Purifying device for wet-process flue gas desulfurization wastewater and using method thereof

A wet flue gas desulfurization and purification device technology, applied in chemical instruments and methods, gaseous discharge wastewater treatment, water/sewage multi-stage treatment, etc. The problem of high energy consumption can reduce the amount of sludge produced, the removal efficiency is high, and the sedimentation effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

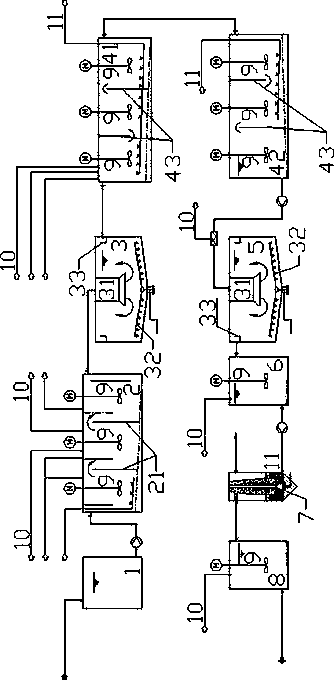

[0058] A purification device for wet flue gas desulfurization wastewater, comprising a wastewater regulating tank 1, a reaction flocculation tank 2, a sedimentation tank 31, a primary defluorination reaction tank 41, a secondary defluorination reaction tank 42, a clarification tank 32, an intermediate And tank 6, quicksand filter 7, drainage tank 8, mixer 9, automatic dosing device 10 and air pipe 11, as figure 1 As shown, the specific structure is:

[0059] Wastewater adjustment tank 1, flocculation tank 2, sedimentation tank 3, primary defluorination reaction tank 41, secondary defluorination reaction tank 42, clarification tank 5, neutralization tank 6, quicksand filter 7 and drainage tank 8 are connected through pipelines in sequence , a lift pump is connected in series on the pipeline;

[0060] The reaction flocculation tank 2 is divided into three grids with partitions 21, four automatic dosing devices 10 are arranged above the notch of the reaction flocculation tank 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com