Dual-axis tracking type photovoltaic or photo-thermal support

A two-axis tracking, photothermal technology, applied in the direction of use feedback control, etc., can solve the problems of strong volatility, short service life, damage to surface vegetation, etc., to improve the absorption efficiency and duration, the overall structure is simple and stable, and the adjustment method simple and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

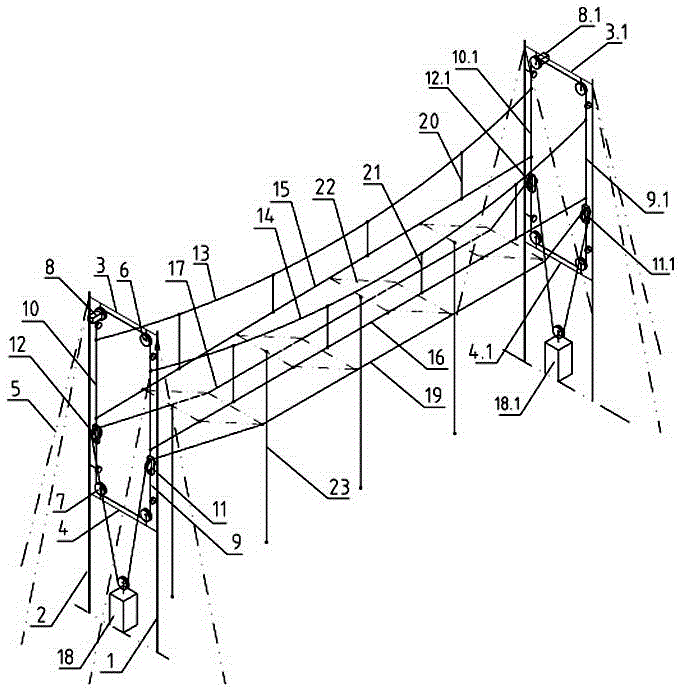

[0028] Such as Figure 1-6 As shown, the dual-axis tracking photovoltaic or photothermal support of the present invention includes a left bearing frame and a right bearing frame arranged longitudinally at intervals from north to south, the left bearing frame is located on the north side, and the right bearing frame is located on the south side; the left bearing frame The frame and the right bearing frame have the same structure, including:

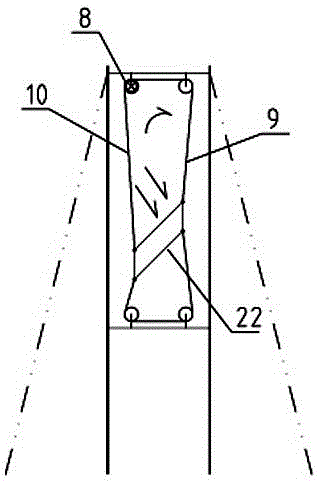

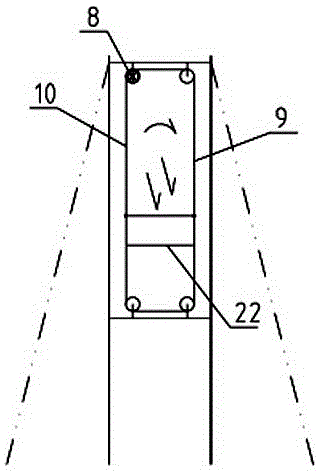

[0029] The front column 1 and the rear column 2 are arranged at intervals along the transverse direction, and the front and rear columns 1 and 2 are connected by the upper beam 3 and the lower beam 4 to form a rectangular frame. The support cable 5 is auxiliary fixed, and is used to offset the load tension on the upper and lower beams 3 and 4; a flexible cable slewing unit is arranged in the rectangular frame, and the flexible cable slewing unit is composed of two fixed pulleys respectively arranged on the upper beam 3 6 and two fixed pul...

Embodiment 2

[0038] Such as Figure 7 As shown, the structure of the dual-axis tracking photovoltaic or photothermal support described in this embodiment is the same as that in Embodiment 1, and also includes a left bearing frame and a right bearing frame arranged longitudinally from north to south, and the left bearing frame is located on the north side , the right bearing frame is located on the south side; the left and right bearing frames have the same structure. The difference between this embodiment and Embodiment 1 is that four flexible cable slewing units are arranged in the rectangular frame to form an array platform to expand the scale, and then a large-scale dual-axis tracking photovoltaic / photovoltaic system is formed by cascading multiple above-mentioned platforms. thermal power station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com