Cable aluminum conductor surface powder scrap and burr cleaning device

A technique for cleaning the surfaces of devices and conductors, used in cable/conductor manufacturing, cleaning methods using gas flow, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

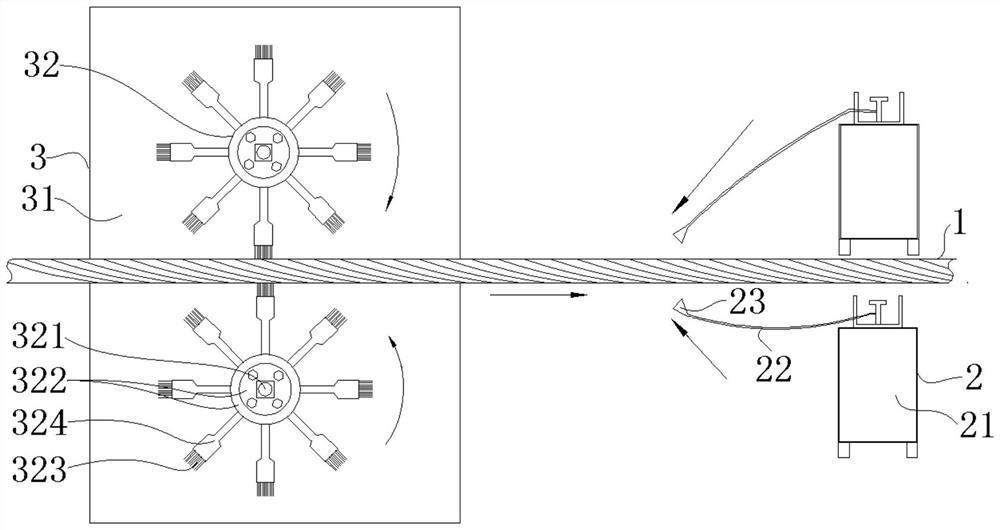

[0040] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the object of the present invention is the compacted round aluminum conductor of the cable, which removes debris, burrs and other foreign matter attached to its surface by the fire mechanism 1 and the brush removal mechanism 3 of the present invention during walking. .

[0041] The walking speed (ie transmission speed) of the aluminum conductor 1 targeted by the present invention is about 23 m / min.

[0042] The brushing mechanism 3 of the present invention is located on the upstream side of the burning mechanism 2, and it removes peelable sundries such as dust attached to the surface of the aluminum conductor 1 in motion with a brush structure.

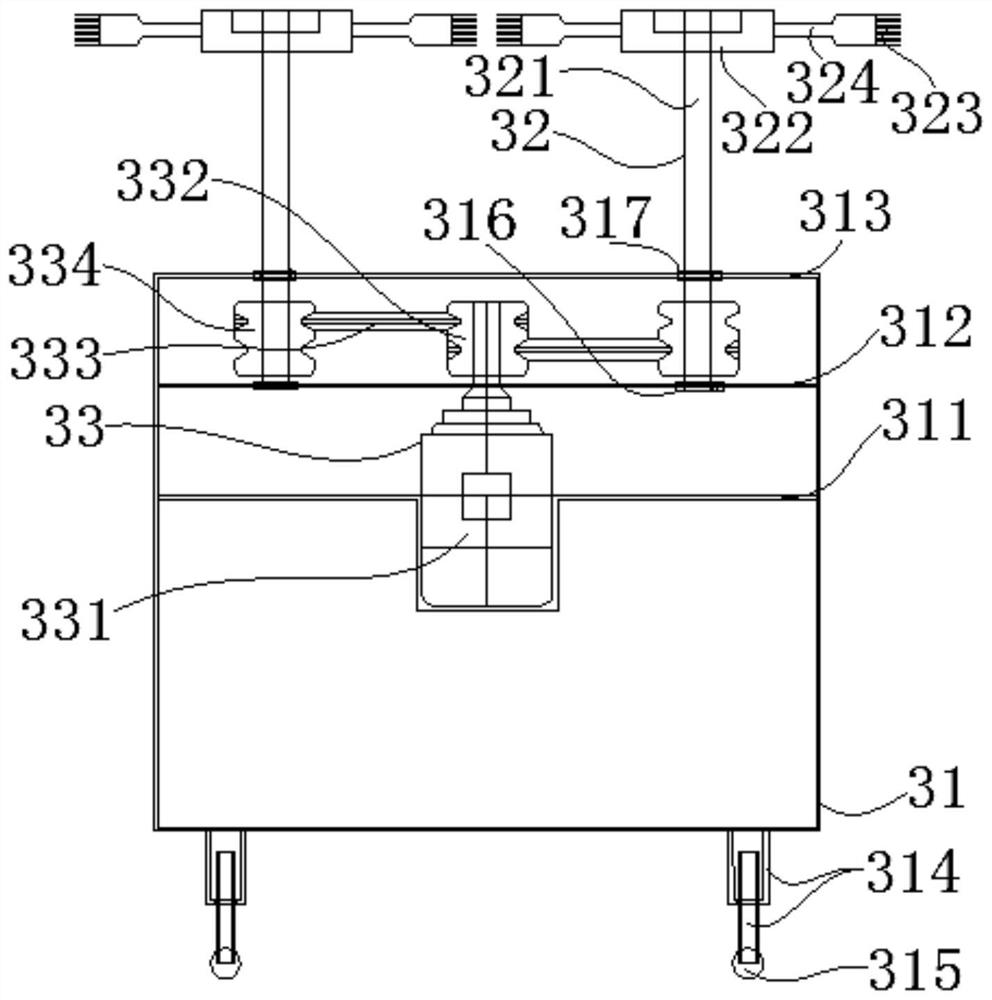

[0043] Specifically, the brushing mechanism 3 of the present invention is mainly composed of a frame 31 , two groups of umbrella brushes 32 and a driving chain 33 .

[0044] The function of the frame 31 is to assemble and support the two groups of umbrella brushes...

Embodiment 2

[0060] The other content of this embodiment is the same as that of Embodiment 1, except that the two groups of umbrella brushes of the brushing mechanism extend laterally from one side of the frame, so that the two groups of umbrella brushes are basically arranged in a symmetrical structure. Distributed on the upper and lower sides of the aluminum conductor in motion.

Embodiment 3

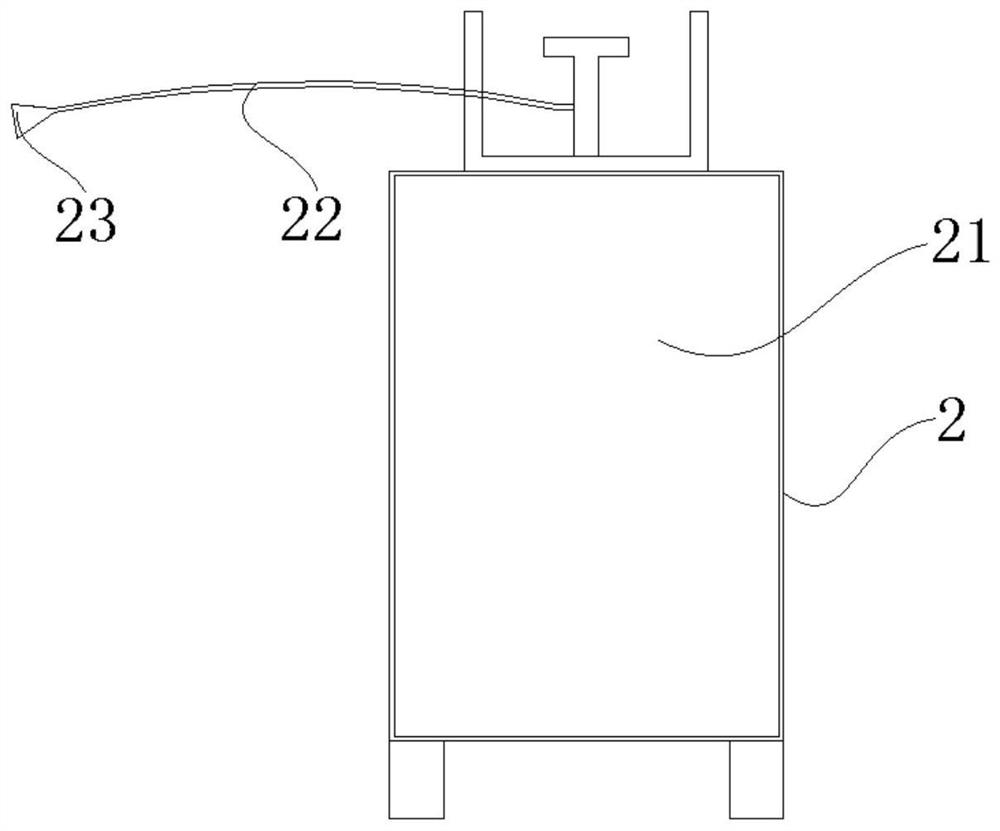

[0062] The other content of this embodiment is the same as that of Embodiment 1, except that the flame mechanism is a set of double nozzle structure, that is, the two flame nozzles are sealed and connected with the common gas storage tank through corresponding gas hoses, and each flame The nozzle has a corresponding nozzle bracket (of course, it can also be the same nozzle bracket but adopts two independent clamping stations).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com