Method for preparing dense precursor ceramic temperature sensor

A technology of temperature sensors and precursors, applied in thermometers, ceramic molding machines, thermometers with electric/magnetic elements that are directly sensitive to heat, etc., can solve the problem of insufficient oxidation resistance and strength, high porosity of precursor ceramics, Uneven conductivity changes and other problems, to achieve the effect of complete compact structure, simple molding method, and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing a dense precursor ceramic temperature sensor, the method comprising the following steps:

[0038] (1) Place the liquid ceramic precursor in a liquid forming mold and keep it warm for 0.5 to 2 hours (for example, 0.5, 0.6, 0.7, 0.8, 0.9, 1, 1.2, 1.5, 1.8 or 2h), to obtain a shaped precursor; the liquid ceramic precursor is placed under the condition of 150°C to 200°C (for example, at a temperature of 150°C to 200°C In the tube furnace) insulation is to make it carry out preliminary cross-linking and curing molding.

[0039] (2) Put the shaped precursor obtained in step (1) at 350°C to 450°C (such as 350°C, 360°C, 370°C, 380°C, 390°C, 400°C, 410°C, 420°C, 430°C, 440°C or 450°C) for 3 to 6 hours (such as 3, 3.5, 4, 4.5, 5, 5.5, or 6 hours) to obtain a precursor block; to mold the precursor at 350 to 450°C (for example, at a temperature of 350 ℃ ~ 450 ℃ tube furnace) insulation is to achieve complete crosslinking and curing of...

Embodiment 1

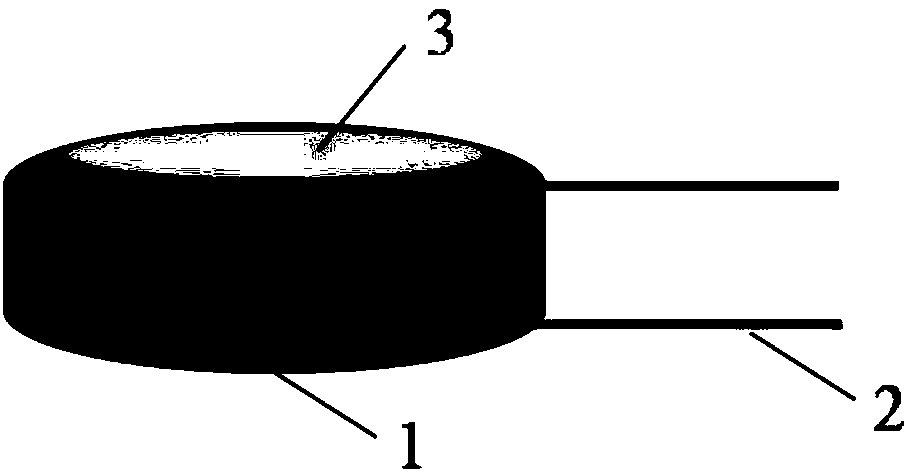

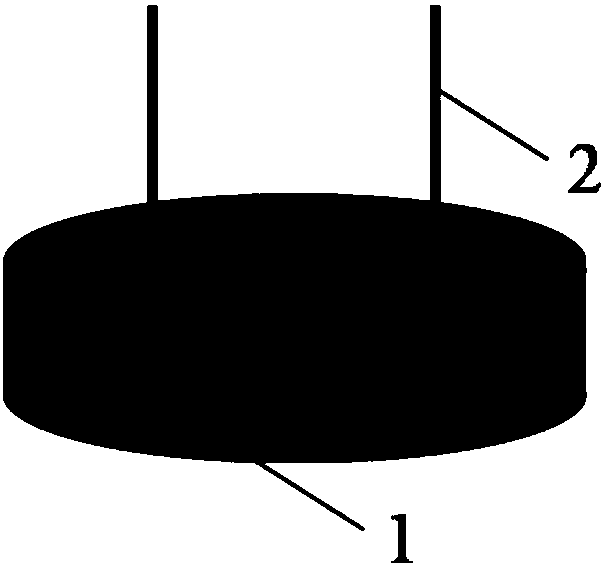

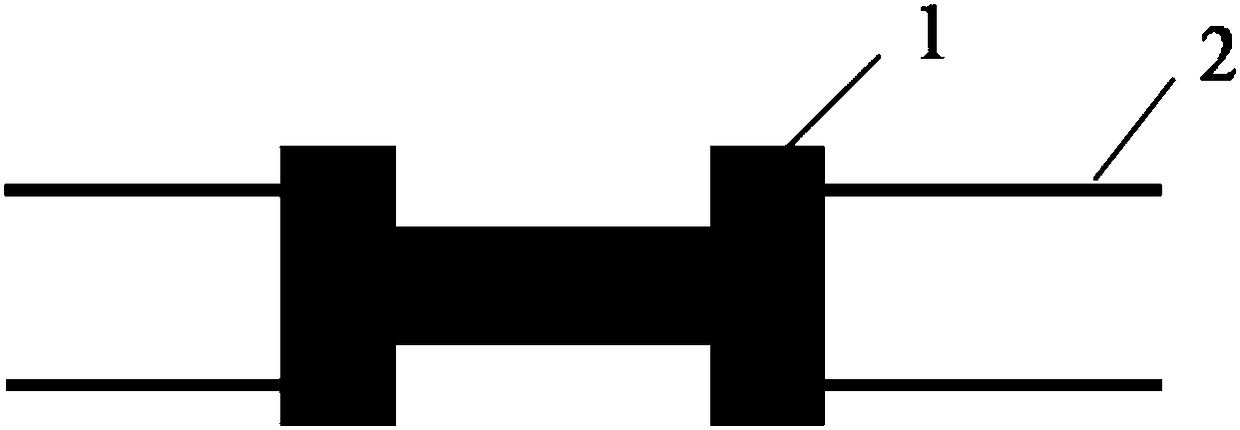

[0054] use as Figure 4 The liquid forming mold shown (the liquid forming mold is made of polytetrafluoroethylene material) prepares a dense type precursor ceramic temperature sensor, the precursor ceramic is a SiCN precursor ceramic, and the electrode is a platinum electrode. The electrodes are connected to the SiCN precursor ceramics by using liquid polysilazane as an adhesive. The SiCN precursor ceramics are prepared as follows.

[0055] Firstly, the air bubbles in the liquid polysilazane are removed by vacuuming (vacuumizing for 1 h), and then the liquid polysilazane is poured into the liquid forming mold; then, the argon protective atmosphere is introduced, and the In a type furnace, the temperature was raised to 180°C at a rate of 3°C / min, and kept for 1 hour for preliminary cross-linking and curing molding to obtain a molding precursor; then the molding precursor was taken out of the liquid molding mold, and the molding precursor was placed in the Put it into a tube f...

Embodiment 2

[0058] Example 2 is basically the same as Example 1, except that the pyrolysis temperature is 1100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com