Three-color external decoration strip for automobile windshield and forming mold and method thereof

A windshield and decorative strip technology, which is applied in the field of automotive windshield three-color outer decorative strip and its forming molds, can solve the problems of three-color product shape and structure restrictions, high equipment investment and mold cost, soft adhesive Solve problems such as poor connection reliability, achieve good practical value, reduce product weight, and improve appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

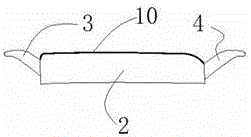

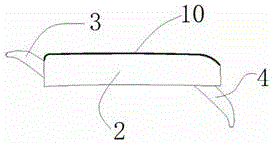

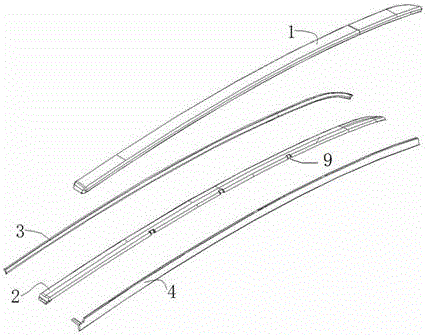

[0029] See image 3 , Figure 4 , the automotive windshield three-color exterior trim strip of the present invention comprises an ABS skeleton 2, a PMMA high-gloss surface layer 1, a TPU front soft edge 3 and a TPU reverse soft edge 4, the PMMA high-gloss surface layer, a TPU front soft edge 3 and a TPU reverse surface The soft edges 4 are all arranged on the ABS skeleton 2, and the ABS skeleton 2 is provided with an injection molding channel 9 communicating with the TPU front soft edges 3 and the TPU reverse soft edges 4; the PMMA high-gloss surface layer 1 is arranged on the There is a hemming on the top of the ABS skeleton 2, and the soft edge 3 on the front side of the TPU and the soft edge 4 on the back side of the TPU are respectively arranged on one side of the PMMA high-gloss surface layer 1 and under the hemming.

[0030] The molding injection mold of the above-mentioned automobile windshield three-color exterior trim strip of the present invention, as Figure 5 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com