Polypropylene-based thermoplastic shielding material for cable, and preparation method thereof

A polypropylene-based, thermoplastic technology, which is applied in the field of polypropylene-based thermoplastic cable shielding materials and its preparation, can solve the problems of decreased mechanical properties and surface smoothness, difficulty in recycling, and great environmental hazards, and achieves improved electrical conductivity and mechanical properties. Performance, avoiding the decline of mechanical properties, and improving the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

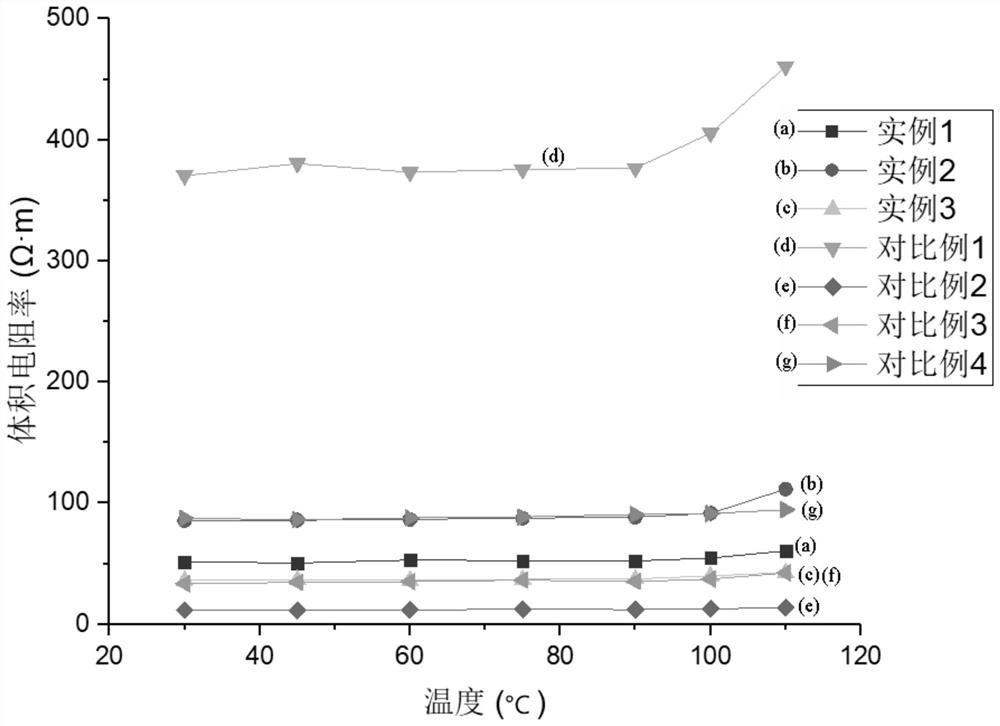

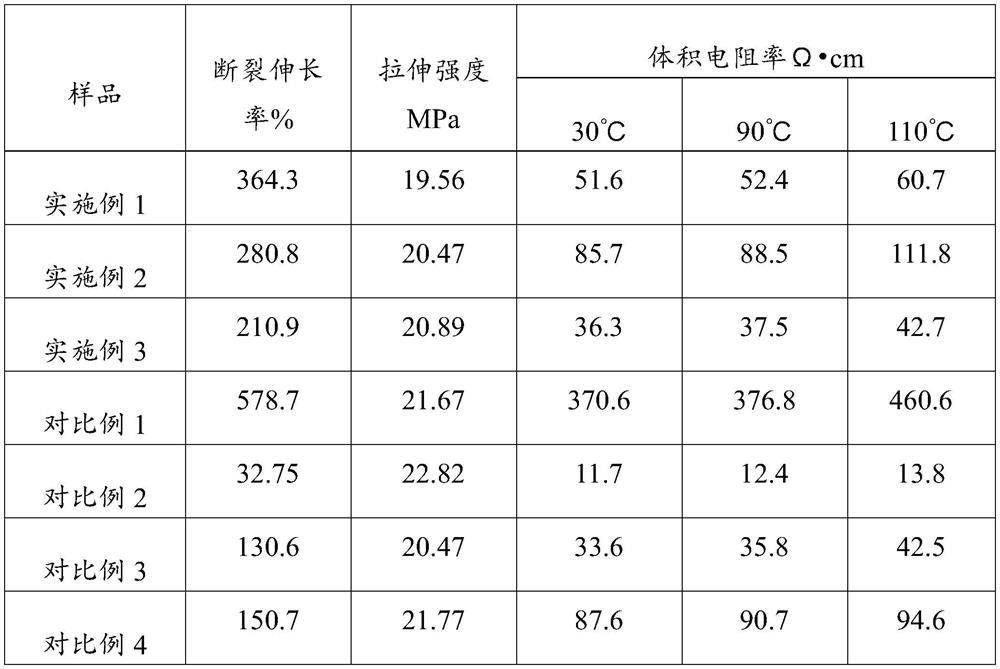

Embodiment 1

[0029] As a shielding compound for polypropylene-based thermoplastic cables according to an embodiment of the present invention, the shielding compound for polypropylene-based thermoplastic cables includes the following components in parts by weight: 100 parts of ethylene propylene block copolymerized polypropylene, 5 parts of conductive Carbon black, 1 part of highly conductive graphene, 1 part of coupling agent A172 (vinyl tri(β-methoxyethoxy) silane), 0.5 part of antioxidant 300, 1 part of lubricant silicone oil, 1 part of anti-adhesive agent ethylene bis stearamide (EBS), the ethylene segment mass fraction in the ethylene propylene block copolymerized polypropylene is 20%, and the average particle diameter of the conductive carbon black is 20~80nm, so The BET specific surface area of the conductive carbon black is 150-500m 2 / g, the number of layers of the highly conductive graphene is 1 to 6 layers, the average layer thickness of the highly conductive graphene is 1 to 5...

Embodiment 2

[0035] As a shielding compound for polypropylene-based thermoplastic cables according to an embodiment of the present invention, the shielding compound for polypropylene-based thermoplastic cables includes the following components in parts by weight: 100 parts of ethylene propylene block copolymerized polypropylene, 7.5 parts of conductive Carbon black, 0.5 parts of highly conductive graphene, 1 part of coupling agent KH550 (γ-aminopropyltriethoxysilane), 0.5 parts of antioxidant 1010, 1 part of lubricant liquid paraffin, 1 part of Anti-adhesive barium stearate, the ethylene segment mass fraction in the ethylene propylene block copolymerized polypropylene is 20%, the average particle diameter of the conductive carbon black is 20-80nm, and the BET specific surface area of the conductive carbon black is 150-500m 2 / g, the number of layers of the highly conductive graphene is 1 to 6 layers, the average layer thickness of the highly conductive graphene is 1 to 5 nm, and the BET ...

Embodiment 3

[0037] As a shielding compound for polypropylene-based thermoplastic cables according to an embodiment of the present invention, the shielding compound for polypropylene-based thermoplastic cables includes the following components in parts by weight: 100 parts of ethylene propylene block copolymerized polypropylene, 10 parts of conductive Carbon black, 0.5 parts of highly conductive graphene, 1 part of coupling agent KH550 (γ-aminopropyltriethoxysilane), 0.5 parts of antioxidant 1010, 1 part of lubricant liquid paraffin, 1 part of Anti-adhesive barium stearate, the ethylene segment mass fraction in the ethylene propylene block copolymerized polypropylene is 20%, the average particle diameter of the conductive carbon black is 20-80nm, and the BET specific surface area of the conductive carbon black is 150-500m 2 / g, the number of layers of the highly conductive graphene is 1 to 6 layers, the average layer thickness of the highly conductive graphene is 1 to 5 nm, and the BET s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com