Fuel cell system including heat exchanger

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell components, etc., can solve the problems of increasing the cost of fuel cell systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

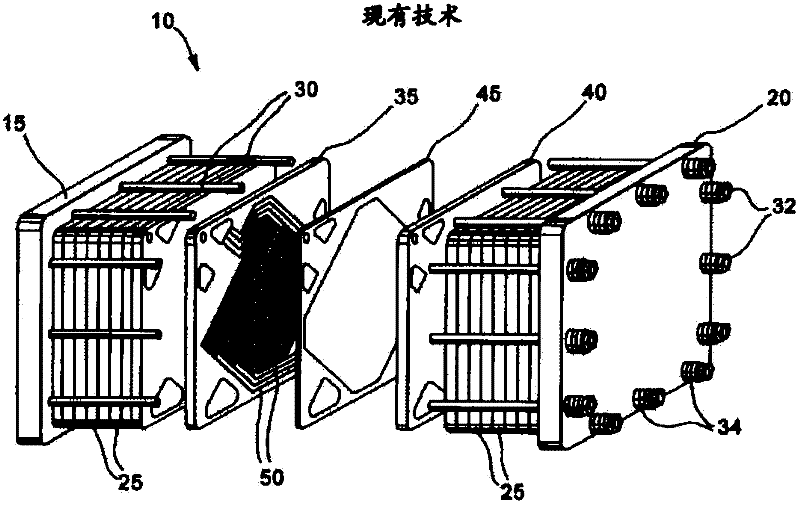

[0016] figure 1 The prior art proton exchange membrane fuel cell stack 10 is shown in an exploded view. The stack 10 includes a pair of end plate assemblies 15 and 20 and a plurality of fuel cell assemblies 25. In this particular example, an electrically insulating tie rod 30 extends between the end plate assemblies 15, 20 to hold and fix the stack assembly 10 in its assembled state by means of a fastening nut 32. A spring 34 interposed between the fastening nut 32 and the end plate 20 pierced on the tie rod 30 applies an elastic compression force to the stack 10 in the longitudinal direction. Reactant and coolant fluid streams are provided to internal manifolds and passages in the stack 10 through inlets (not shown) in the end plate 15 and discharged from outlets (not shown).

[0017] Each fuel cell assembly 25 includes an anode flow field plate 35, a cathode flow field plate 40, and an MEA 45 interposed between the plates 35 and 40. The anode and cathode flow field plates 35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com