Patents

Literature

82results about How to "Conductivity effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

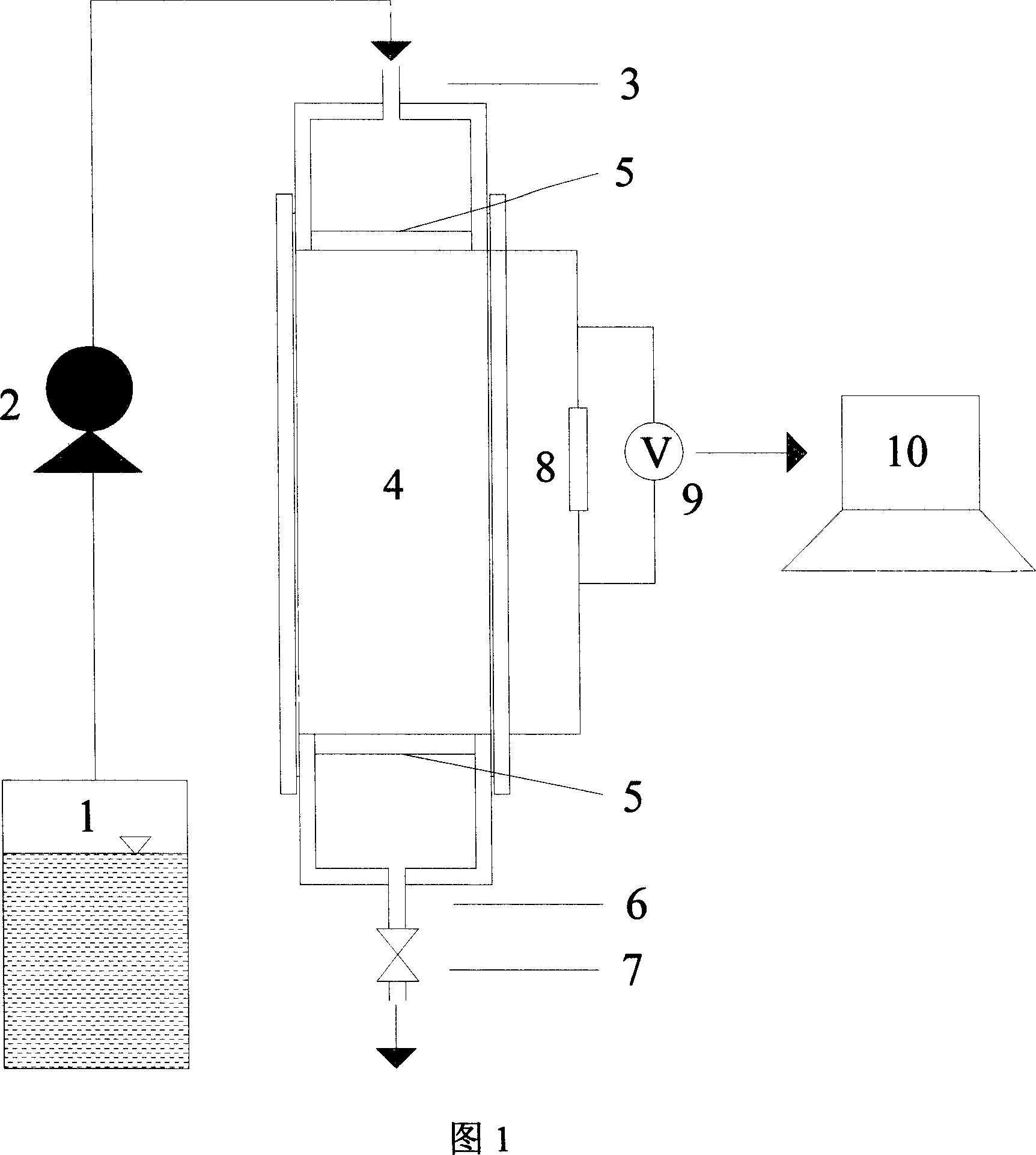

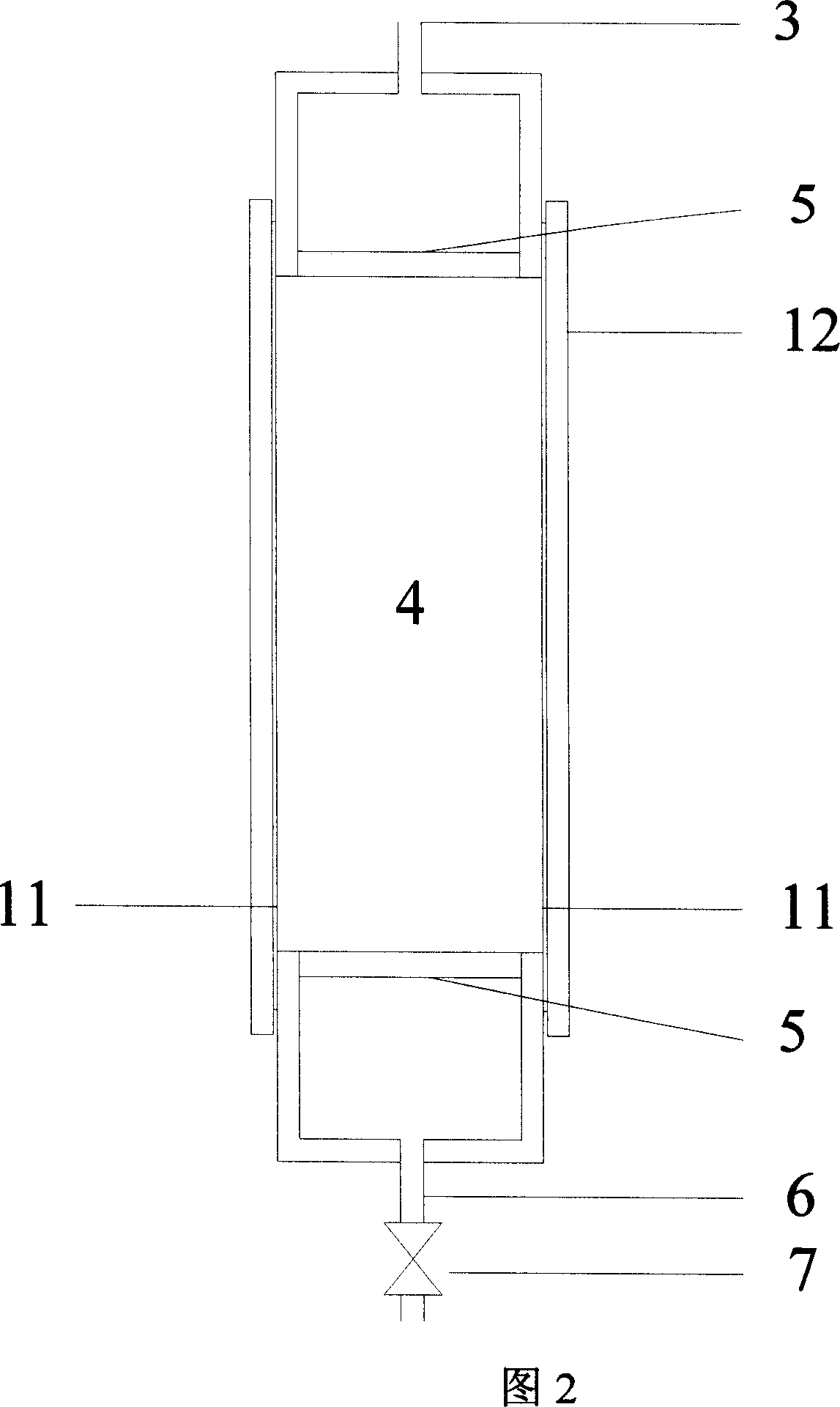

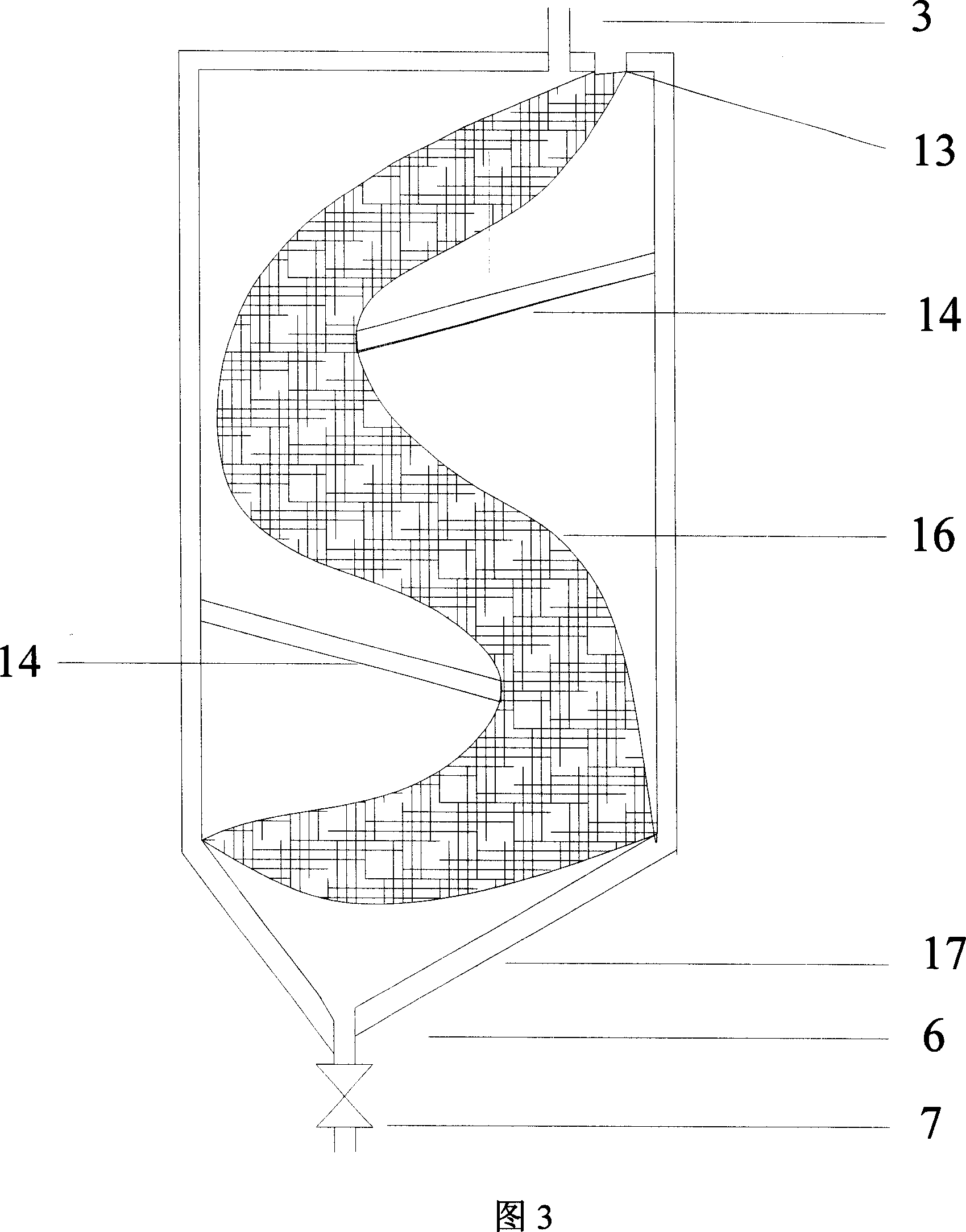

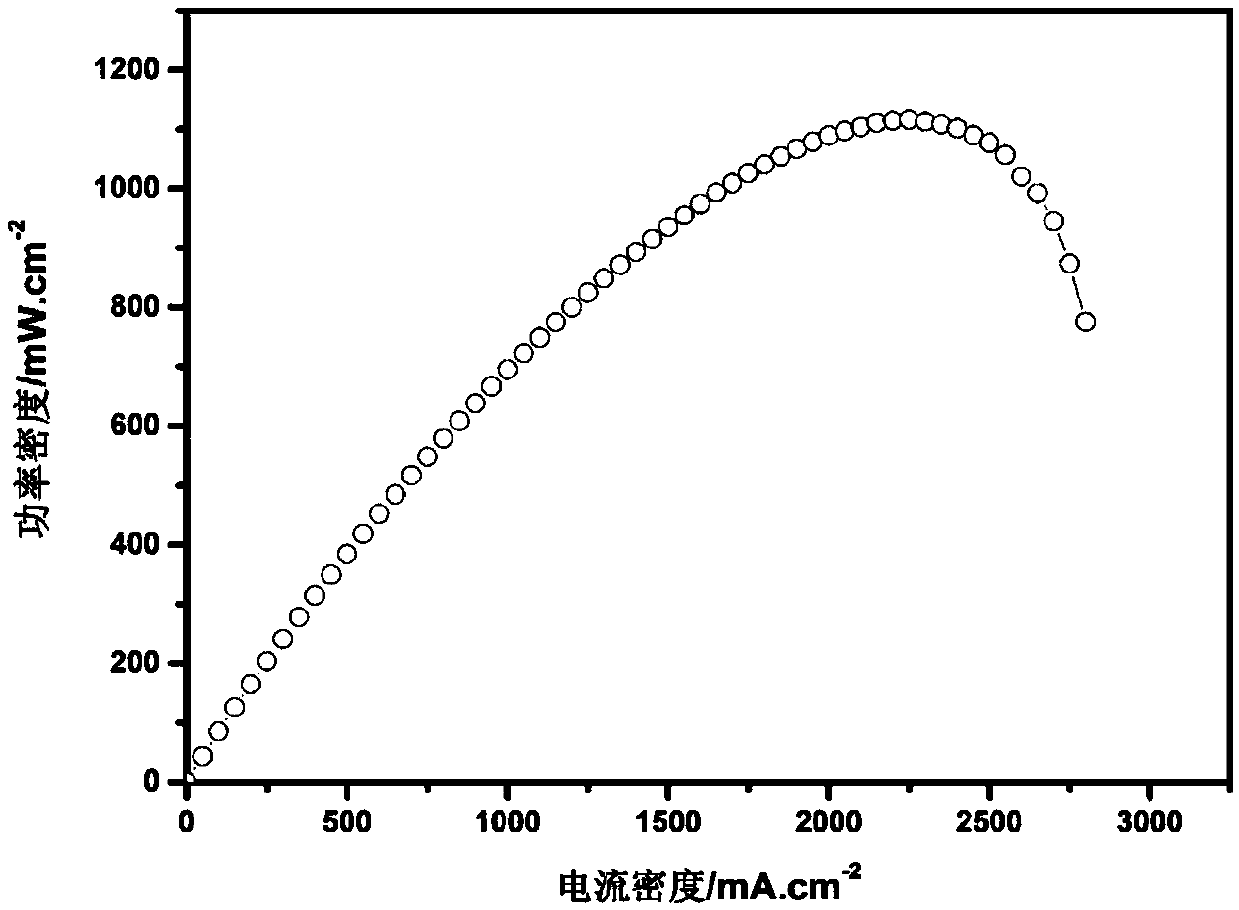

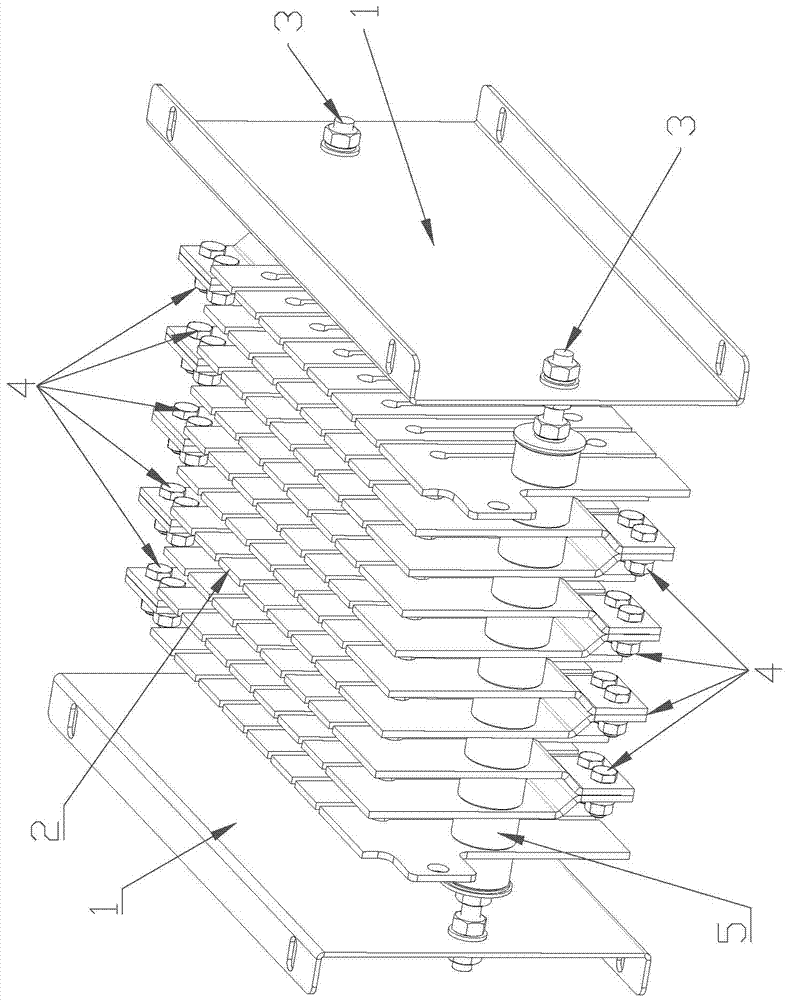

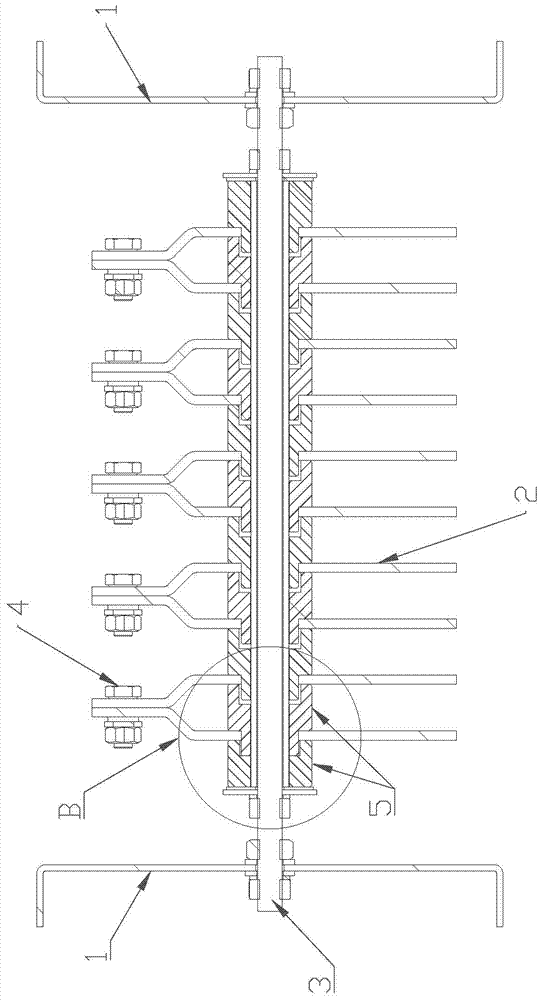

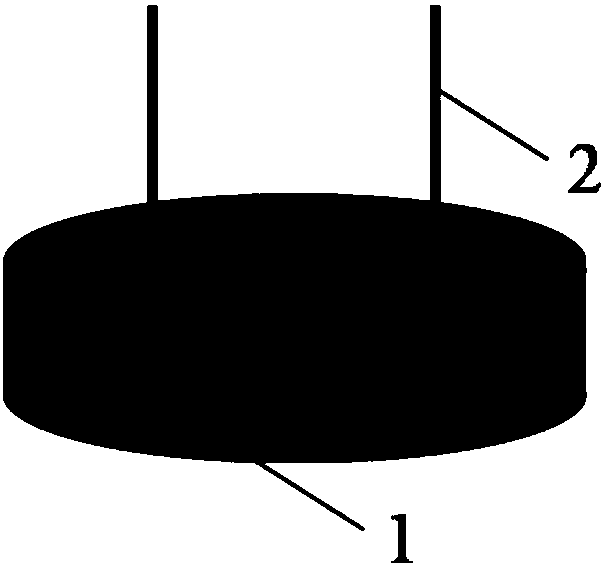

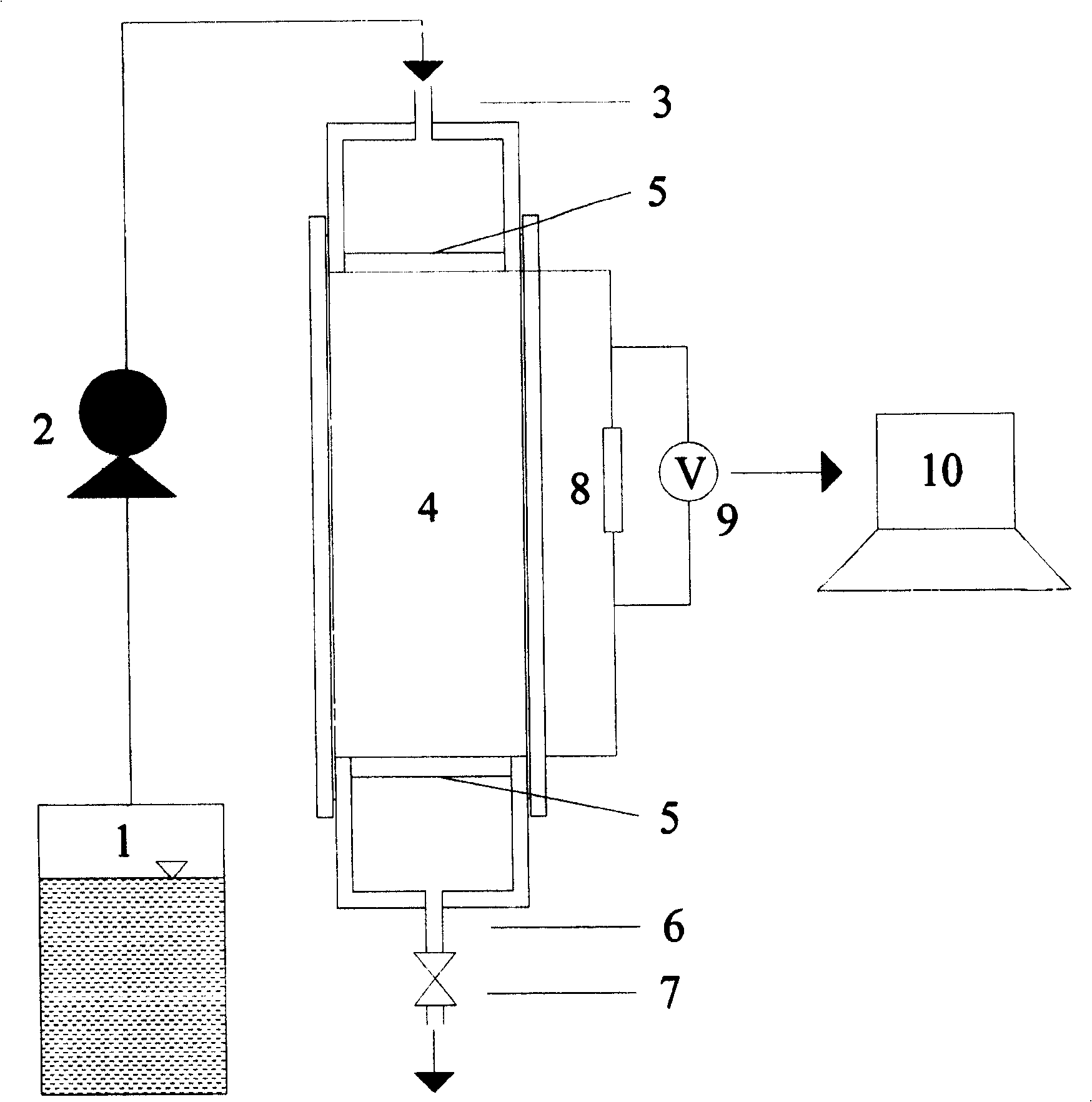

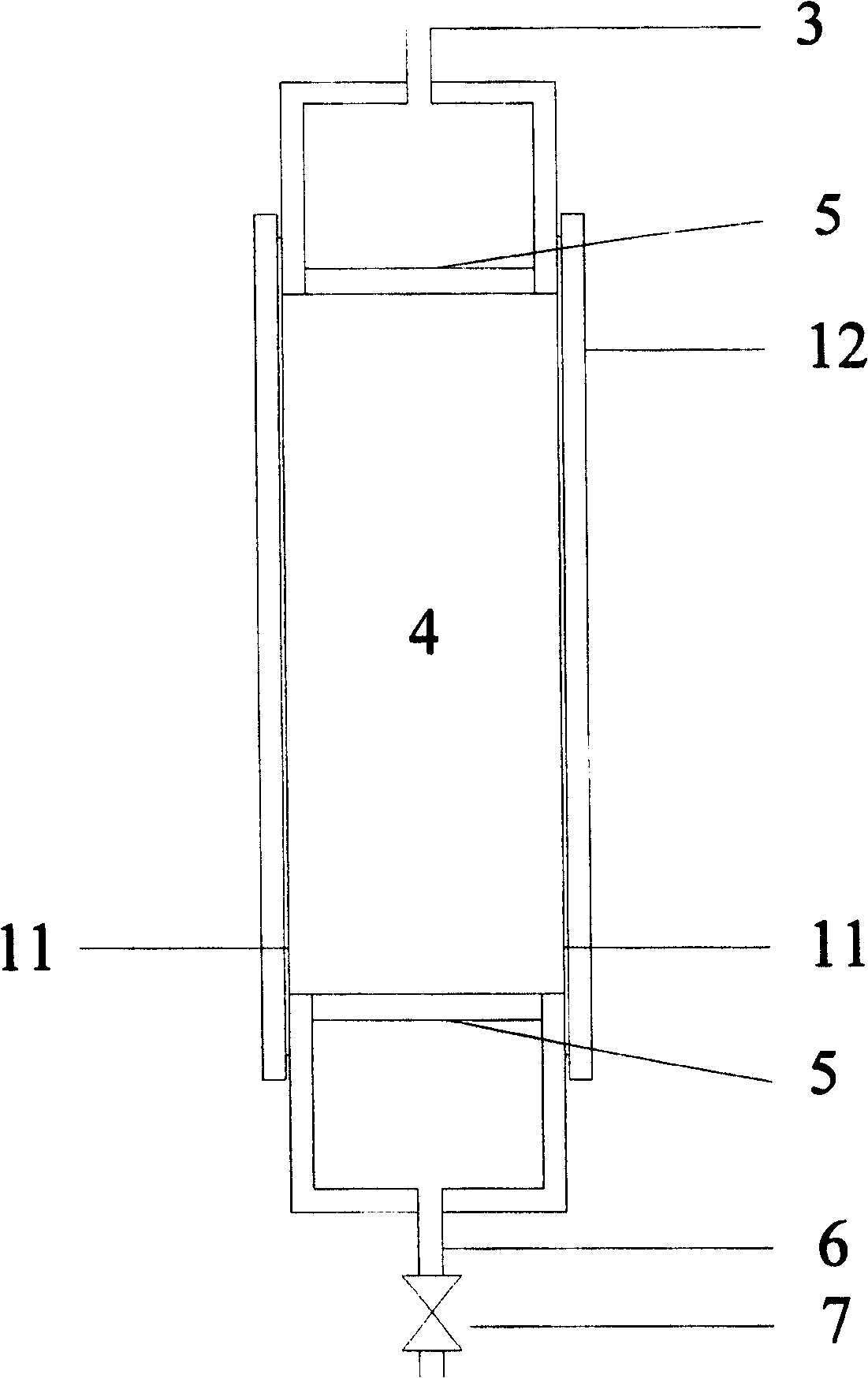

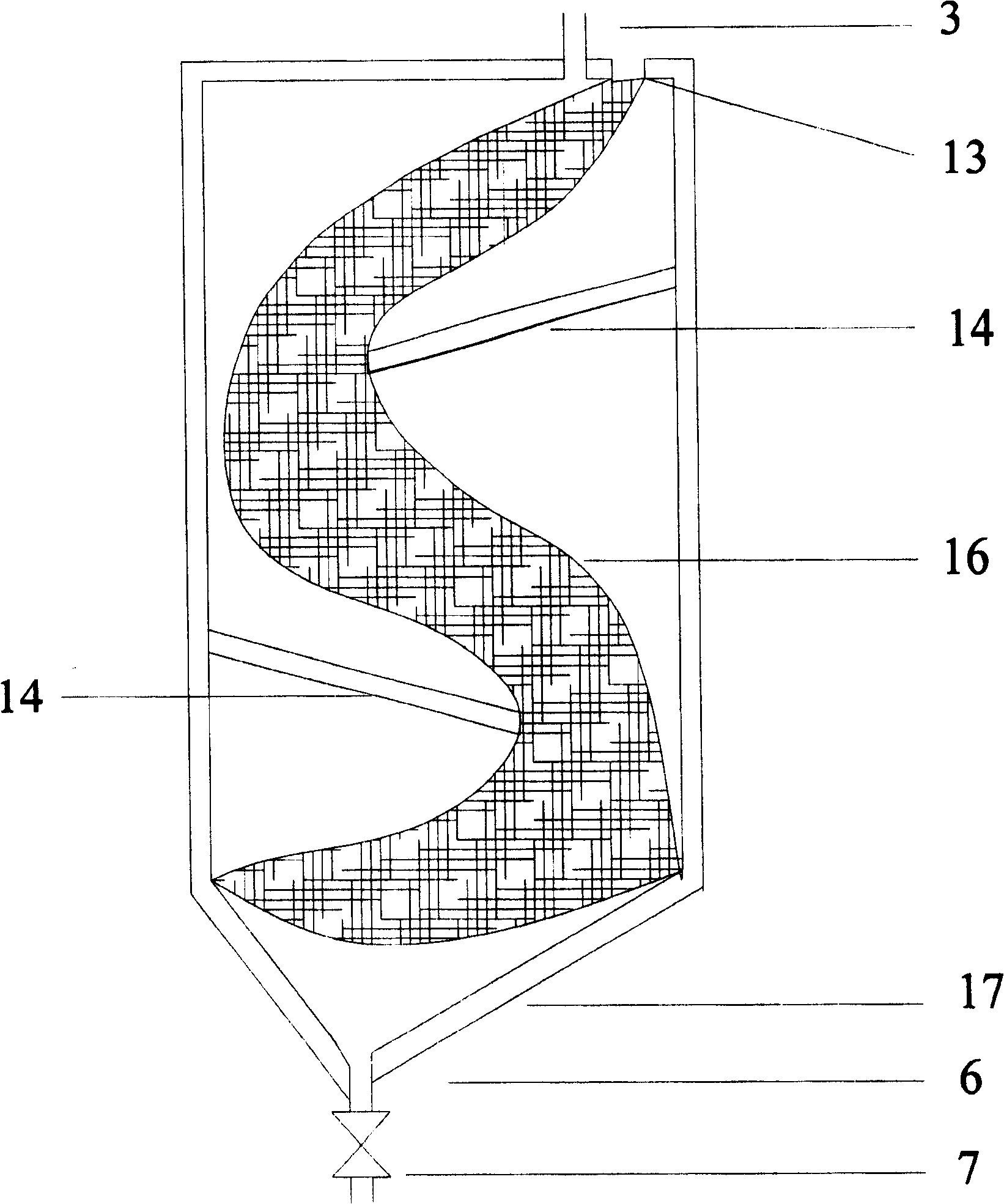

Stackable single cell microbe fuel battery

The invention discloses a pile type single room microbiological fuel cell; the battery is the sheet style structure, battery thickness is 5-30 centimeter, two groups of membrane electrodes altogether used an anode chamber, which is advantageous for composing the large-scale microbiological fuel cell heap, in order to output a greater voltage and electric current to satisfy the different current collector demand. The monomer battery uses the air type negative pole, does not need aeration, simultaneously does not need to add vector to the negative pole room, can greatly reduces the movement cost, and avoids the environmental pollution which creates by adding vector. In the anode chamber increases the carbon fiber to enhance the anode relative surface product, may enhance the monomer battery current density 3-10 times. The battery movement uses the method of upside feed-water, the base high and dry, reduced the backflow equipment demand, but also can save 50% -70% of the electrical energy. The invention is a clean advanced energy technology; and it has the broad application prospect in the municipal, industry, agricultural and spatial organic waste water processing.

Owner:BEIHANG UNIV

Metal bipolar plate and preparation method thereof and fuel cell

ActiveCN109560290AImprove corrosion resistanceLarge specific surface areaCell electrodesFuel cellsFuel cellsBinding force

The invention discloses a metal bipolar plate and a preparation method thereof and a fuel cell, and relates to the technical field of the fuel cell. An adopted technical scheme is as follows: the metal bipolar plate comprises a metal substrate, a conducting coating, and an anti-corrosion coating; the conducting coating is deposited on the metal substrate; the anti-corrosion coating is deposited onthe conducting coating; and the material of the conducting coating is the conductive metal oxide. The metal dipolar plate further comprises an amorphous carbon film deposited on the anti-corrosion coating. The fuel cell comprises the above metal bipolar plate. The metal bipolar plate is mainly used for improving the binding force of the metal substrate and the coating in the metal bipolar plate,the coating is hard to fall off after being used for a long time, and the corrosion resistance of the metal bipolar plate is improved.

Owner:浙江锋源氢能科技有限公司

Civil aluminum alloy conductor, wiring and preparation method thereof

ActiveCN101937733AImprove corrosion resistanceStrong corrosion resistanceFlexible cablesMetal/alloy conductorsElectrical conductorManufacturing technology

The invention provides a method for manufacturing civil aluminum alloy wiring, belonging to the technical field of wire and cable design and manufacture. The manufacture method comprises the following steps: adding aluminum ingots, aluminum-iron master alloy, aluminum-boron master alloy and aluminum-rare earth master alloy into a shaft furnace; casting into a cast strip after smelting; rolling into an aluminum alloy rod through a rolling mill; preparing an aluminum alloy filament by the aluminum alloy through cold drawing; annealing, and performing extruded insulation on the aluminum alloy wire, wherein the insulation material is silane-crosslinked polyethylene; adding low halogen or halogen-free flame retardant during insulation; and performing warm water crosslinking or steam crosslinking treatment on the aluminum alloy wiring after the extruded insulation is completed. The aluminum alloy wiring has excellent conductivity, tensile property and bending performance; and the wire has better flame retardant performance and longer service life.

Owner:于贵良 +1

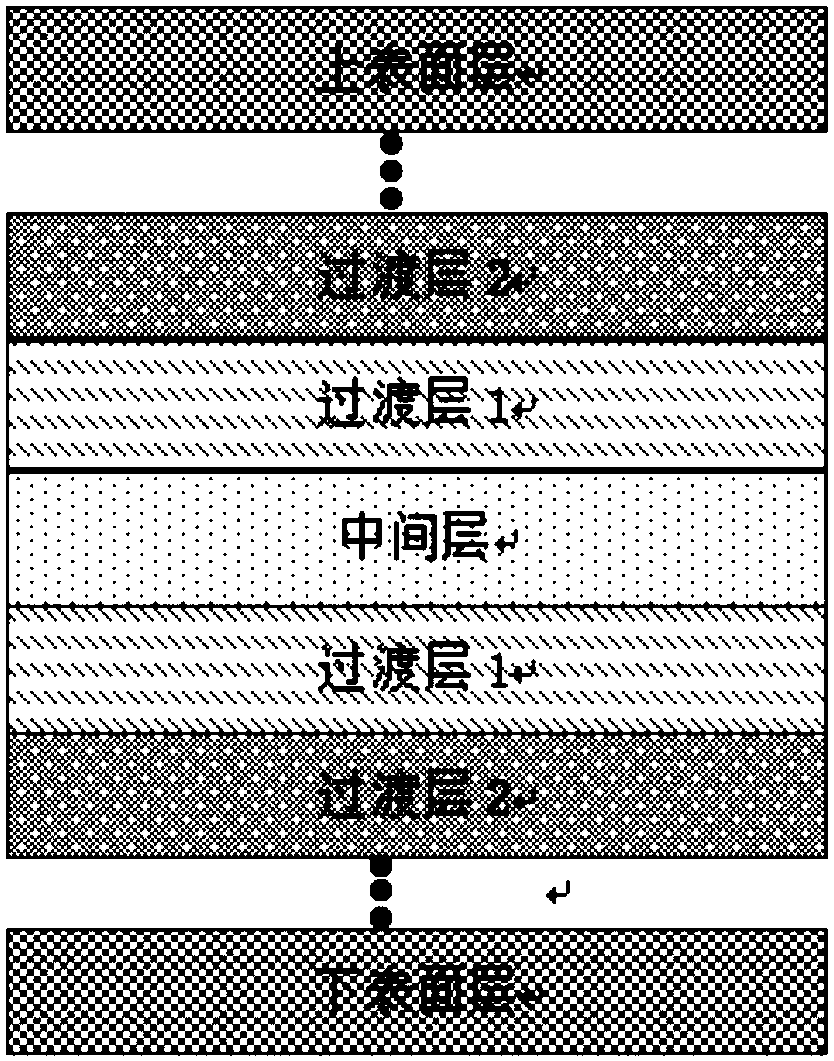

Composite bipolar plate for fuel cell as well as preparation method and application of composite bipolar plate

ActiveCN109514962AReduce the difficulty of demouldingImprove corrosion resistance and airtightnessLaminationLamination apparatusSurface layerElectrical resistivity and conductivity

The invention provides a composite bipolar plate. The composite bipolar plate comprises an upper surface layer, a lower surface layer and one or more intermediate layers, wherein one or more transition layers exist between the upper surface layer or the lower surface layer and each intermediate layer. The lower surface layer, the transition layer, the intermediate layer, the transition layer and the upper surface layer are sequentially placed into a die with a flow field and is spread and cold pressed to prepare a preform. Then, the preform is hot-pressed and is finally subjected to processessuch as demolding and aftertreatment to prepare the composite bipolar plate. The composite bipolar plate provided by the invention effectively balances the conflict between conductivity and bending strength and has good bending strength, conductivity and gas permeability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method for silver-coated copper powder

InactiveCN107096916APrevent oxidationAvoid exposure to dissolved oxygenTransportation and packagingMetal-working apparatusPhosphateSurface oxidation

The invention relates to a preparation method for silver-coated copper powder, and belongs to the technical field of preparation of conductive materials. According to the preparation method, firstly, nano-copper powder is immersed in a sulfuric acid solution, the surface oxide layer of the nano-copper powder is removed through ultrasonic acid pickling, then dopamine is adsorbed on the surface of the nano-copper powder in an aqueous solution and is subjected to automatic polymerization on the surface of the nano-copper powder under an alkaline condition to form a uniform coating layer, the strong complexing adsorption capacity of the formed polydopamine coating layer is utilized for adsorbing silver ions in a silver nitrate solution, and potassium dihydrogen phosphate is used as a reducing agent in a nitrogen atmosphere to reduce the silver ions to form a uniform silver coating, and finally just vacuum drying and sintering needs to be carried out on the silver coating. According to the silver-coated copper powder prepared through the method, the silver can form a uniform and dense coating on the surface of the copper powder, so that the conductivity of the copper powder is improved, and the anti-oxidation temperature is higher than 620 DEG C.

Owner:嘉兴市南湖区翊轩塑料五金厂(普通合伙)

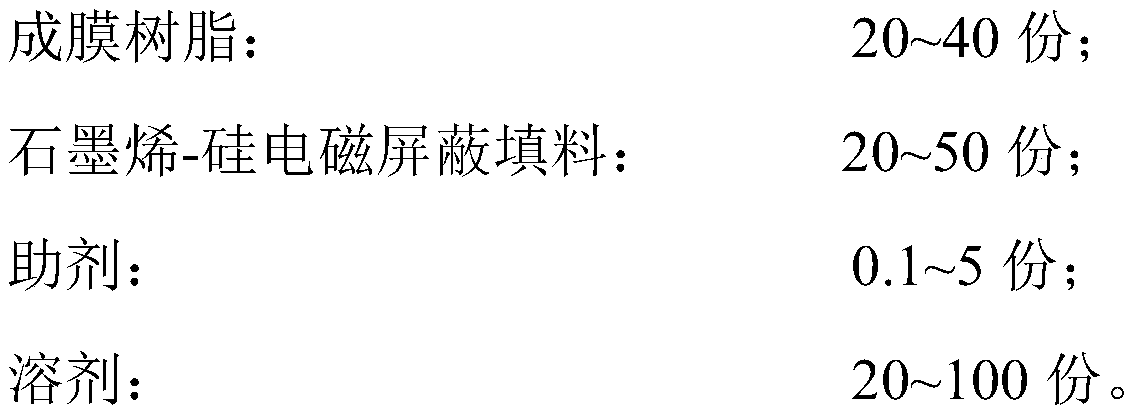

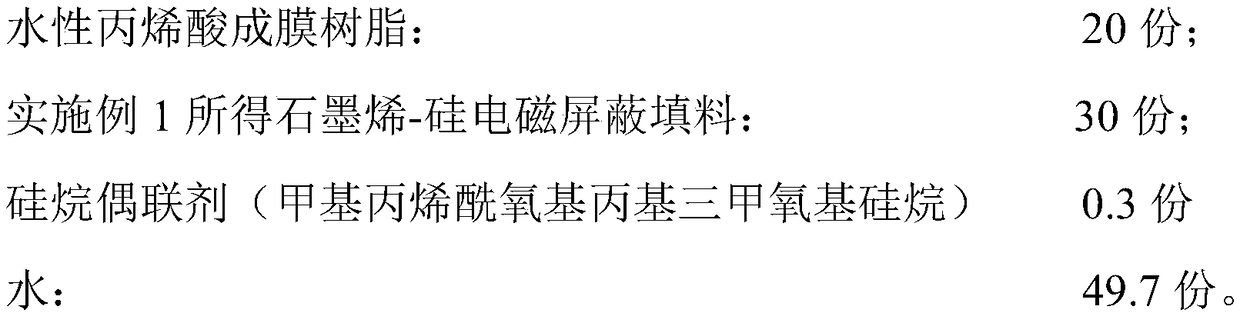

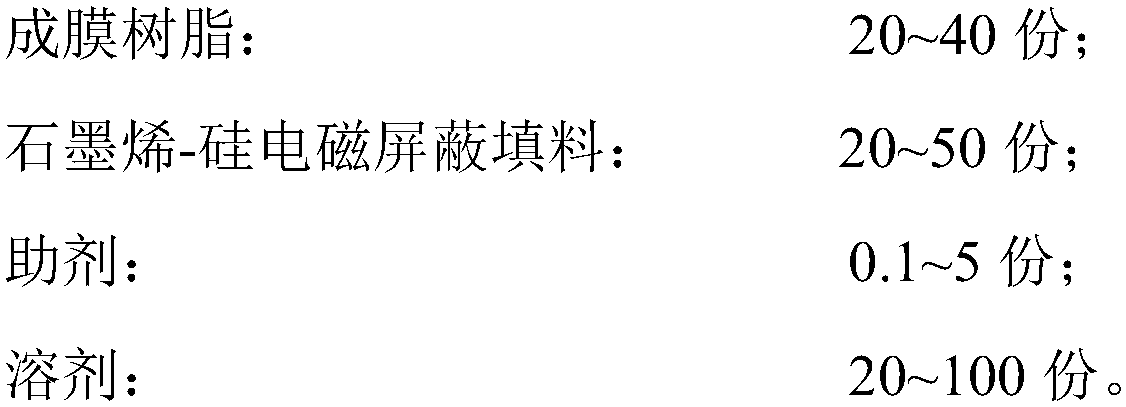

Graphene-silicon electromagnetic shielding filler and electromagnetic shielding coating

ActiveCN108117811AImprove conductivityConductivity effectAnti-corrosive paintsElectrically-conductive paintsElectromagnetic shieldingComposite matrix

The invention belongs to the field of electromagnetic shielding materials and discloses graphene-silicon electromagnetic shielding filler and electromagnetic shielding coating. The graphene-silicon electromagnetic shielding filler is prepared by the following steps: adding tetraethyl orthosilicate into an ethanol water solution; then adding ammonia water as a catalyst; reacting at the temperatureof 30 to 60 DEG C to obtain nano silicon dioxide sol; then adding graphene and ultrasonically stirring and uniformly dispersing to obtain a mixed solution; drying the mixed solution to obtain a nano silicon dioxide-graphene compound; uniformly mixing the obtained nano silicon dioxide-graphene compound with magnesium powder; raising the temperature to be 500 to 1000 DEG C and carrying out high-temperature thermal reduction reaction; washing and drying to obtain the graphene-silicon electromagnetic shielding filler. According to the graphene-silicon electromagnetic shielding filler disclosed bythe invention, the graphene and semiconductor silicon are doped and compounded, so that the electrical conductivity of a compound is remarkably improved and the electromagnetic shielding performance of the compound is further enhanced; the adverse effect, cased by a composite matrix in an existing composite material, on the electrical conductivity of the graphene is avoided.

Owner:惠州市栢诗新材料有限公司

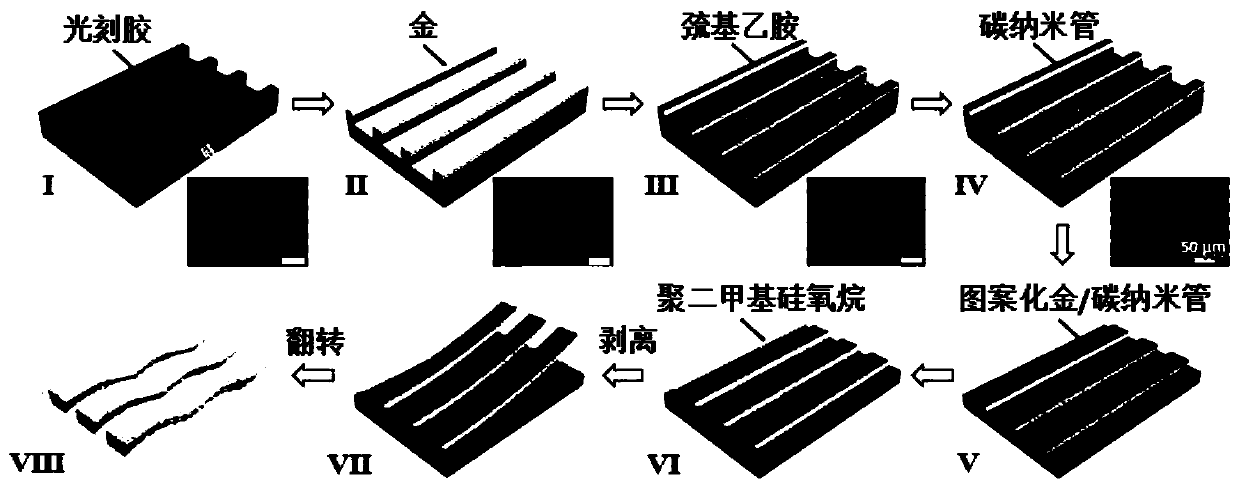

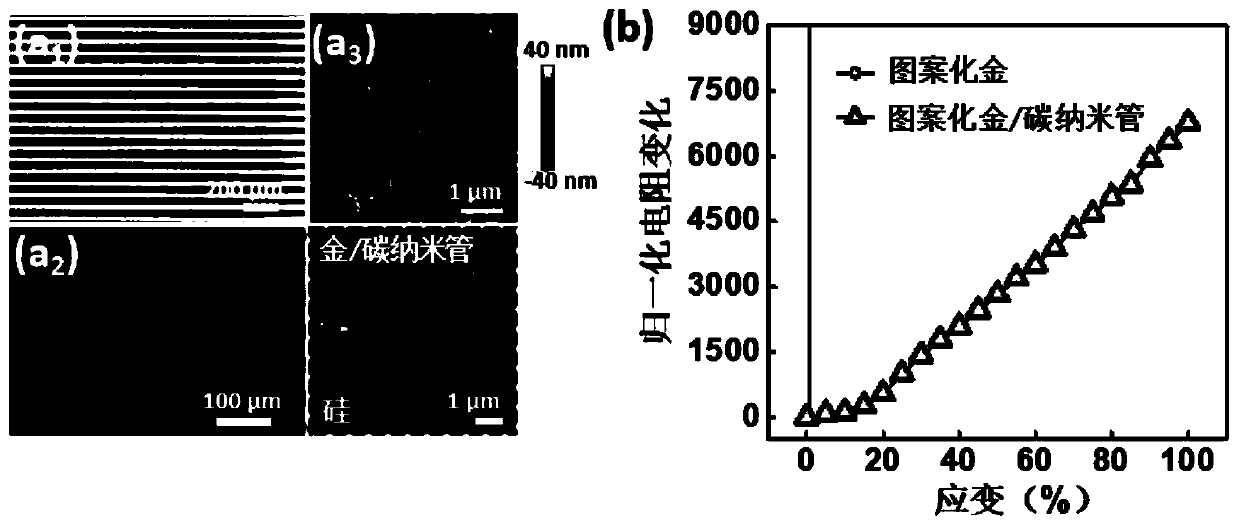

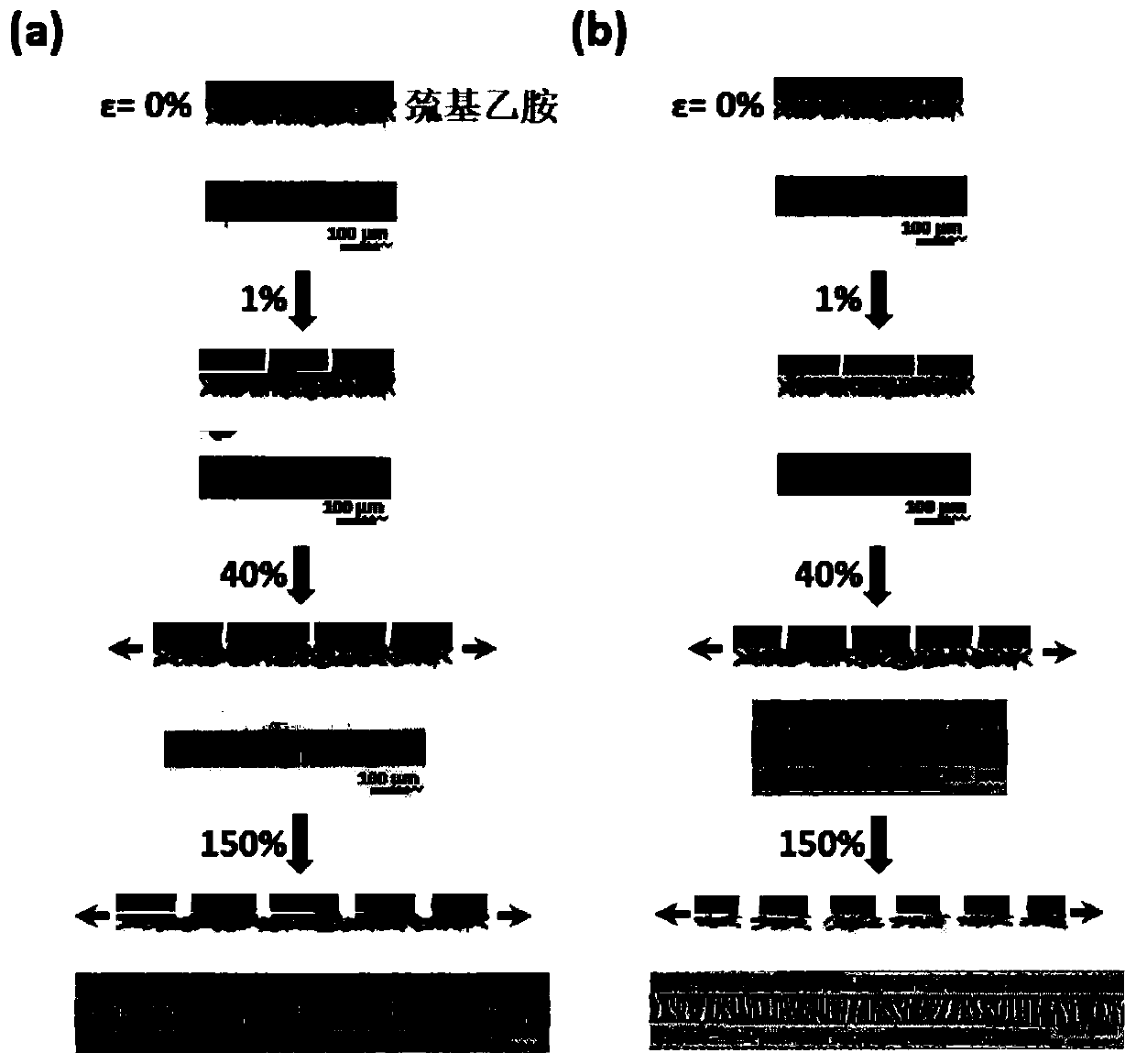

High-precision patterned stretchable electrode and preparation method thereof

ActiveCN109801739AGood stretchabilityImprove flexibilityConductive layers on insulating-supportsMetal/alloy conductorsMercaptoethylaminesElastic substrate

The invention discloses a high-precision patterned stretchable electrode and a preparation method thereof. The high-precision patterned stretchable electrode is a patterned electrode attached to an elastic substrate. The patterned electrode is a metal electrode connected with a carbon nano tube. The metal electrode is a gold electrode. The metal electrode is connected with the carbon nano tube through mercaptoethylamine. The high-precision patterned stretchable electrode is prepared by the method provided in the invention. The method comprises the following steps: evaporating metal on a substrate provided with an electrode pattern to obtain a metal electrode; spraying a carbon nano tube on the surface of the metal electrode; preparing an elastic substrate on the surface of the carbon nanotube, and stripping the elastic substrate from the substrate. According to the patterned stretchable electrode provided by the invention, the advantages of high conductivity of a traditional gold electrode and high aspect ratio and large specific surface area of a carbon nano tube are combined. The advantage complementation is fully realized, and the high-precision patterned stretchable electrodewith high tensile property and good conductivity is prepared.

Owner:NORTHEAST NORMAL UNIVERSITY

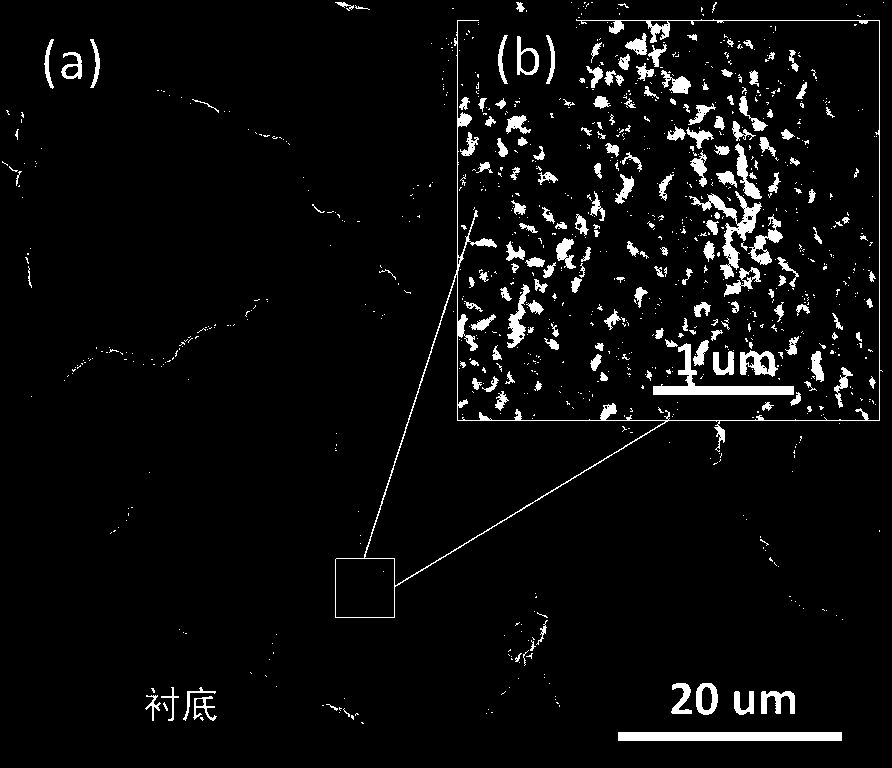

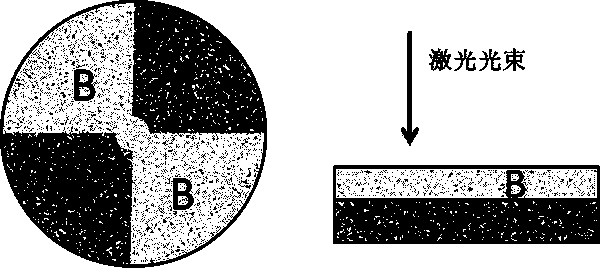

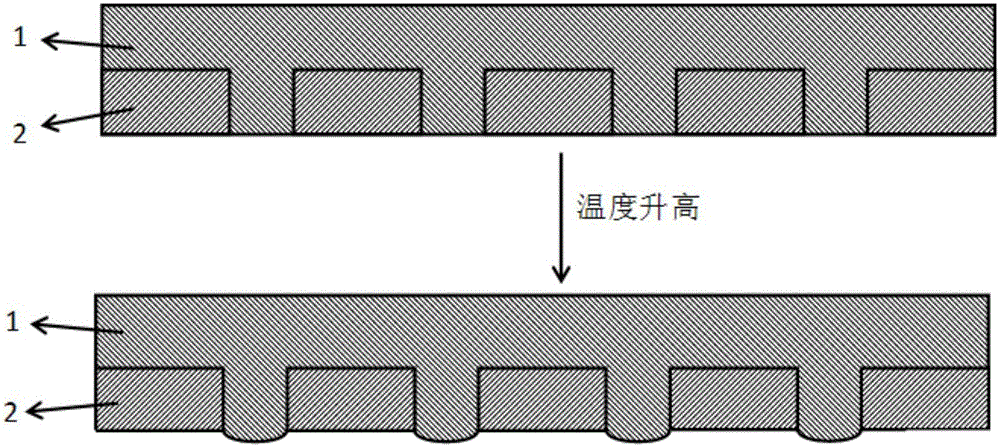

Preparation method of thickness-controllable nano-porous metal thin film

InactiveCN104372300AEasy to manufactureContinuously adjustable temperatureVacuum evaporation coatingSemiconductor/solid-state device manufacturingThermal insulationAlloy thin film

The invention relates to a method for preparing a nano-porous metal thin film by virtue of laser pulse deposition. The method comprises the following steps: firstly preparing a hollow metal sheet A according to a required proportion, and compounding the metal sheet A and a metal sheet B to form a target material; then depositing a layer of an alloy thin film on a substrate by using the target material as a raw material by virtue of a pulse laser deposition method, wherein the vacuum degree in a vacuum cavity is 10<-5> to 10<5>Pa, the substrate temperature is 50-1100 DEG C in thin film deposition, the laser frequency is 1-10Hz, and the laser energy is 50-300mj; adjusting the thickness of an alloy thin film according to pulse laser times and laser energy density; annealing the alloy thin film in an annealing furnace for 0.5-6 hours at 80-1000 DEG C; and soaking the alloy thin film subjected to annealing treatment into a NaOH solution with the concentration of 1-10wt% or an H2SO4 solution with the concentration of 1-10wt%, and performing de-alloying to obtain the nano-porous metal thin film. According to the method disclosed by the invention, the alloy does not need to be smelted at high temperature, the thin film thickness can be accurately controlled according to the pulse times, raw materials can be saved, and apertures can be adjusted according to the heating and thermal insulation time.

Owner:UNIV OF JINAN

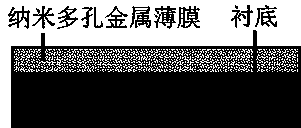

Method for preparing silver metal oxide electrical contact material through internal oxidation method to improve welding-resistant performance

InactiveCN110951980AReduce solid solubilityReduce bond strengthContactsSmelting processInternal oxidation

The invention discloses a method for preparing a silver metal oxide electrical contact material through an internal oxidation method to improve welding-resistant performance. According to the technical scheme, excess nickel elements are added in the smelting process, and can be fully alloyed with a silver substrate in the melting process, along with decreasing of the cast ingot temperature, the nickel elements are oversaturated to be separated out in a silver alloy, and separated-out nickel particles are evenly distributed in the silver substrate. In the subsequent internal oxidation process,the silver alloy can be fully oxidized, only the surfaces of the nickel particles in the silver substrate are oxidized, the interiors of the nickel particles in the silver substrate cannot be oxidized, the binding strength between oxidation aggregation layers on the surfaces of the nickel particles and the silver substrate is low, and thus the tensile strength of the material is lowered. In the electrical contact process, due to the existence of the nickel particles evenly distributed in silver metal oxide, the welding force of a welding bridge can be effectively decreased, the welding position between contacts is easier to disconnect, and thus the welding-resistant performance of the silver metal oxide material is improved.

Owner:FUDA ALLOY MATERIALS

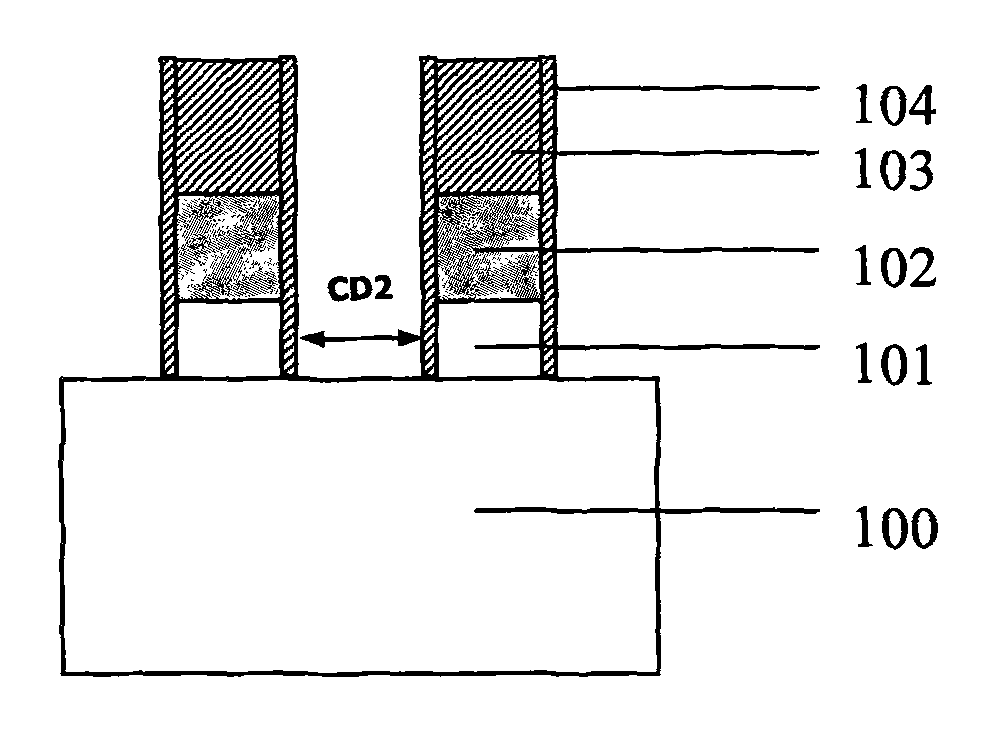

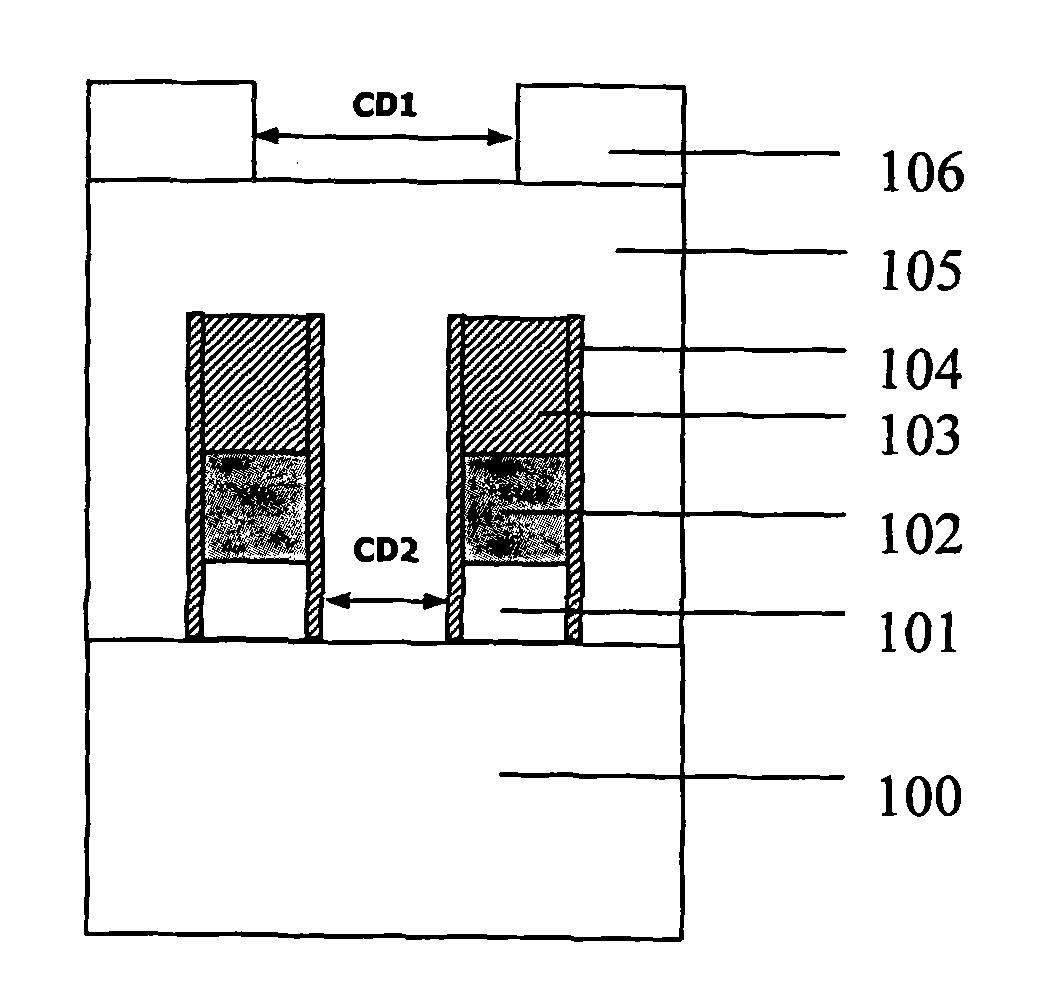

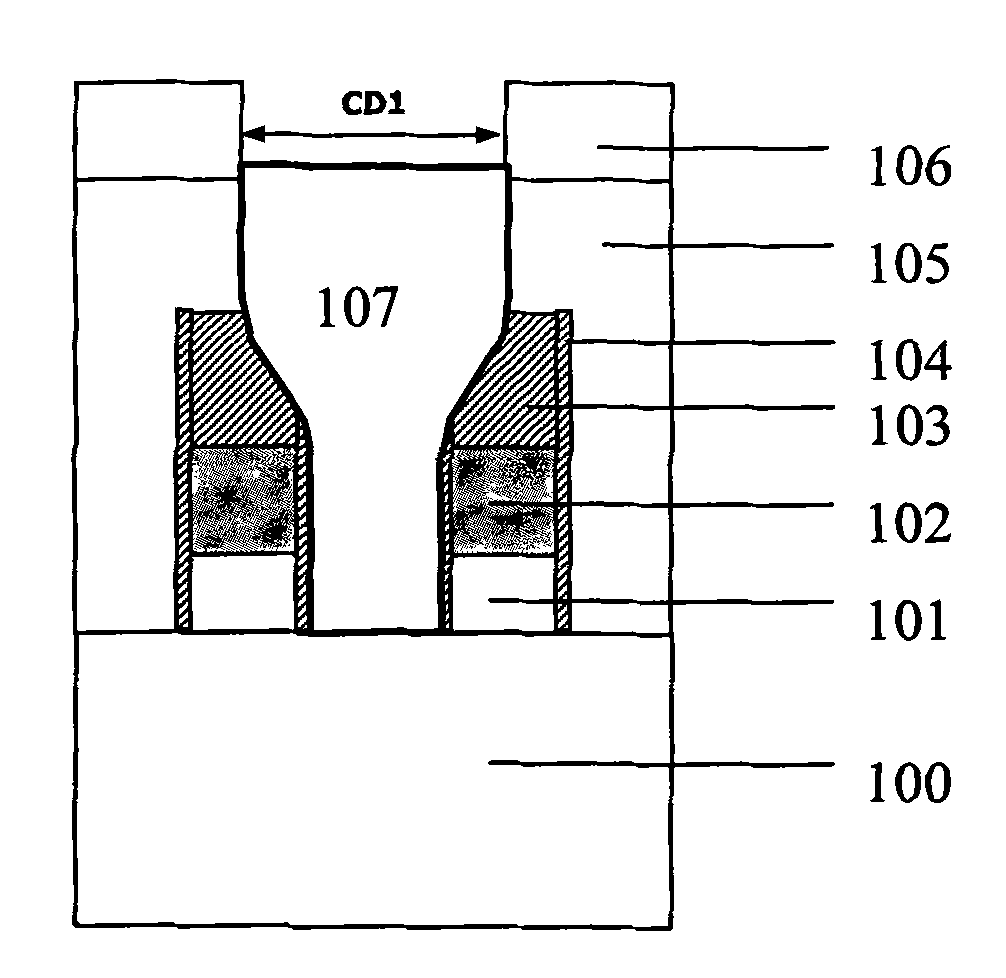

Method for manufacturing self-alignment metal interconnection wire

InactiveCN102034734AConductivity effectIncreasing the thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesMetal interconnectInsulation layer

The invention discloses a method for manufacturing a self-alignment metal interconnection wire, comprising the following steps of: providing a semiconductor substrate with more than one grid electrode structure, wherein the grid electrode structure comprises a grid electrode layer, a grid conducting layer and a first hard mask layer which are successively positioned on the semiconductor substrate; forming a first photoresist layer of which the surface is higher the grid electrode structure; etching the first photoresist layer with plasmas, and exposing the first mask layer and partial grid conducting layer; etching the exposed grid conducting layer to cause sinks generating on the grid conducting layer; removing the first photoresist layer; forming side walls, for filling the sinks, on two sides of the grid electrode structure; forming inter-layer dielectric layers on the semiconductor substrate and the grid electrode structure; etching the inter-layer dielectric layers to the semiconductor substrate and forming a contact hole on a set position; and filling a metal layer into the contact hole to form the metal interconnection wire. With the method, the thickness of an insulation layer between the grid conducting layer and the metal interconnection wire is increased, and the phenomenon of breakdown between the grid conducting layer and the metal interconnection wire can be avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

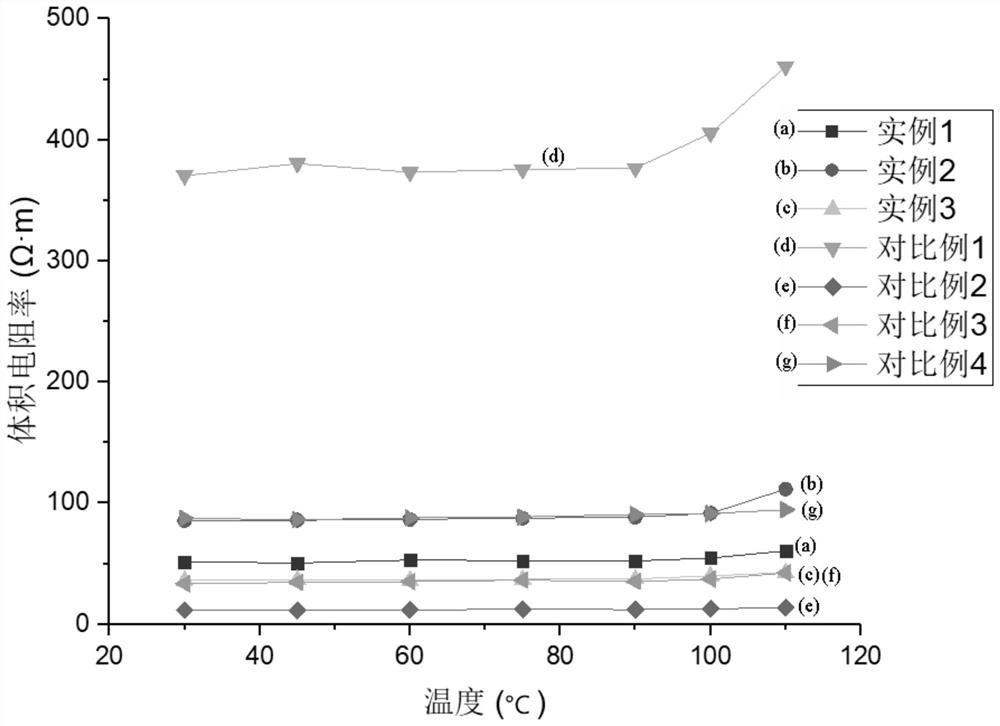

Polypropylene-based thermoplastic shielding material for cable, and preparation method thereof

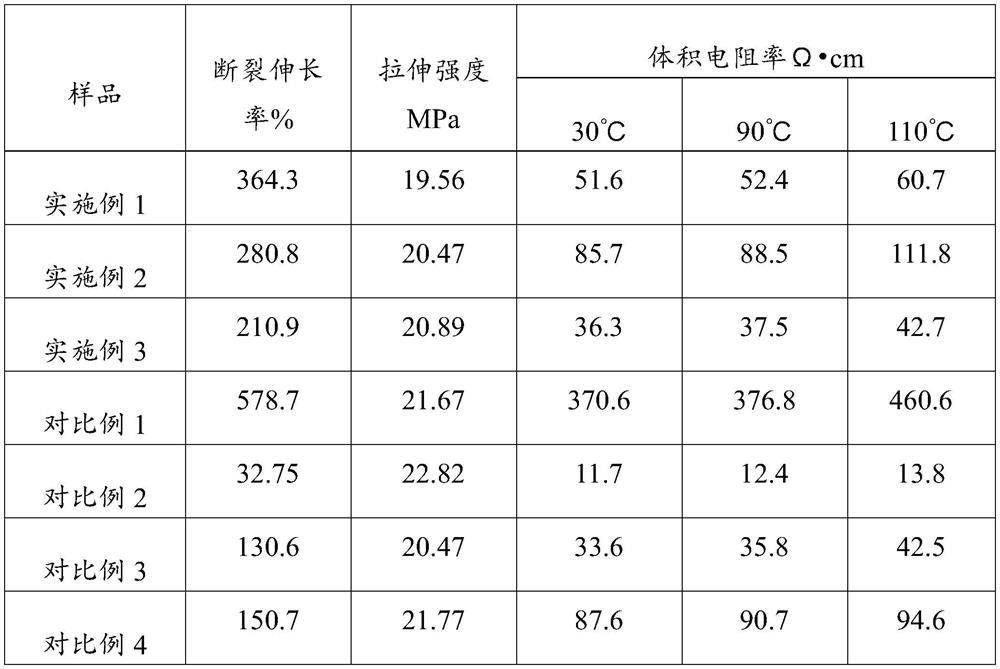

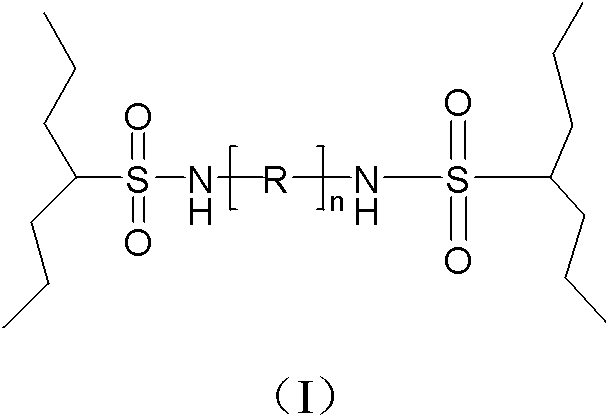

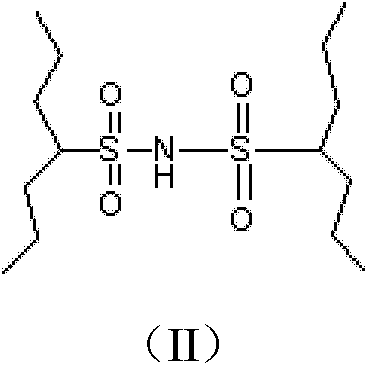

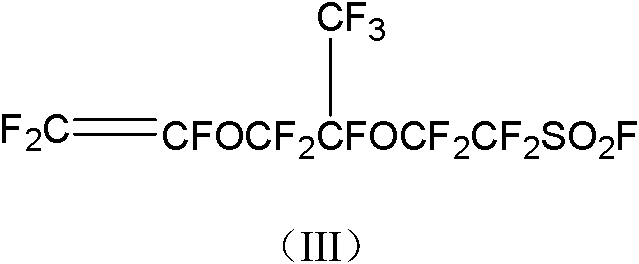

The invention provides a polypropylene-based thermoplastic shielding material for a cable and a preparation method of the shielding material. The shielding material comprises the following componentsin parts by weight: 100 parts of ethylene-propylene block copolymer polypropylene, 3-20 parts of conductive carbon black, 0.5-1.5 parts of high-conductivity graphene, 0.5-1.5 parts of a coupling agentand 1.4-4.5 parts of an auxiliary agent, wherein the auxiliary agent comprises an antioxidant, a lubricant and an anti-bonding agent; and the mass fraction of ethylene fragments in the ethylene-propylene block copolymer polypropylene is 5%-30%. According to the shielding material in the invention, the problem that mechanical properties are reduced due to the fact that high-content conductive carbon black needs to be added for improving the conductivity of a conventional polypropylene-based thermoplastic shielding material for the cable is solved, and the polypropylene-based thermoplastic shielding material for the cable in the invention has excellent conductivity and mechanical properties, and still has excellent conductivity and mechanical properties under a high-temperature condition through cooperation among the ethylene-propylene block copolymer polypropylene, the conductive carbon black and the high-conductivity graphene.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Flow battery diaphragm and its preparation method

ActiveCN102522575APrevent penetrationReduce penetrationCell component detailsFuel cell detailsCross-linkNetwork structure

The invention relates to a flow battery diaphragm and its preparation method. The flow battery diaphragm is a film formed by a perfluorinated sulfonic acid resin and at least one surface of the film reacts with a cross-linking agent to form a chemical bonding cross-linking network structure. Due to the existence of the surface cross-linking structure, vanadium ion permeability and water mobility of the film are greatly reduced in comparison with that of a traditional film. At the meantime, as the perfluorinated sulfonic acid resin is used as the film-forming resin, the diaphragm in a battery is endowed with excellent chemical stability and long service life. The invention also provides a preparation method of the flow battery diaphragm.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

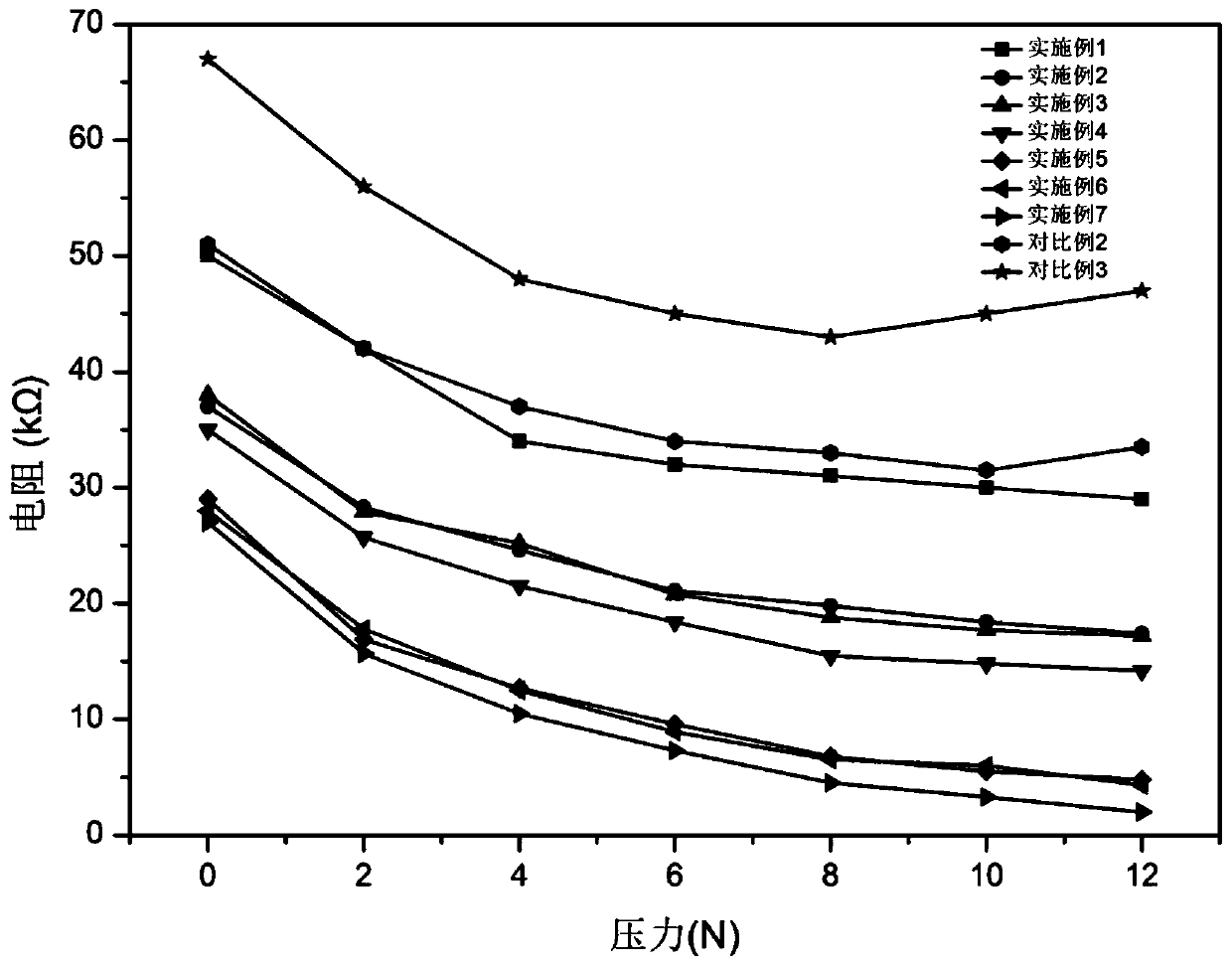

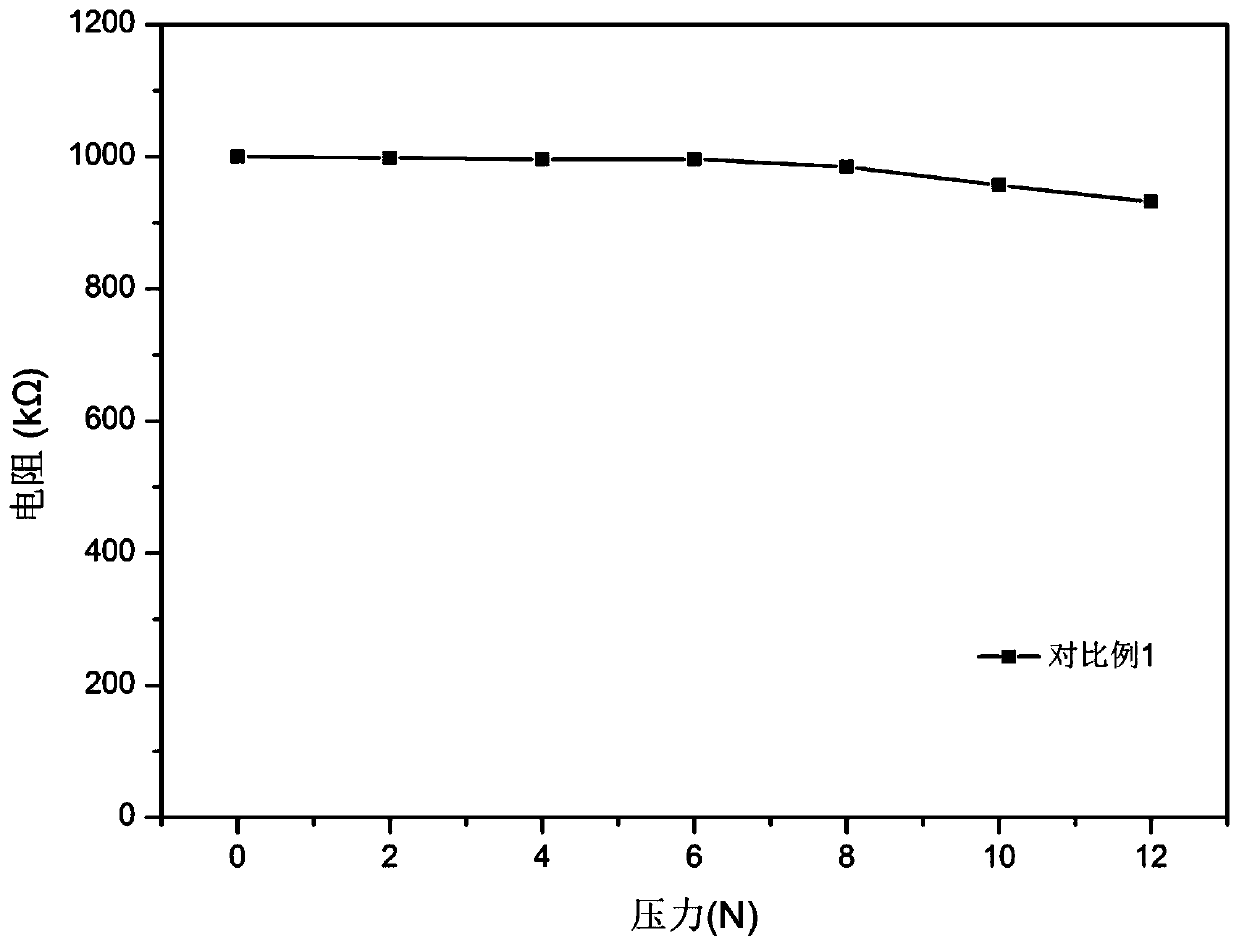

Pressure sensitive composite material used in flexible sensor and preparation method thereof

InactiveCN110330794AGood electrical insulation propertiesGood aging resistanceFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsSolventPressure sensitive

Relating to the sensor field, the invention discloses a pressure sensitive composite material used in a flexible sensor and a preparation method thereof. The pressure sensitive composite material usedin a flexible sensor comprises the following components by weight: 350-450 parts of silicone rubber, 25-100 parts of conductive particles, 5-20 parts of a nano modified material, 15-40 parts of an assistant, and 85-115 parts of a solvent. The conductive particles include carbon black and carbon nanotubes. The preparation method includes: dispersing the conductive particles and the nano modified material in the assistant to form a dispersion solution; adding silicone rubber into the dispersion solution, and stirring the substances evenly to obtain a mixed solution; and performing vacuum dryingon the mixed solution to obtain the pressure sensitive composite material. According to the invention, carbon black and carbon nanotubes are used as the conductive particles together, and the combined use of carbon black and carbon nanotubes in the silicone rubber can play a role of synergistic enhancement, the electrical conductivity and stability of the conductive particles and the mechanical properties of the composite material are all greatly improved, the pressure sensitive composite material has higher perception sensitivity, and the pressure perception range is improved.

Owner:SHAOXING UNIV YUANPEI COLLEGE

Method for improving electrical interconnection characteristic of carbon nano tube

ActiveCN102881651AAvoid damageEasy to removeNanoinformaticsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceOrganic solvent

The invention provides a method for improving the electrical interconnection characteristic of a carbon nano tube. The problem of overlarge interconnection resistance brought by low space occupancy of the carbon nano tube is solved through a through hole filling technology. The method mainly comprises the following steps: the carbon nano tube is firstly grown in a prefabricated through hole, then a layer of photoresist is coated in a rotating mode on the whole surface, and high-temperature hardening treatment is carried out on the photoresist; then the whole structure is polished by a chemical mechanical polishing method, the surplus photoresist is removed with an organic solvent after polishing, metal is filled in the through hole, and chemical mechanical polishing is carried out again after filling; and finally an electrode is arranged on the top of the carbon nano tube to realize metallization contact. The method disclosed by the invention has the advantages that a method for fixing the carbon nano tube is provided, a gap of the carbon nano tube is filled with the metal more effectively, the contact resistance of the carbon nano tube and the metal is reduced, the whole process is compatible with the currently commonly used process of semiconductors, and the method is easy to realize.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

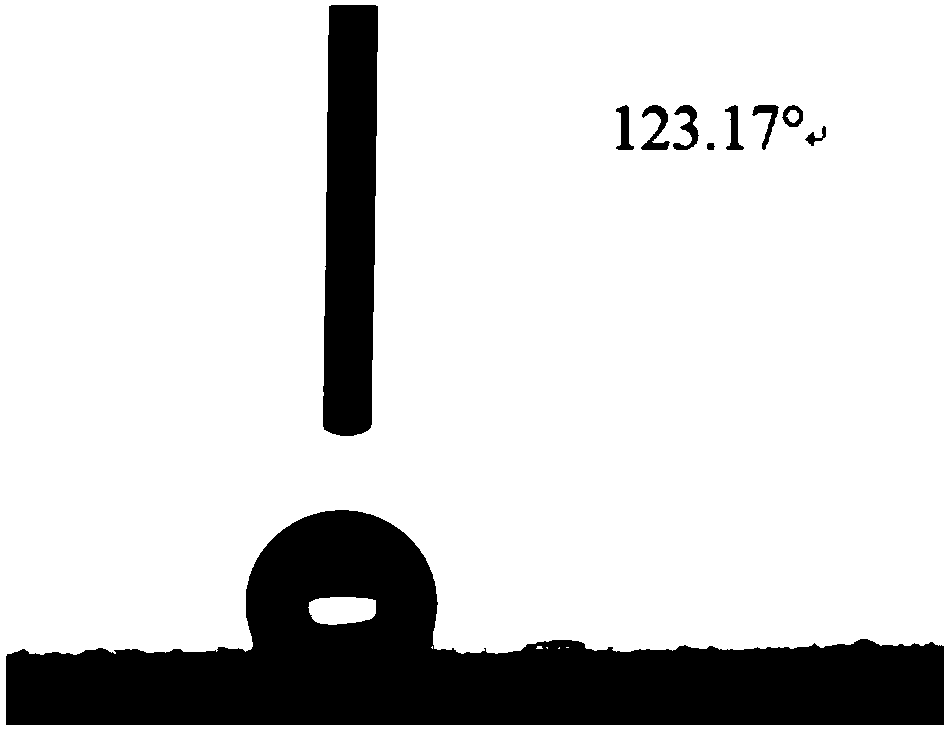

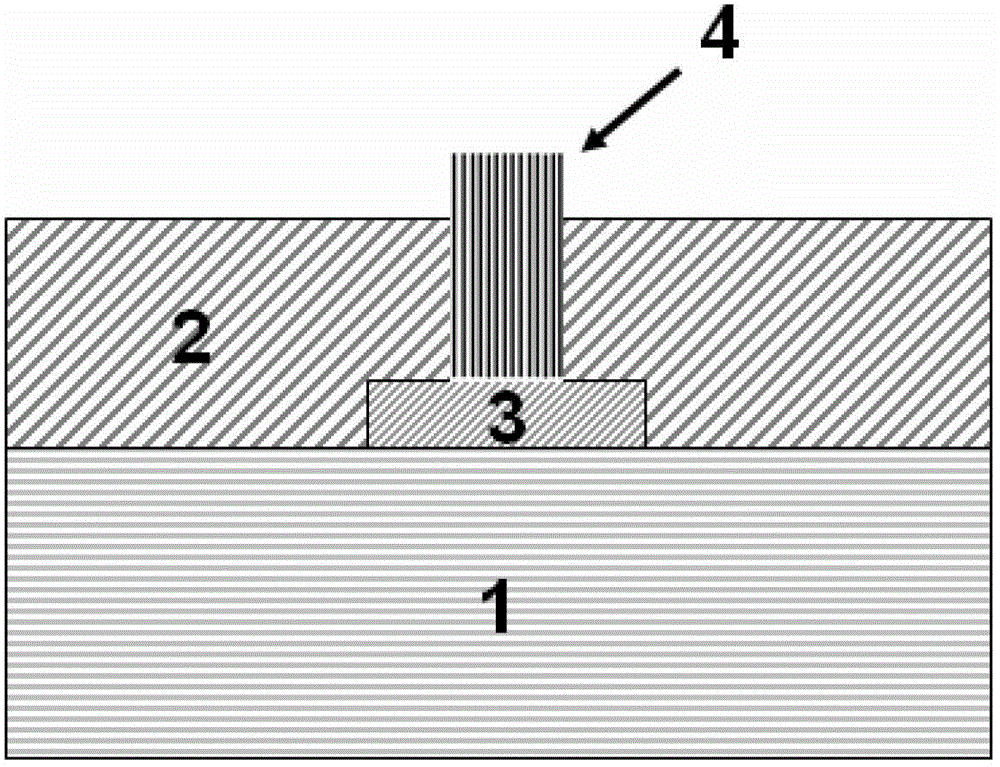

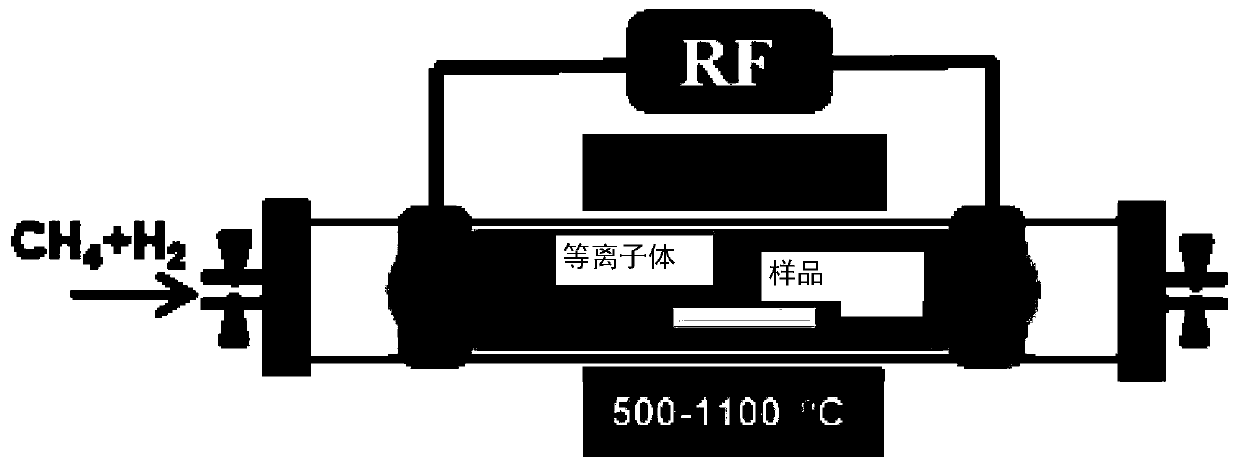

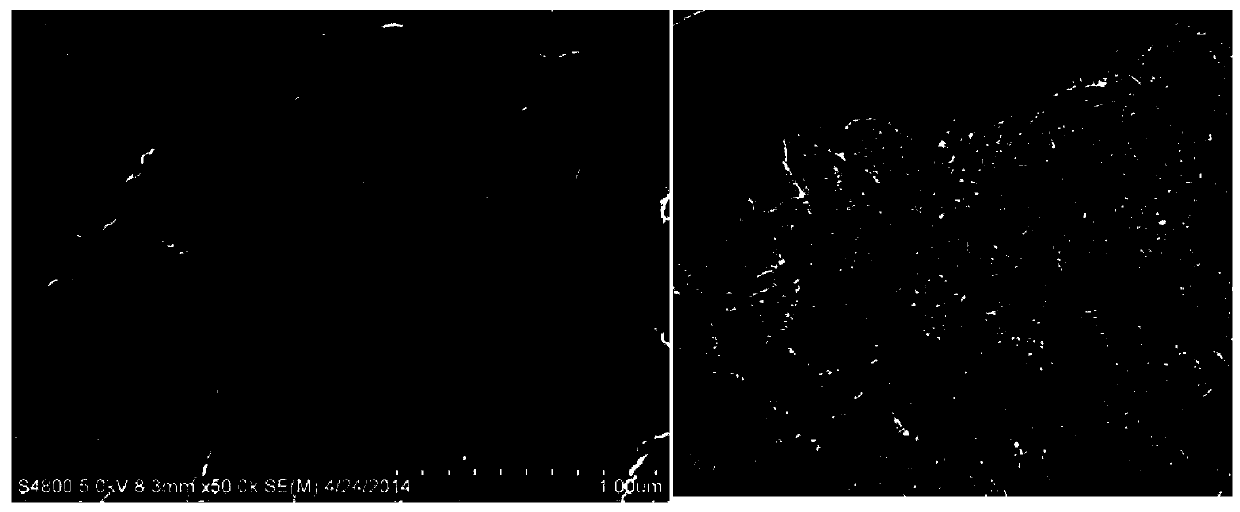

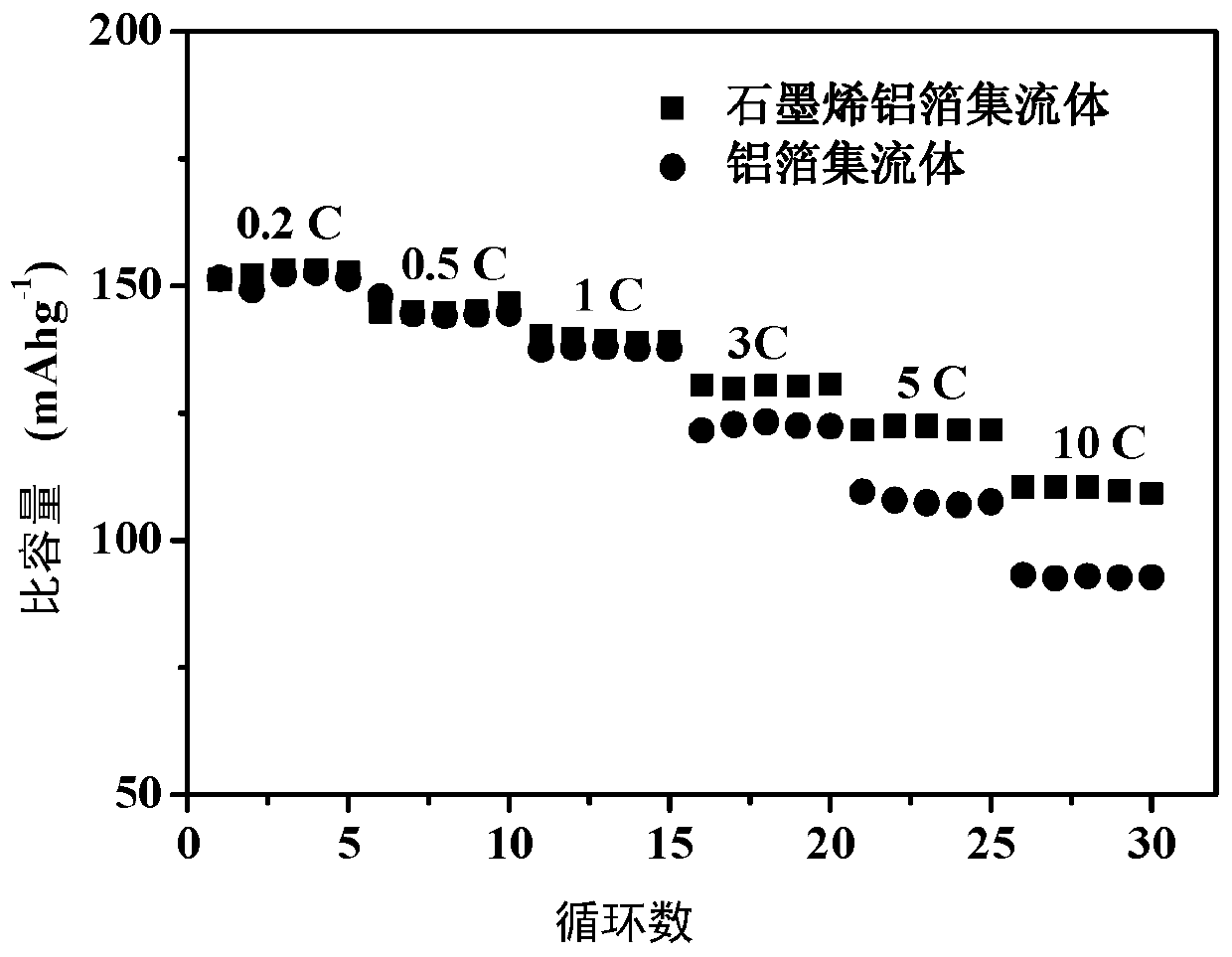

Graphene modification current collector prepared by employing plasma-assisted chemical vapor deposition and preparation method thereof

InactiveCN109950544AImprove power performanceLower internal resistanceElectrode carriers/collectorsSecondary cellsInternal resistancePower performance

The present invention relates to a graphene modification current collector prepared by employing plasma-assisted chemical vapor deposition and a preparation method thereof. The graphene modification current collector comprises a substrate and a grapheme thin film having a three-dimensional continuous structure formed by mutual connection of grapheme nanosheets vertically grown at the surface of the substrate. The graphene modification current collector can effectively reduce the internal resistance of an electrode and can improve the high-power performance of the battery.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

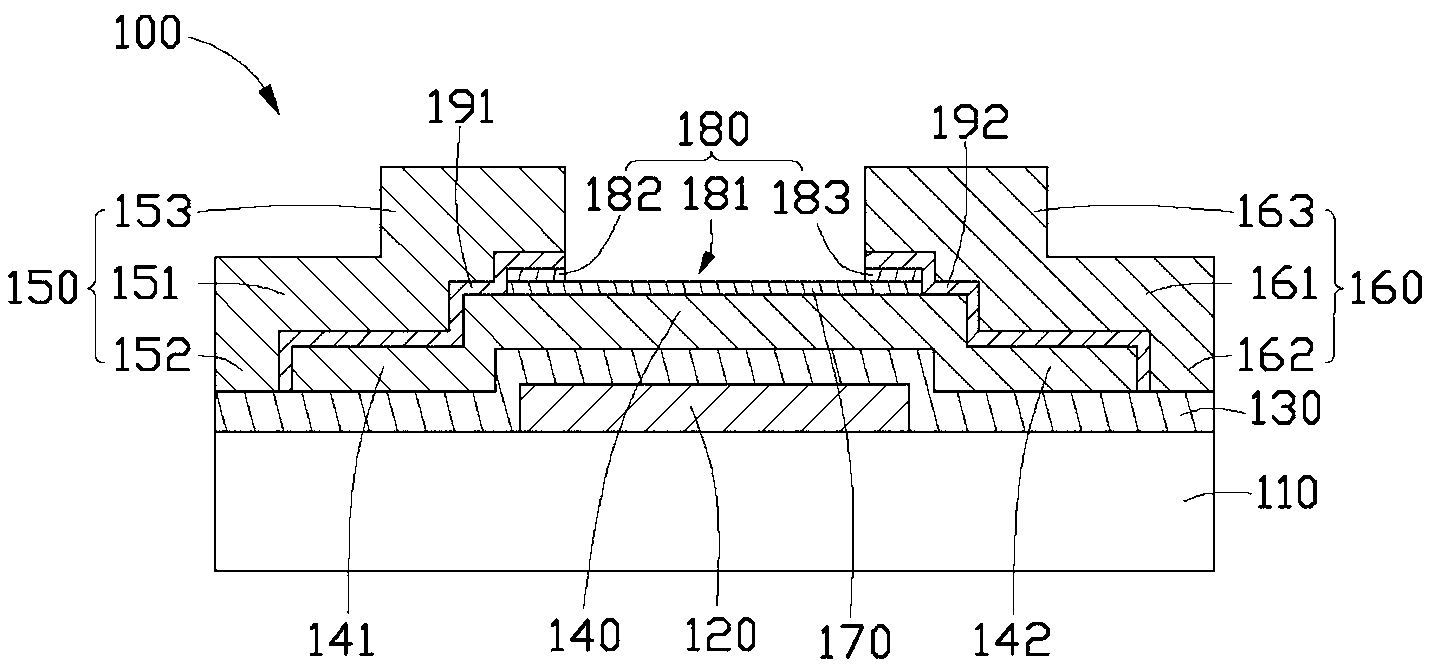

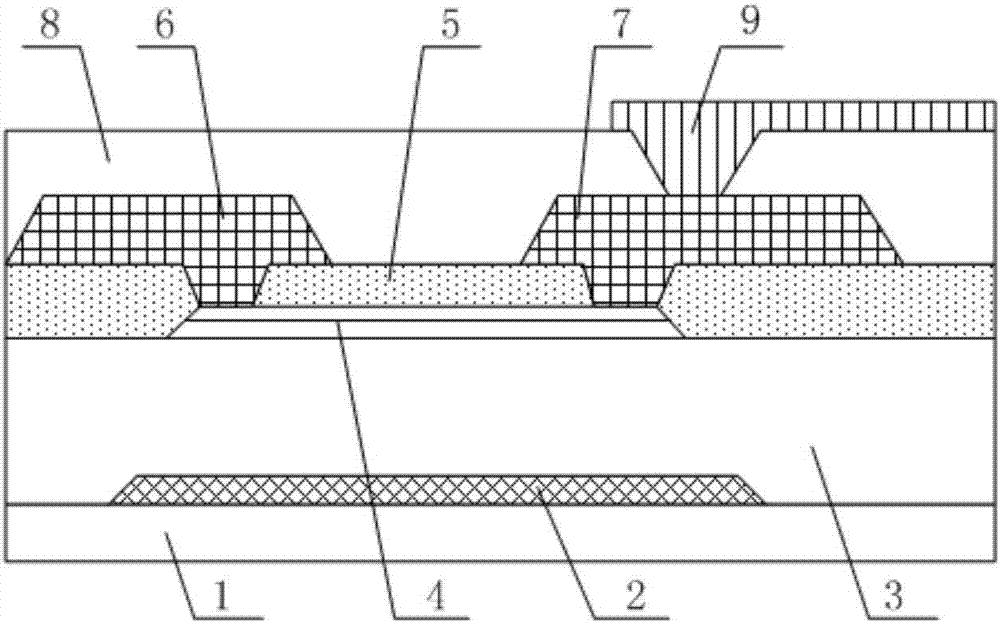

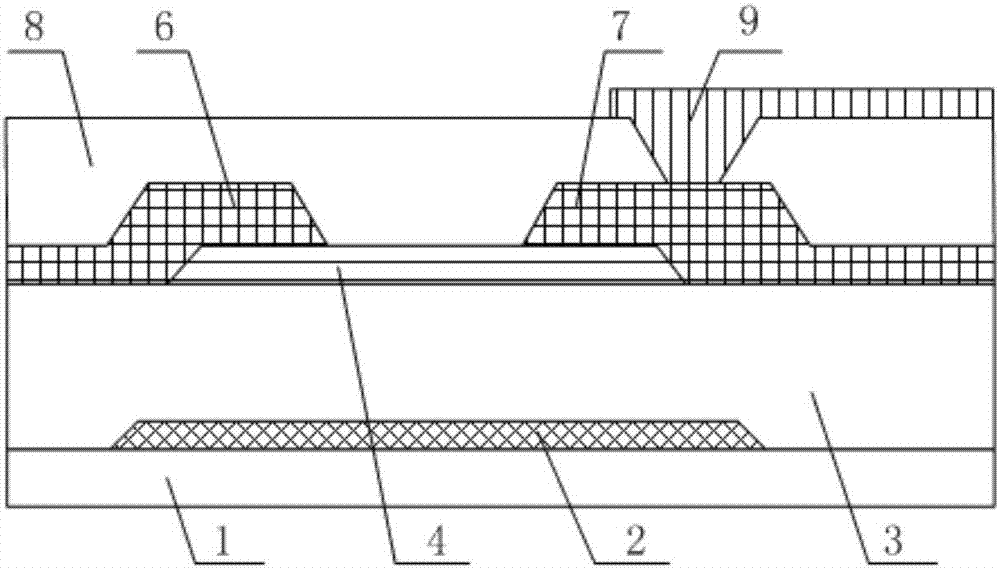

Thin film transistor

The invention discloses a thin film transistor which comprises a substrate, a gate arranged on the substrate, a gate insulation layer covering the gate and an active layer covering the gate insulation layer, wherein the active layer comprises a trench layer, a source and a drain; the source and the drain are respectively arranged on two opposite sides of the trench layer and are electrically connected with a corresponding source electrode and a corresponding drain electrode; a first etching barrier layer and a second etching barrier layer are sequentially arranged on the surface of the trench layer; a groove for exposing the first etching barrier layer is formed in the middle of the second etching barrier layer and divides the second etching barrier layer into a first region and a second region; the source electrode extends from the surface of the source to cover the first region; and the drain electrode extends from the surface of the drain to cover the second region. By the structure, the influence caused by metal atom dispersion or electron migration of the source electrode or the drain electrode on the conductive performance of the trench layer can be effectively prevented; and the reliability is improved.

Owner:海宁经开产业园区开发建设有限公司

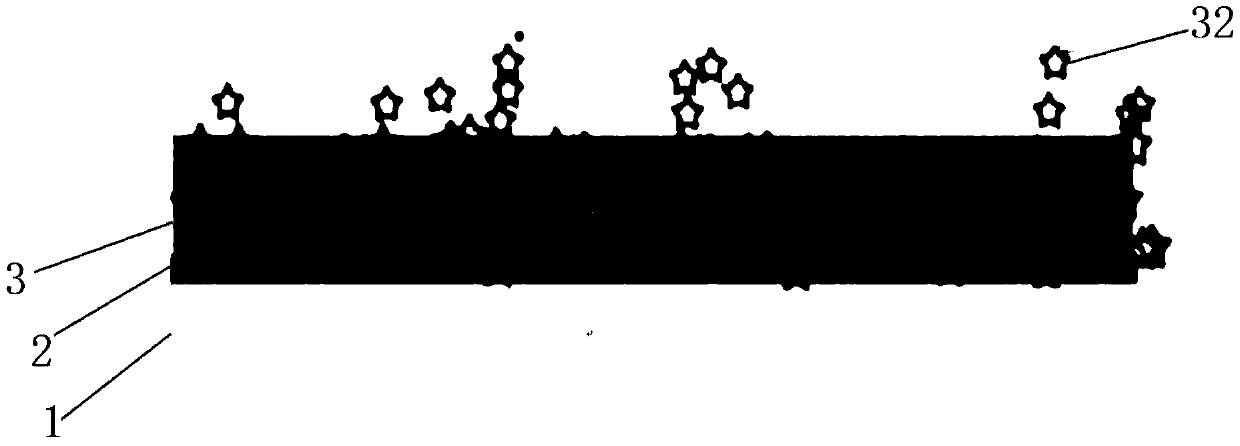

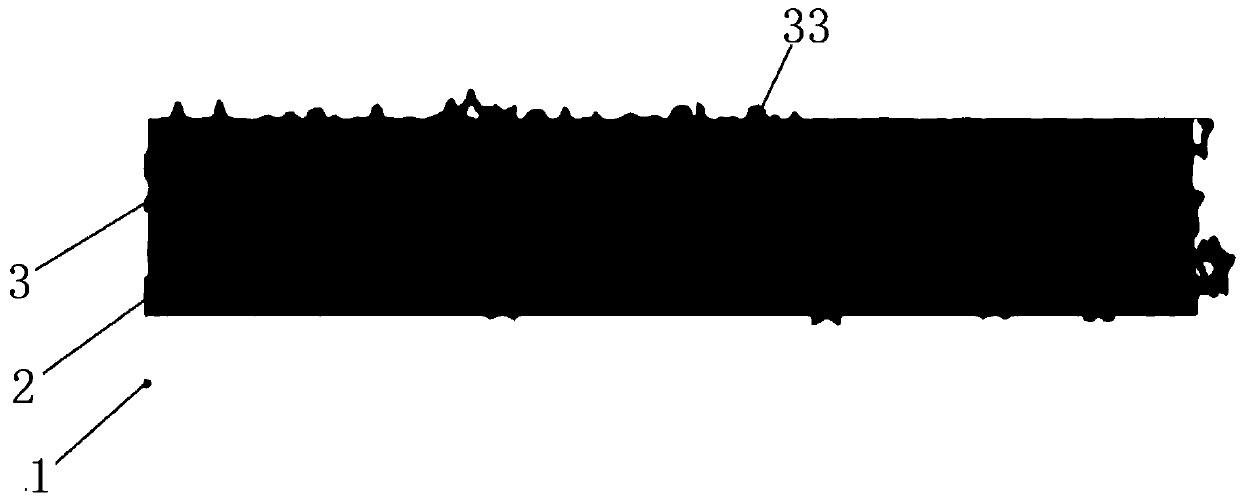

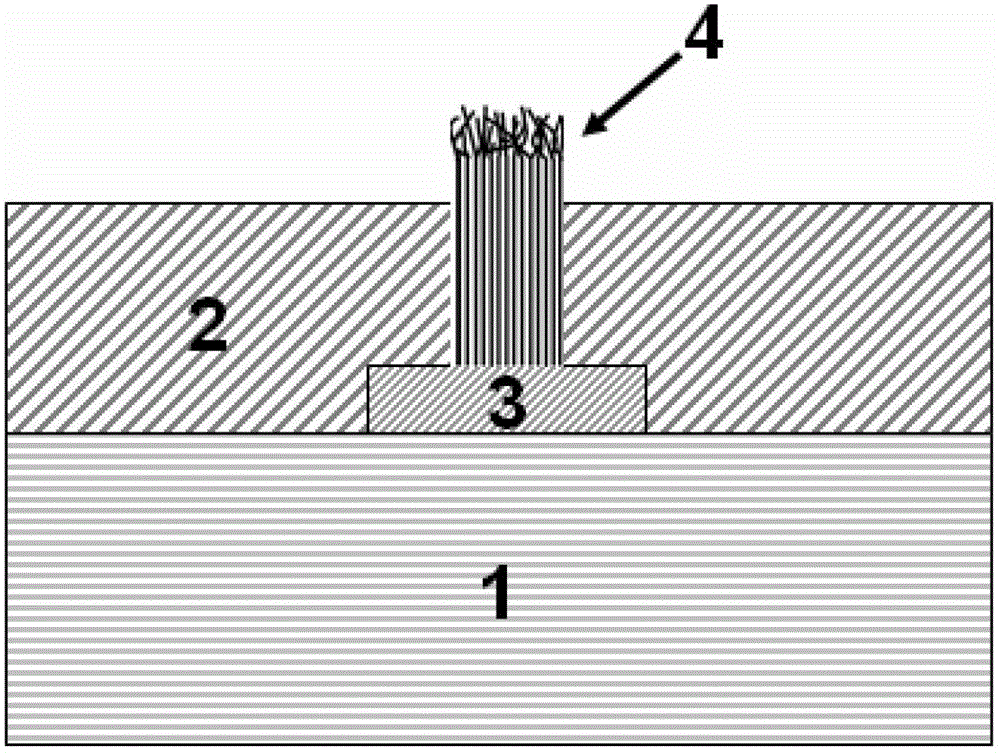

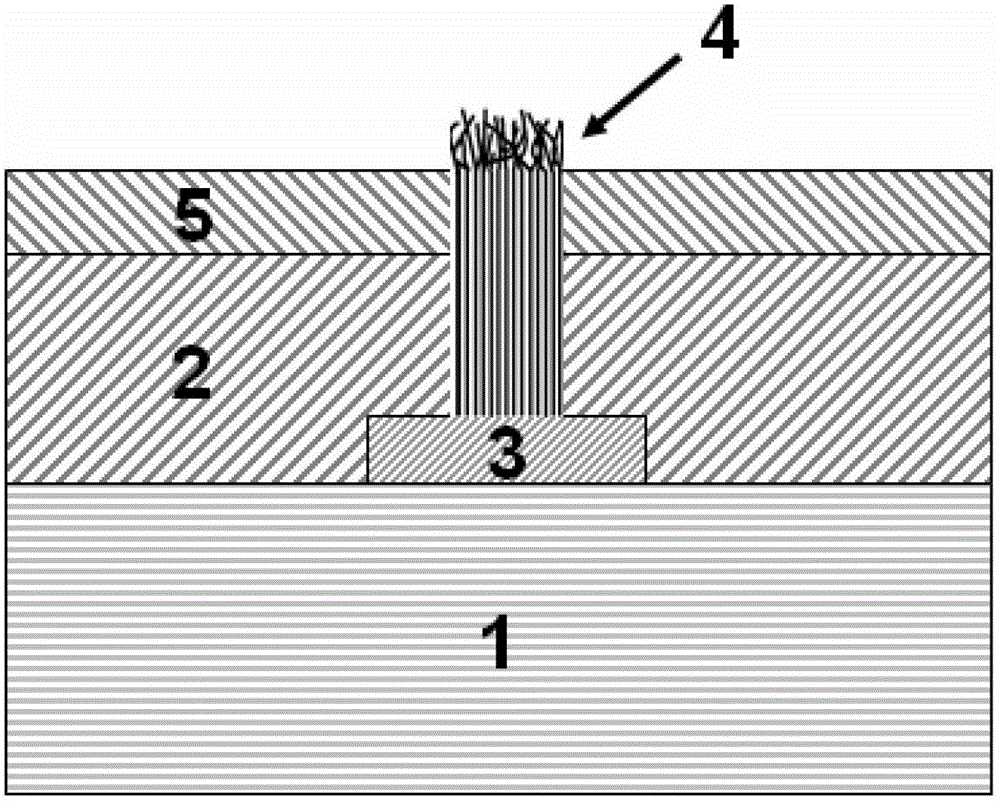

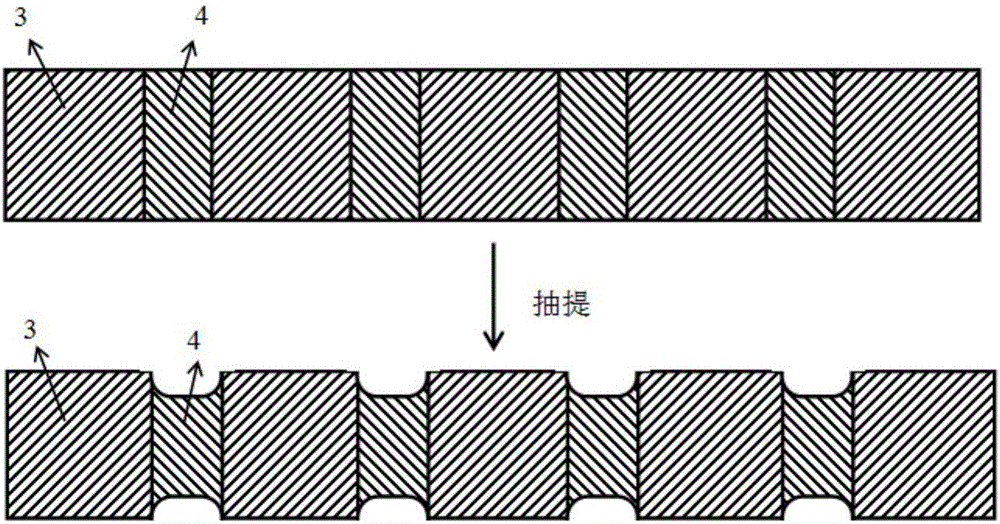

High polymer material and metal composite material, and preparation process therefor

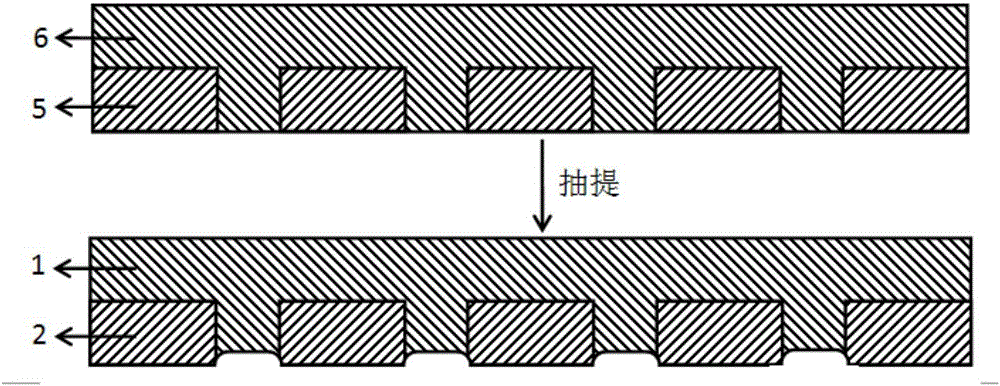

ActiveCN106373792AImprove conductivityConductivity effectContact materialsNon-conductive material with dispersed conductive materialSolvent extractionNanotechnology

The invention discloses a high polymer material and a metal composite material, and a preparation process therefor. The high polymer material containing an extractable material and a porous metal are compounded and formed under a certain condition to prepare a sheet; and then the prepared sheet is subjected to solvent extraction to enable the extractable material therein to be extracted so as to obtain the composite material, wherein the high polymer material of the composite material is shrunk or collapsed. According to the composite material prepared by the preparation method, the porous metal protrudes out of the surface of the conductive composite material, so that the composite material is more suitable for being used as an electric contact material.

Owner:NANTONG MEMTECH TECH

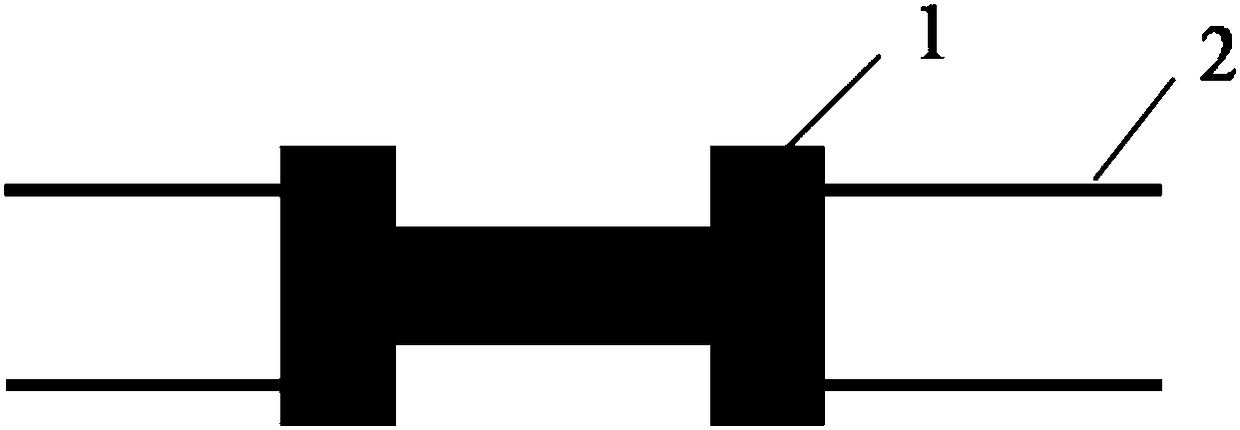

Wind power resistor with stable insulating property

InactiveCN107393668AGuaranteed insulation performanceConductivity effectResistor detailsElectrically conductiveEngineering

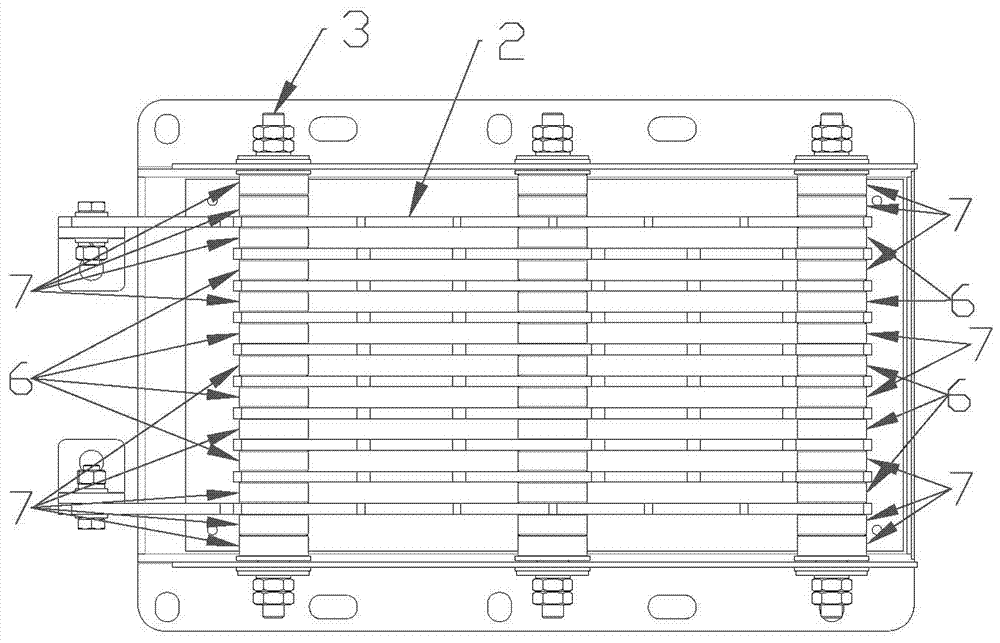

The invention discloses a wind power resistor with a stable insulating property. The wind power resistor comprises a plurality of resistor discs arranged in parallel and stringing rods for stringing the plurality of resistor discs; conductive parts are connected to end parts of the resistor discs and are used for electrically conducting the plurality of resistor discs; a plurality of insulating parts are stringed on the stringing rods and are used for electrically insulating every two adjacent resistor discs; a flange is arranged on each insulating part in an extending manner; the resistor discs sleeve the corresponding flanges, so that the resistor discs are separated from the stringing rods by the flanges. Compared with the prior art, the wind power resistor has the advantages that an electric conducting part between every two adjacent resistor discs is arranged at the end parts of the resistor discs and is away from the insulating part easily forming condensation, so that the influence of the condensation on electrical conductivity between the adjacent resistor discs or the insulating property between the resistor discs and the outside can be avoided. In addition, the flanges are arranged on the insulating parts and are used for separating the resistor discs from the stringing rods, so that the insulating property between the resistor discs and the stringing rods can be sufficiently ensured.

Owner:GUANGDONG FULLDE ELECTRONICS +1

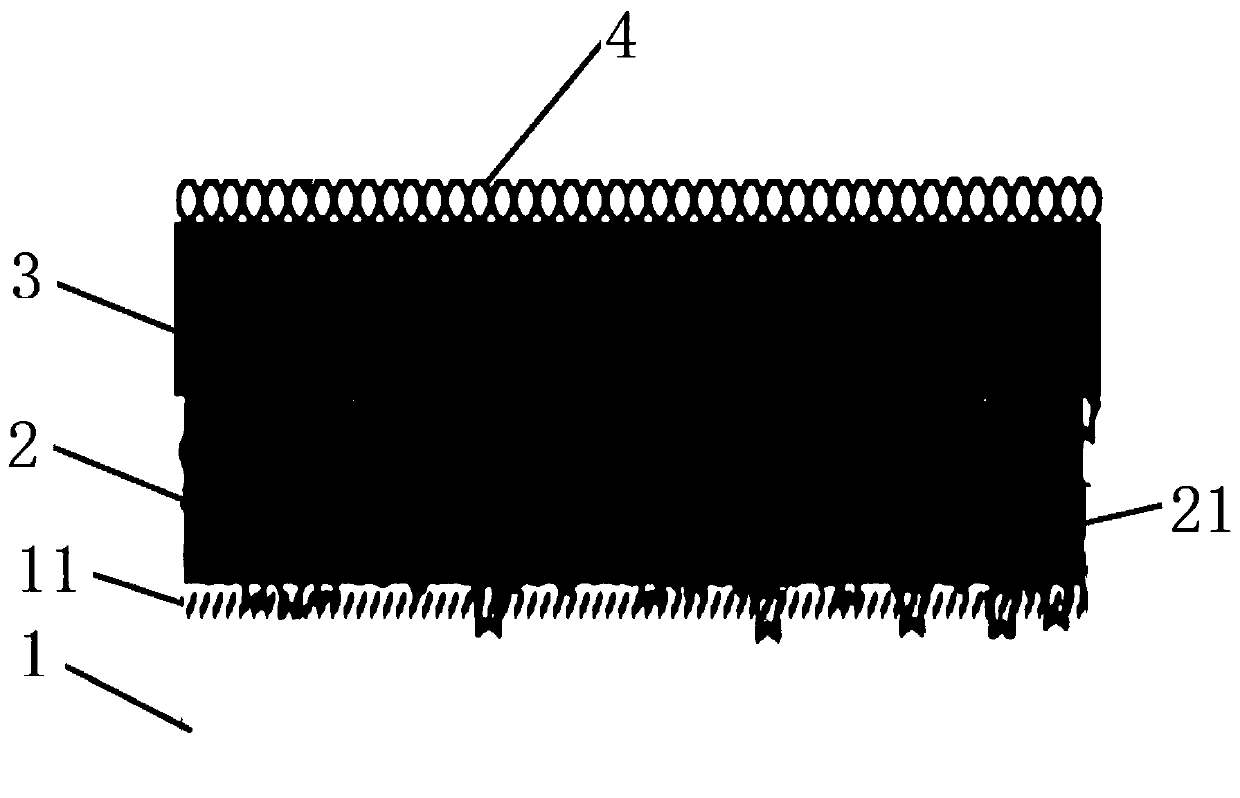

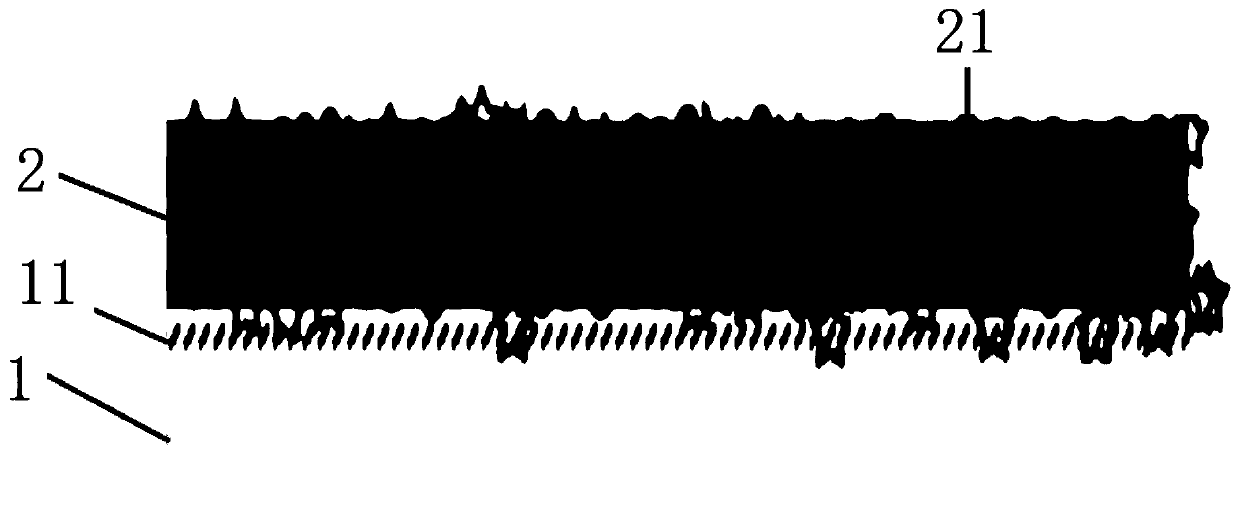

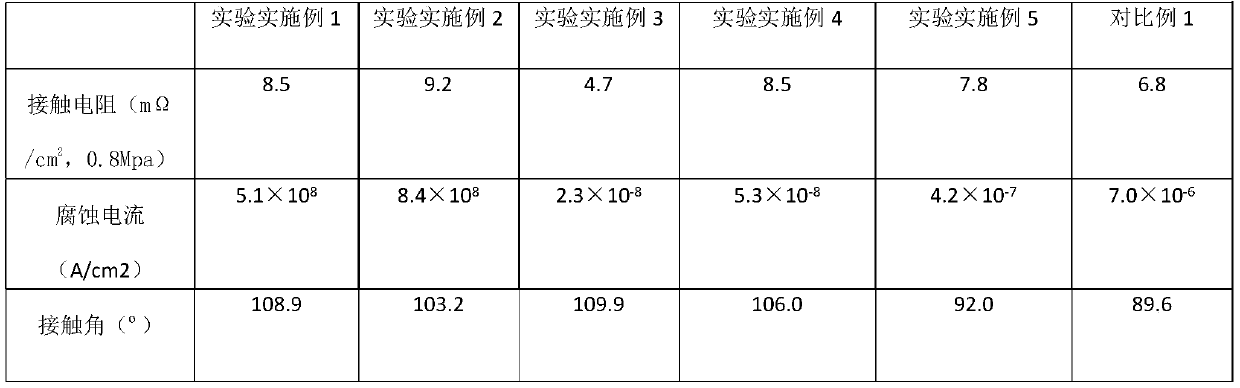

Metal bipolar plate, preparation method of metal bipolar plate and fuel cell

PendingCN109755592AImprove corrosion resistanceImproves corrosion resistance and electrical conductivityCell electrodesFuel cellsConductive coatingCorrosion resistant

The invention relates to a metal bipolar plate, a preparation method of the metal bipolar plate and a fuel cell, and relates to the technical field of fuel cells. According to the technical scheme, the metal bipolar plate comprises a metal substrate, a corrosion-resistant coating layer and a conductive coating layer, wherein the metal substrate comprises a first surface which is subjected to nitriding treatment; the corrosion-resistant coating layer is deposited on the first surface of the metal substrate; and the conductive coating layer is deposited on the corrosion-resistant coating layer.The preparation method of the metal bipolar plate comprises the steps of performing preprocessing on the metal substrate, performing high-temperature nitriding treatment, depositing the corrosion-resistant coating layer on the first surface, subjected to nitriding treatment, of the metal substrate, and depositing the conductive coating layer on the corrosion-resistant coating layer. The fuel cellcomprises the metal bipolar plate. According to the method, the corrosion resistance and the conductivity of the metal bipolar plate are mainly improved, the bonding force between the coating layer and the metal substrate is improved, and the service life of the metal bipolar plate and the fuel cell is prolonged.

Owner:浙江锋源氢能科技有限公司

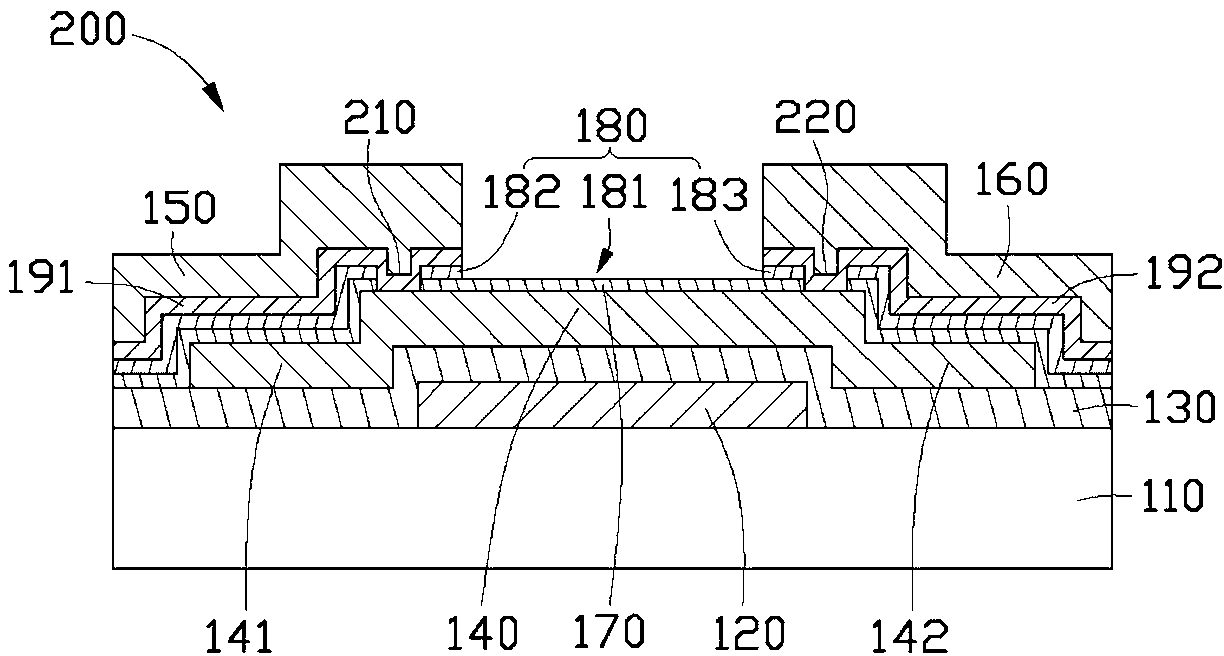

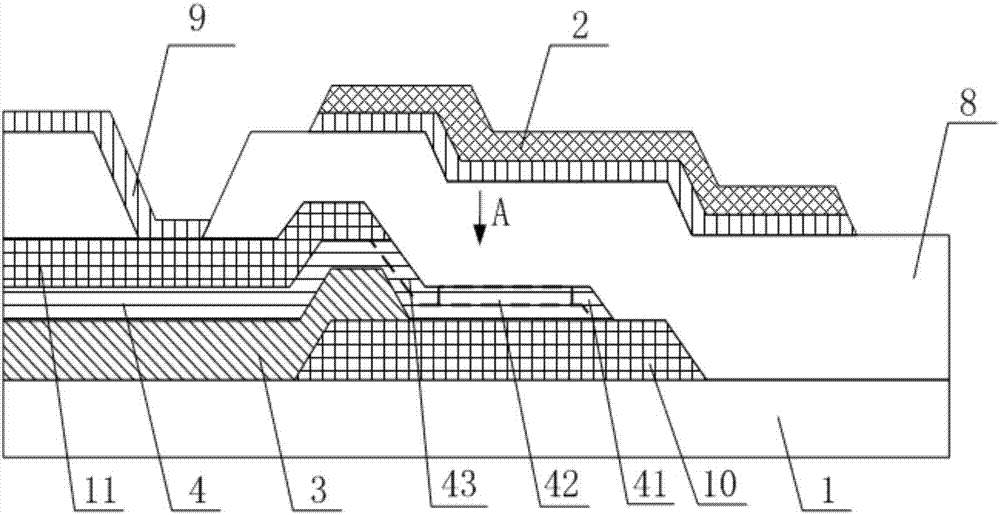

Thin film transistor, manufacturing method therefor and array substrate

The invention discloses a thin film transistor, a manufacturing method therefor and an array substrate and relates to the technical field of display technology; the thin film transistor, the manufacturing method therefor and the array substrate are used for improving a yield rate of the thin film transistor while downsizing the thin film transistor. The thin film transistor is formed on a substrate base plate and comprises a grid and an active layer; a surface, facing to substrate base plate, of the active layer is provided with a first signal metal layer; a surface, facing away from the first signal metal layer, of the active layer is provided with a second signal metal layer; the active layer comprises an electric conduction channel forming zone; the second signal metal layer does not cover the electric conduction channel forming zone of the active layer. The thin film transistor, the manufacturing method therefor and the array substrate are used for downsizing the thin film transistor.

Owner:FUZHOU BOE OPTOELECTRONICS TECH CO LTD +1

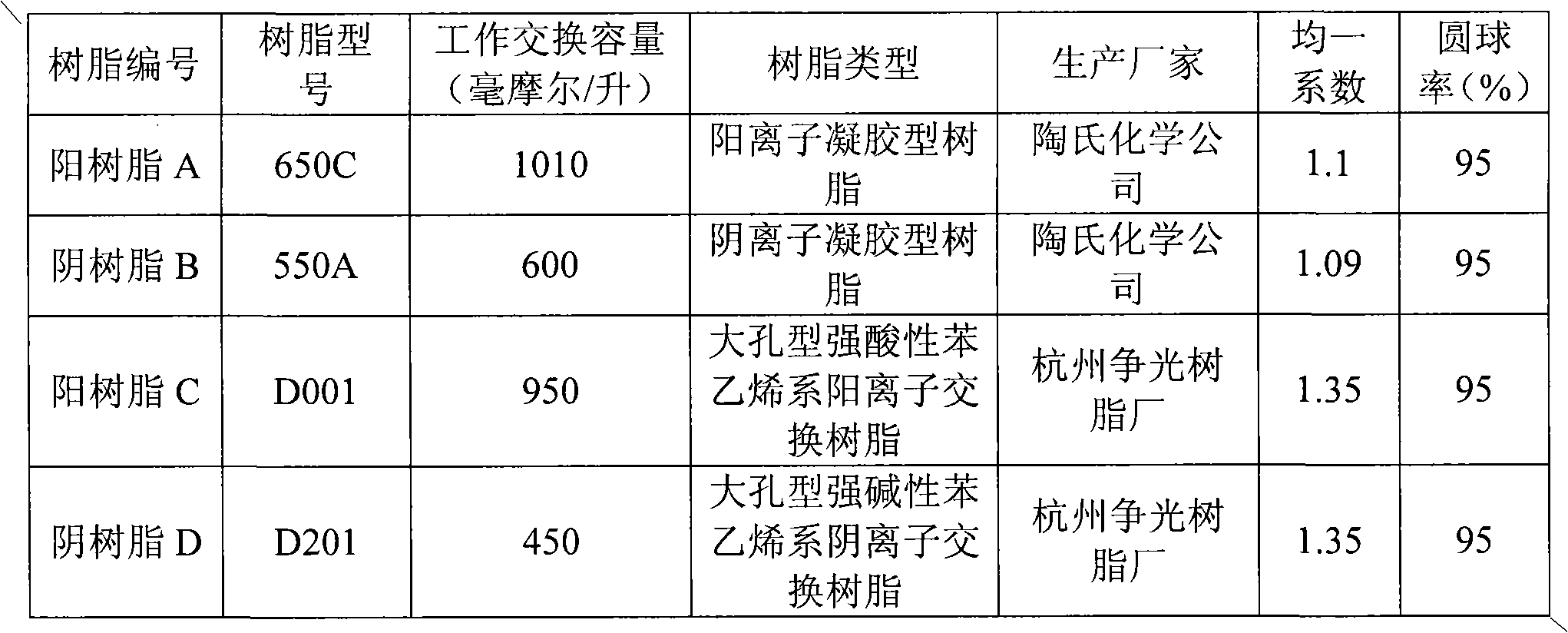

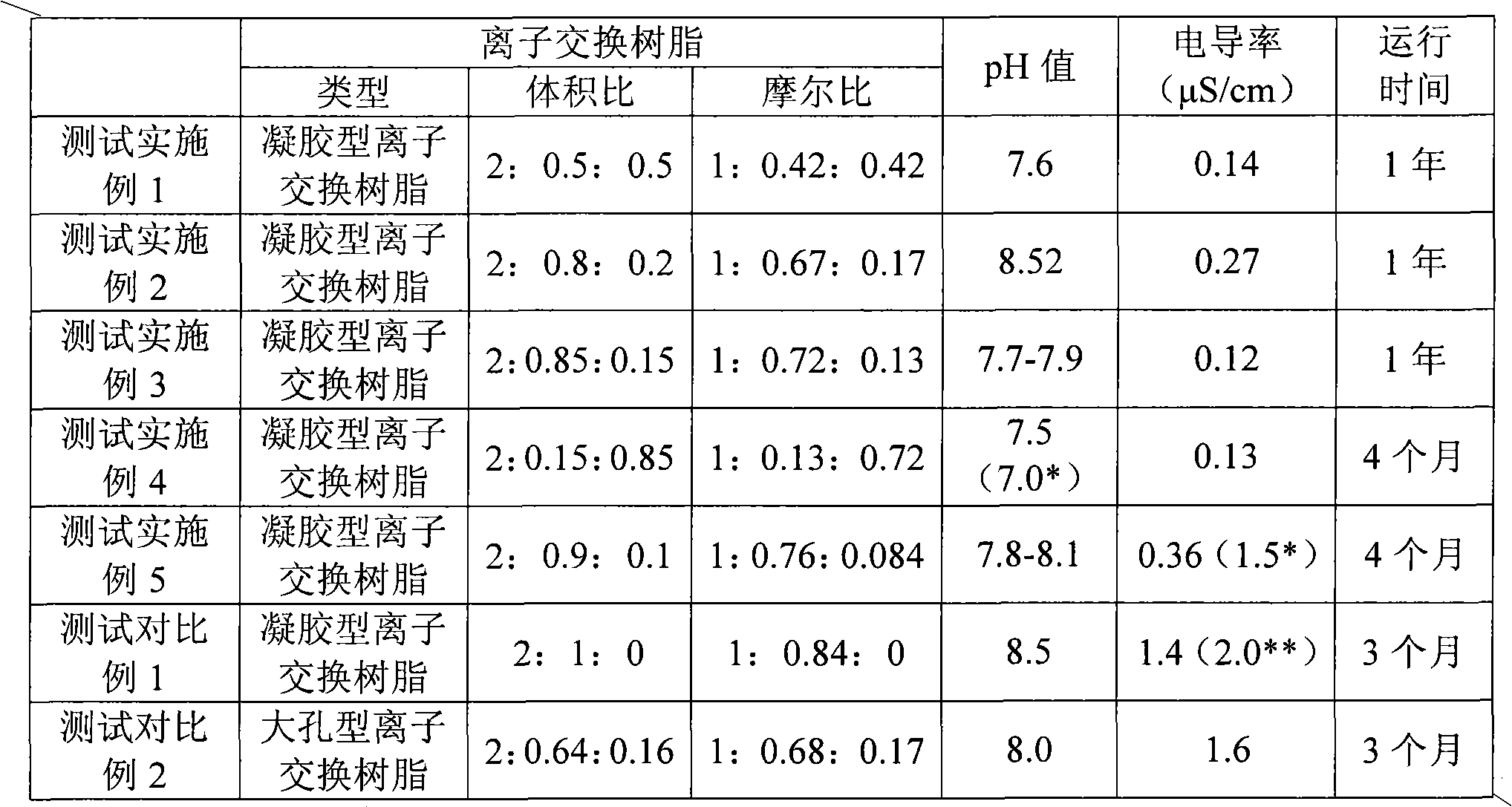

Mixed resin and preparation method thereof

InactiveCN101898159AEasy to prepareEasy to operateAmphoteric ion-exchangersPhysical chemistryIon-exchange resin

The invention relates to a mixed resin, comprising OH-type ion exchange resin, Na-type ion exchange resin and H-type ion exchange resin, wherein the OH-type ion exchange resin, the Na-type ion exchange resin and the H-type ion exchange resin are gel-type ion exchange resin. The invention also provides a preparation method thereof, comprising the step of mixing the OH-type ion exchange resin, the Na-type ion exchange resin and the H-type ion exchange resin. The mixed resin is used for treating cold water in a generator to keep the pH value of the cold water above 7.5 for long time, and bring no adverse impact to the conductivity of the cold water and no corrosion to the inner parts of the generator.

Owner:CHINA SHENHUA ENERGY CO LTD +2

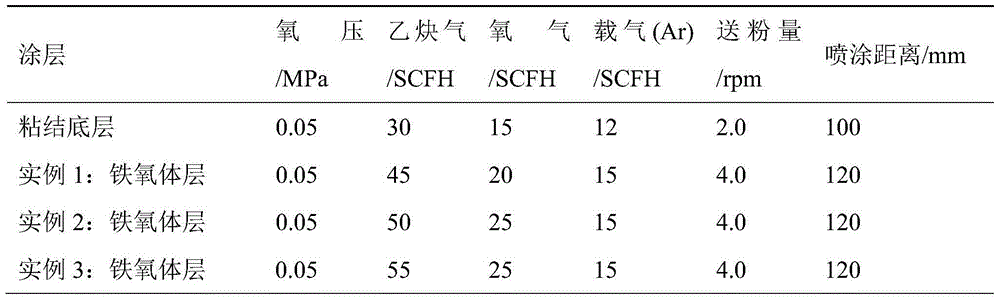

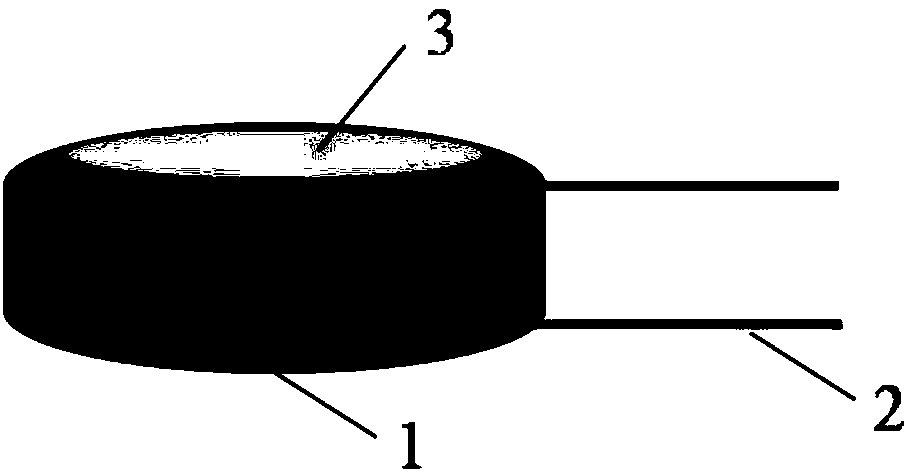

Method for preparing lithium ferrite anticorrosive coatings by flame spraying

ActiveCN103981477AHigh bonding strengthAccelerated corrosionMolten spray coatingConductive coatingOxygen

The invention relates to a method for preparing lithium ferrite anticorrosive coatings by flame spraying. Lithium ferrite conductive anticorrosive coating materials, prepared by adopting a manipulator through optimizing the technological parameters of oxygen-acetylene flame spraying, have excellent corrosion resistance and conductivity. The preparation method, provided by the invention, has the advantages of simple process, high deposition rate, strong repeatability and low facility request, can directly implement the spraying construction on site so as to meet the construction and repair requirements of actual grounding network engineering, and can be applied to metallic matrix surfaces with different shapes or different sizes; in particular, the preparation method has more advantages when preparing large-area anticorrosive conductive coatings for practical application; and meanwhile, the maintenance is simple in the workpiece service process, so that the preparation method is suitable for industrial popularization and application.

Owner:STATE GRID CORP OF CHINA +1

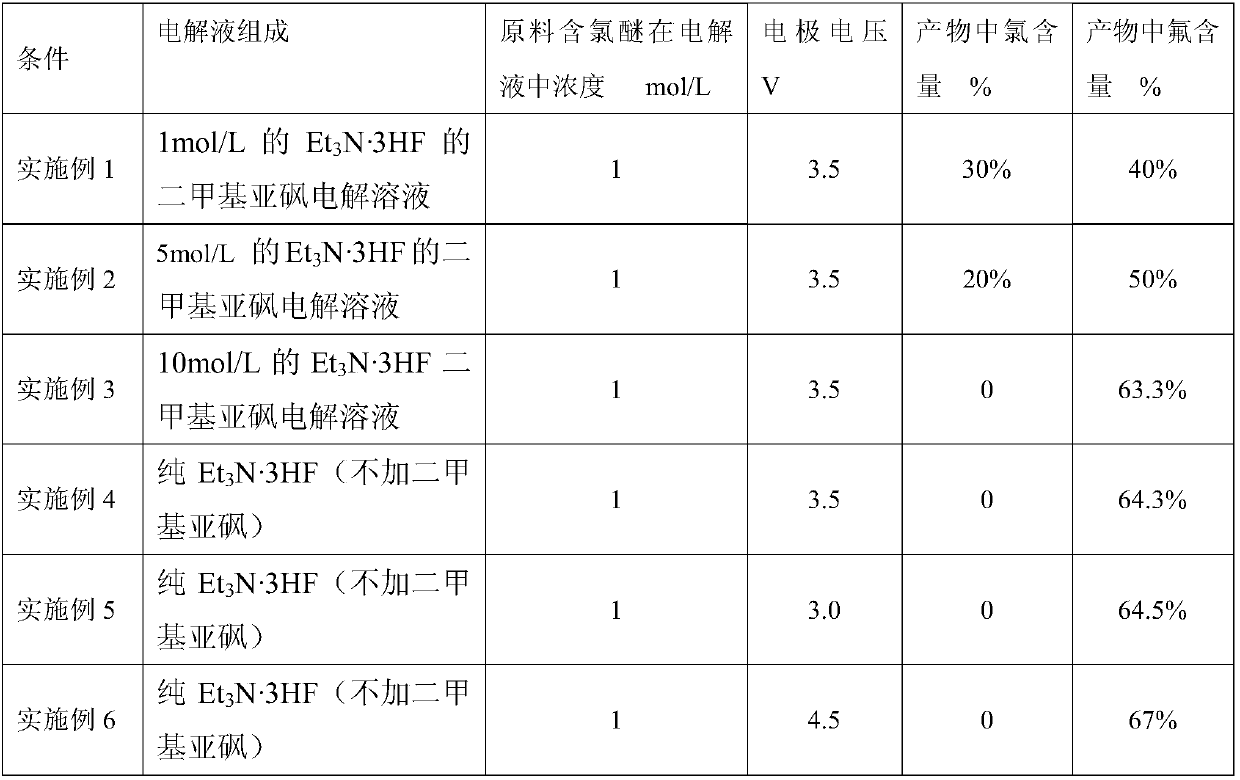

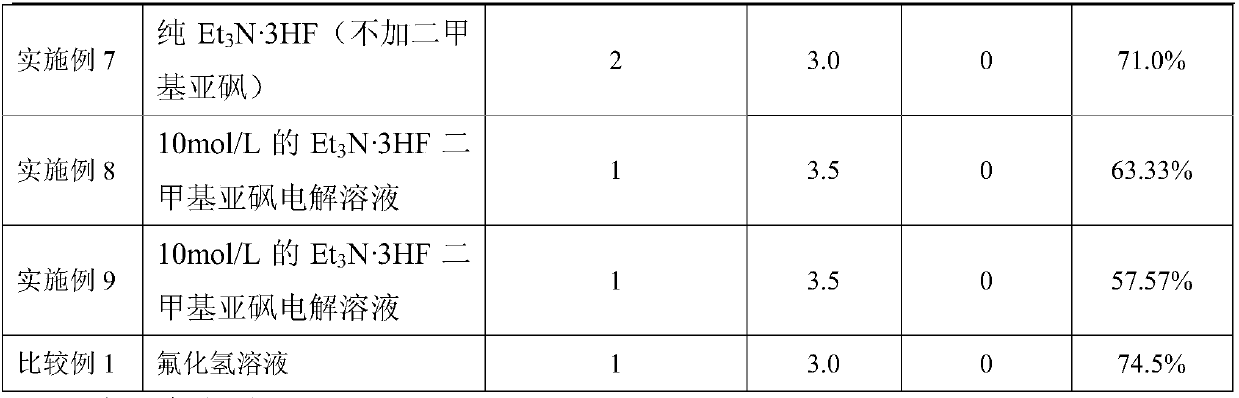

Electrochemical fluorination preparation method of hydrogen fluoride ether

ActiveCN107761130AConductivity effectGood fluorination performanceOrganic chemistryElectrolysis componentsHydrogen fluorideEther

The invention relates to a preparation method of hdrogen fluoride ether, in particular to an electrochemical fluorination preparation method of hydrogen fluoride ether. A chloroether compound, a fluorination reagent and an aprotic solvent are added into a fluorination electrolytic cell for fluorination to generate a chlorine-free hydrogen fluoride ether product, and the fluorination reagent is Et3N-3HF; the aprotic solvent is dimethyl sulfoxide; the concentration of the Et3N-3HF in the dimethyl sulfoxide ranges from 10 to 15 mol / L; the electrode voltage of the fluorination electrolytic cell iscontrolled at 3.5 V. By the use of the Et3N-3HF, the selective fluorination performance is extremely high, and the product contains fewer impurities, is higher in purity, and is higher in yield underhigh selectivity; by the adding of the aprotic solvent, in the initial stage of electrolysis, relatively good influence is generated on the conductivity of the solution. According to the electrochemical fluorination preparation method of the hydrogen fluoride ether, by chloroether compound serving as a main raw material, various hdrogen fluoride ether compounds such as perfluoroethyl methyl ethercan be prepared; furthermore, the reaction replacement selectivity is improved; after post-treatment, the content of target products in the prepared product is 99.9 percent.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Method for preparing dense precursor ceramic temperature sensor

ActiveCN108344518AConductivity effectGood process repeatabilityThermometers using electric/magnetic elementsCeramic shaping apparatusOxidation resistantUltimate tensile strength

The invention relates to a method for preparing a dense precursor ceramic temperature sensor. The method comprises the steps of: placing a liquid ceramic precursor in a liquid forming mold and keepingthe iquid ceramic precursor at 150 to 200 degrees centigrade for 0.5 to 2h to obtain a formed precursor; keeping the formed precursor at 350 to 450 degrees centigrade for 3 to 6h to obtain a precursor block; pyrolyzing the precursor block at 1000 to 1450 degrees centigrade for 3 to 6h to obtain a precursor ceramic; connecting an electrode to the precursor ceramic to obtain a dense precursor ceramic temperature sensor. The invention uses a liquid forming method, and directly cures the liquid ceramic precursor at a high temperature without adding a curing agent, thereby obtaining a dense precursor ceramic temperature sensor suitable for an extreme environment. The temperature sensor has good oxidation resistance, high strength and accurate measurement results.

Owner:HARBIN INST OF TECH

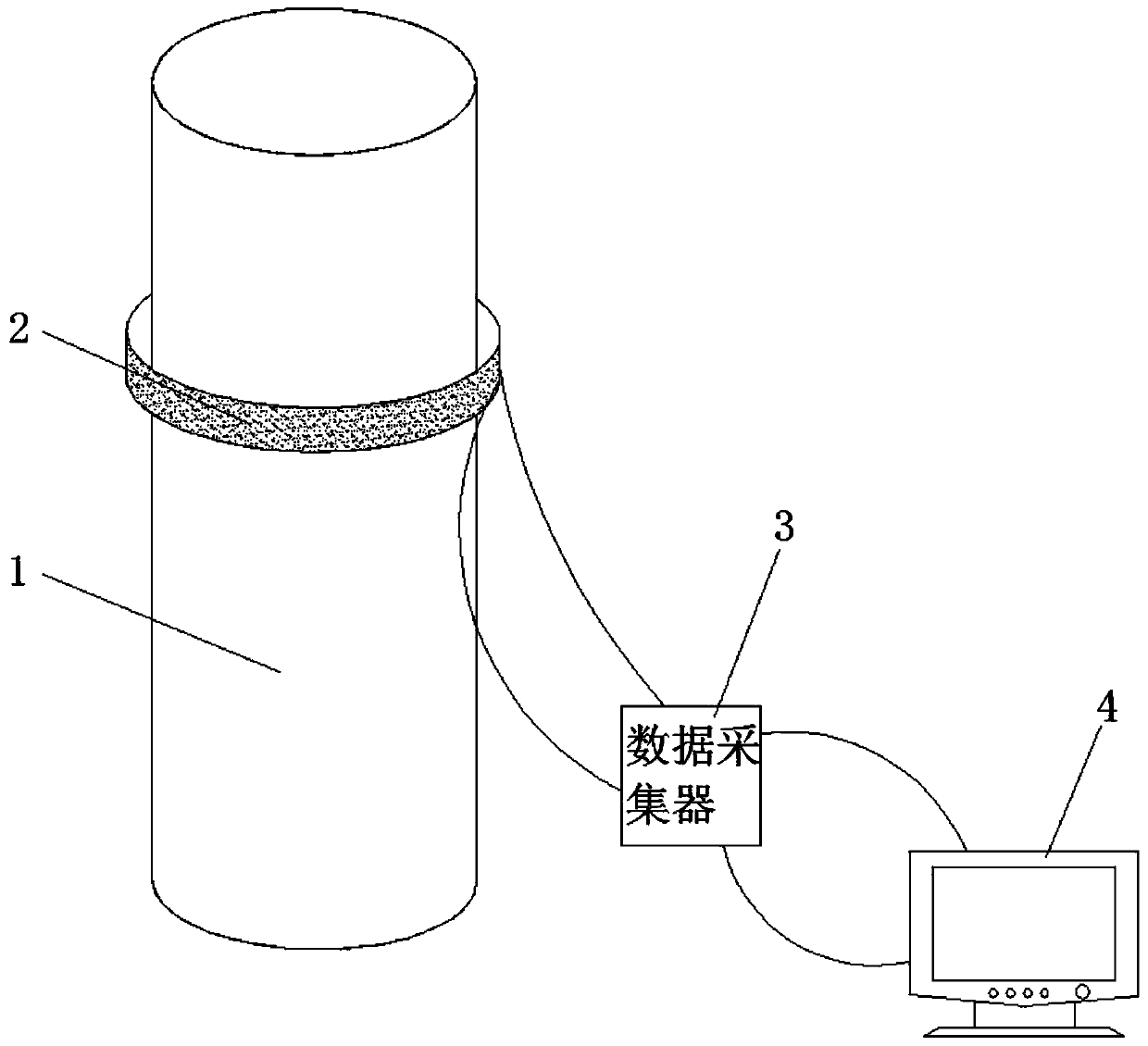

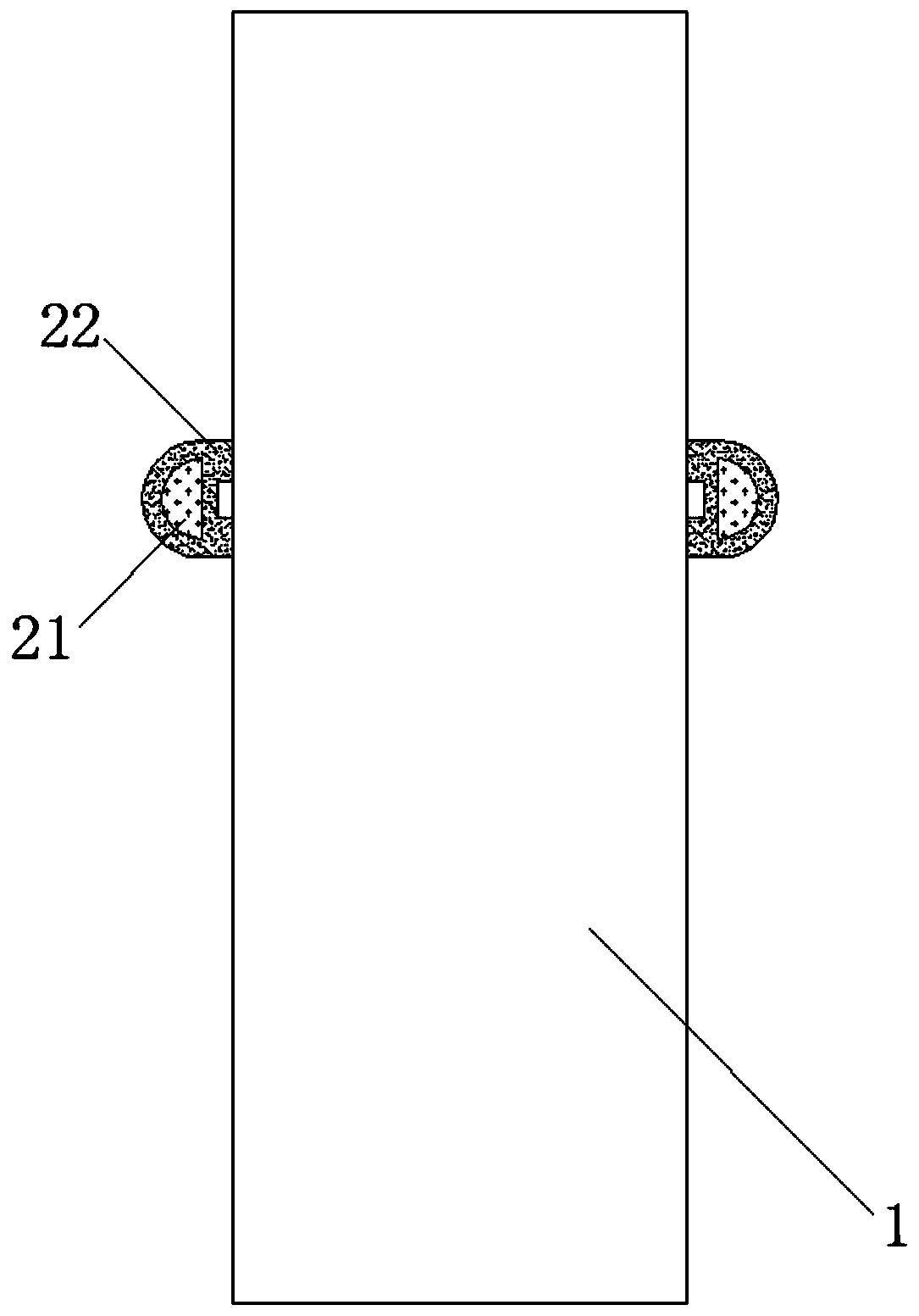

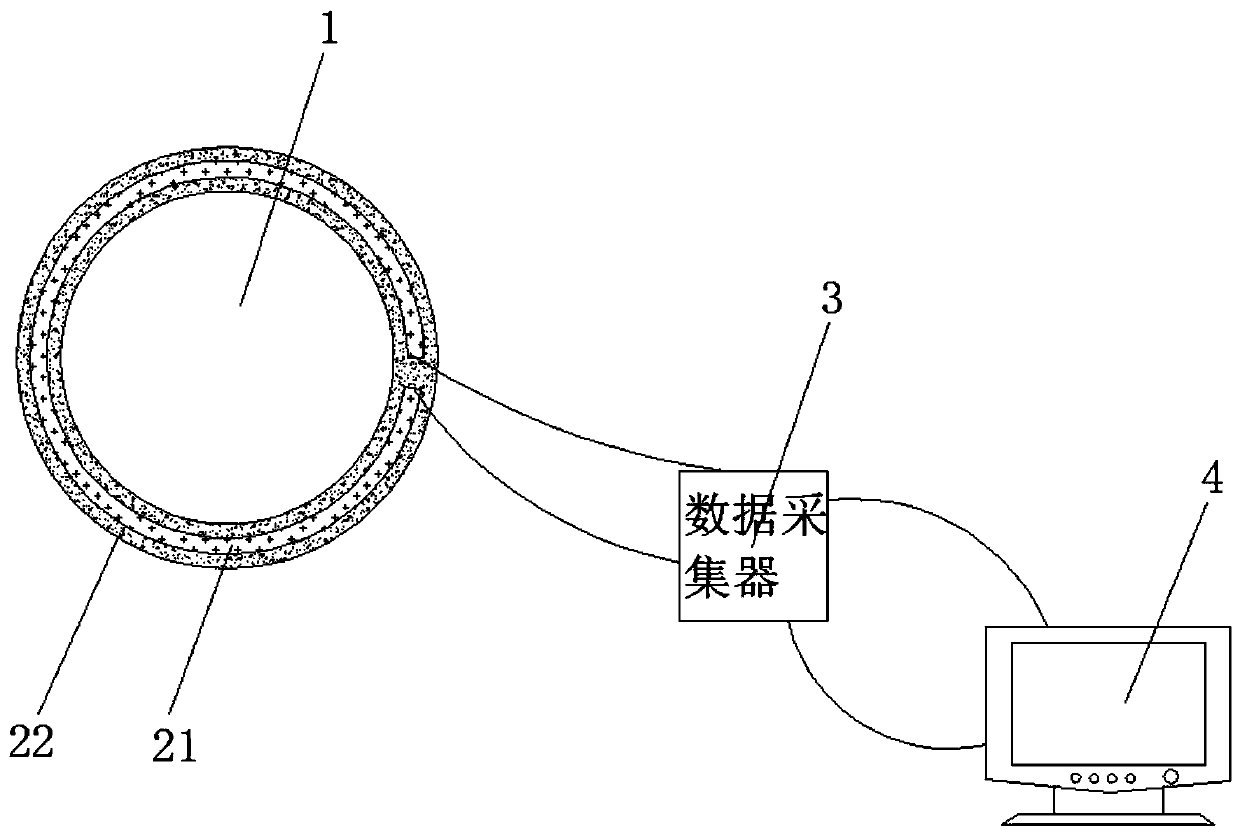

Graphene rubber strain test device and rock strain measurement method

ActiveCN109974572AIncrease elasticityLow resistivityElectrical/magnetic solid deformation measurementGrapheneStrain gauge

The invention provides a graphene rubber strain test device and a rock strain measurement method. The graphene rubber strain test device is used for measuring strain of a rock test block, and comprises a graphene rubber strain gauge, a data collector and a display which are connected in sequence, wherein the graphene rubber strain gauge comprises a graphene rubber strip, the graphene rubber stripis formed by mixing graphene and elastic rubber, and two ends of the graphene rubber strip are connected with the data collector through lead wires respectively. The graphene rubber strip made by mixing the graphene and the elastic rubber has good electrical conductivity, the graphene rubber strip is hooped on the rock test block, the graphene rubber strip is deformed synchronously when the rock test block is slightly deformed by a force, and the deformation of an object can be sensed sensitively. When the graphene rubber strip is deformed, the resistivity inevitably changes, and the strain ofthe rock test block can be precisely converted and obtained through measuring variation of resistivity of the graphene rubber strip during the deformation process.

Owner:SHAOXING UNIVERSITY

Copper-nickel-tin alloy used for socket and preparation method thereof

InactiveCN110777280AHigh strengthImprove corrosion resistanceMetallic material coating processesHeat resistanceAlloy

The invention belongs to the technical field of alloy materials, and particularly relates to a copper-nickel-tin alloy used for a socket and a preparation method thereof. The copper-nickel-tin alloy comprises the following components of, in percentage by weight, 8 wt%-12 wt% of Ni, 2.5 wt%-3.8 wt% of Sn, 0.07 wt%-0.16 wt% of Si, 0.02 wt%-0.09 wt% of B, 0.03 wt%-0.06 wt% of W, 0.01 wt%-0.02 wt% ofBe, and the balance Cu. According to the copper-nickel-tin alloy used for the socket, the components of the copper-nickel-tin alloy for the socket are optimized and adjusted, the elements have a synergistic effect, the strength, the corrosion resistance, the heat resistance and the elasticity of the copper-nickel-tin alloy can be remarkably improved, and the prepared copper-nickel-tin alloy can bestored for a long time in the air and can still maintain bright and beautiful appearance without darkening.

Owner:安徽实友电力金具有限公司

Stackable single cell microbe fuel battery

The invention discloses a pile type single room microbiological fuel cell; the battery is the sheet style structure, battery thickness is 5-30 centimeter, two groups of membrane electrodes altogether used an anode chamber, which is advantageous for composing the large-scale microbiological fuel cell heap, in order to output a greater voltage and electric current to satisfy the different current collector demand. The monomer battery uses the air type negative pole, does not need aeration, simultaneously does not need to add vector to the negative pole room, can greatly reduces the movement cost, and avoids the environmental pollution which creates by adding vector. In the anode chamber increases the carbon fiber to enhance the anode relative surface product, may enhance the monomer battery current density 3-10 times. The battery movement uses the method of upside feed-water, the base high and dry, reduced the backflow equipment demand, but also can save 50% -70% of the electrical energy. The invention is a clean advanced energy technology; and it has the broad application prospect in the municipal, industry, agricultural and spatial organic waste water processing.

Owner:BEIHANG UNIV

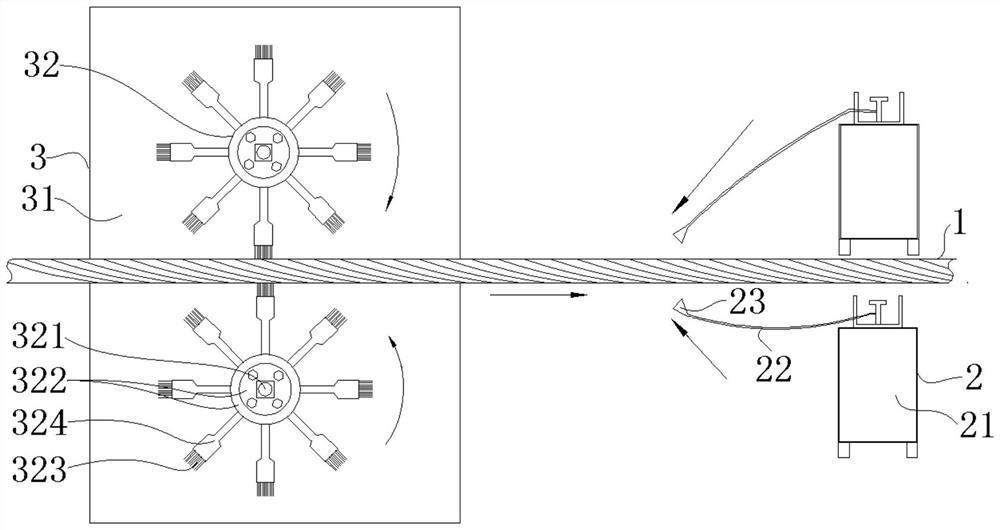

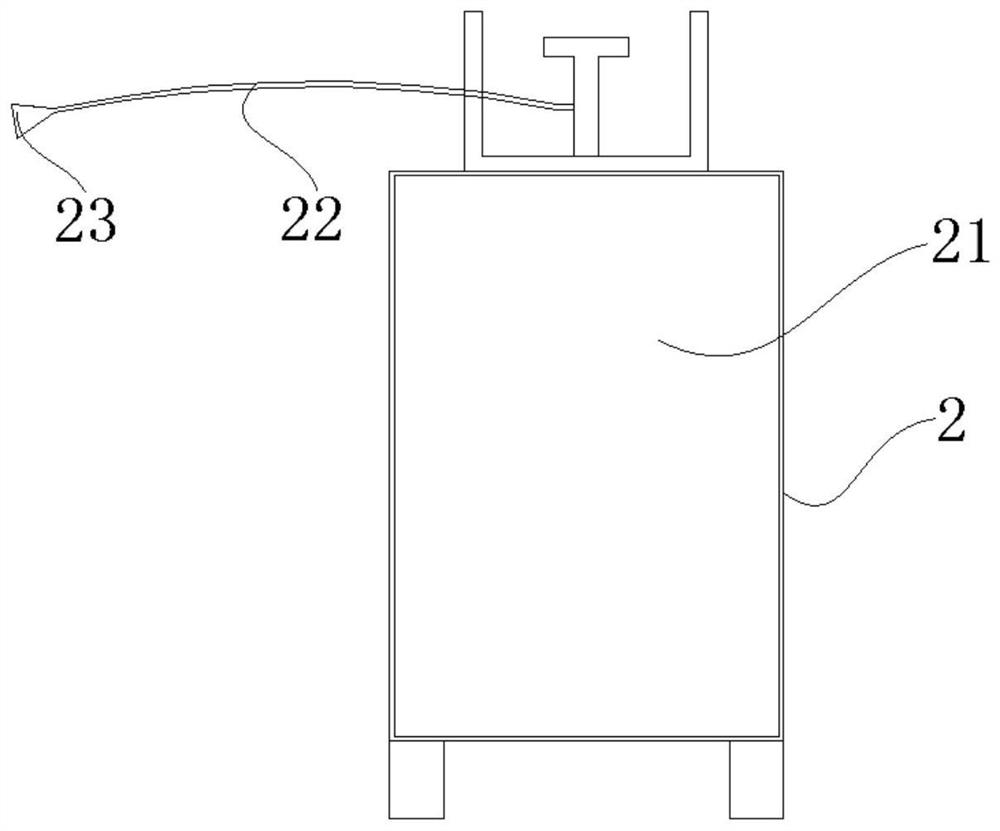

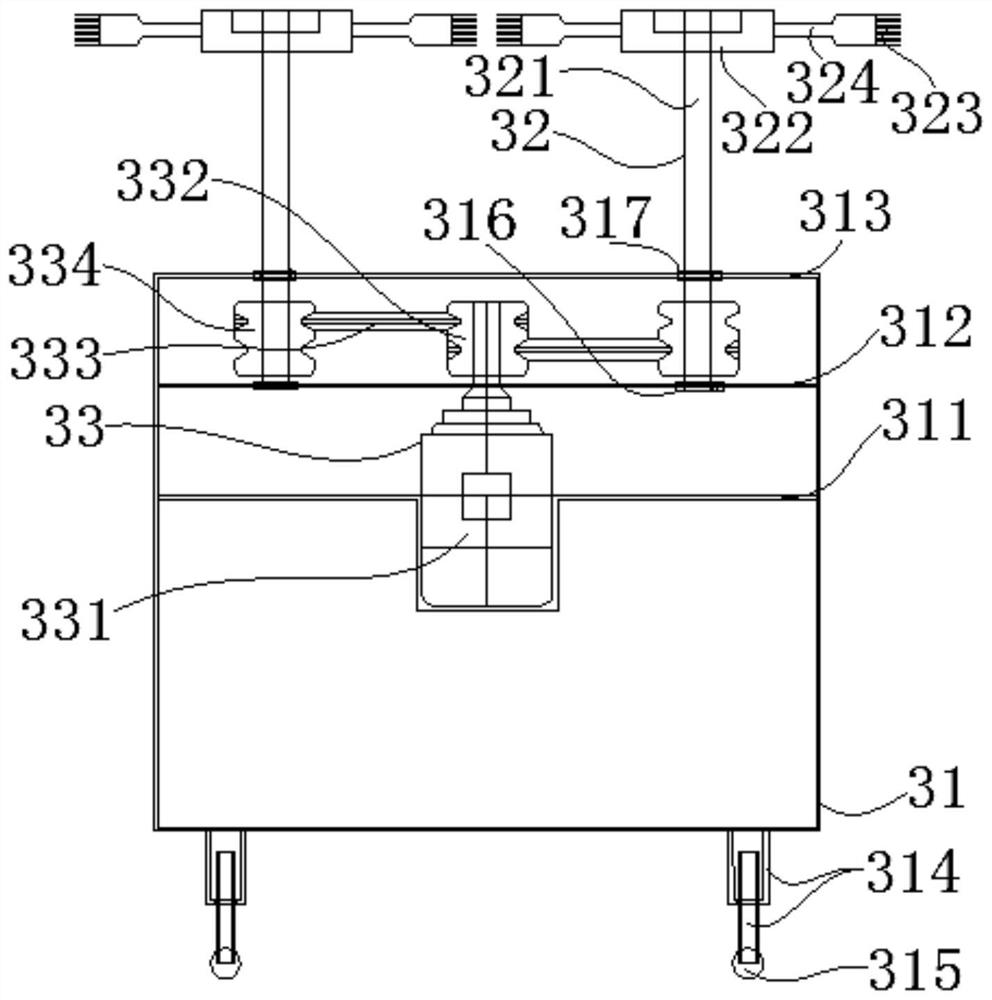

Cable aluminum conductor surface powder scrap and burr cleaning device

PendingCN113851279AConductivity effectReliable removalApparatus for heat treatmentCleaning using toolsScrapElectrical conductor

The invention discloses a cable aluminum conductor surface powder scrap and burr cleaning device which comprises a fire burning mechanism capable of spraying out flames of 800-1000 DEG C. Flame nozzles of the fire burning mechanism are arranged on the side of a walking aluminum conductor, and the aluminum conductor walks through a matching structure of the flames sprayed out by the flame nozzles. Aiming at the particularity of sundries such as powdered scraps and burrs attached to the surface of a compressed circular aluminum conductor of a cable, the fire burning mechanism sprays flames to the surface of the walking aluminum conductor, so that the current surface of the aluminum conductor passes through the flames in a relatively short way; on one hand, dust, burrs and other sundries attached to the surface of the aluminum conductor can be reliably removed, and on the other hand, the structure and the conductivity of the aluminum conductor are not damaged.

Owner:SICHUAN JIUZHOU WIRE & CABLE

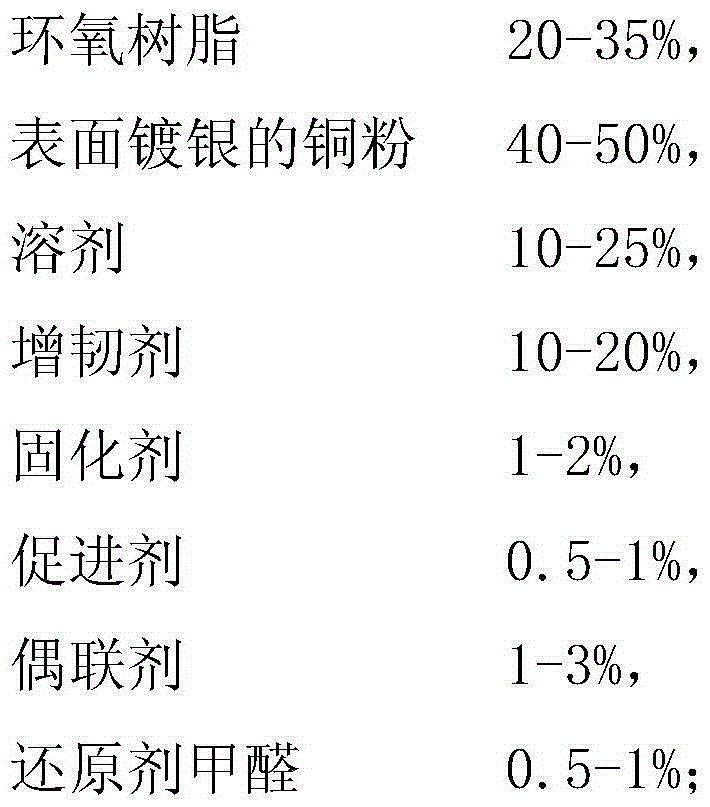

Preparation method of epoxy resin conductive adhesive film

ActiveCN104017511BImprove work efficiencyLow costNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxySilver plate

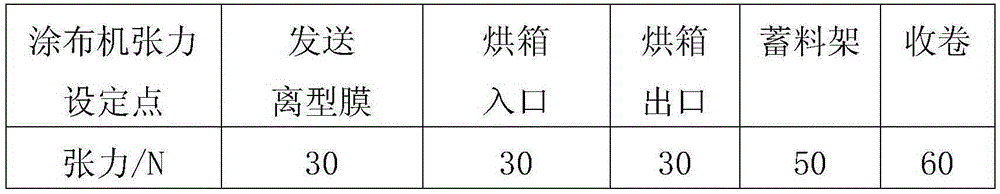

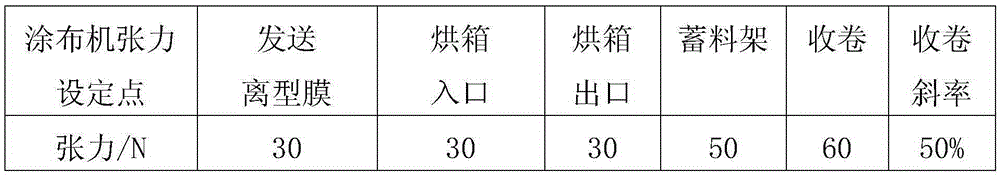

The invention discloses a preparation method of an epoxy resin conductive adhesive film and a conductive adhesive layer of the epoxy resin conductive adhesive film. The conductive adhesive layer of the epoxy resin conductive adhesive film comprises the following components in percentage by mass: 20-35% of epoxy resin, 40-50% of copper powder with silver plated on the surface, 10-25% of a solvent, 10-20% of a toughening agent, 1-2% of a curing agent, 0.5-1% of a promoter, 1-3% of a coupling agent and 0.5-1% of a reducing agent namely formaldehyde. The preparation method comprises the steps of firstly mixing components, then coating mixed slurry on a release film by using a coating machine, and implementing the process according to the set temperature and tension in the coating process. Single metal powder is replaced by using a composite conductive filling material of the copper powder with silver plated on the surface, and the specific temperature and tension values set aiming at the characteristics of the slurry on the coating machine are combined so as to ensure that the working efficiency of the coating machine can be increased to reach 10-15m / min, and the production efficiency of products can be improved by more than 3 times at most.

Owner:SHANDONG JINDING ELECTRONICS MATERIALS CO LTD

Insulating material used for electrode surface of lithium battery and preparation method of insulating material

ActiveCN102314959AAvoid battery fire or explosion accidentsImprove securityMetallic oxidesSolventOxide

The invention provides a preparation method of insulating material used for electrode surface of a lithium battery. The material comprises the following components in percentage by weight: 75%-96% of Al2O3, 0.5%-15% of gas phase SiO2 and 2.5-15% of bonding agent. The preparation method comprises the following steps of: baking each ingredient firstly; then grinding Al2O3 and SiO2 to prepare a mixed material; adding the bonding agent into a solvent and stirring to obtain bonding agent slurry; and then mixing the mixed material and the bonding agent slurry and stirring uniformly, and carrying out defoaming treatment in vacuum to finally obtain the insulating material. The material is used for coating the electrode surface of the lithium battery to form a metal oxide insulating film; even though a battery diaphragm is damaged under the condition of high temperature, short circuit between a positive electrode and a negative electrode also can be prevented, accidents are avoided, and the safety of a power high-capacity lithium battery is improved greatly.

Owner:SHUANGDENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com