Preparation method of epoxy resin conductive adhesive film

A technology of epoxy resin and conductive adhesive film, applied in epoxy resin adhesive, conductive adhesive, film/sheet adhesive, etc., can solve the problem of difficult uniform coating, low heat resistance, poor toughness, etc problem, to achieve the effect of long storage time, low viscosity and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

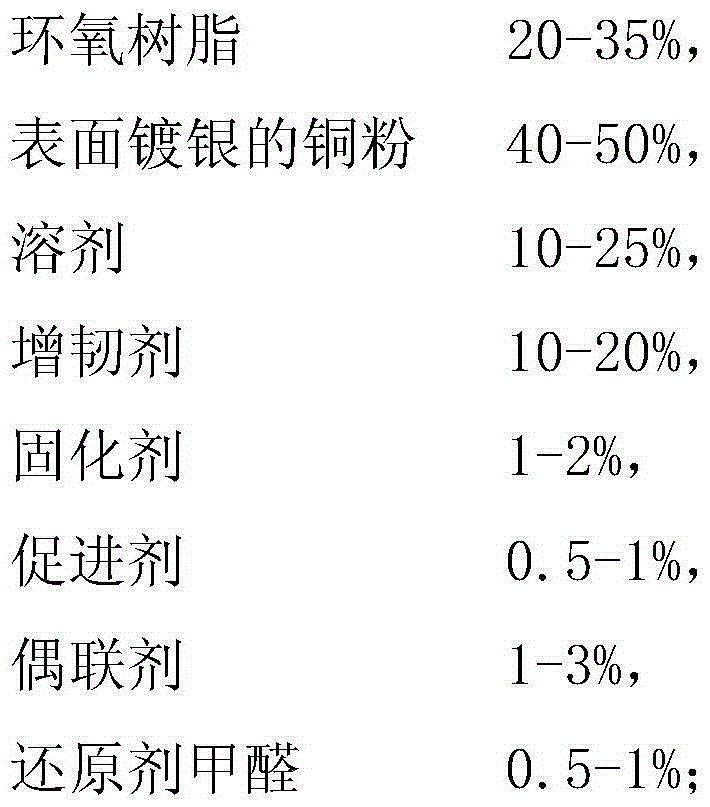

[0025] The epoxy resin conductive adhesive film provided in this embodiment includes a release film and a conductive adhesive layer coated on the release film. The conductive adhesive layer includes the following components in terms of mass percentage:

[0026]

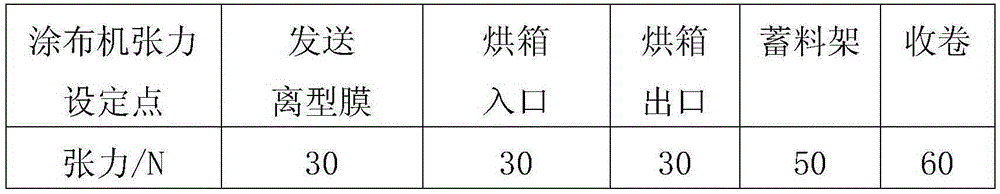

[0027] The preparation method includes the following steps: firstly mix epoxy resin, toughening agent and curing agent, then add accelerator, coupling agent and reducing agent, fully stir, then add copper powder and solvent coated with silver on the surface of conductive filler, and airtightly mix , to effectively avoid the volatilization of the solvent; then use the coating machine to coat the above-mentioned mixed slurry on the release film, and during the coating process, set the temperature and tension as follows:

[0028] 1) Coating machine temperature setting

[0029] Coating Oven Section

CH1

CH2

CH3

CH4

CH5

CH6

CH7

temperature / ℃

70

90

100

120

13...

Embodiment 2

[0035] The epoxy resin conductive adhesive film provided in this embodiment includes a release film and a conductive adhesive layer coated on the release film. The conductive adhesive layer includes the following components in terms of mass percentage:

[0036]

[0037] The toughening agent is a mixture of nitrile rubber and high molecular weight epoxy resin;

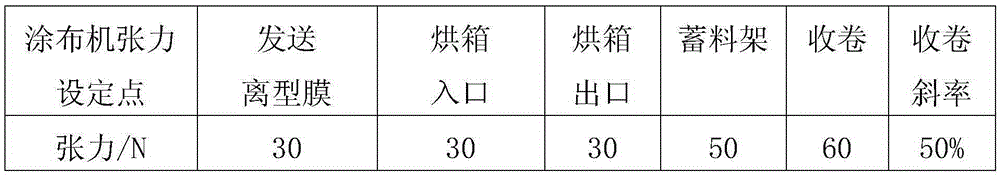

[0038] The preparation method includes the following steps: firstly mix epoxy resin, toughening agent and curing agent, then add accelerator, coupling agent and reducing agent, fully stir, then add copper powder and solvent coated with silver on the surface of conductive filler, and airtightly mix , to effectively avoid the volatilization of the solvent; then use the coating machine to coat the above-mentioned mixed slurry on the release film, and during the coating process, set the temperature and tension as follows:

[0039] 1) Coating machine temperature setting

[0040] Coating Oven Section

CH1

...

Embodiment 3

[0046] The epoxy resin conductive adhesive film provided in this embodiment includes a release film and a conductive adhesive layer coated on the release film. The conductive adhesive layer includes the following components in terms of mass percentage:

[0047]

[0048] The preparation method includes the following steps: firstly mix epoxy resin, toughening agent and curing agent, then add accelerator, coupling agent and reducing agent, fully stir, then add copper powder and solvent coated with silver on the surface of conductive filler, and airtightly mix , to effectively avoid the volatilization of the solvent; then use the coating machine to coat the above-mentioned mixed slurry on the release film, and during the coating process, set the temperature and tension as follows:

[0049] 1) Coating machine temperature setting

[0050] Coating Oven Section

CH1

CH2

CH3

CH4

CH5

CH6

CH7

temperature / ℃

70

90

100

120

13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com