Confocal micro imaging system using dummy pinhole

A technology of confocal microscopic imaging and virtual pinholes, which is applied in the field of confocal microscopic systems, can solve the problems of light energy loss, resolution reduction, troublesome cleaning of pinholes, etc., and achieve the effect of convenient adjustment and positioning and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

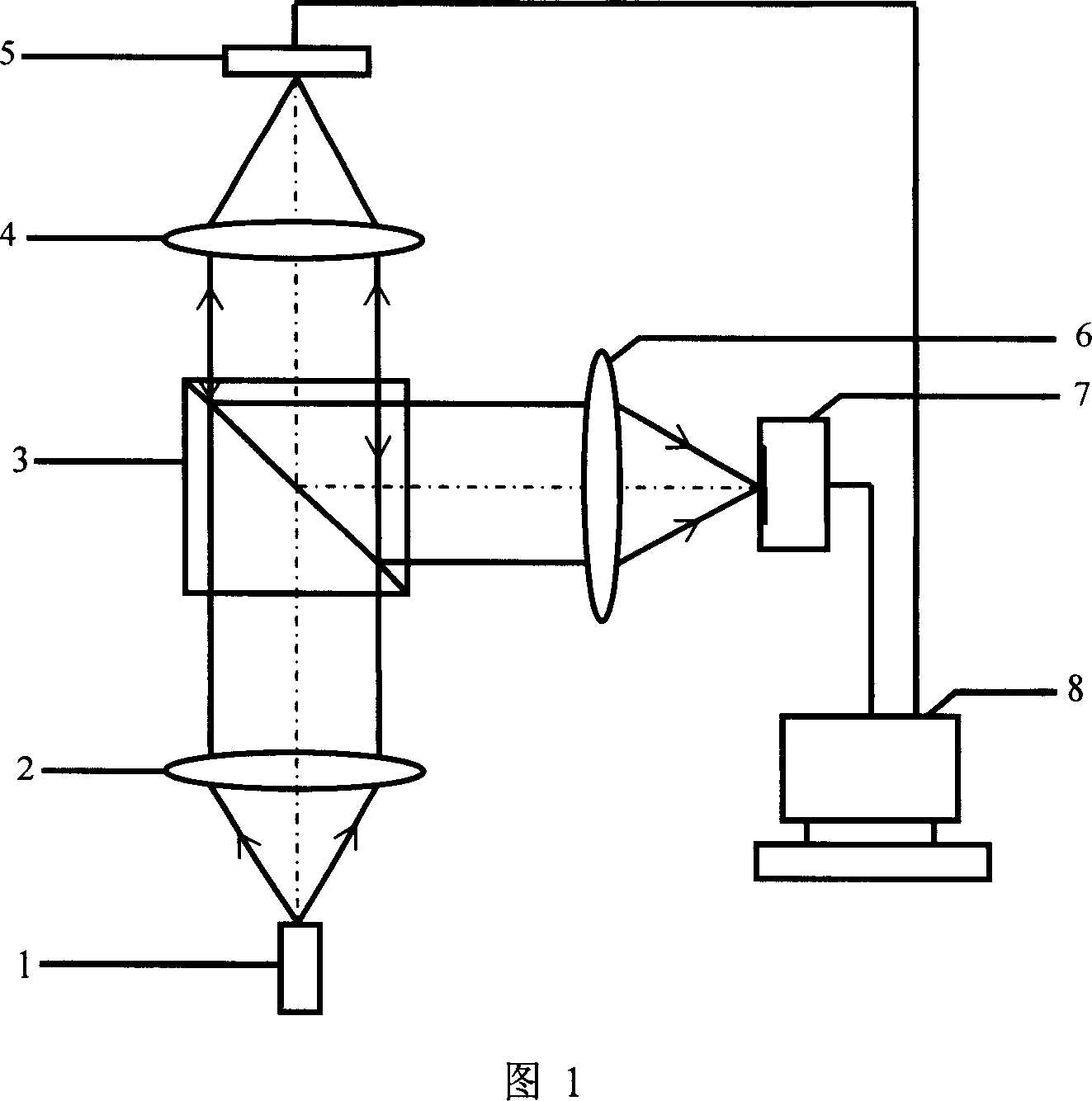

[0043] Figure 1 shows the schematic diagram of the optical path of the confocal microscopic imaging system using a virtual pinhole, point light source 1, collimator lens 2, beam splitter 3 and microscopic objective lens 4, which are sequentially connected in optical path to form the illumination optical path of the system; The system 5 controls the movement of the sample to be measured; the microscope objective lens 4, the beam splitter 3, the collecting lens 6, and the CCD7 are sequentially connected in an optical path to form the detection optical path of the system; the computer 8 controls the scanning system 5 and the CCD7, and performs data acquisition, processing and Image reconstruction. In this embodiment, the plan apochromatic objective lens of Olympus is adopted as the microscope objective lens 4, and the numerical aperture is 0.4; the scanning system 5 adopts the P-611.3S piezoelectric ceramic three-dimensional translation stage of the German PI company, the precisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com