Electrode for vacuum self-consuming furnace and welding method thereof and vacuum self-consuming melting feeding method

A vacuum consumable furnace and consumable electrode technology, which is applied in the direction of electric heating devices, electrical components, heating through discharge, etc., can solve the problem of residual weight deviation of consumable electrode weight, large variation range of ingot shrinkage cavity depth, and influence on compensation The stability of the shrinkage effect and other issues can be achieved to achieve the effects of reducing consumption, improving skinning efficiency, and reducing the consumption of turning tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In the present invention, the selection of the material of the auxiliary electrode is not particularly limited, it can be selected according to the conventional methods in this field, usually a material with a slightly higher hardness is selected, for example, titanium alloys with models TA1, TA2, TA3, and TA4 are selected. . The material of the consumable electrode is the same as that of the ingot. The material of the transition electrode is preferably the same as that of the ingot. In order to make full use of resources and reduce costs, in a preferred embodiment, the transition electrode is made of a billet head formed during the forging process of an ingot melted in a vacuum consumable furnace. The specific production method can be carried out according to the conventional methods in this field. For example, the preparation method of the transition electrode can include: forging the billet head formed in the process of forging and opening the ingot obtained by smel...

Embodiment approach

[0028] According to a specific embodiment of the present invention, the preparation method may include: firstly connecting the power supply to the transition electrode and the auxiliary electrode, so that the arc heat generated between the transition electrode and the auxiliary electrode melts one end surface of the transition electrode to form a molten pool, and then Cut off the power supply, and insert the auxiliary electrode into the molten pool. After cooling, the auxiliary electrode and the transition electrode are welded together; The arc heat generated during the arc makes the upper end of the consumable electrode melt to form a molten pool, then cut off the power supply, insert the other end of the transition electrode into the molten pool, and after cooling, the transition electrode and the consumable electrode are welded together.

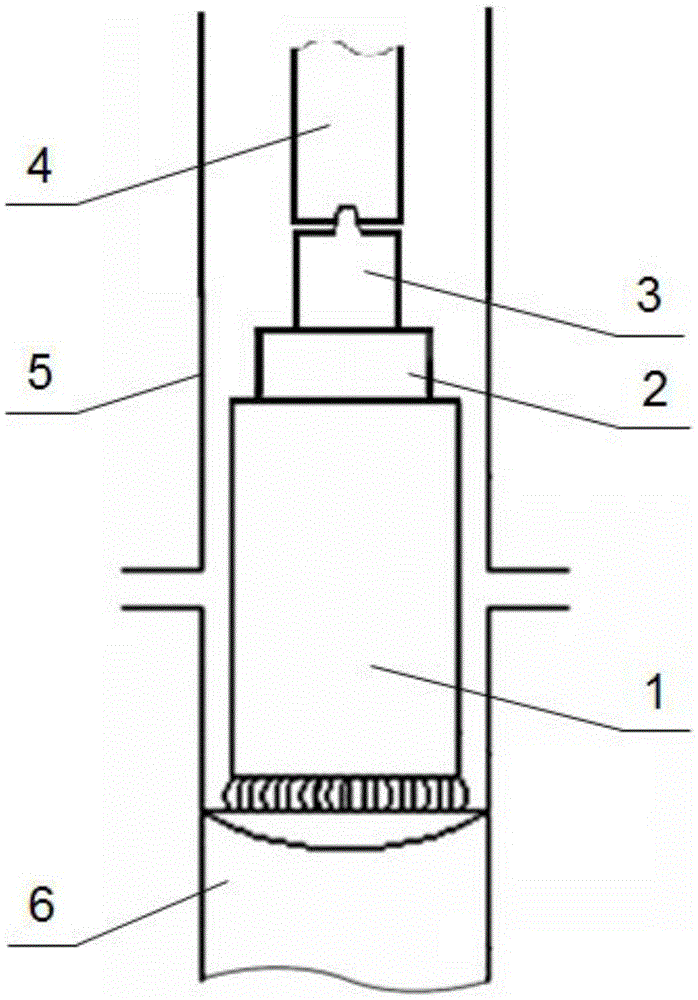

[0029] According to a specific embodiment of the present invention, the preparation method may include: figure 1 In the connection mode ...

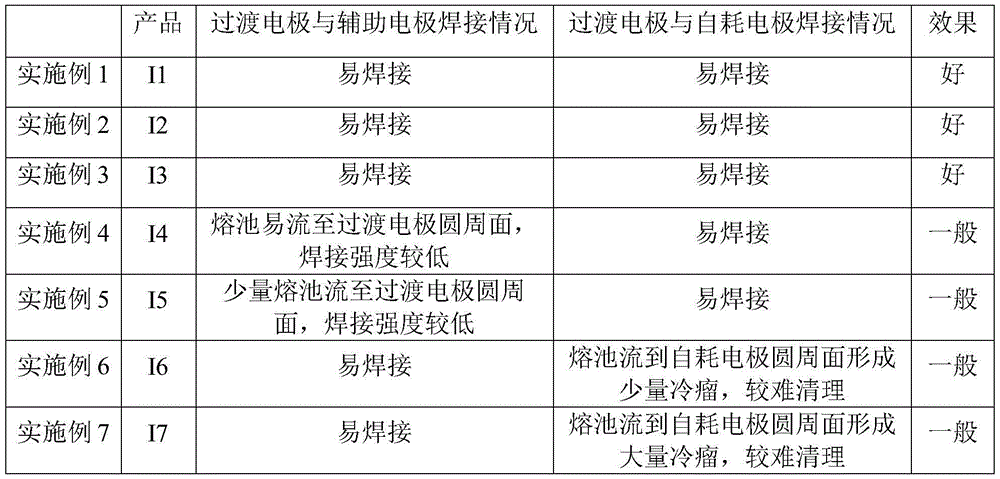

Embodiment 1

[0041] Use the vacuum consumable furnace to melt the obtained ingot and form the billet head during the forging process to make a transition electrode with a diameter of 620mm and a length of 500mm, and prepare an auxiliary electrode with a diameter of 400mm and a length of 500mm and an auxiliary electrode with a diameter of 900mm and a length Consumable electrodes of 3000mm. according to figure 1 In the connection mode shown, first connect the power supply to the transition electrode and the auxiliary electrode (the current is 3kA, the voltage is 24V), and then gradually increase the current to 9kA, so that the arc heat generated between the transition electrode and the auxiliary electrode makes the transition electrode a After the end surface melts to form a molten pool (it takes about 10 minutes), cut off the power supply and insert the auxiliary electrode into the molten pool. After cooling, the auxiliary electrode is welded with the transition electrode; then connect the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com