High-precision patterned stretchable electrode and preparation method thereof

A patterned electrode, patterned technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of reduced contact area, affected signal fidelity, low device integration, etc., to achieve good conductivity and cost. The effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

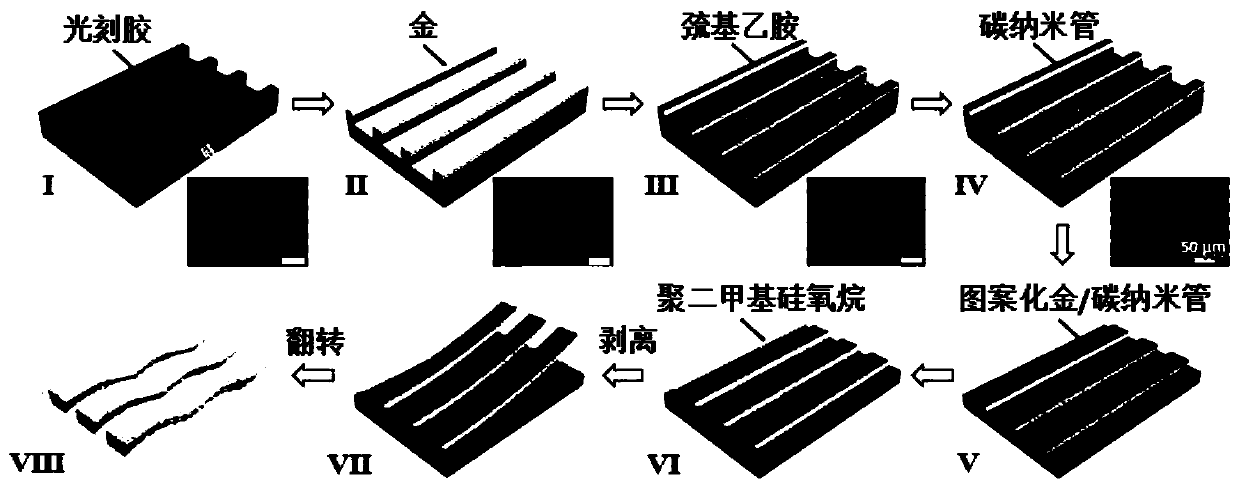

[0059] Example 1. Preparation of high-precision stretchable electrodes based on photolithographic patterning

[0060] according to figure 1 The flow diagram shown in the figure prepares flexible and high-precision patterned stretchable electrodes, and the steps are as follows:

[0061] Firstly, use photolithography to photoetch the electrode pattern on the substrate, then vapor-deposit the gold electrode, then modify it with mercaptoethylamine, and then spray the carbon nanotubes. Polydimethylsiloxane PDMS is spin-coated on the chemical electrode, and after polydimethylsiloxane PDMS is cured, the high-precision pattern electrode and polydimethylsiloxane PDMS are transferred from the substrate together; the specific Proceed as follows:

[0062] 1. Cleaning of silicon substrate: Clean the cut silicon wafer in absolute ethanol and secondary deionized water in turn, and then dry it with nitrogen.

[0063] 2. Octadecyltrichlorosilane (OTS) modifies the surface of the silicon sub...

Embodiment 2

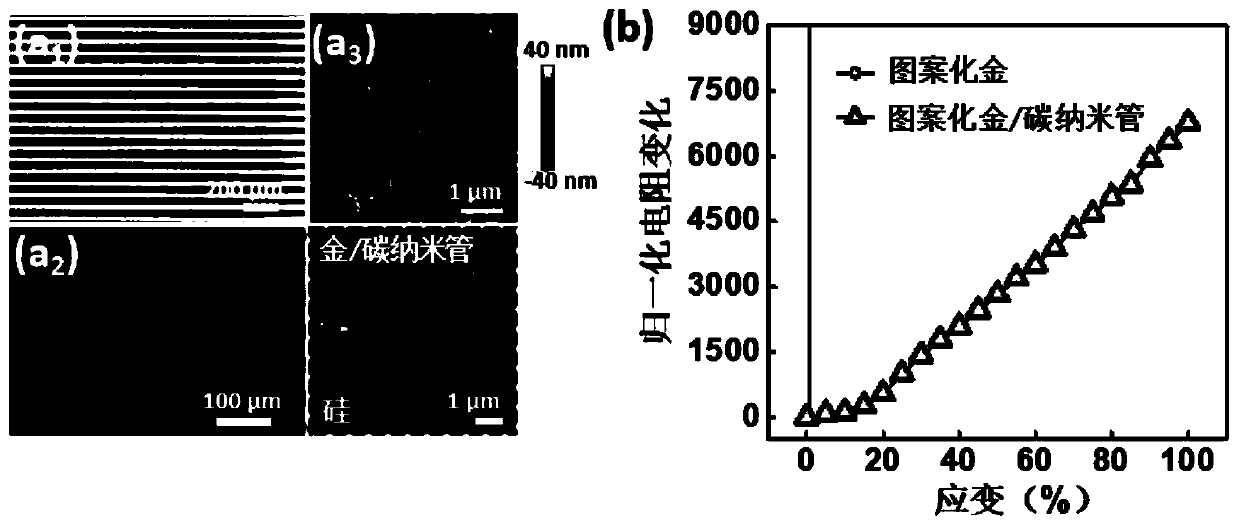

[0082] Example 2. Preparation of high-precision patterned stretchable electrodes with and without mercaptoethylamine modification based on photolithographic patterning. The steps are as follows:

[0083] 1. Preparation of high-precision patterned stretchable electrodes modified with mercaptoethylamine, the steps are as follows:

[0084] 1. Cleaning of silicon substrate: Clean the cut silicon wafer in absolute ethanol and secondary deionized water in turn, and then dry it with nitrogen.

[0085] 2. Octadecyltrichlorosilane (OTS) modifies the surface of the silicon substrate, and the specific steps are as follows: (1) the surface of the silicon chip is hydroxylated: the silicon chip after step 1 is treated in the piranha washing solution (volume ratio (7:3 mixed solution of concentrated sulfuric acid and hydrogen peroxide, specifically 35mL of concentrated sulfuric acid and 15mL of hydrogen peroxide) soaked for 30min, then took out the silicon wafer, and rinsed the substrate wit...

Embodiment 3

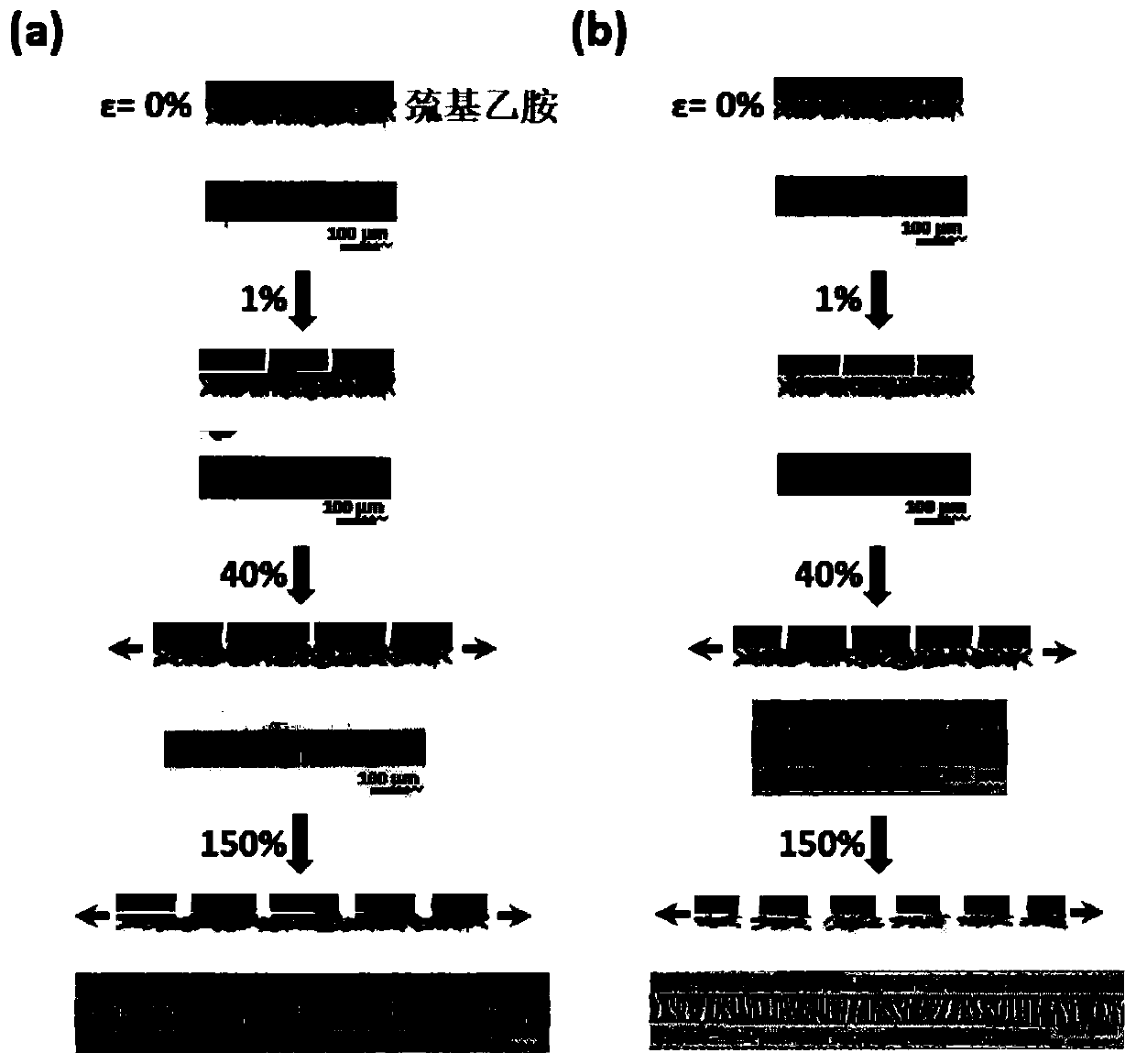

[0123] Example 3. Preparation of high-precision stretchable electrodes with different line widths based on photolithographic patterning

[0124] First, use photolithography to photoetch different high-precision line patterns on the substrate, then evaporate gold electrodes, then perform mercaptoethylamine modification, and then spray carbon nanotubes to obtain high-precision Au / SWCNTs patterned electrodes , and then spin-coat polydimethylsiloxane PDMS on the patterned electrode, after the polydimethylsiloxane PDMS is cured, the high-precision pattern electrode and polydimethylsiloxane PDMS are transferred from the substrate together down; the specific steps are as follows:

[0125] 1. Cleaning of silicon substrate: Clean the cut silicon wafer in absolute ethanol and secondary deionized water in turn, and then dry it with nitrogen.

[0126] 2. Octadecyltrichlorosilane (OTS) modifies the surface of the silicon substrate, and the specific steps are as follows: (1) the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com