Positive electrode of lithium-sulfur battery with multifunctional elastic protection layer

A lithium-sulfur battery, protective layer technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., to achieve the effect of alleviating structural damage and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

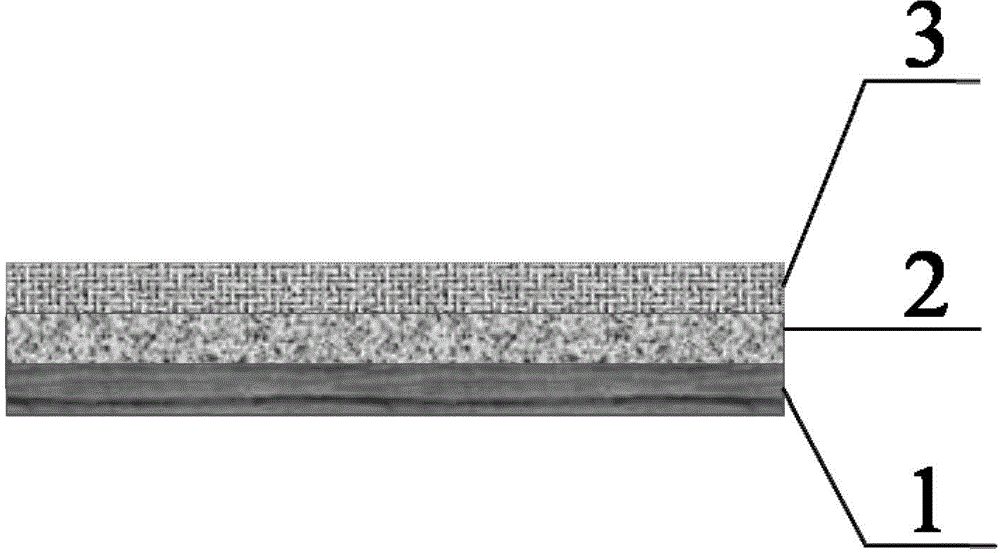

preparation example Construction

[0032] The preparation method of the positive electrode material layer is not limited, for example, it can be prefabricated by coating. In one example, the positive electrode material layer formed as a positive electrode sheet is prepared by mixing sulfur, conductive carbon black, and a binder to form a slurry, coating it on the surface of the current collector or conductive film, and then drying and rolling. And cutting to get the electrode sheet. In another example, the positive electrode material layer formed into the positive electrode sheet is prepared by the following method: heat-treating the mixture of sulfur and conductive material, then mixing it with conductive carbon black and a binder to form a slurry, and coating it on the current collector or The surface of the conductive film is dried, rolled and cut to obtain an electrode sheet. In another example, the preparation method of the unsupported positive electrode film includes the following steps: ultrasonically di...

Embodiment 1

[0052] 1. Mix the conductive agent Ketjen black with sublimated sulfur and binder styrene-butadiene rubber carboxyl & methyl cellulose in solvent water through ball milling. In the slurry, the quality of conductive agent Ketjen black, sublimated sulfur and binder The ratio is 40:50:10, the anode of lithium-sulfur battery is prepared by drying after coating on aluminum foil;

[0053] 2. Dissolve acetylene black and polyacrylonitrile in a nitrogen, nitrogen-dimethylformamide solution at a mass ratio of 1:1, and stir well to obtain a precursor solution;

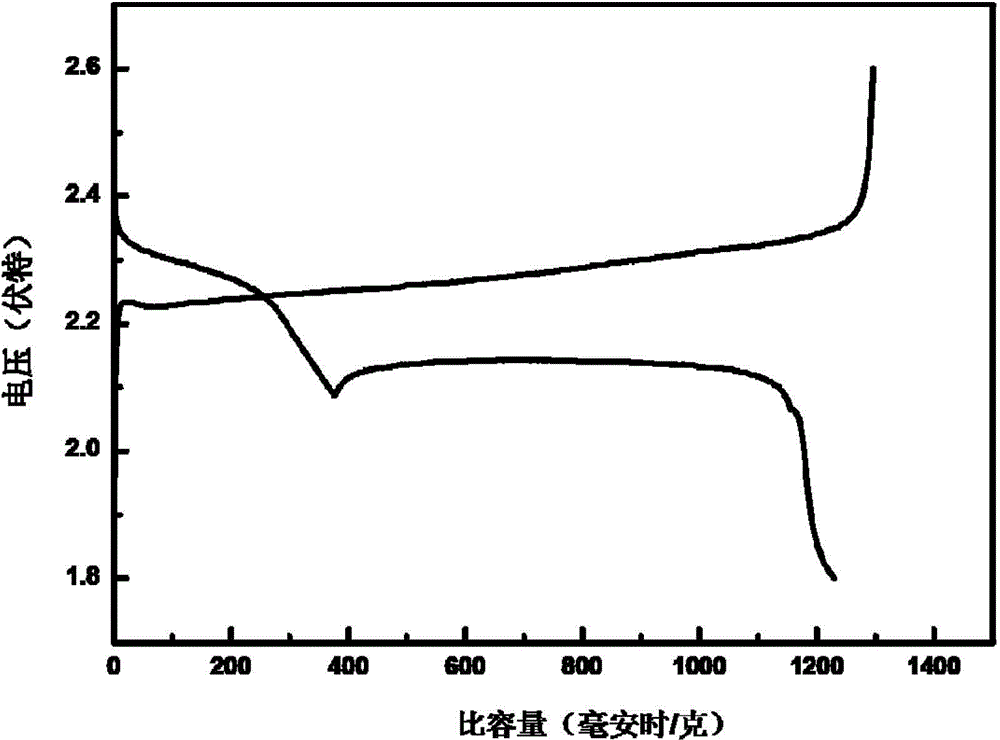

[0054] 3. Transfer the precursor solution to the syringe of the electrospinning instrument, the DC voltage is 15KV, the working distance is 15cm, the pre-prepared lithium-sulfur battery cathode is used to collect the nanofibers, and after drying, they are rolled to obtain a nanofiber protective layer structure Lithium-sulfur battery positive electrode. Use this electrode as the positive electrode and metal lithium as the counter ele...

Embodiment 2

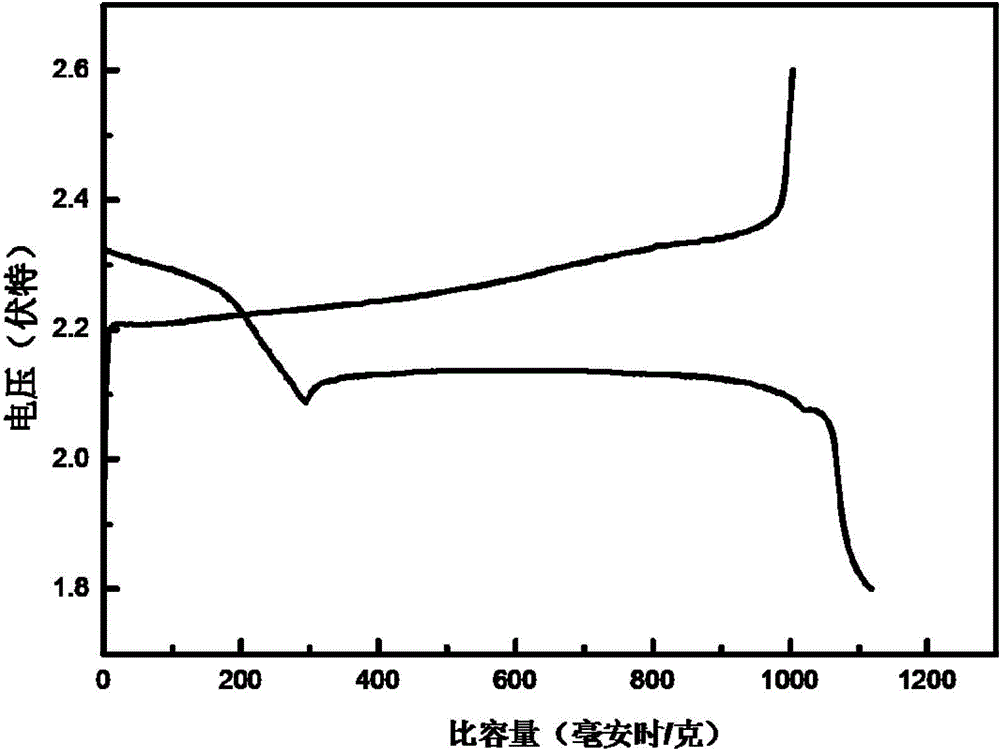

[0058] 1. The conductive agent Ketjen black, sublimed sulfur and binder polyvinylidene fluoride are uniformly mixed by ball milling in the solvent N-methylpyrrolidone to make a slurry. In the slurry, the conductive agent Ketjen black, sublimated sulfur and viscose The mass ratio of the binder is 40:50:10, the aluminum foil is coated and then dried, and after the solvent is volatilized, vacuum drying is performed to prepare the pre-prepared lithium-sulfur battery positive electrode;

[0059] 2. Select conductive graphite material, prepare a porous conductive layer on the surface of the lithium-sulfur battery positive electrode prepared by a nano-printer, and roll it after drying to obtain a lithium-sulfur battery positive electrode protected by an elastic layer structure. The thickness of the protective layer is about 5.2 μm. The scanning electron microscope photo of the cross section of the positive electrode of the lithium-sulfur battery is as Image 6 Shown. The CR2025 button ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com