Liquid discharging device and liquid discharging method

A technology of equipment and droplets, applied in inking device, printing and other directions, can solve the problems of complex selection of driving print heads, equipment burden, and inconspicuous stripes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

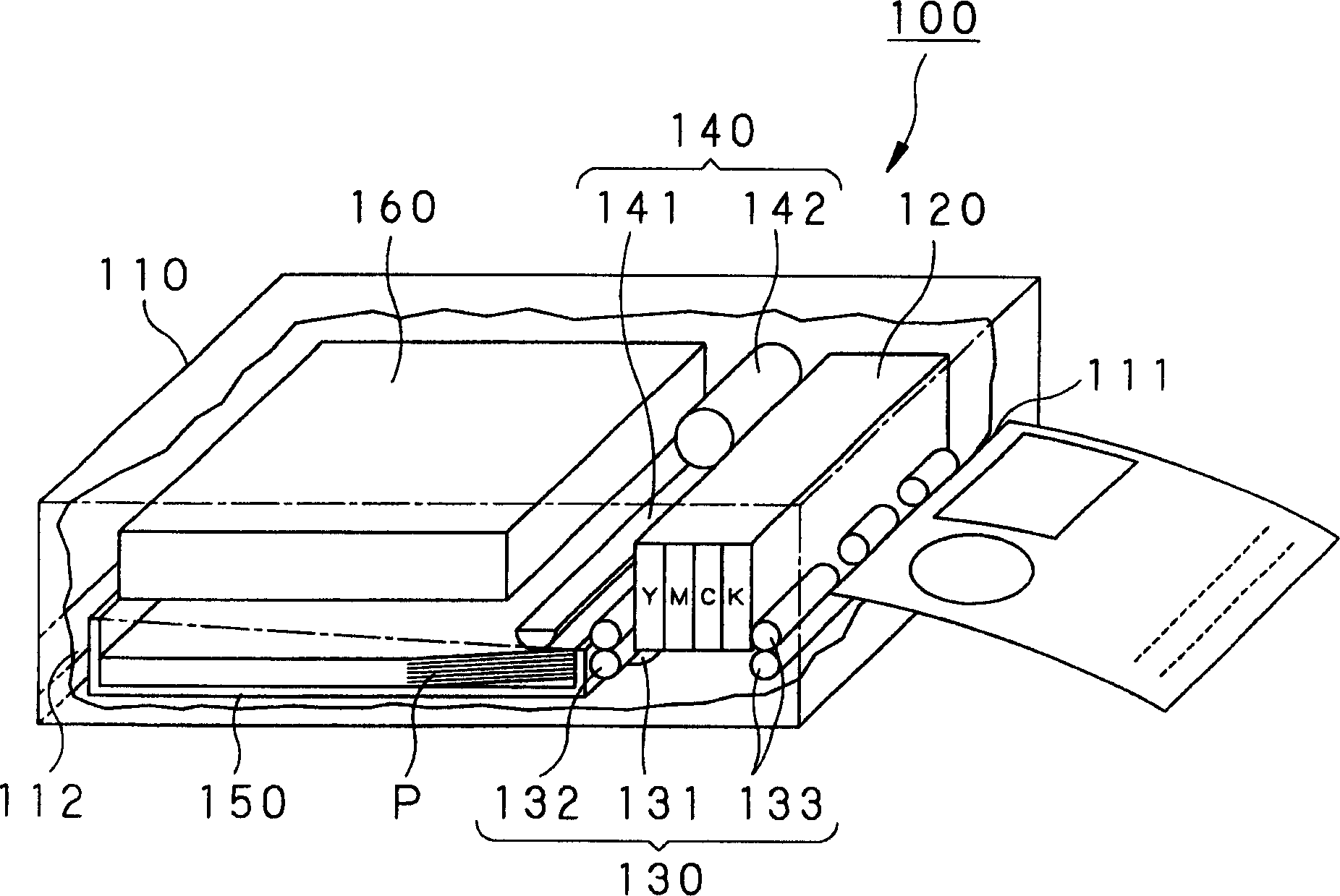

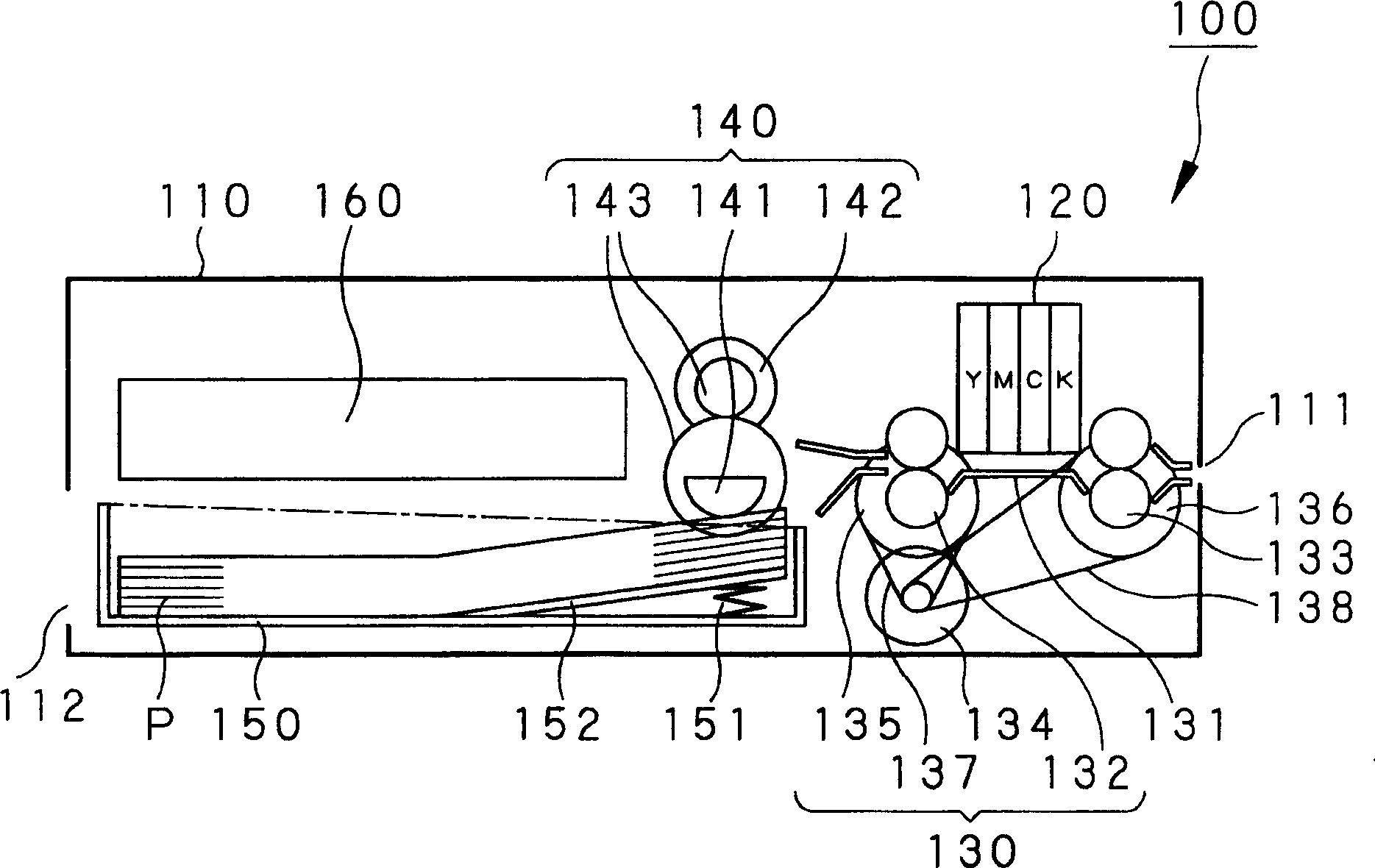

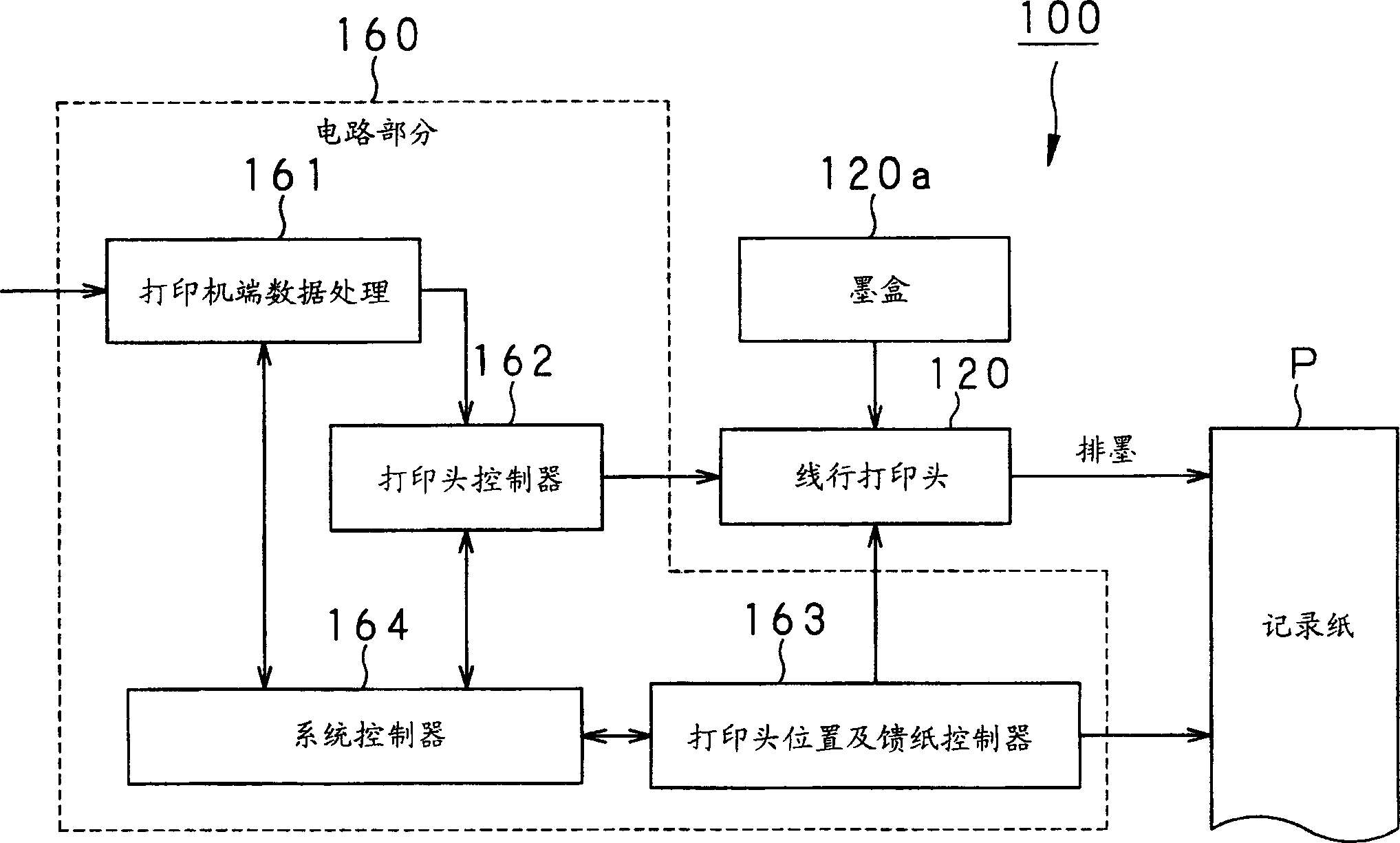

[0064] Embodiments of the present invention will be described below with reference to the drawings. Such as figure 1 , 2 The ink jet printer 100 of the illustrated embodiment is a liquid discharge device having a line print head 120 as a liquid discharge print head.

[0065] The ink jet printer 100 has a print head unit which will be described later as a driving unit for discharging liquid ink droplets. The line printhead 120 in the inkjet printer 100 has a recording range substantially consistent with the width of the paper P, and has a PNM (Pulse Number Modulation) system that realizes the density adjustment function of the dot diameter by the number of ink droplets. For the purpose of explanation here, it is assumed that the maximum number of single-color ink droplets required to make a dot is 8.

[0066] The inkjet printer 100 has a structure in which a line head 120 , a paper feeder 130 , a paper feeder 140 , a paper tray 150 , and an electric circuit part 160 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com