Treatment method for nitrogen oxide tail gas discharged from industrial production furnace, and apparatus thereof

A nitrogen oxide and kiln technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of operator health damage, difficulty in removal, and high dust content, and achieve good gas-liquid mixing effect. The effect of convenient size adjustment and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

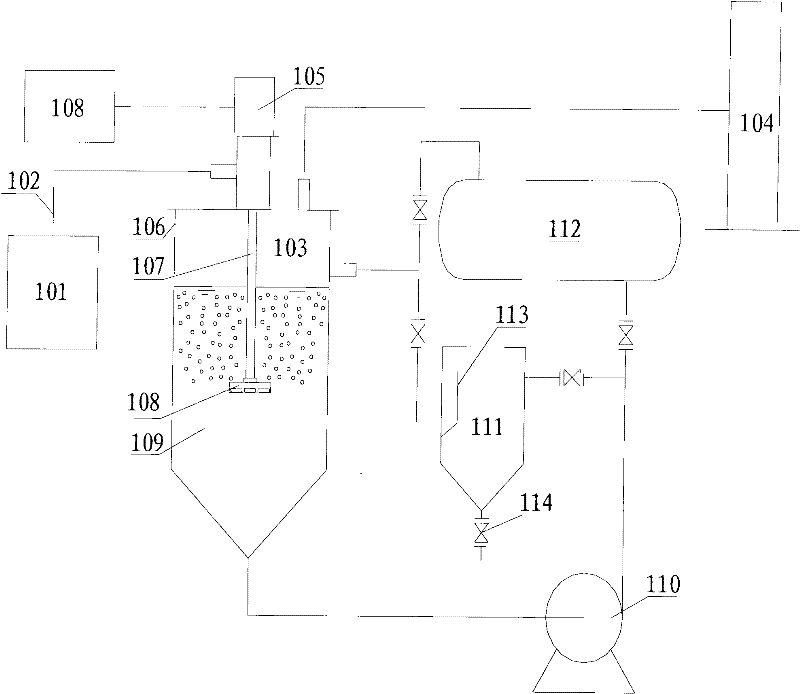

[0031] Such as figure 1 As shown, the exhaust gas containing nitrogen oxides produced by the industrial kiln 101 enters the self-priming gas-liquid mixing equipment 103 through the pipeline 102 for treatment. Discharge.

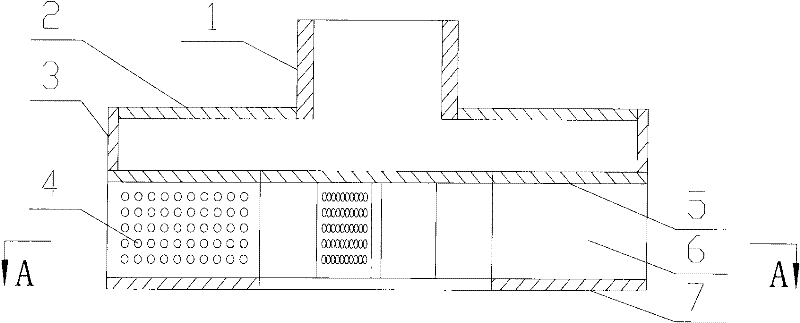

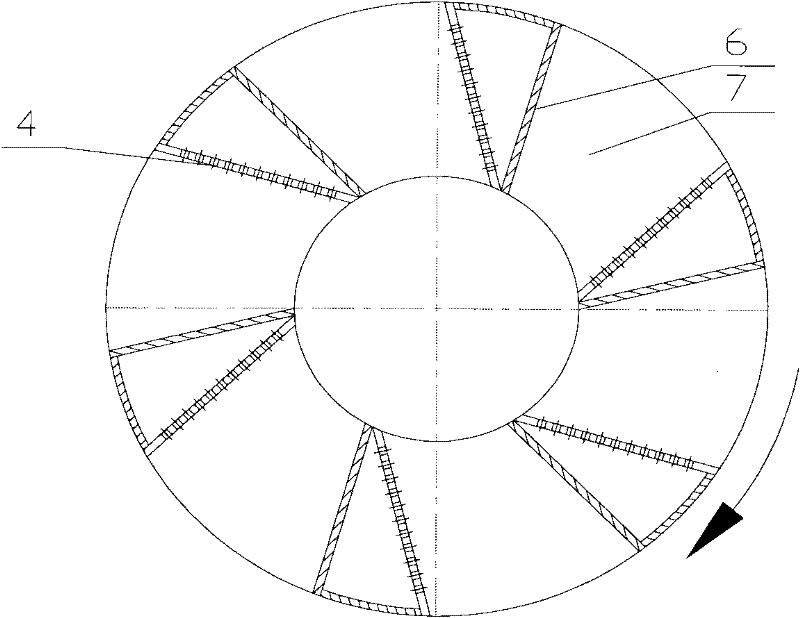

[0032] Self-priming gas-liquid mixing equipment 103 is made up of motor 105, tank body 106, impeller shaft 107, impeller 108 and transmission and sealing mechanism. Absorbent liquid 109 is housed in the tank. The absorption liquid is transported to the settling tank 111 and cooler 112 through the pump 10 for desilting and cooling operations. There are overflow weir 113 and mud discharge valve 114 in the settling tank. The settling tank 111 and the cooler 112 are located at a high position, and after settling and cooling, the absorption liquid flows back to the tank body 106 of the self-priming gas-liquid mixing device 103 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com