Recycling device of mud generated during well drilling and well repairing

A technology of mud recovery and drilling repair, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc. It can solve problems affecting the layout of table tools and other tool work, working space obstacles, and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, the present invention will be further described through specific embodiments in combination with the content of the invention and the accompanying drawings.

[0023] The embodiments of the present invention are not limited to the following examples, and various changes made without departing from the gist of the present invention fall within the protection scope of the present invention.

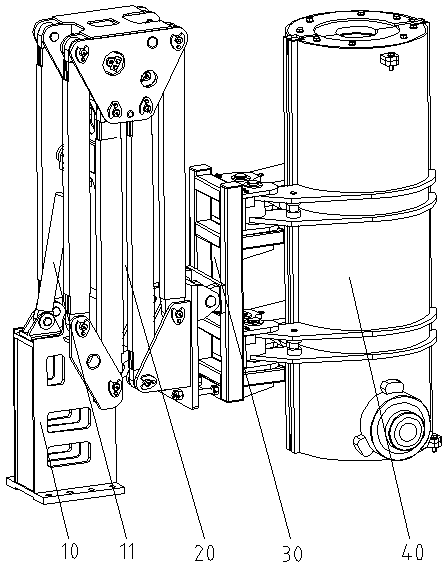

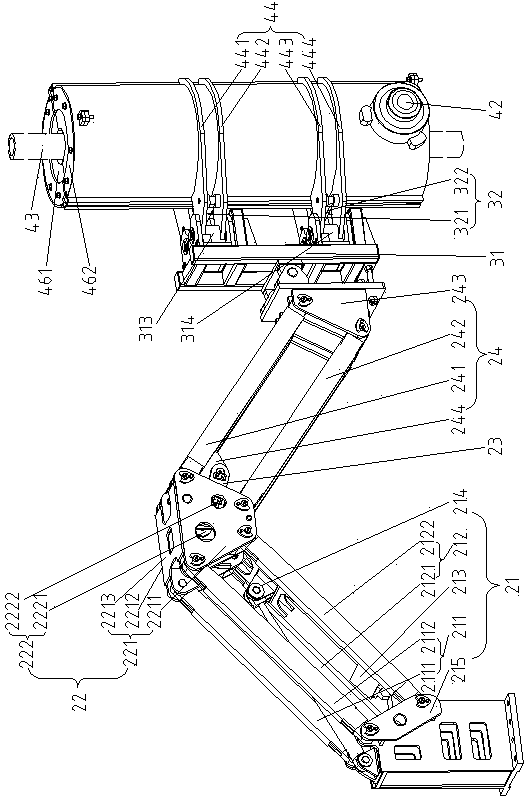

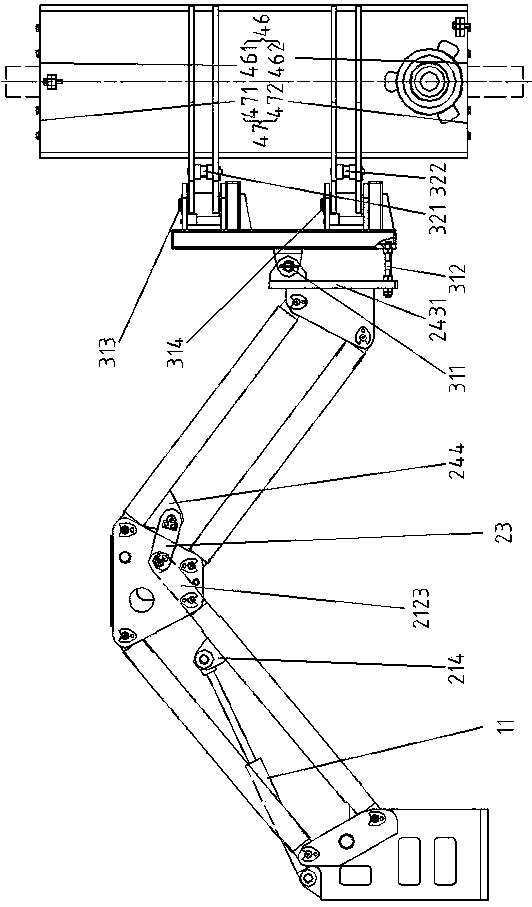

[0024] like figure 1 , figure 2 As shown, the drilling and workover mud recovery device includes an outrigger base 10 , an outrigger cylinder 11 , an outrigger 20 , an opening and closing clamping mechanism 30 and a mud cylinder 40 .

[0025] Wherein, the outrigger 20 includes a rear outrigger 21 , a middle connecting seat 22 , a middle connecting rod 23 and a front outrigger 24 .

[0026] Wherein, the rear outrigger 21 comprises a rear outrigger 211, a rear main outrigger 212, a mechanical limit block 213, a rear hinged seat 214 and a rear outrigger hinge plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com