Microorganism flocculant producing strain by using bean dregs and process for producing same

A microbial flocculant and a technology for producing bacteria, which is applied in the field of water treatment agent-flocculant, can solve the problems of high production cost, low output, failure to reach the stage of practical application and industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

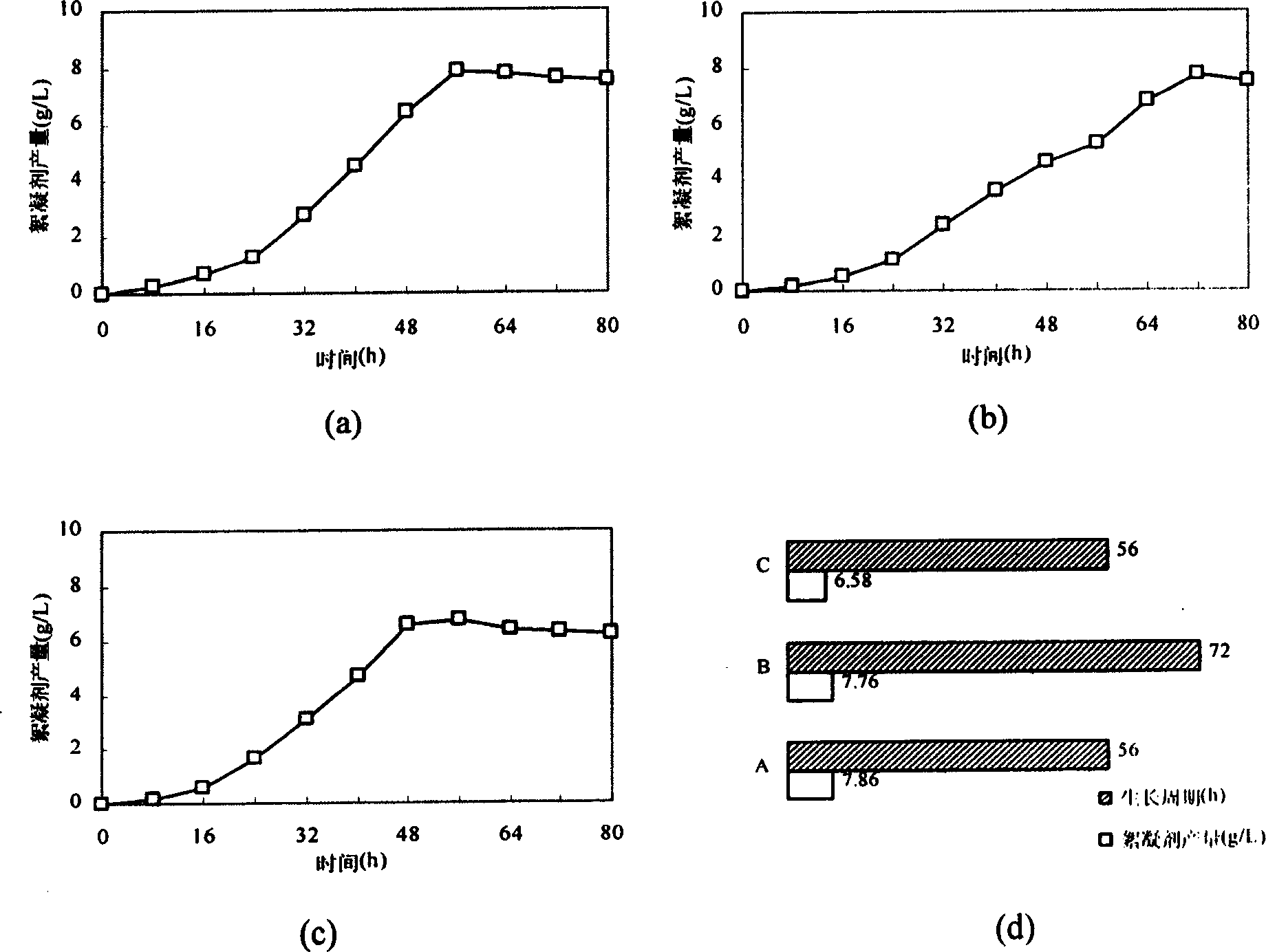

[0034] Pick a few colonies from the preservation slant of strain GA1, inoculate them into a 50mL shaker flask containing 15mL of seed medium, and culture them at 30°C for 24h at a shaker speed of 150r / min. The bacterial concentration is about 1.0×10 8 CFU / mL. This culture solution was used as a seed solution for inoculation of the GA1 flocculant.

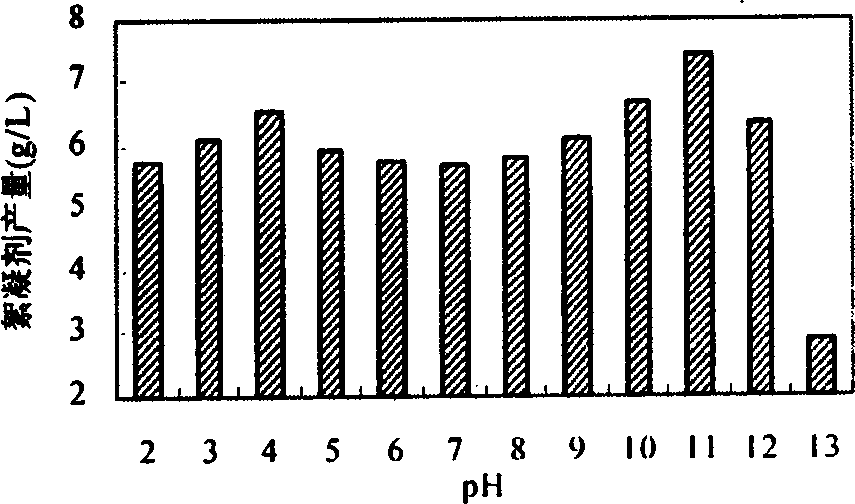

[0035] The concentration of the soybean dregs (wet weight, water content 85.5%) medium was 200 g / L, the pH value was adjusted to 11.0, and the soybean dregs medium was hydrolyzed under high pressure and high temperature (0.1 MPa, 121° C.) for 30 minutes.

[0036] Adjust the initial pH value of the bean dregs medium to 6.5 under aseptic operation, inoculate with 1% seed solution, and adopt the optimum temperature of 30°C for bacterial growth in the initial 24 hours of cultivation. ℃ and shaking table speed 150r / min, the optimal temperature of bacterial cell synthesis flocculant is 25 ℃ and shaking table speed 100r / min in the 32h of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com