Delay self-closing water-saving valve

A water-saving valve and bonnet technology, which is applied in the direction of valve devices, functional valve types, fluid distribution valves, etc., can solve problems such as easy blockage of orifice holes, valve failure, and failure to reset the push rod, so as to achieve stable water discharge and convenient maintenance , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

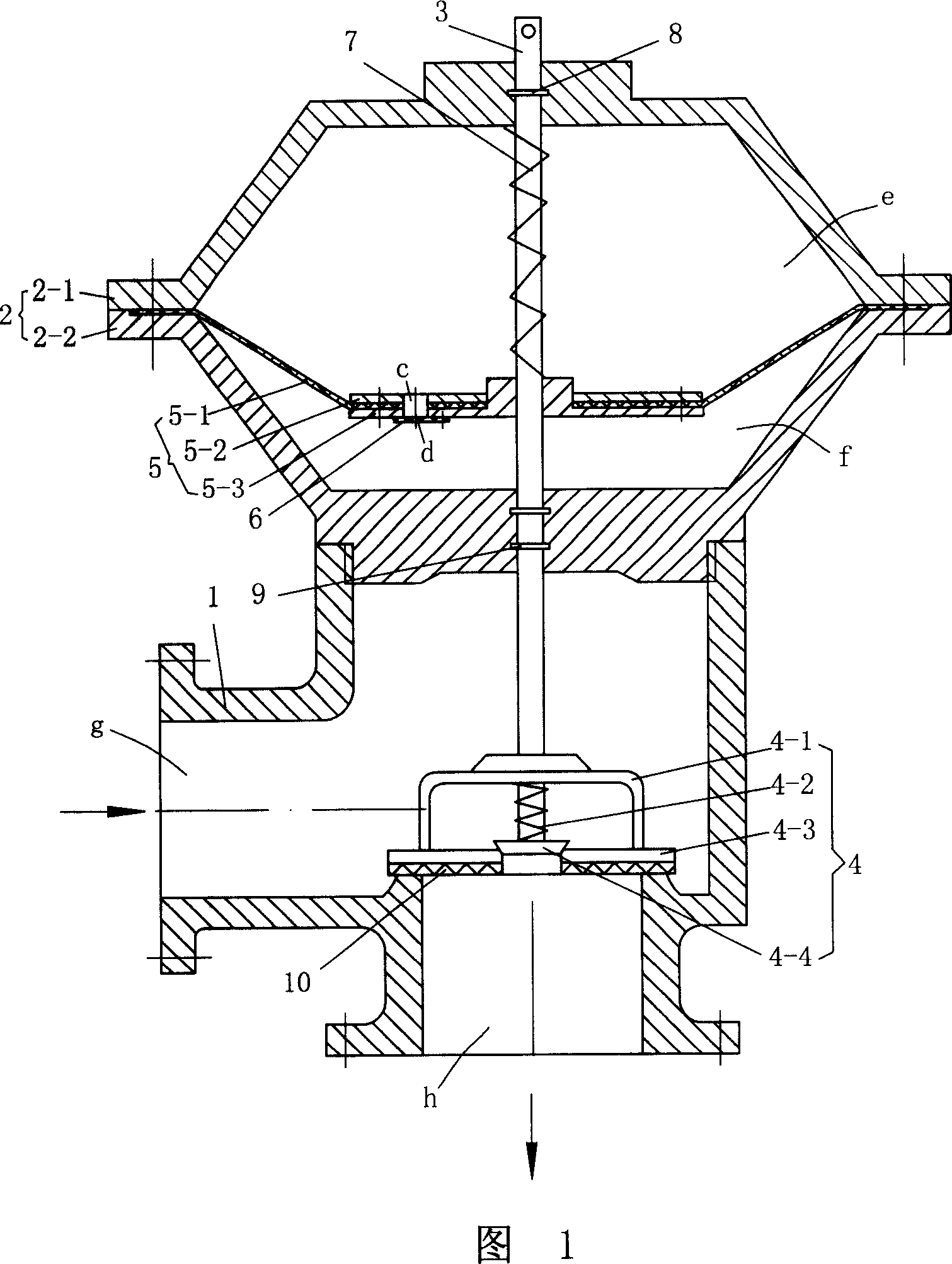

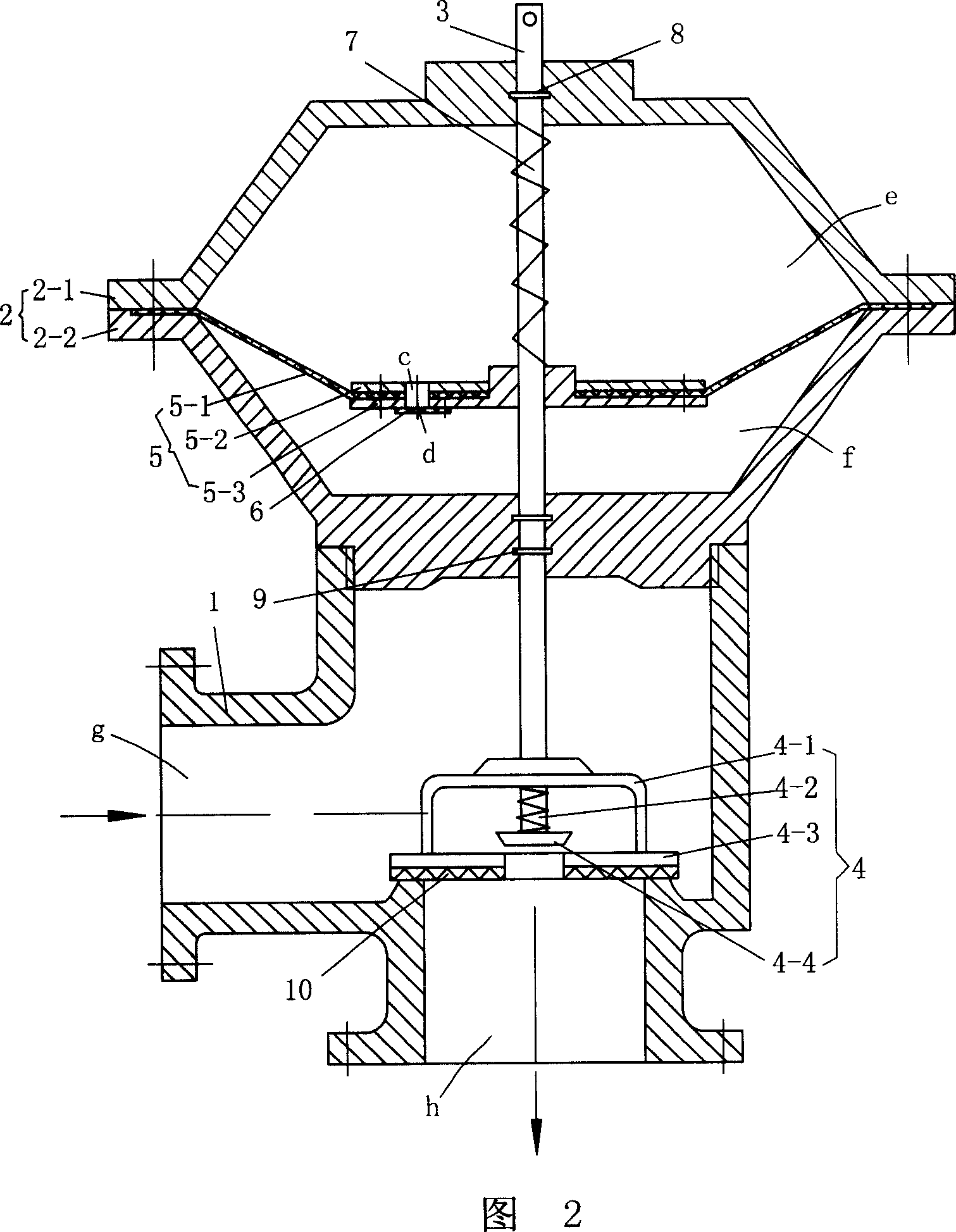

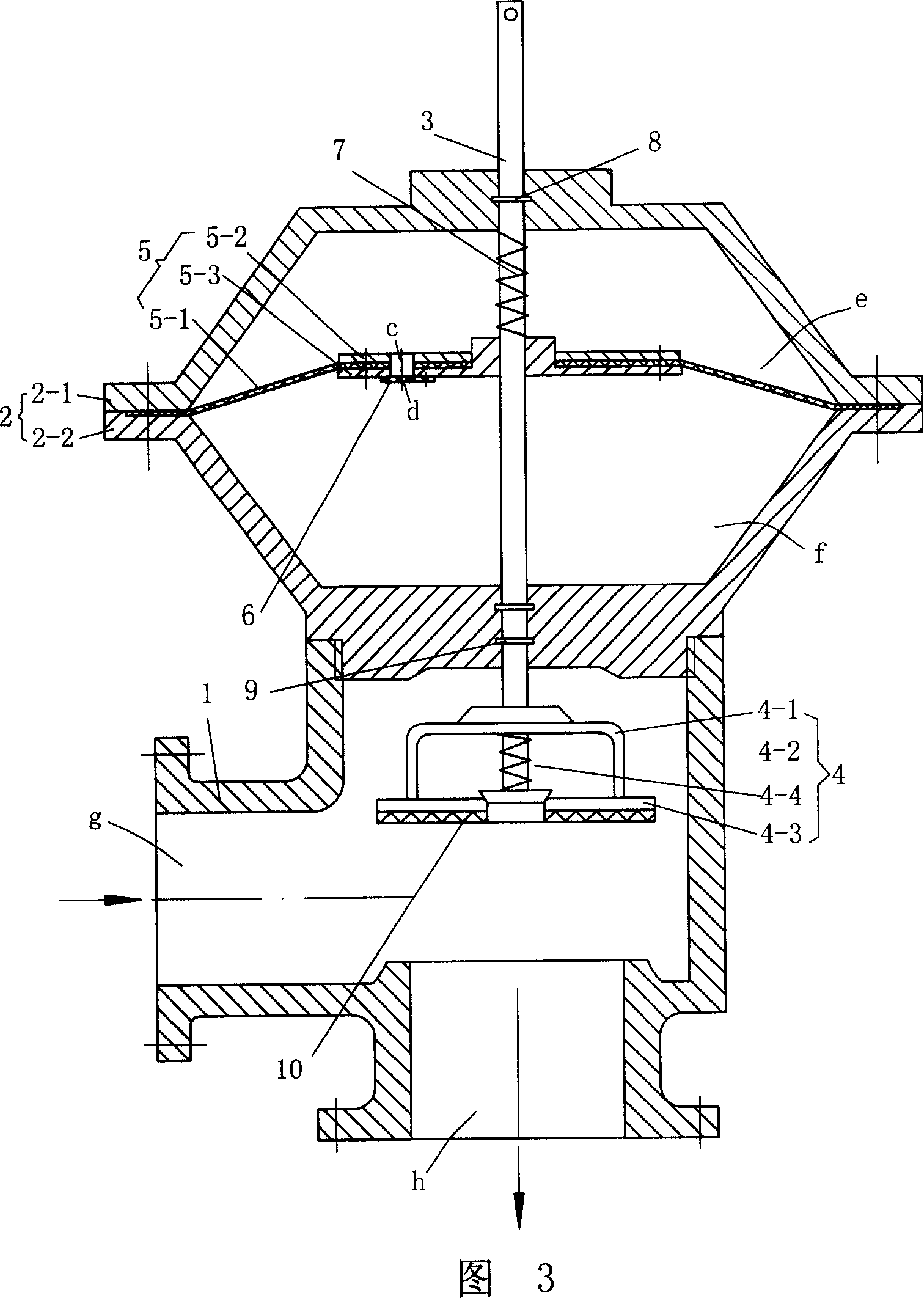

[0024] Embodiment 1 shown in FIG. 1 is in a closed state. This embodiment has a valve body 1 , a valve cover 2 , a valve stem 3 and a valve core 4 , and the valve body 1 is provided with a water inlet g and a water outlet h. The water inlet g is arranged on the side of the valve body 1 , and the water outlet h is arranged at the bottom of the valve body 1 .

[0025] The bonnet 2 is composed of an upper bonnet 2-1 and a lower bonnet 2-2, the lower bonnet 2-2 is threadedly connected with the valve body 1, and the upper bonnet 2-1 and the lower bonnet 2-2 are enclosed by The sealed space is the air cavity, which is provided with an elastic diaphragm 5 that is fixedly clamped between the upper and lower valve covers 2-1 and 2-2. The elastic diaphragm 5 connects the upper and lower valve covers 2-1, The space between 2-2 is divided into an upper air chamber e and a lower air chamber f. The upper valve cover 2-1, the diaphragm 5 and the lower valve cover 2-2 are respectively provi...

Embodiment 2

[0031]In this embodiment, the diaphragm 5 includes a disc-shaped diaphragm 5-1, a pressing plate 5-2 fixed on the upper surface of the central part of the disc-shaped diaphragm 5-1, and a pad fixed on the bottom surface of the central part of the disc-shaped diaphragm 5-1 Plate 5-3, the center of the pressure plate 5-2 is provided with a boss 5-21, the pressure plate 5-2 is provided with a valve stem hole passing through the boss 5-21, the disc diaphragm 5-1 and the backing plate 5-3 The parts corresponding to the pressure plate bosses 5-21 are provided with connecting holes. The pressure plate bosses 5-21 pass downward through the connecting holes on the diaphragm 5-1 and the backing plate 5-3, and the valve stem 3 passes through the pressure plate bosses. The valve stem hole of 5-21 is tightly matched with the valve stem hole. The air hole on the pressure plate 5-2 on the same axis, the air hole on the disc diaphragm 5-1 and the air hole on the backing plate 5-3 form the diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com