An air cooling device matched with drying equipment

A technology of air cooling device and drying equipment, which is applied in drying, lighting and heating equipment, drying solid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

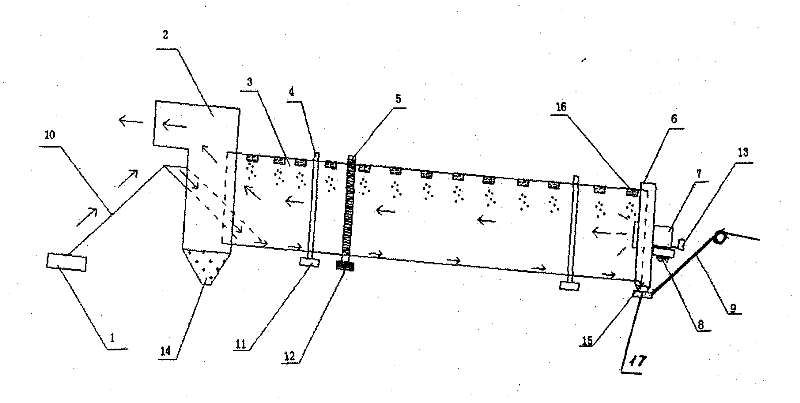

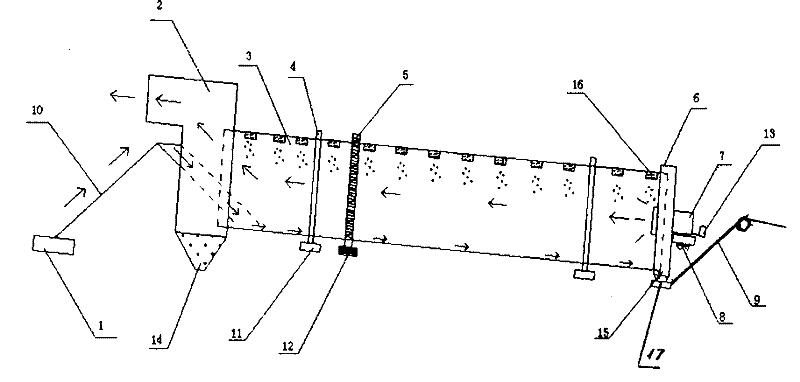

[0014] Example 1: Combining figure 1 , the present invention is an air-cooling device matched with drying equipment, which is composed of a feeding unit, a rotating drum unit, a discharging unit, a cold air supply unit and a bearing unit, the feeding unit is connected with the rotating drum unit, and the rotating The drum unit is connected to the cold air supply unit, the discharge unit and the carrying unit; the feed unit includes a feeding conveyor (1) and a feeding conveyor belt (10), and the feeding conveyor (1) is connected to the feeding conveyor belt (10 ), the rotary drum unit includes a heat exhaust dust outlet (2), a dust storage bucket (14), a rotary drum (3), a lifting plate (16), a closed port at the end of the drum (6) and The installation inclination angle between the discharge hopper (15), the rotary drum (3) and the ground is 3° to 5°, the origin of the inclination angle is located at the tail of the rotary drum (3), and the heat and dust outlet (2) is connect...

Embodiment 2

[0021] Example 2: Combining figure 1 , the working process of the present invention is as follows: the material in the hot state (the material described in this embodiment is lignite) dried by the drying equipment is input to the rotary drum unit by the feeding unit, and is passed through the rotary drum (3) The lifting plate (16) inside lifts the material continuously from the upper part of the rotary drum (3). The cold air blown into the cold air nozzle (7) will air-cool the tumbled and lifted materials. During the air-cooling process, some dust enters the dust storage hopper (14) and is recovered, and the rest of the flue gas dust passes through the heat exhaust dust outlet ( 2) Enter the dust removal equipment for purification and separation. The rotary drum (3) relies on the roller belt embedded in the outside to carry the load through the rollers (11) installed on the base. The bull gear (5) embedded in the outer side of the rotary drum (3) meshes with the pinion of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com