Kitchen garbage crushing and dewatering integrated treatment device and method

A kitchen waste and treatment device technology, which is applied to chemical instruments and methods, separation methods, solid waste removal, etc., can solve the problems of large volume, complex structure, low moisture content of mud cake, etc., and achieve stable and reliable operation. Multiple application scenarios and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

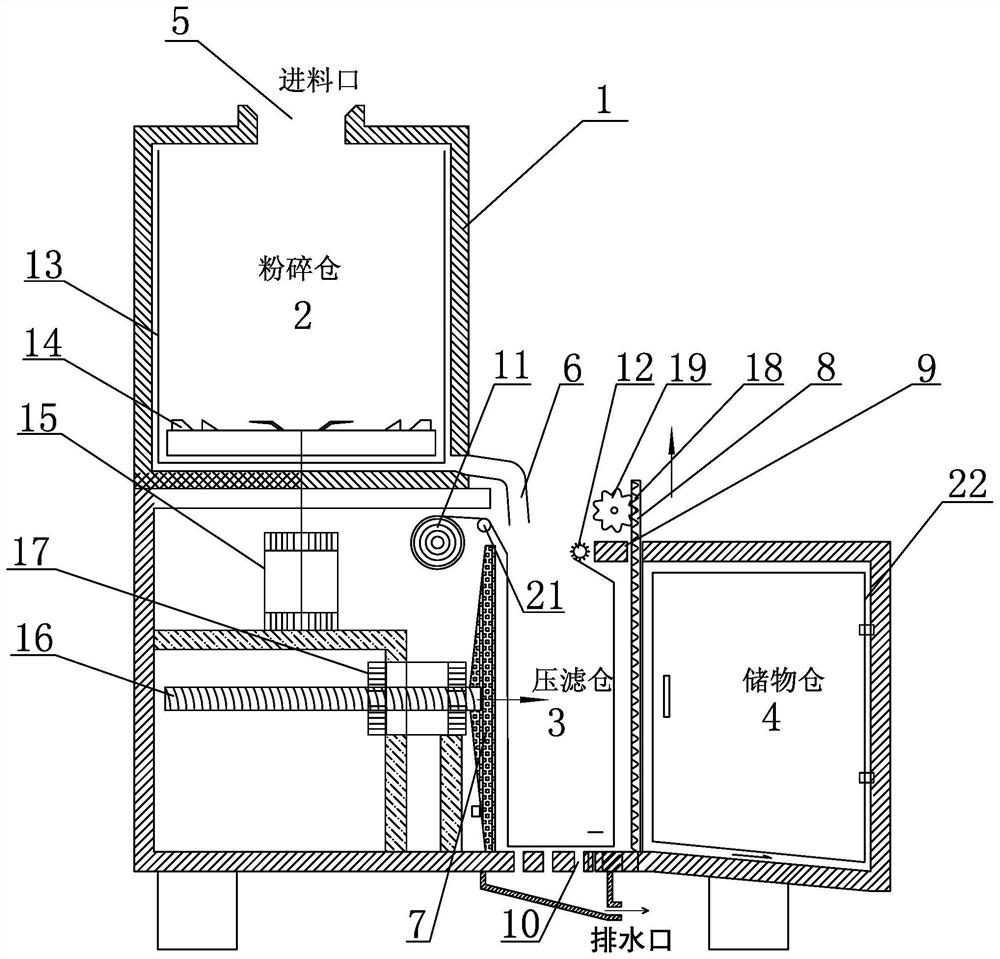

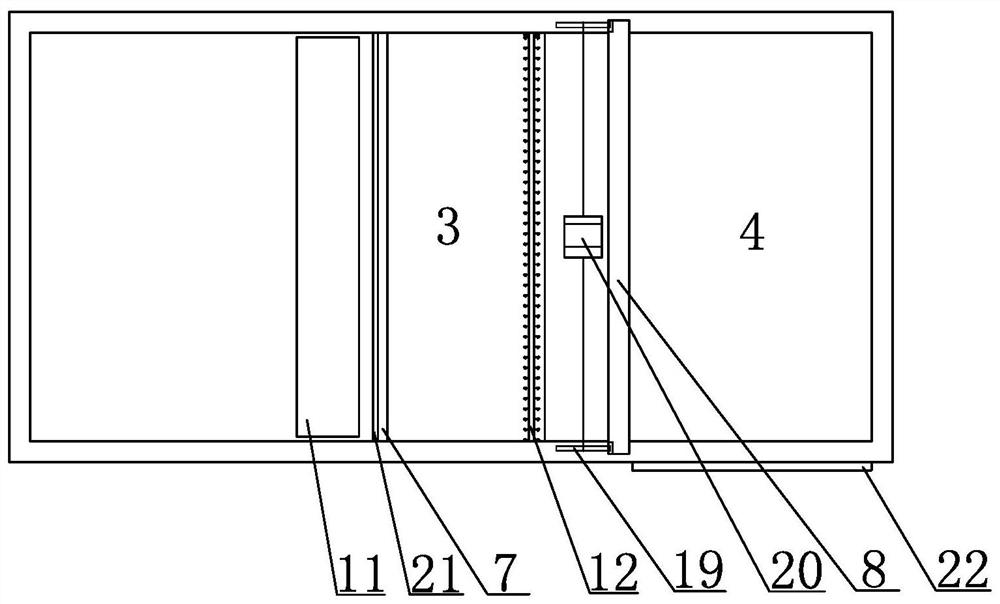

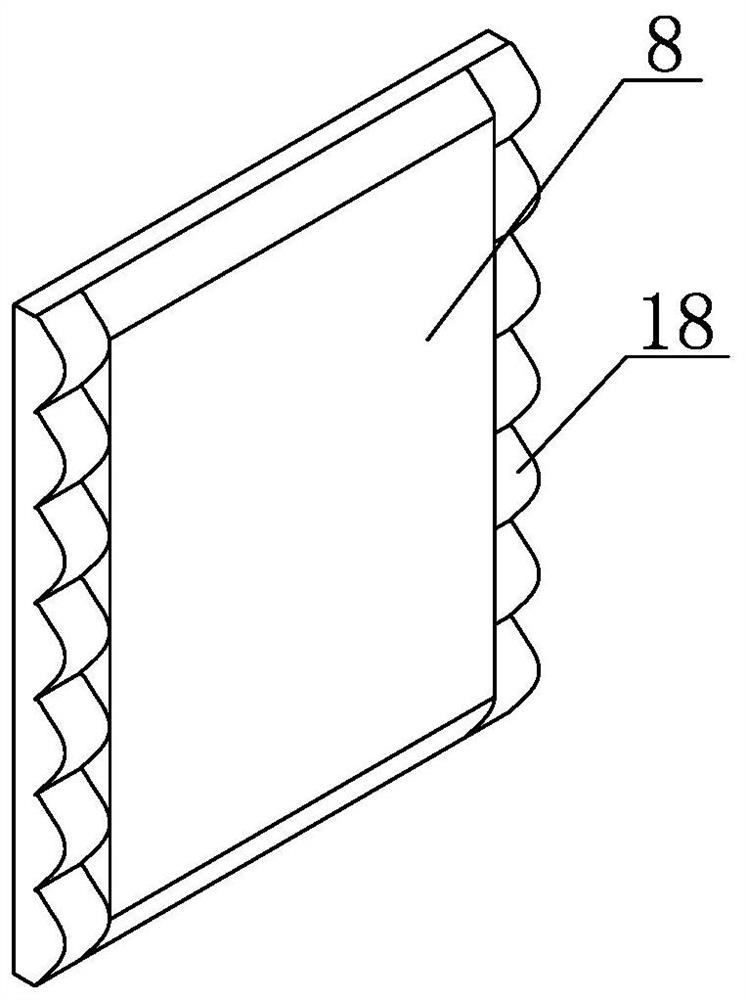

[0031] An integrated treatment device for kitchen waste crushing and dehydration, such as figure 1 with figure 2 As shown, it includes a housing 1, the upper part of the housing 1 is provided with a crushing bin 2, the lower part of the housing 1 is provided with a filter press bin 3 and a storage bin 4, the top of the crushing bin 2 is provided with a feed port 5, and the crushing bin The bottom of the side wall of 2 is provided with a discharge pipe 6 for sending the pulverized garbage to be dehydrated into the filter press chamber 3; And the other side of the filter press chamber 3 is longitudinally provided with a pressure-bearing baffle 8 that can move longitudinally, and the pressure-bearing baffle 8 is separated between the filter press chamber 3 and the storage bin 4, and the top of the filter press chamber 3 is close to One side of the pressure-bearing baffle plate 8 is provided with a filter press chamber top plate 9, and the bottom of the filter press chamber 3 is...

specific Embodiment 2

[0036] A method for integrated processing of kitchen waste crushing and dehydration using the device in the first embodiment above, comprising the following steps:

[0037] (1) After the kitchen waste enters the crushing bin 2 through the feed port 5, the first motor 15 is turned on to crush the kitchen waste through the crushing disc 14, and the unground large particle size kitchen waste is intercepted by the filter cartridge 13 and Continuously crushed by the crushing disc 14, the crushed small particles enter the filter press chamber 3 through the discharge pipe 6 along with the water flow;

[0038] (2) During the falling process of the garbage to be dehydrated, the filter cloth cylinder 11 is driven to rotate, and the filter cloth is pressed down by the falling material and laid in the filter press chamber 3, and forms a U-shaped surround on the garbage to be dehydrated, and part of the moisture contained in the garbage to be dehydrated Filter out under the action of gravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com