Nut fixed piece and nut fixed structure

A technology for fixing structures and fixing parts, applied in the direction of threaded fasteners, nuts, fixing devices, etc., can solve the problems of replacement, easy damage of nuts, and inability of bolts to penetrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

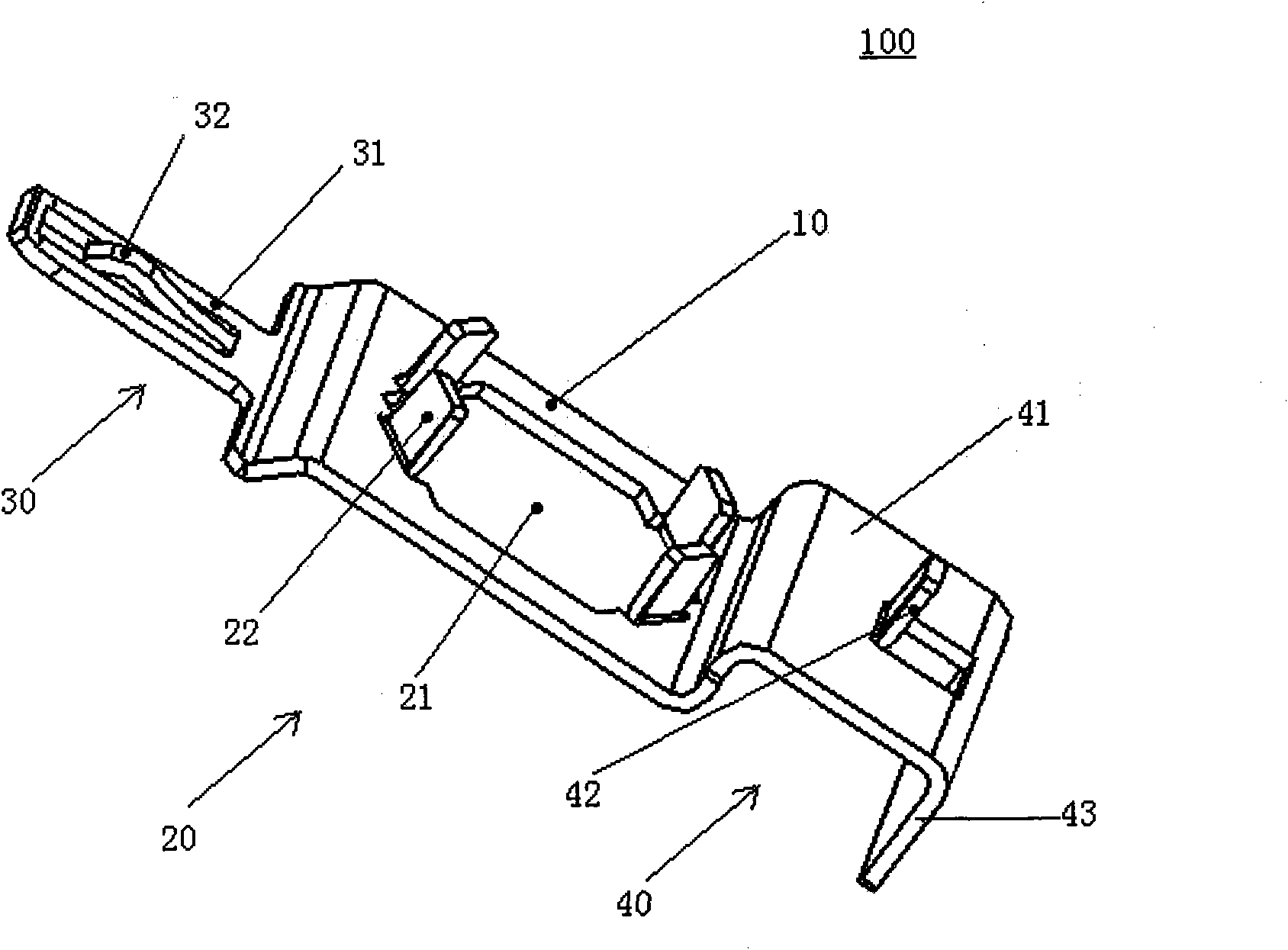

[0045] According to an embodiment of the present invention, the mounting part 20 may include a hole 21 formed on the plate-shaped main body 10, the shape of the hole 21 is consistent with the shape of the nut 200, so that the nut 200 can be inserted and fixed on the Inside the hole 21.

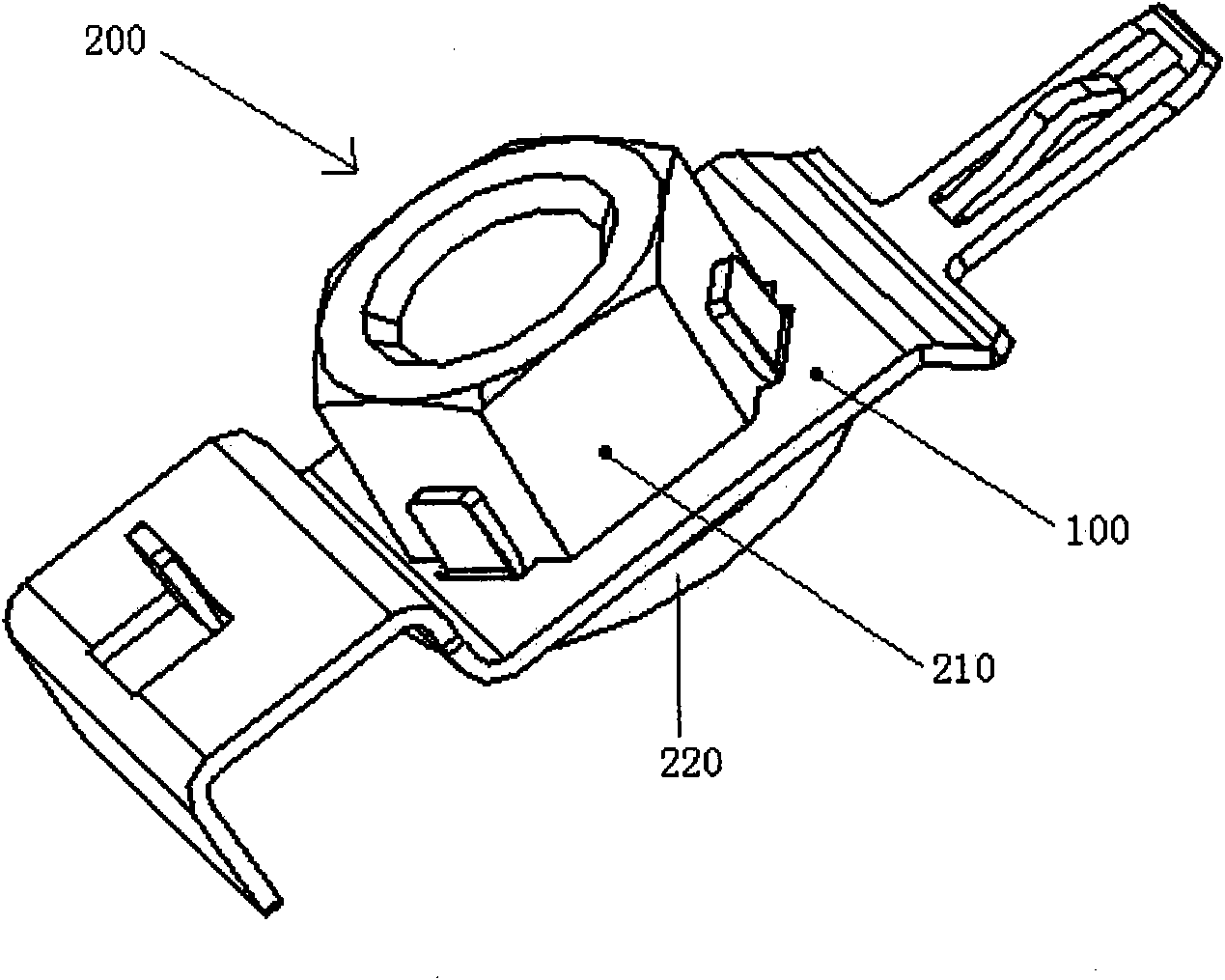

[0046] Such as figure 2 As shown, in this embodiment, the nut is preferably a flange nut, which includes a nut body 210 and a flange surface 220 . During installation, the nut body 210 can be passed through the hole 21 upwards from the lower surface of the plate-shaped main body 10 , so that the flange surface 220 is closely attached to the lower surface of the plate-shaped main body 10 . The outer surface of the nut body 210 may be slightly larger than the size of the hole, so that there is an interference connection between the two, so that the nut can be firmly fixed on the nut holder.

[0047] In this embodiment, the nut is preferably a flange nut, but the present invention is not limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com