compositionsChemical solutionMolybdate

The invention relates to a preparation method of a chemical solution of terbium-doped tungsten molybdate green fluorescent microcrystalline. The green microcrystalline provided by the invention can be expressed by a general formula A0.925(WO4)0.5(MoO4)0.5:Tb3+0.05, wherein A=Ca, Sr and Ba. The preparation method comprises the following steps of: preparing the molar ratio of various raw materials required by a certain amount of target system, A0.925(WO4)0.5(MoO4)0.5:Tb3+0.05 microcrystalline, weighing a certain consistency and relative volume of A(NO3)2, TbCl3 solutions in a polytertrafluoroethylene beaker, respectively adding the relative amounts of Na2MoO4 and Na2WO4 solutions, stirring at the room temperature for 15-30min, and putting the polytertrafluoroethylene beaker into a high-pressure reaction kettle; naturally cooling down to the room temperature after carrying out a hydrothermal reaction under 80-180 DEG C for 15-30h; and centrifugalizing and cleaning in deionized water sediments, and baking the sediments under 100-150 DEG C to obtain the A0.925(WO4)0.5(MoO4)0.5:Tb3+0.05 solid solution luminescent microcrystalline. The invention has the advantages of environment protection, energy conservation, simple preparation processes and devices and low reaction temperature. The terbium-doped tungsten molybdate green fluorescent microcrystalline prepared by the preparation method disclosed by the invention has the advantages of pure phase, uniform granularity, suitable grain size, regular appearance, highly pure and bright green and excellent practicability.

Owner:SICHUAN NORMAL UNIVERSITY

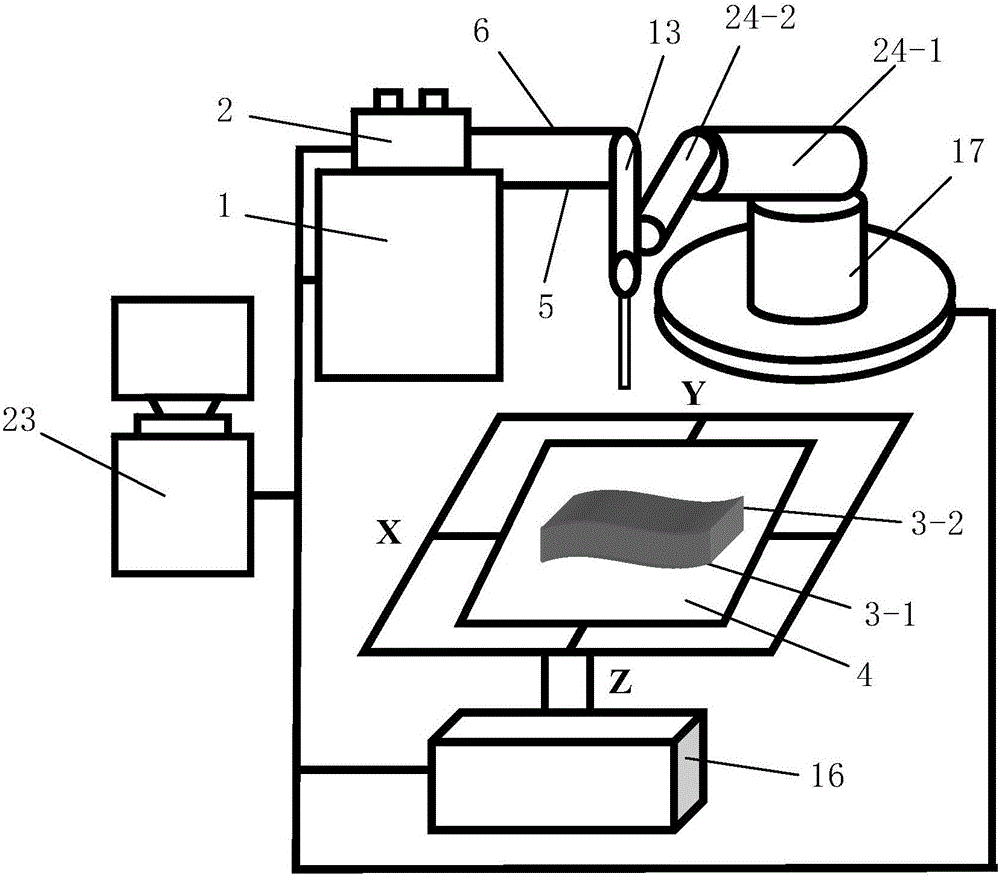

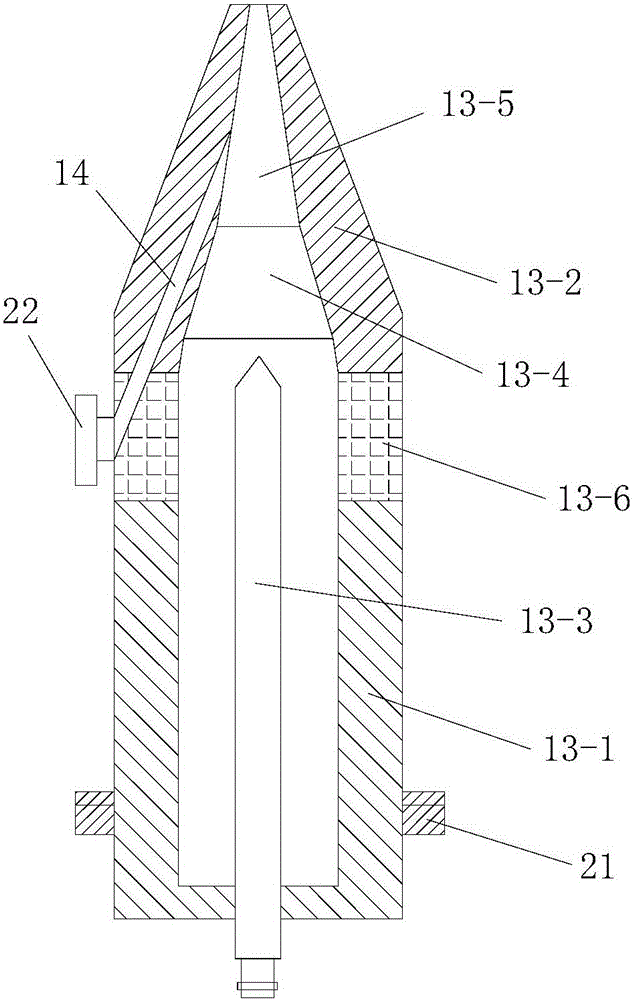

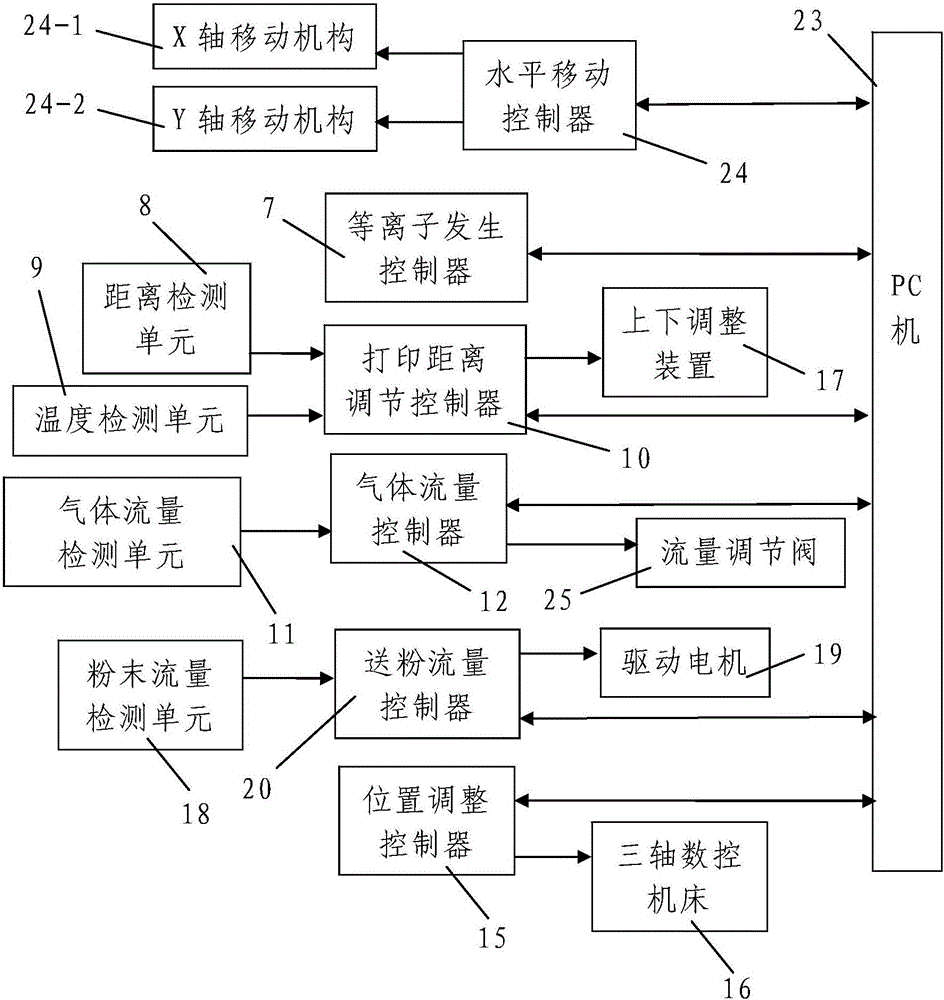

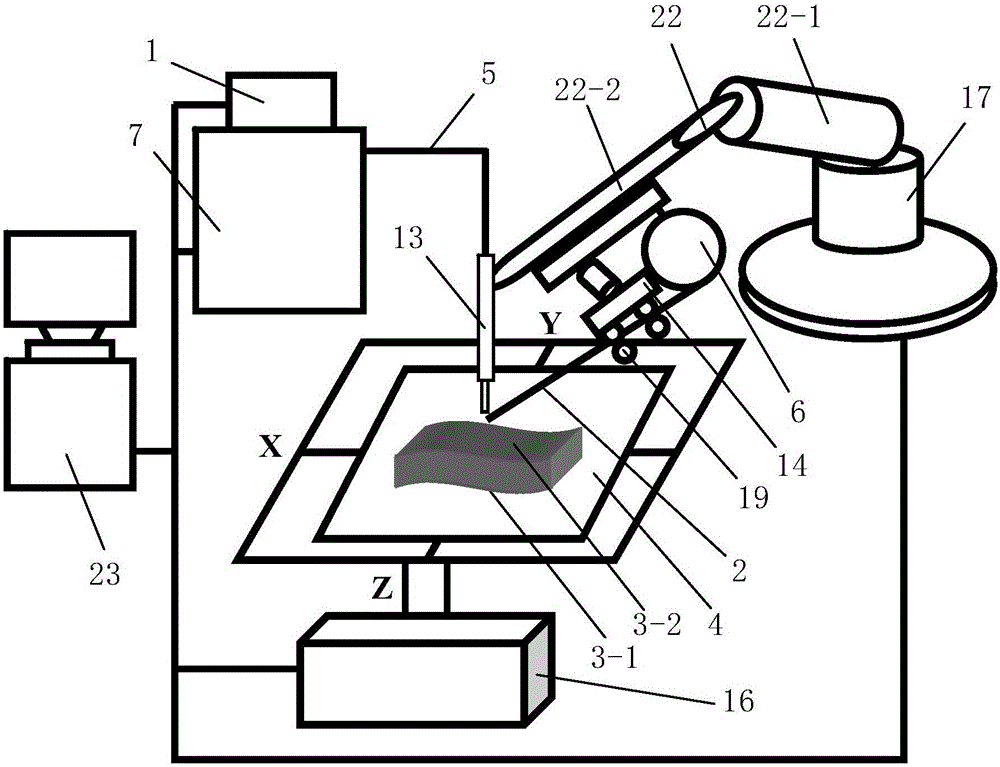

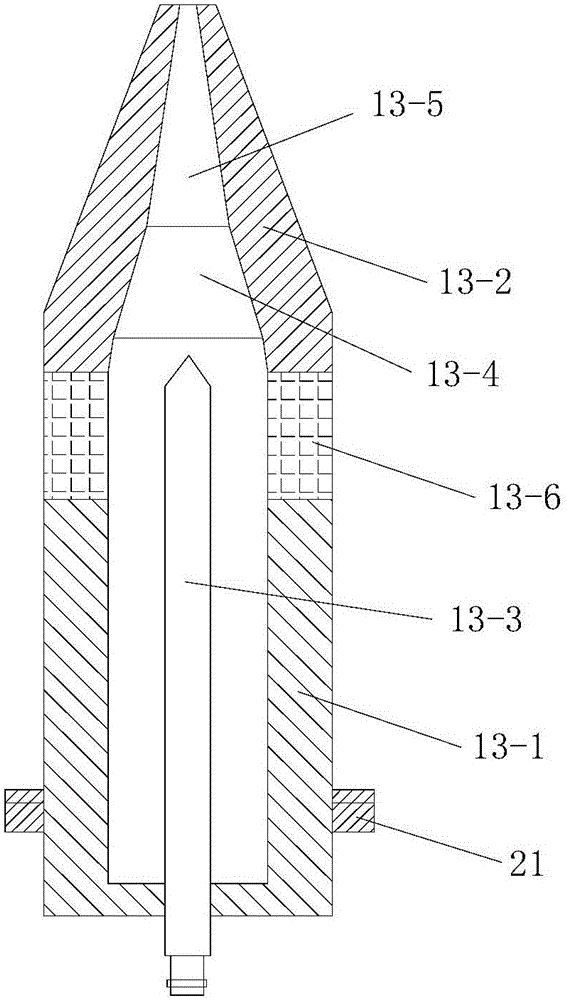

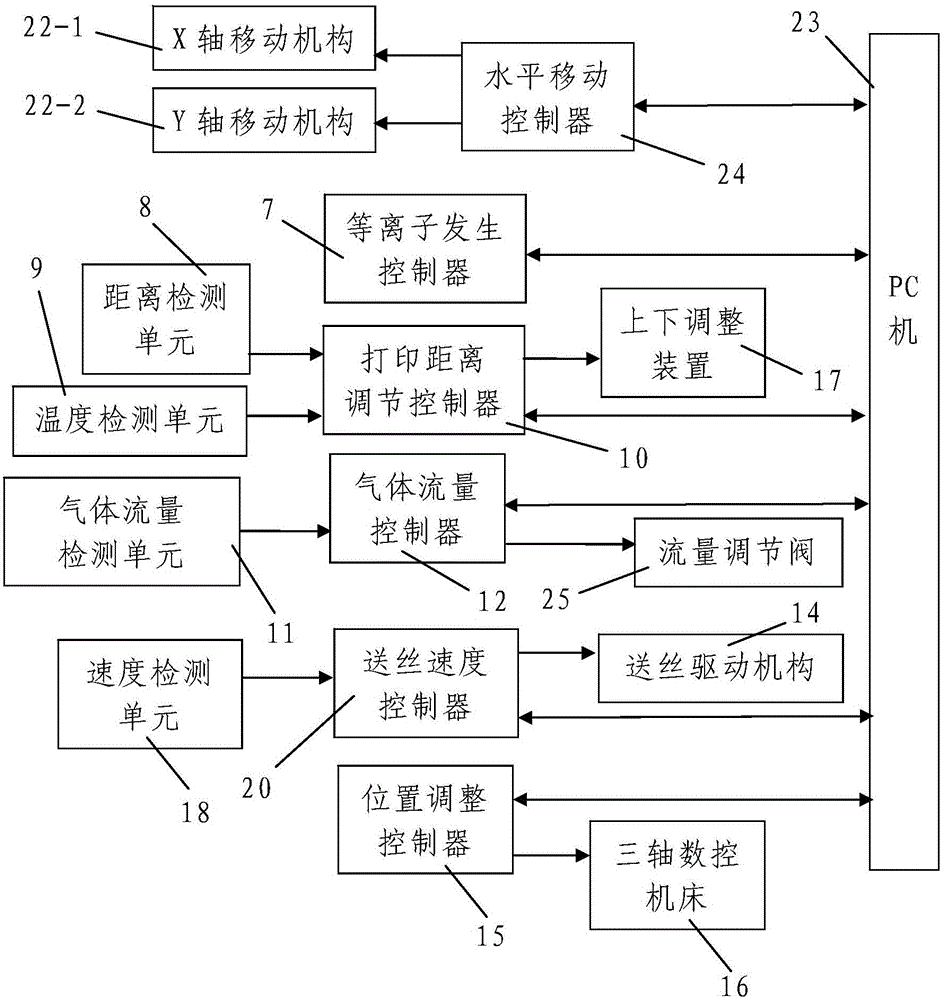

Mould plasma 3D printing equipment and mould plasma 3D printing method

InactiveCN105750542ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyTemperature controlPlasma generator

The invention discloses a mould plasma 3D printing equipment and a mould plasma 3D printing equipment method. The equipment consists of a monitoring system, a plasma beam processing system, a horizontal printing table for placing a to-be-formed mould and a temporary fixing member, wherein the plasma beam processing system consists of a plasma generator, a printing position adjusting device, a gas supply device and a powder supplier; the printing position adjusting device comprises a horizontal moving device and a printing distance adjusting device; the monitoring system comprises a horizontal movement controller, a temperature detection unit, a distance detection unit and a printing distance adjustment controller; the temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises the following steps: (I) obtaining three-dimensional stereo model and carrying out hierarchical slicing treatment; (II) scanning path filling; (III) printing path obtaining; and (IV) carrying out layer-by-layer printing from bottom to top. The equipment and the method disclosed by the invention have the advantages of reasonable design, simplicity and convenience in operation, high efficiency and good use effect; and moreover, the forming process is directly carried out in the atmospheric environment, and the formed mould has good quality.

Owner:SINOADDITIVE MFG EQUIP CO LTD

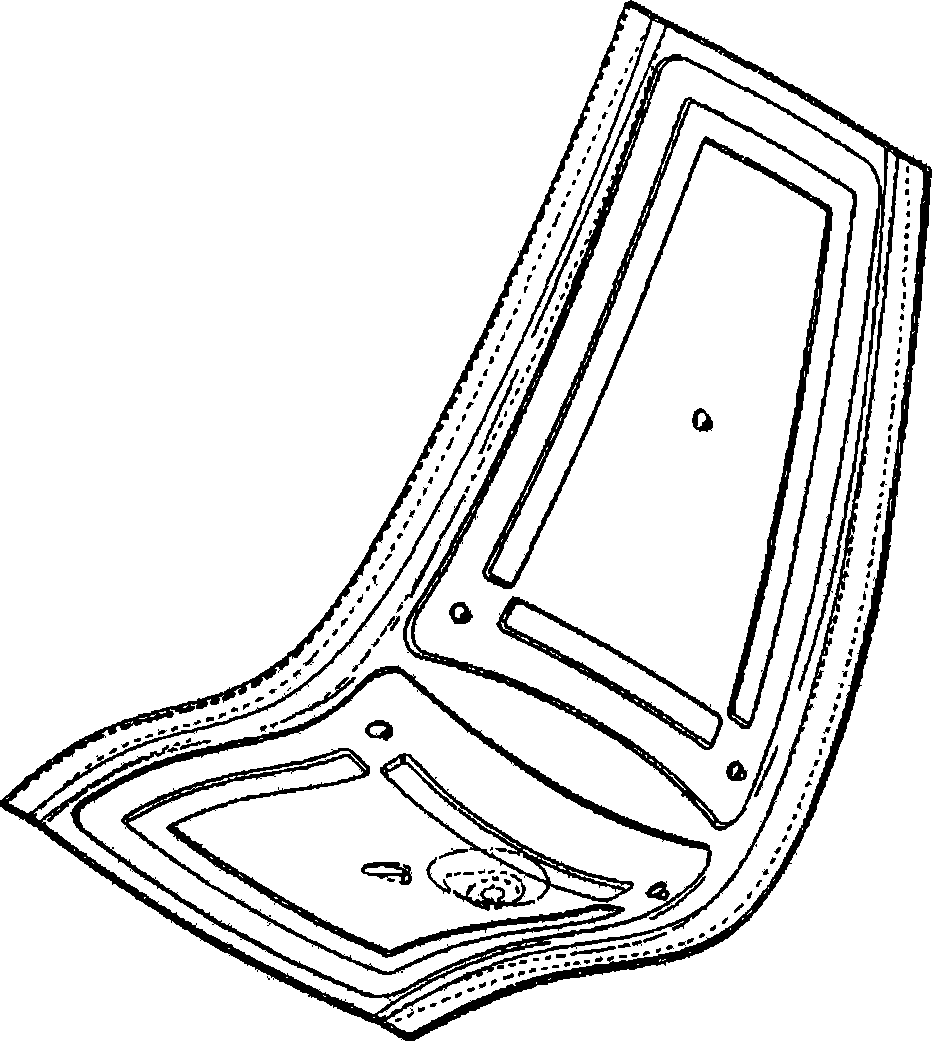

Glass fibre reinforced plastic and leisure seat made thereof

The invention relates to glass fiber reinforced plastic and a leisure chair made of the same. The glass fiber reinforced plastic is characterized in that the plastic is made of the following raw material in portion by weight: 9 to 10 portions of gel coat, 60 to 65 portions of RTM resin, 30 to 35 portions of closed modules carpet, and 5 to 6 portions of chopped strand mat. The leisure chair is characterized in that the leisure chair is made of the glass fiber reinforced plastic as the raw materials. The invention uses unsaturated polyester resin, fiberglass cloth, curing agents, accelerator, polyurethane foam and calcium carbonate filling, and the like, uses a pair of foaming molds, a pair of glass fiber reinforced plastic molds, and adopts a resin transfer molding process to manufacture glass fiber reinforced plastic products.

Owner:上海耀华大中新材料有限公司

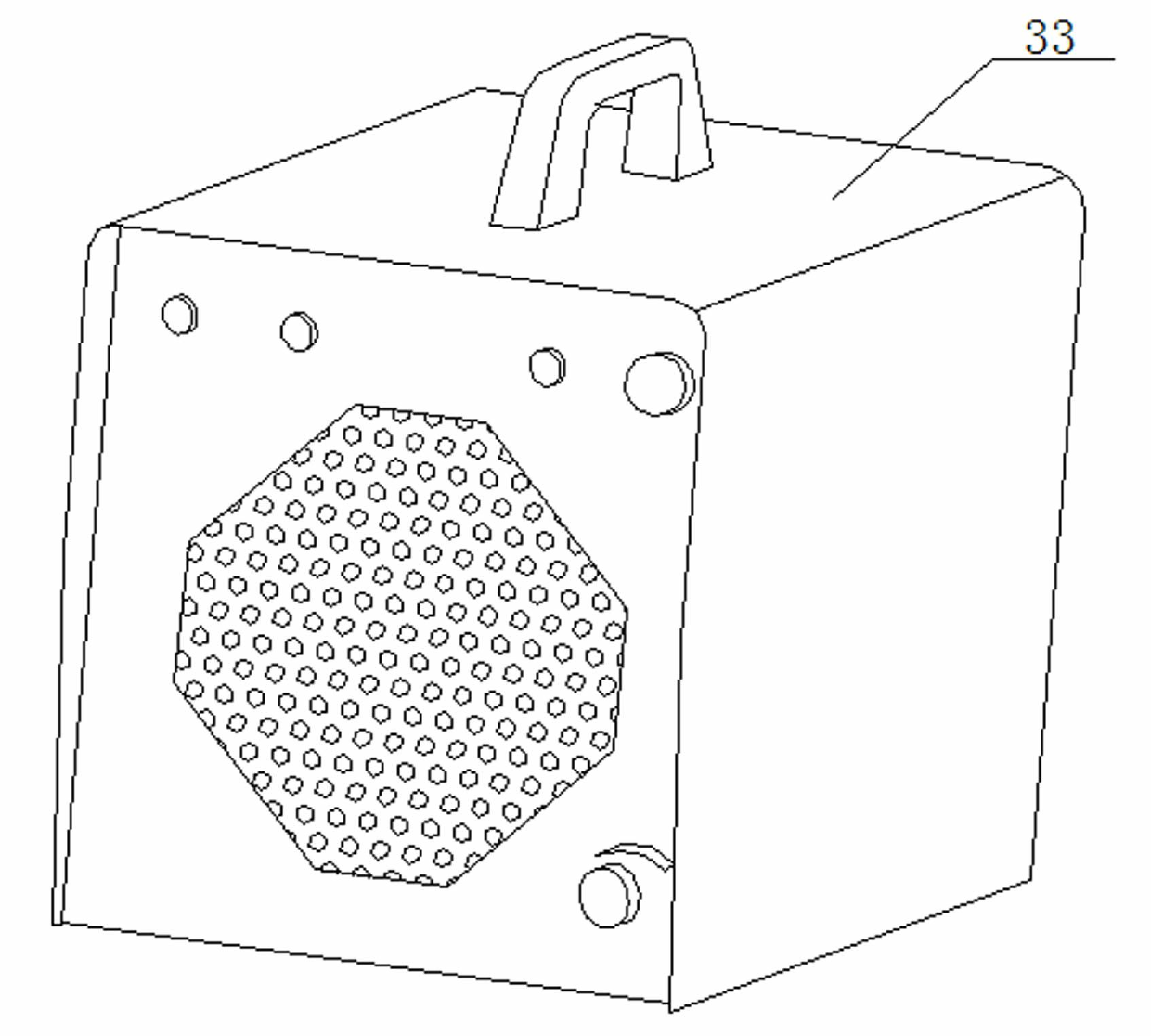

An air cooling device matched with drying equipment

InactiveCN102261831ASolve the above problemsWon't catch fireDrying solid materialsCold airGear wheel

The invention provides an air cooling device matched with drying equipment. The feeding unit is connected to the rotating drum unit, and the rotating drum unit is connected to the cold air supply unit, the discharging unit and the carrying unit; the feeding conveyor is connected to the feeding conveyor belt, and the heat and dust discharge port is connected to the dust storage hopper and the rotating drum. The installation inclination angle between the type drum and the ground is 3° to 5°, the discharge conveyor is connected to the discharge conveyor belt, the cold air supply nozzle is connected to the fan, the fan is connected to the motor, the roller belt is connected to the roller, and the large gear is connected to the gear transmission combination. The lifting plate installed in the rotary drum continuously lifts the material to be refrigerated from top to bottom, and receives the cold air sent by the tail fan for cooling, so that the material reaches a condensed state. The invention adopts the principle of air cooling to cool down the lignite and dust with high temperature and recover the dust, so that there is no fire and no dust during transportation, and the environmental protection and low carbon meet the standard.

Owner:王远大

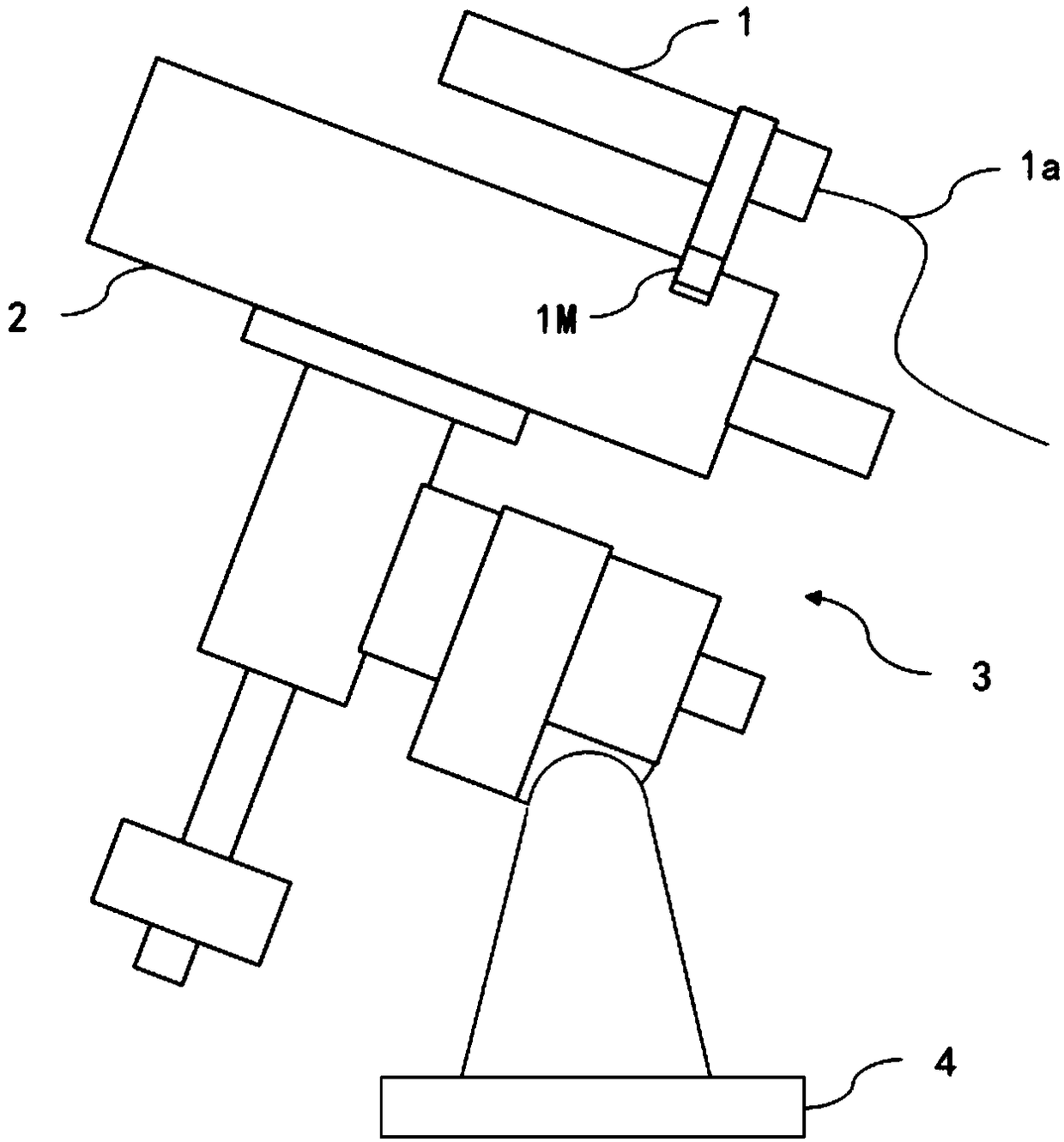

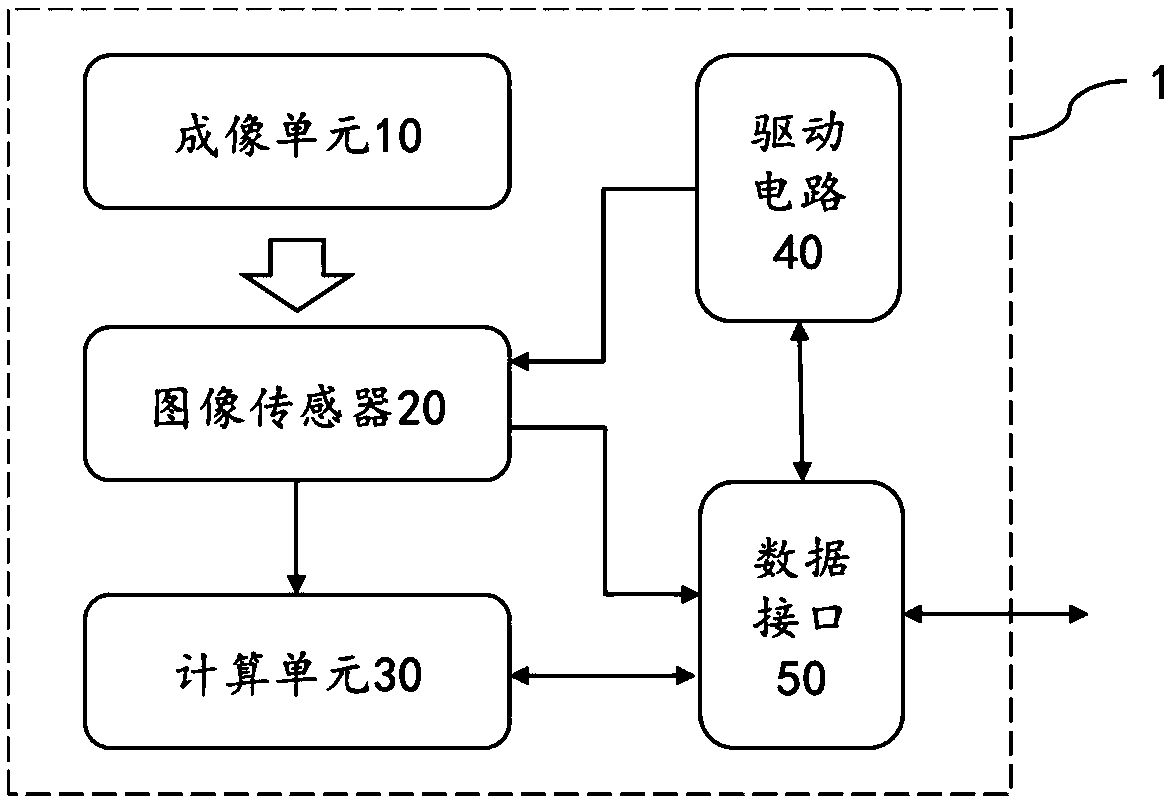

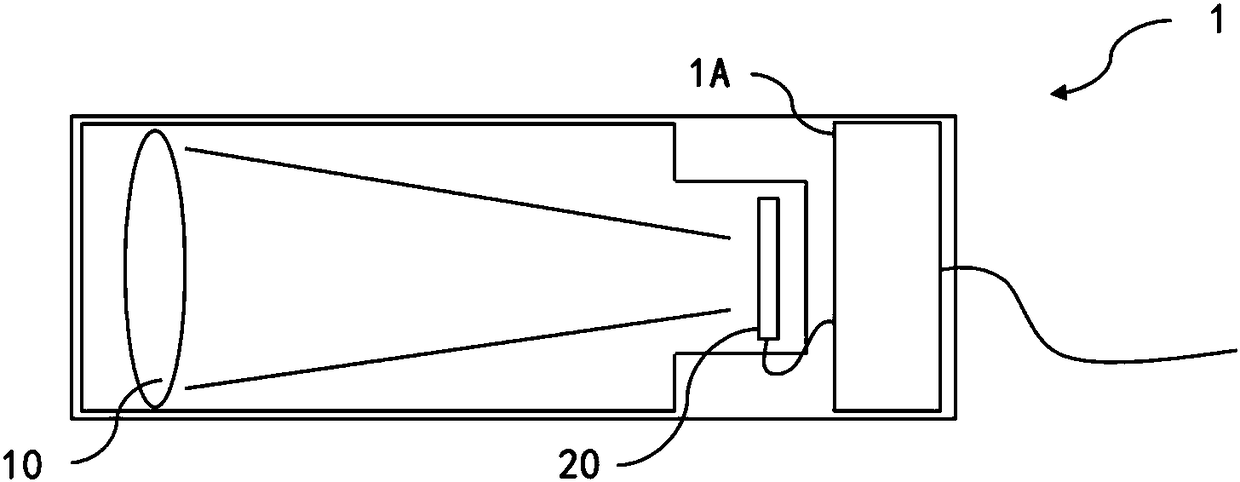

Electronic star-finding mirror, astronomical telescope, and electronic star-finding computing device

PendingCN108594422ASolve the above problemsCharacter and pattern recognitionTelescopesCamera lensSky

The invention discloses an electronic star-finding mirror, which is used for assisting a main telescope of an astronomical telescope to find a target object. The electronic star-finding mirror comprises an imaging unit and an optical lens, wherein the imaging unit comprises an optical lens and is used for imaging the target sky area; an image sensor disposed on a focal plane of an optical lens ofthe imaging unit for sensing an image of a target day region obtained by the imaging unit; and a calculation unit that receives the image from the image sensor and is configured to perform the following processing based on the image: extracting a star point in the image; and identifying the star point in the image to obtain the name and / or the equatorial coordinate of the star point by matching the star point with the star table database. The application also discloses an astronomical telescope comprising the electronic star-finding mirror and an electronic star-finding computing device whichis used for matching with an electronic star-finding mirror. Compared with the traditional optical finder, the electronic star-finding mirror is more convenient for operation and use.

Owner:LIGHT SPEED VISION BEIJING

Die plasma 3D rapid molding equipment and molding method

InactiveCN105689714ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyPlasma generatorMonitoring system

The invention discloses die plasma 3D rapid molding equipment and molding method. The equipment is composed of a monitoring system, a plasma beam machining system, a horizontal printing table for containing a to-be-molded die and a temporary fixing piece; the plasma beam machining system is composed of a plasma generator, an air supply device, a wire feeding device and a printing position adjusting device; the printing position adjusting device comprises a horizontal movement device and a printing distance adjusting device; and the monitoring system comprises a horizontal movement controller, a temperature detecting unit, a distance detecting unit and a printing distance adjusting controller, and a temperature regulation and control unit is composed of the temperature detecting unit and the printing distance adjusting controller. The molding method includes the steps of (1) three-dimensional model obtaining and layered slicing treatment; (2) scanning path filling; (3) scanning path obtaining; and (4) layer-by-layer printing from bottom to top. The die plasma 3D rapid molding equipment is reasonable in design, easy and convenient to operate, high in efficiency and good in using effect, the molding process is directly executed under the atmospheric environment, and the quality of the die is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

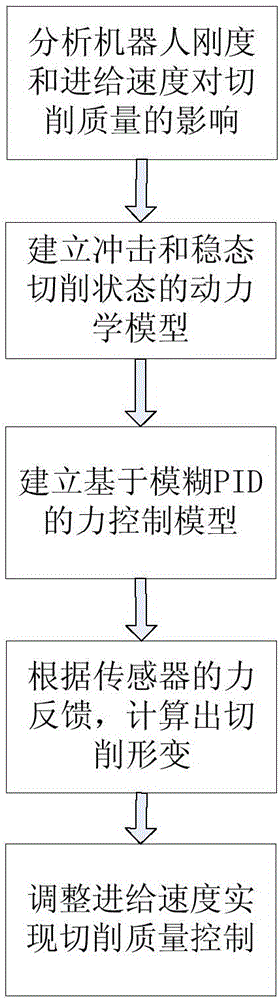

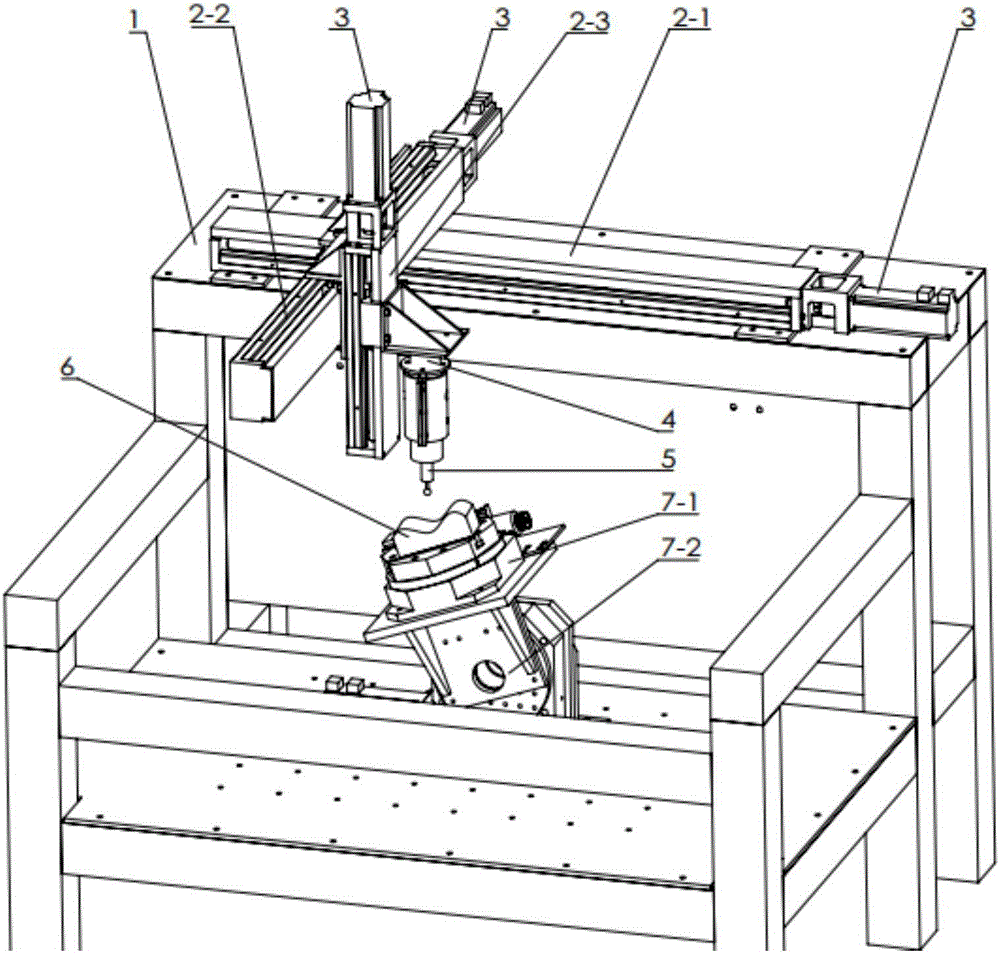

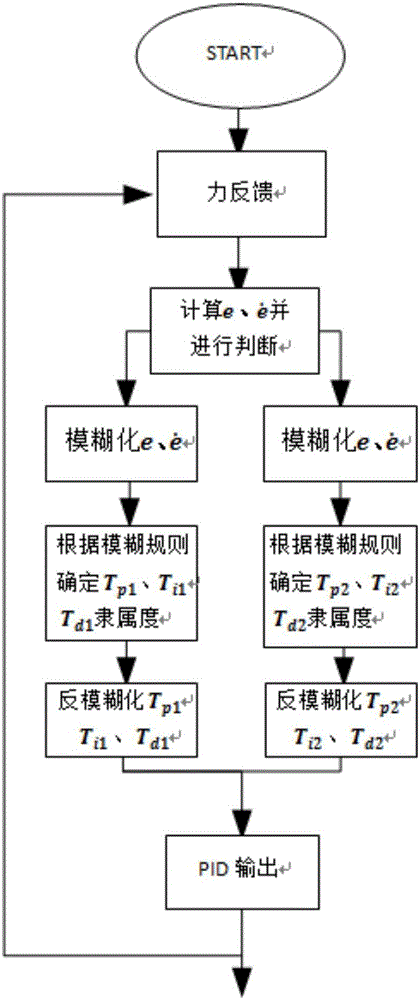

Robot curved-surface cutting force control method for solving deformation problem of robot

ActiveCN106393111ASolve the above problemsProgramme-controlled manipulatorFuzzy ruleRectangular coordinates

The invention discloses a robot curved-surface cutting force control method for solving the deformation problem of a robot. The robot curved-surface cutting force control method comprises the steps that a robot stiffness matrix is established according to the structure of a rectangular-coordinate robot cutting system, then a rigid impacting state and a stable cutting state in the cutting process are set according to the complex of robot cutting, and a robot impacting amplitude formula and a robot stable-cutting deformation formula are derived; and with cutting force as the control target, stress of the tail end of the robot is measured through a six-dimensional force sensor and compared with target force, real-time cutting force errors and the error changing speed are worked out, fuzzy processing is conducted with the real-time cutting force errors and the error changing speed as control input, the PID parameter as fuzzy reasoning output and the feed speed as PID control output, a fuzzy rule is established for classified judgment of the cutting state, the stress of the tail end is tested in real time through the force sensor for judging the cutting force deviation condition and selecting the proper PID parameter, a PID control model is adjusted in real time, and control over the cutting force is achieved by adjusting the robot cutting feed speed.

Owner:SOUTH CHINA UNIV OF TECH

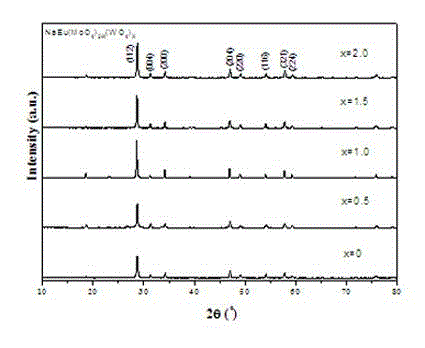

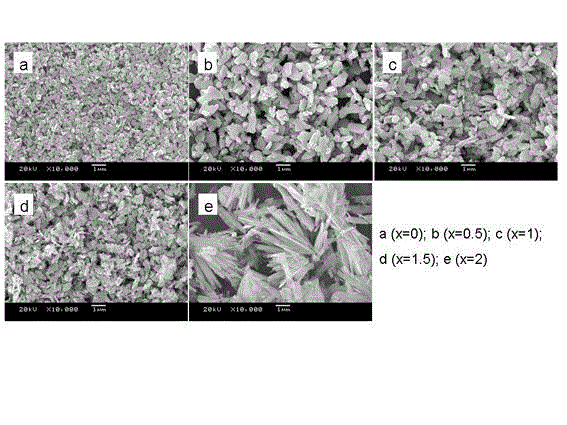

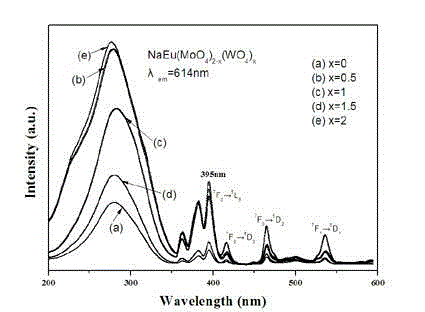

NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals and chemical solution preparation method thereof

InactiveCN102942925ASolve the above problemsImprove practicalityLuminescent compositionsChemical solutionProcess equipment

The invention belongs to the field of scheelite-structure luminescent materials, relates to a research on novel composite tungsten molybdate phosphors which are NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals, and especially relates to a chemical solution preparation method of the NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals. The NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals have a general formula of NaEu(MoO4)2-x(WO4)x, wherein x is greater than or equal to 0 and less than or equal to 2. The chemical solution preparation method comprises the following steps of weighing Na2MoO4 and Na2WO4 solutions having corresponding volumes according to a mole ratio of all raw materials for preparation of a certain amount of the NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals as a target system, putting the weighed Na2MoO4 and Na2WO4 solutions into a Teflon beaker with a stirrer, respectively adding a corresponding amount of an EuCL3 solution into the Teflon beaker, stirring at a normal temperature for 15 to 30 minutes, adjusting a pH value to 6-9, putting the Teflon beaker into a high-pressure reactor, carrying out a hydrothermal reaction process at a temperature of 80 to 160 DEG C for 15 to 30 hours, naturally cooling to a room temperature, carrying out centrifugal separation of precipitates, washing by deionized water, and drying at a temperature of 100 to 150 DEG C to obtain the NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals. The chemical solution preparation method adopts simple process equipment and allows a low reaction temperature. Rare earth-doped tungsten molybdate fluorescent microcrystals obtained by the chemical solution preparation method have a pure phase, a uniform and appropriate particle size and regular morphology, can emit high purity and high brightness red light, and have good practicality.

Owner:SICHUAN NORMAL UNIV

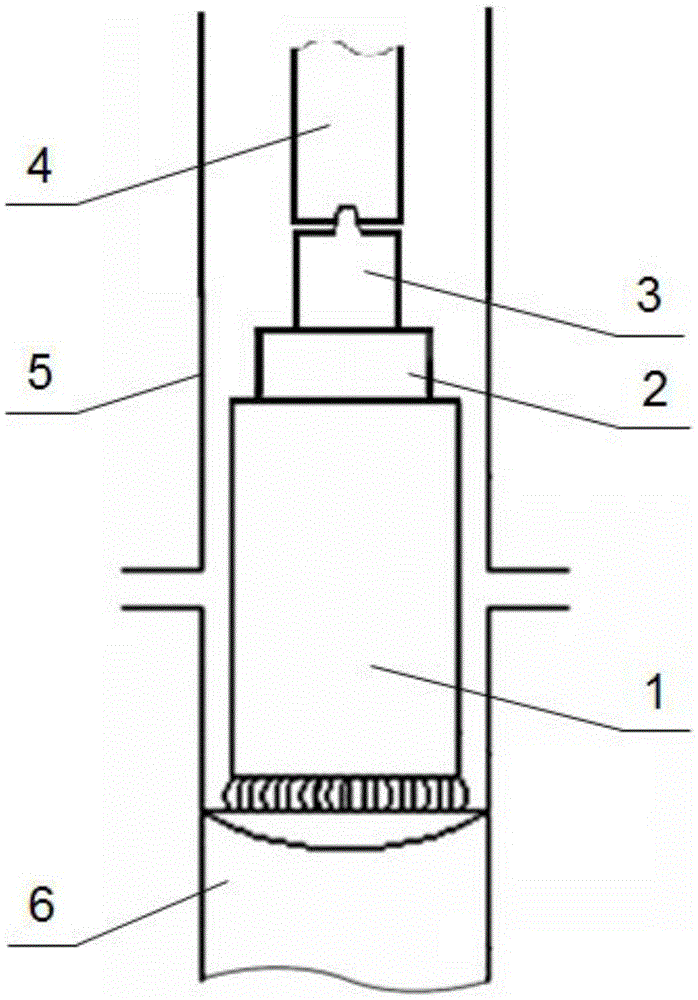

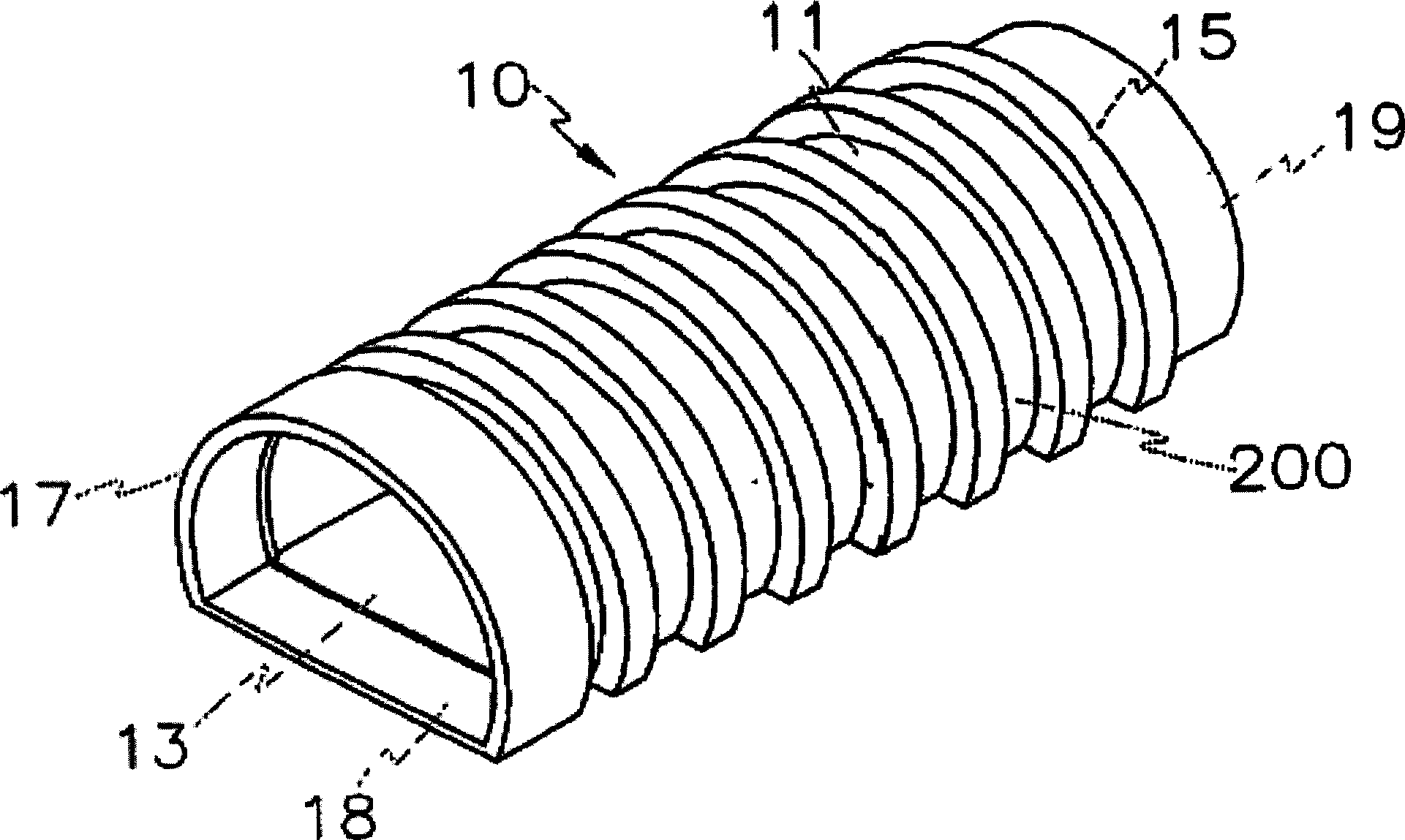

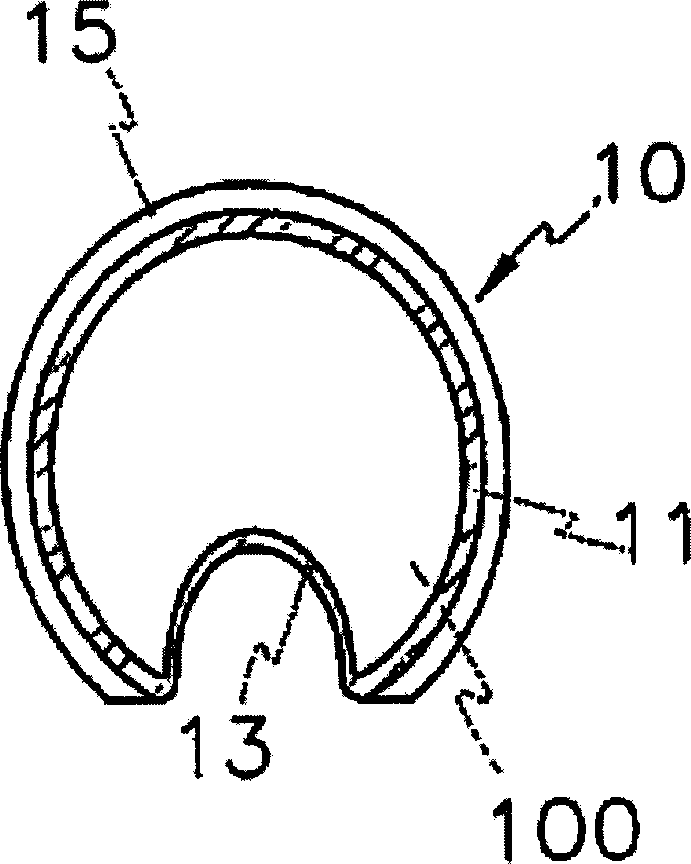

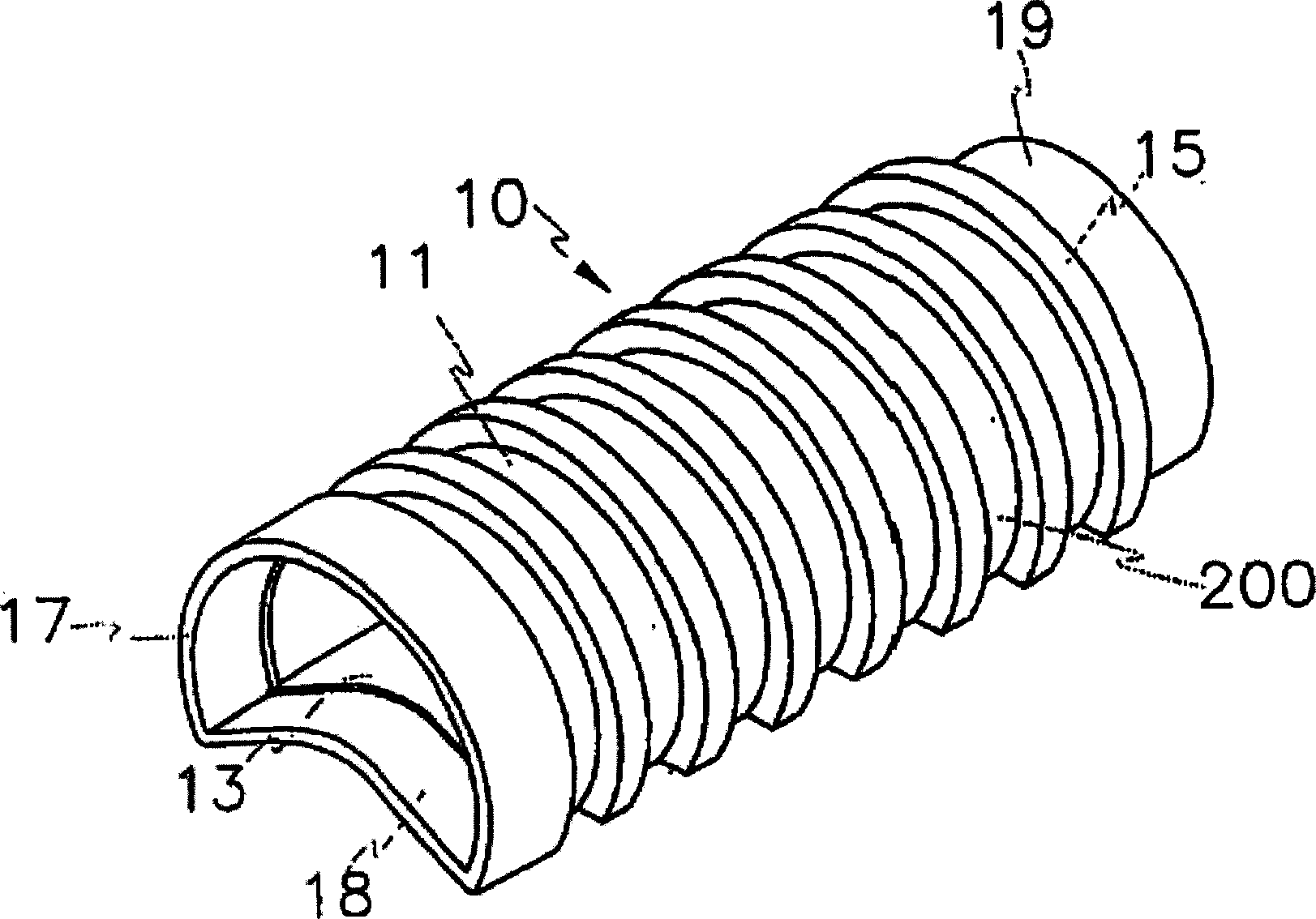

Endoprosthesis

The present invention is to provide an endoprosthesis, generally called a stent, that is designed to be firmly fixed into patient's body lumen regardless of the change of configuration of a body lumen such as an airway, thereby improving its stability and increasing its durability by flexibly and increasing its durability by flexibly corresponding to the operating state of the body lumen such as the airway.

Owner:医学界一流股份公司

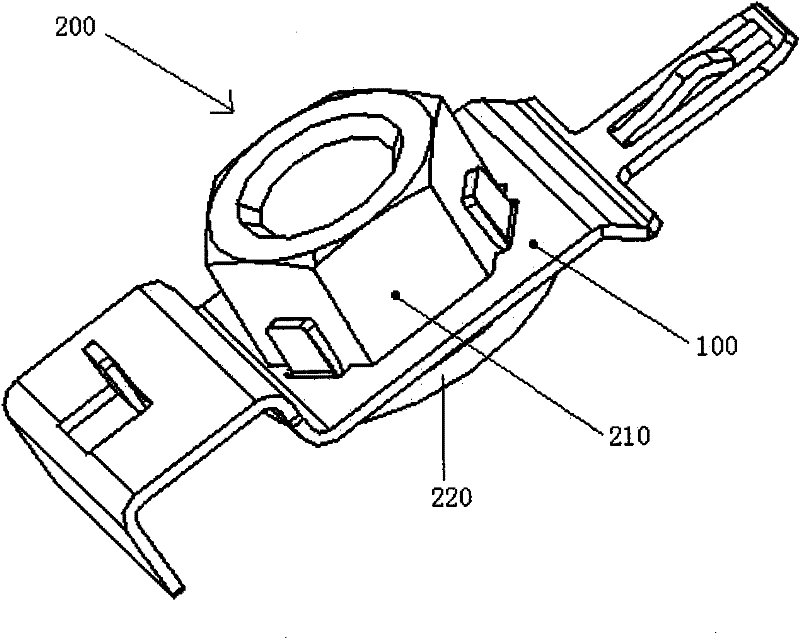

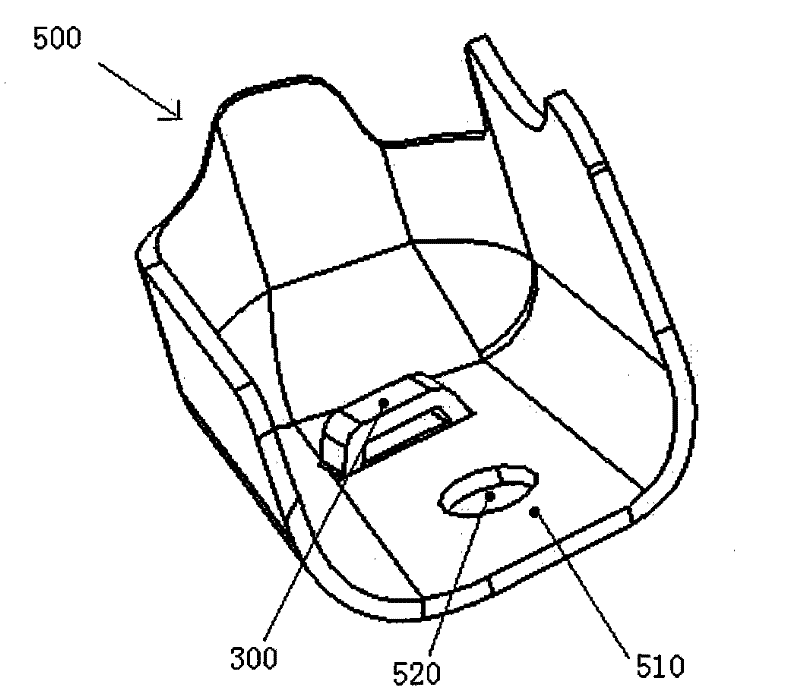

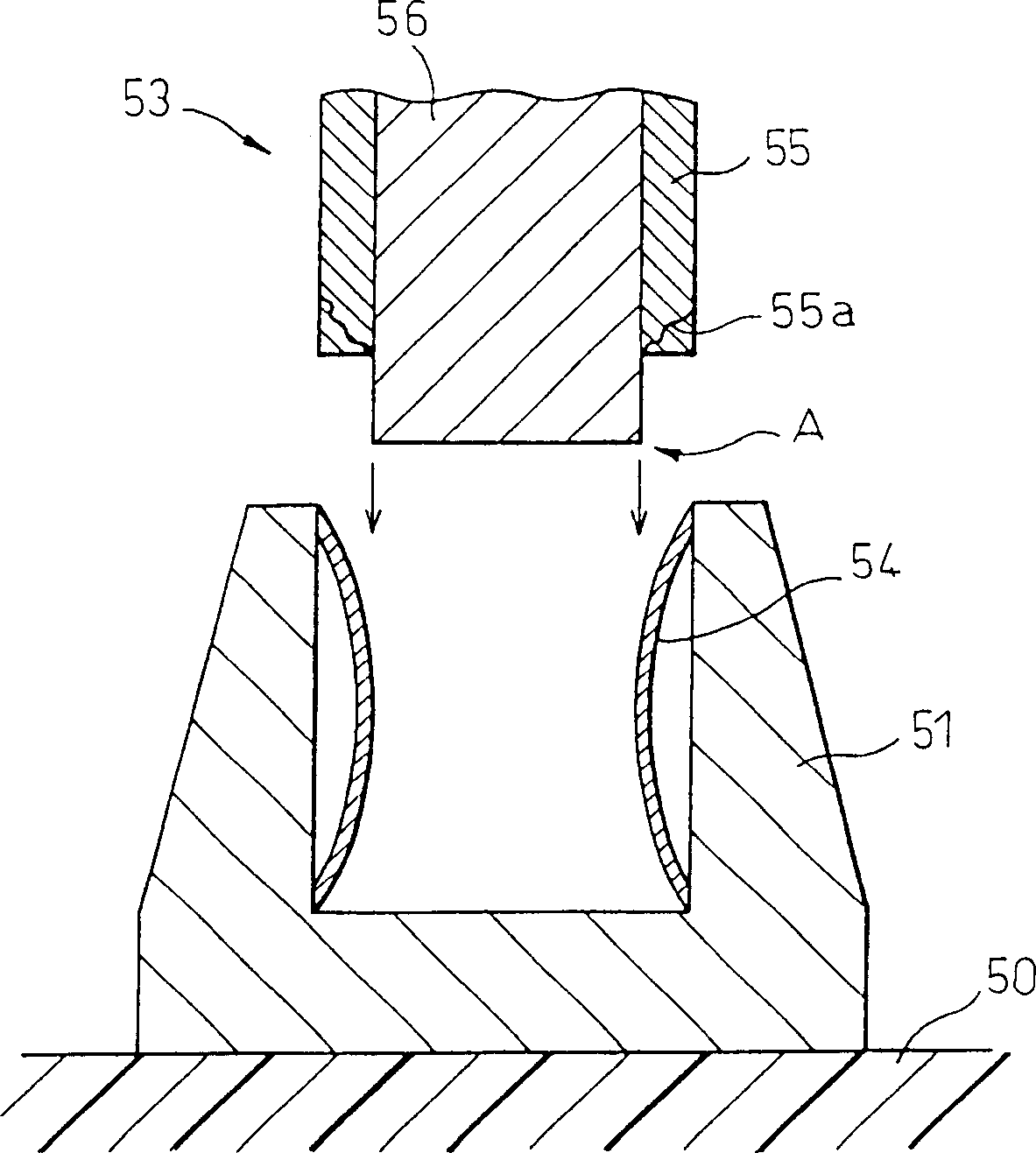

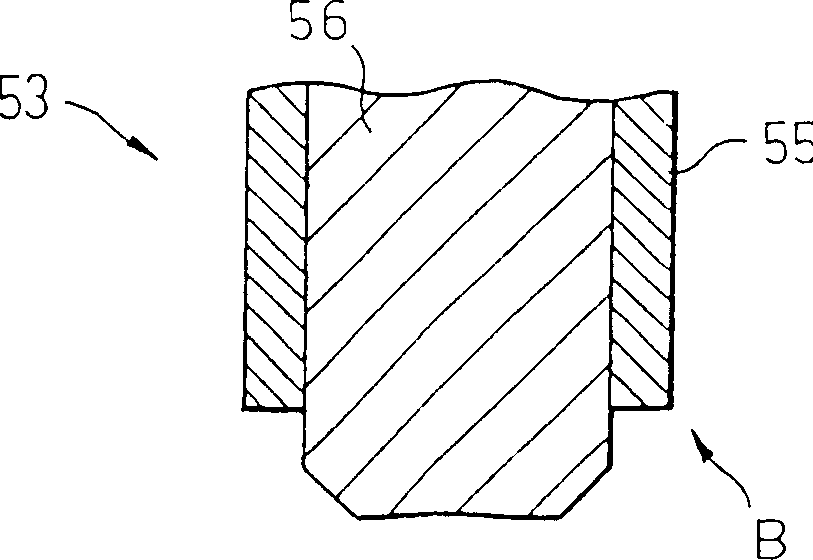

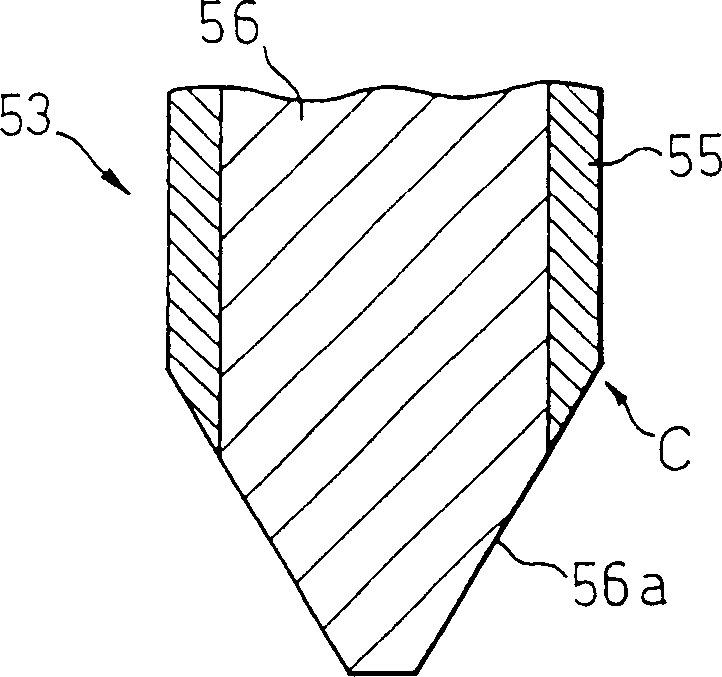

Nut fixed piece and nut fixed structure

Owner:BEIQI FOTON MOTOR CO LTD

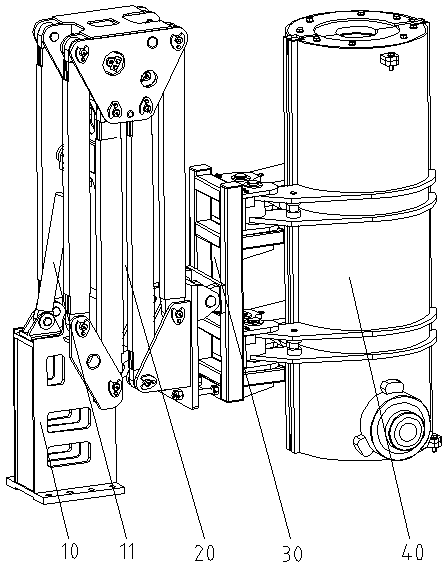

Recycling device of mud generated during well drilling and well repairing

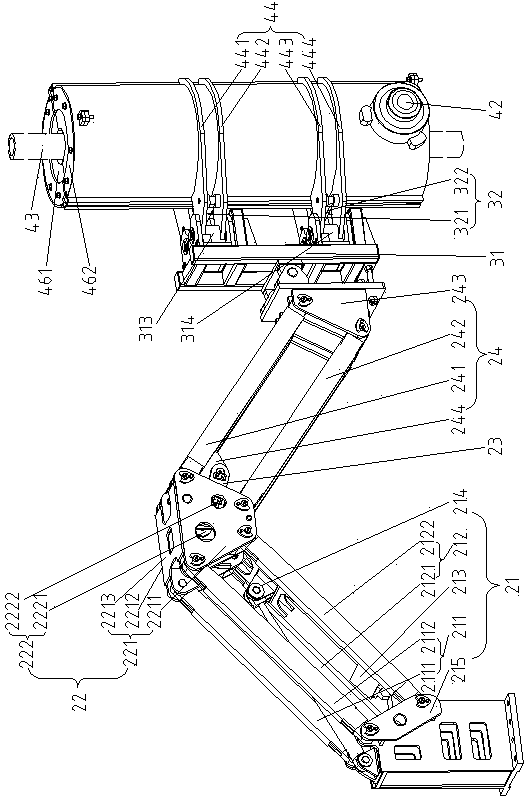

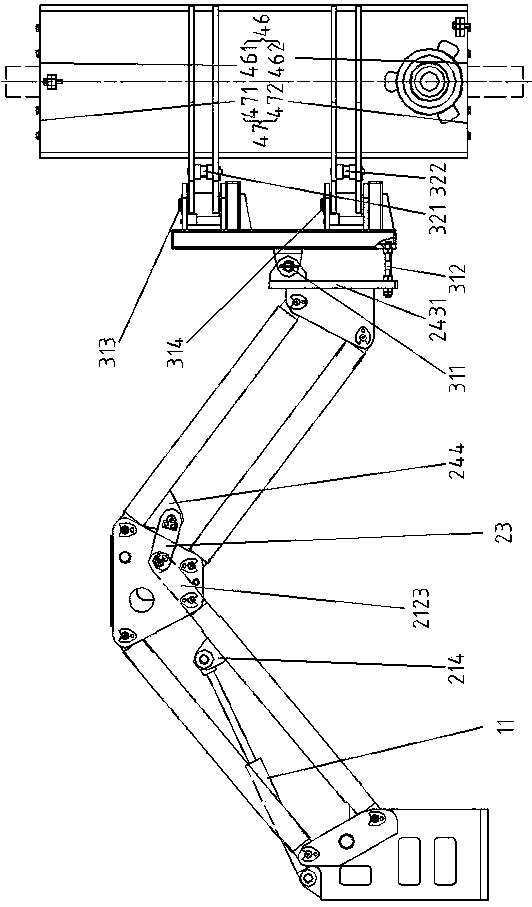

A recycling device of mud generated during well drilling and well repairing comprises a supporting and stretching frame foundation, a supporting and stretching hydraulic cylinder, a supporting and stretching frame, an opening and closing type clamping mechanism and a mud barrel. The recycling device of the mud generated during well drilling and well repairing is of a bionic arm structure. Only one supporting and stretching hydraulic cylinder is needed to drive a rear supporting and stretching frame body and a front supporting and stretching frame body of the supporting and stretching frame to move at the same time so as to achieve the stretching and folding of the supporting and stretching frame. Compared with an existing recycling device of the mud generated during well drilling and well repairing which is driven by multiple cylinders, the recycling device of the mud generated during well drilling and well repairing has the advantages that the structure is more compact, a control system is simple and higher in reliability, and the centering capacity of the mud barrel is good. Furthermore, due to the fact that the supporting and stretching frame can be folded when the recycling device is not used, the recycling device of the mud generated during well drilling and well repairing has the advantages that occupied space is reduced and influence on working of other tools is reduced when compared with an existing recycling device of the mud generated during well drilling and well repairing which is driven by a single cylinder.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

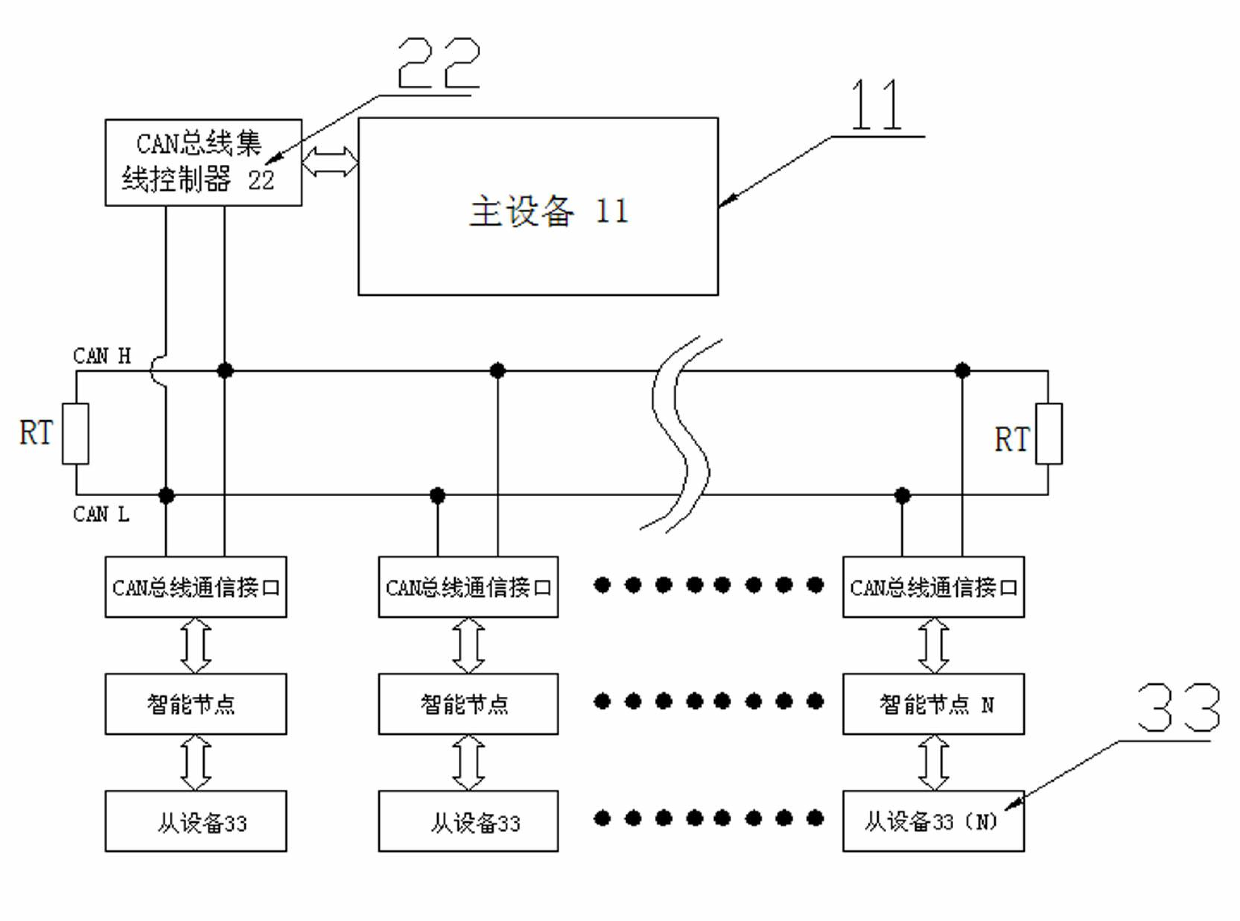

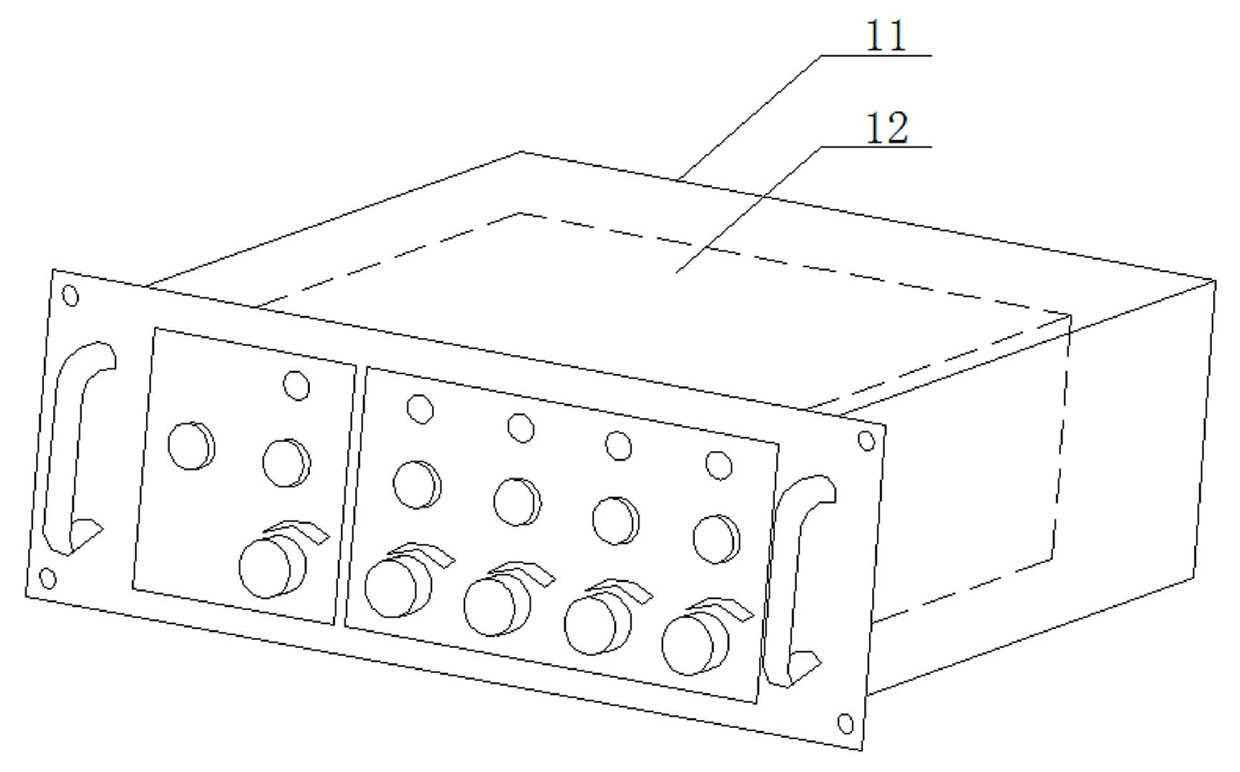

Digital duplex remote networking wired interphone

InactiveCN102420628ASolve the above problemsAdd shockproof function designTransmissionCommunication interfaceArea network

The invention discloses a digital duplex remote networking wired interphone and relates to the technical field of interphones. The digital duplex remote networking wired interphone comprises master equipment (11), a controller area network (CAN) bus line concentration controller (22) and slave equipment (33), wherein the master equipment (11) is connected with the CAN bus line concentration controller (22); the slave equipment (33) is connected with intelligent nodes which are distributed at all logging well holes; and the intelligent nodes are connected with the CAN bus line concentration controller (22) through CAN bus communication interfaces and cables. By adoption of the digital duplex remote networking wired interphone, real-time voice communication between an operator in a well logging vehicle and staff on a well can be realized. The digital duplex remote networking wired interphone has a voice communication protocol at a security level, can stably operate under the severe working condition, and has the characteristics of water-proof, moisture-proof and dust-proof performance, wide working temperature range, and the like.

Owner:DAQING LIANSHENG TECH

Graphite composited overhead ground wire and preparation method thereof

ActiveCN104599743AImprove conductivityImprove tensile propertiesNon-insulated conductorsMetal/alloy conductorsCarbon fibersSkin effect

The invention provides a graphite composited overhead ground wire and a preparation method thereof. The graphite composited overhead ground wire comprises an inner core composed of a first composited graphite line, a secondary outer layer which is formed by lengthways arranging second composited graphite lines about the outer side of the inner core, and an outermost layer which is formed by knitting metal fibers about the secondary outer layer; the secondary outer layer completely wraps the inner core, and the outermost layer completely wraps the secondary outer layer; the first composited graphite line is prepared by intertwining composited graphite strips; the second graphite lines are prepared by intertwining the composited graphite strips about the metal fibers; each composited graphite strip comprises two vermicular graphite layer, a framework fiber and a carbon fiber, wherein the framework fiber and the carbon fiber are paved between the two graphite layers and are wrapped with adhesive layers. The graphite composited overhead ground wire has the advantages of being light in weight, low in resistance, low in inductive reactance and low in surface effect; the graphite composited overhead ground wire can be matched with an arrester so as to expand the lightning protection range of the overhead ground wire; in addition, the process is simple, the cost is low, and the engineering application effect is obvious.

Owner:WUHAN UNIV

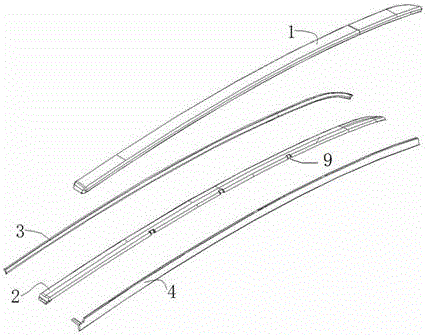

Three-color external decoration strip for automobile windshield and forming mold and method thereof

ActiveCN105965768AImprove appearance qualityImprove the level of environmental protectionEngine sealsVehicle sealing arrangementsEngineeringSpecular surface

The invention discloses a three-color external decoration strip for an automobile windshield and a forming mold and method of the three-color external decoration strip. The three-color external decoration strip for the automobile windshield comprises an ABS framework, a PMMA specular surface layer and TPU soft edges. The PMMA specular surface layer and the TPU soft edges are arranged on the ABS framework. The ABS framework 2 is provided with injection molding channels communicating with the front TPU soft edge 3 and the back TPU soft edge 4. According to the forming mold, the body framework is placed in a double-color injection mold as an insert, and then the three-color specular product, which is integrally formed from the three materials comprising the ABS body framework, the PMMA specular body surface layer and the TPU soft edges, is obtained; and besides, the technical breakthrough of front and back rubber coating is achieved through the combination of sliding blocks and sealing rubber cutters, and the problems caused when existing three-color injection molds are used are well solved. According to the three-color external decoration strip for the automobile windshield, under the condition of the same structure, the appearance quality and the environmental protection level of products are improved, and the product cost and the product weight are reduced.

Owner:湖南浩润汽车零部件有限公司

Foam PS transom proximate matter and a preparation method thereof

InactiveCN101445632AOvercome shortcomingsAvoid pollutionVentilation arrangementWing framesFoaming agentPolystyrene

The invention relates to a transom proximate matter and also relates to a preparation method thereof. A foam Ps transom proximate matter comprises a base material which is characterized in that the base material comprises the following raw materials according to the weight by parts: 50-75 parts of EPS regeneration particles, 25-50 parts of HIPS, 0.5-1.0 parts of saleratus, 0.1-1.5 parts of AC vesicant, and 2-4 parts of blowing promoter. The foam PS transom proximate matter prepared by a coextrusion method inherits the advantages of wood and micro expanded materials and overcomes shortcomings of the two materials. The raw material of the base material of the foam Ps transom proximate matter uses expandable polystyrene (EPS) in a great measure, thoroughly solves so called 'white foam' pollution in manufacturing production and current production; and scrapping materials can be recycled and reused in course of processing.

Owner:SHANGHAI BESTON PLASTICS

Skin-care product contg. tortoise skin collagen composition, and its prepn. method

InactiveCN1785160ASolve the above problemsCosmetic preparationsToilet preparationsHydroxyprolineHypersensitive response

A skin-protecting protect for suppress lipid peroxide, delaying sanility and removing spots and wrinkles features that its additive contains turtle skin collagen which is prepared from turtle skin through extracting by enzymolyzing.

Owner:HUNAN NORMAL UNIVERSITY

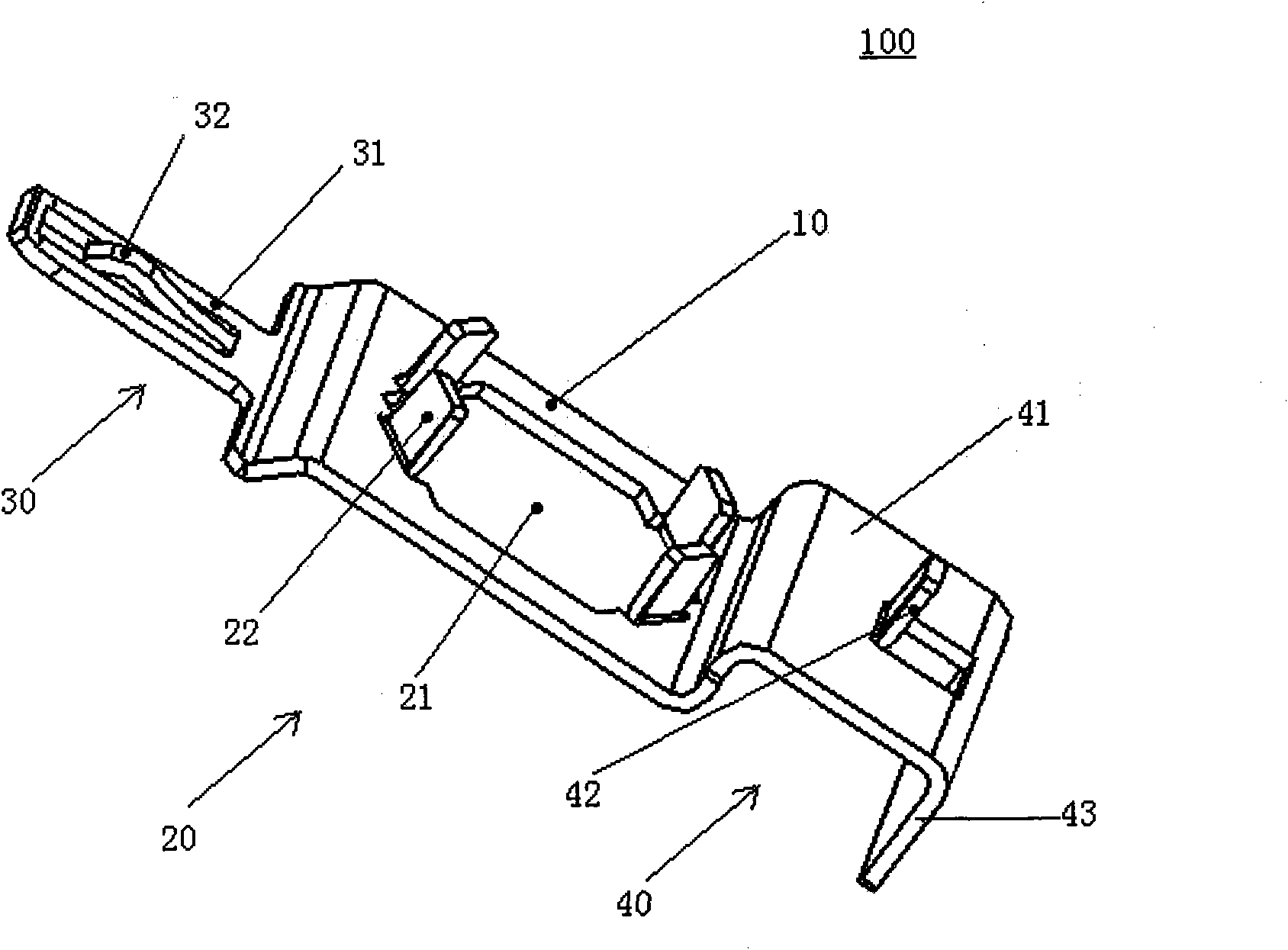

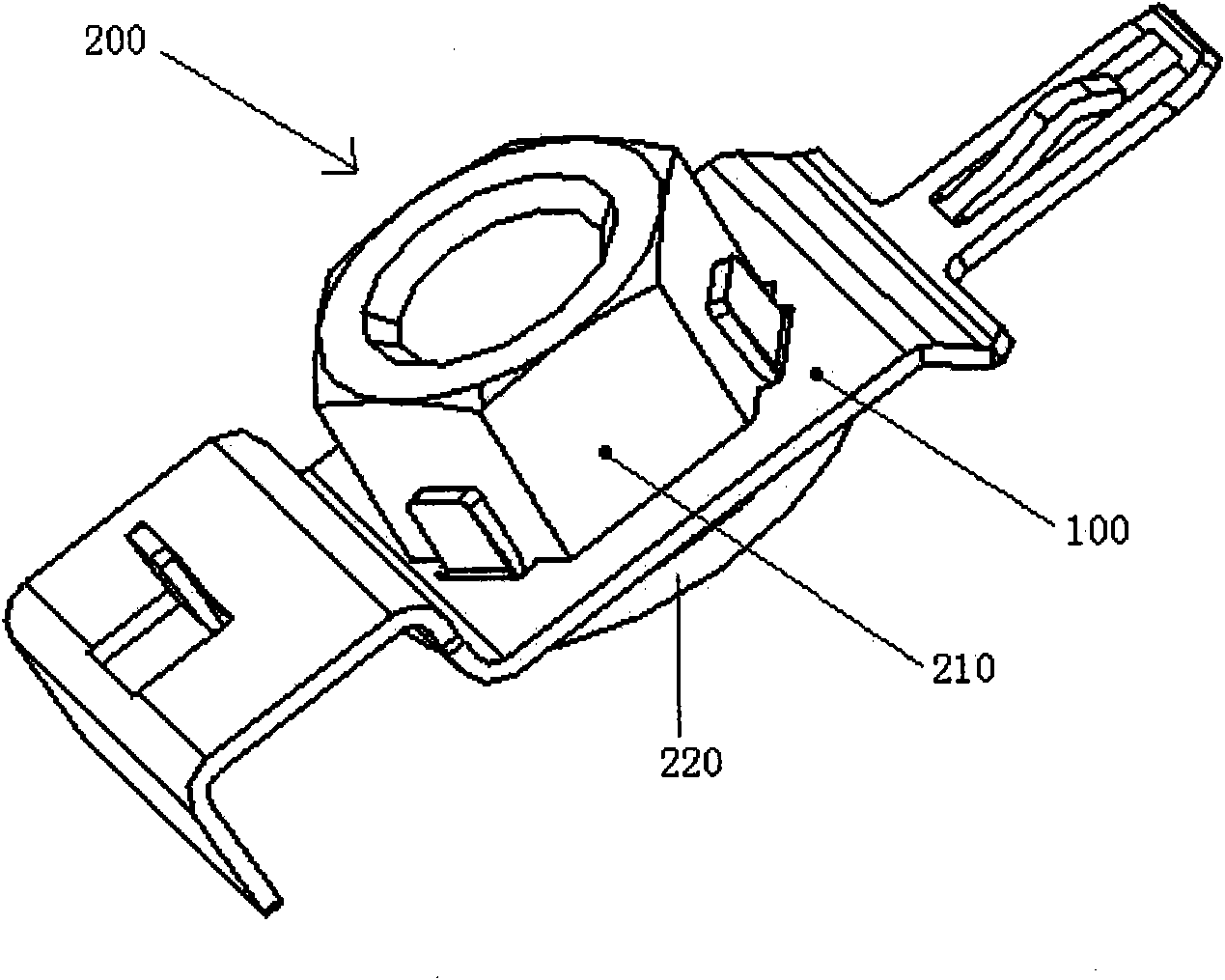

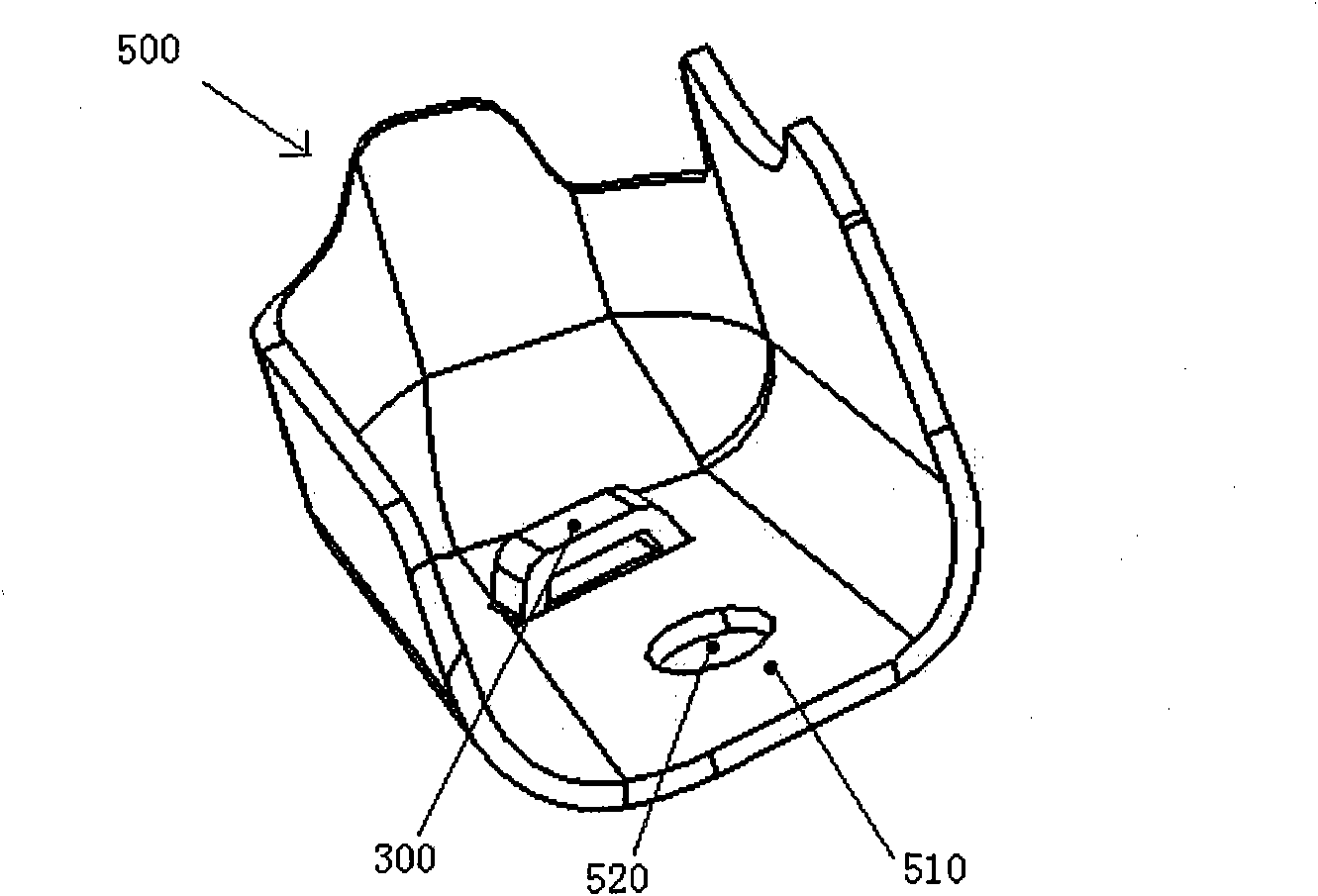

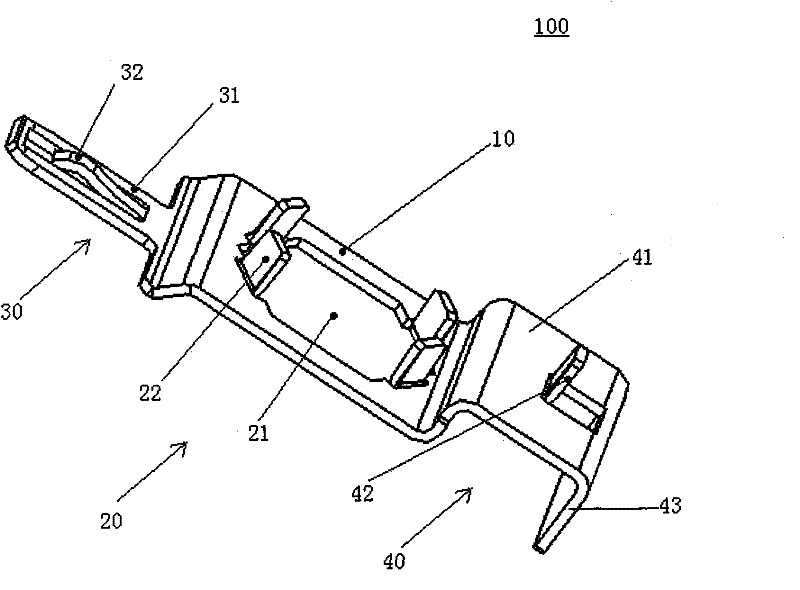

Nut fixed piece and nut fixed structure

ActiveCN101839269BSimple structureSolve the above problemsNutsSecuring devicesEngineeringMechanical engineering

Owner:BEIQI FOTON MOTOR CO LTD

Bayonet connector, its mfg. method, electronic insertion sheet and electronic appliance

InactiveCN1278460CSolve the above problemsEasy to manufacturePrinted circuit assemblingLine/current collector detailsExtremity PartEdge connector

A card edge connector comprises a connector body and a conductive pad, and is constructed such that the conductive pad terminates at a predetermined distance from the end of the tip portion of the connector body, and that there is further provided a protective pad, adjacent to the terminating portion of the conductive pad, which is formed at the same time with the formation of a wiring pattern in a post-fabrication step of the wiring pattern. Using the card edge connector, an electric card and an electric equipment are also provided.

Owner:FUJITSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com