Efficient treatment system and treatment method for organic wastewater of bulk drug production in pharmaceutical industry

A technology for organic wastewater and treatment systems, applied in water/sewage treatment, natural water treatment, special compound water treatment, etc., can solve the problems of poor comprehensive biodegradability, low B/C, high salt content, etc. biochemical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

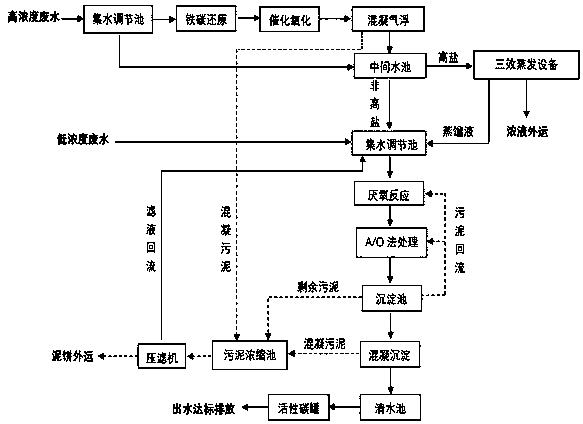

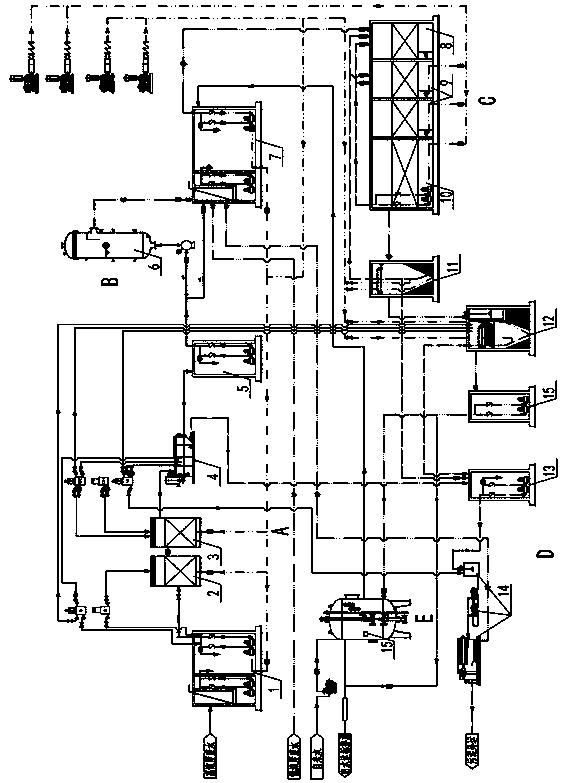

[0061] A high-efficiency treatment system for the production of organic wastewater from raw materials in the pharmaceutical industry, including: a high-concentration wastewater pretreatment unit A, a three-effect evaporation unit B, a biochemical treatment unit C, a sludge filter press unit D, and an advanced treatment unit E for activated carbon filtration;

[0062] Wastewater enters from the high-concentration water collection adjustment tank of high-concentration wastewater pretreatment unit A, and is connected through pipelines. After being treated by iron-carbon reduction tank, catalytic oxidation tank and coagulation air flotation machine, the effluent flows to the intermediate pool by itself, and the slag flows into the sewage by itself. Mud concentration pool; according to the water quality of the intermediate pool, through the adjustment of the pipeline valve, it is connected to the three-effect evaporation equipment of the three-effect evaporation unit B and the low-co...

Embodiment 2

[0074] Experimental application example: high-efficiency treatment system for organic wastewater produced by raw materials in the pharmaceutical industry.

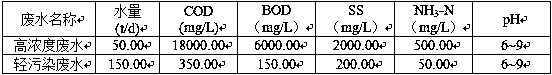

[0075] For a pharmaceutical company in the north, the discharge of high-concentration organic wastewater is about 50 t / d, and the discharge of low-concentration wastewater is about 150 t / d. The wastewater treatment station is established by using the treatment system of the present invention, and its design scale is 200m 3 / d, in which, after the high-concentration organic wastewater passes through the high-concentration wastewater pretreatment unit, dosing room, and three-effect evaporation unit, the combined low-concentration wastewater enters the biochemical treatment unit, the sludge filter press unit and the advanced treatment of activated carbon filtration Unit treatment, the final water quality is up to standard discharge, and the sludge is transported out by pressing and filtering.

[0076] The water quality indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com