Dephotoresist agent

A photoresist and remover technology, applied in detergent compounding agents, optics, optomechanical equipment, etc., can solve problems such as reducing the removal efficiency of photoresist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Preparation of Formaldehyde-Monoethanolamine Condensate

[0044] (aldehyde / amine=0.5 molar ratio)

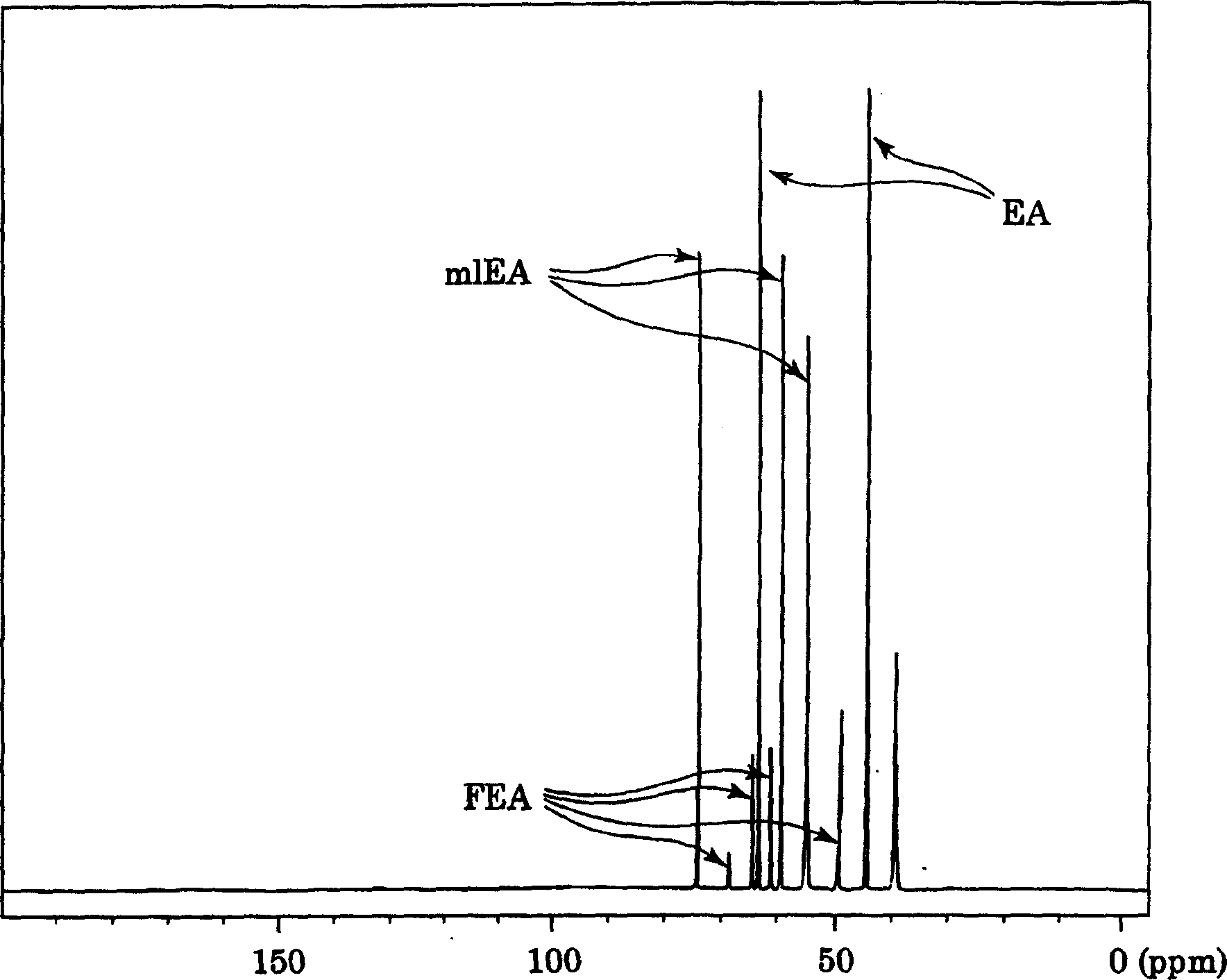

[0045] Under the condition that the solution temperature was 70°C or lower, 15 g of paraformaldehyde was slowly added to 61.0 g of monoethanolamine with stirring, thereby preparing a reaction product A in a solution state. All reaction steps were performed under nitrogen flow. reaction product A 13 The C-NMR spectrum (DMSO-d6) is shown in figure 1 middle. exist figure 1 Among them, EA represents monoethanolamine, mlEA represents hydroxymethylethanolamine, and FEA represents the reaction product of formaldehyde-monoethanolamine.

[0046] Synthesis Example 2

[0047] Preparation of Formaldehyde-Monoethanolamine Condensate

[0048] (aldehyde / amine=0.8 molar ratio)

[0049] Under the condition that the solution temperature was 70°C or lower, 24 g of paraformaldehyde was slowly added to 61.0 g of monoethanolamine with stirring, thereby preparing a reaction product A in...

Embodiment

[0057] 1 EA 65 Reaction product A 5 DMSO 30 20s

[0058] 2 EA 65 Reaction product A 5 DMAC 30 20s

[0059] 3 EA 65 Reaction product B 5 DMSO 30 30s

[0060]4 EA 66.5 Reaction product B 3.5 DMSO 30 40s

[0061] 5 EA 69 Reaction product A 1 DMSO 30 60s

Embodiment 11

[0086] Except for replacing monoethanolamine with isopropanolamine, the rest of the preparation steps of Synthesis Example 1 were repeated to prepare the formaldehyde-isopropanolamine reaction product. In the same manner as in Example 1, a photoresist removal test was carried out using the formaldehyde-monoethanolamine reaction product thus prepared. After 20 seconds of immersion, the photoresist layer was completely removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com