Method for preparing lithium ferrite anticorrosive coatings by flame spraying

A technology of lithium ferrite and flame spraying, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the requirement that the whole life of the grounding device cannot be met, and the ferrite conductive anti-corrosion coating has not been prepared and other problems, to achieve good spraying adaptability, optimize spraying process parameters, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

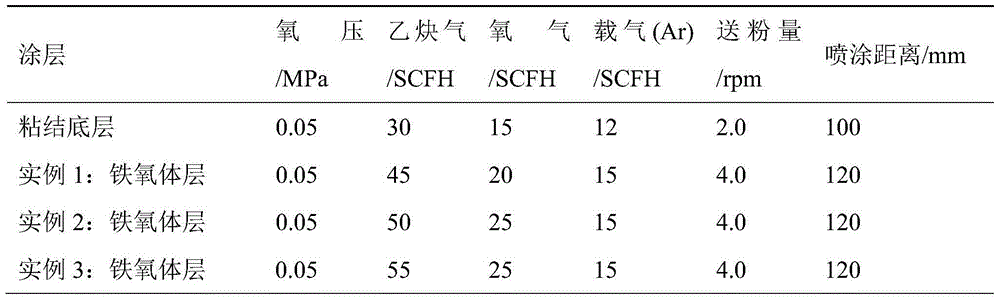

[0029] Oxygen-acetylene flame spraying was adopted, and the bonding primer and lithium ferrite layer shown in Table 1 were respectively used for the metal bonding primer and the spraying process parameters of Example 1: Lithium ferrite layer. The spraying powder materials of the junction layer and ferrite are sprayed successively on the cleaned and sandblasted Q235 steel substrate, the bonding layer is 0.11mm, and the ferrite coating is 0.22mm.

[0030] The average porosity of the ferrite conductive coating is calculated to be 3.6% by using Ia32 image analysis software.

[0031] The bonding strength of the coating and the substrate was measured on a universal testing machine by the bonding tensile method, and the bonding strength of the coating was measured to be 25.6Mpa by stretching at a tensile speed of 1mm per minute.

[0032] The electrical resistance of the coating was tested by the two-terminal method and the resistivity was calculated. In order to reduce the contact r...

example 2

[0035]Oxygen-acetylene flame spraying is used, the metal bonding primer and the ferrite layer respectively adopt the bonding primer shown in Table 1 and Example 2: the spraying process parameters of the ferrite layer, and the bonding primer with a particle size of 20 to 100 μm is used. The spraying powder material of ferrite and ferrite is sprayed onto the cleaned and sandblasted Q235 steel substrate successively, the bonding bottom layer is 0.10mm, and the ferrite coating is 0.20mm.

[0036] The average porosity of the ferrite coating was calculated to be 2.0% by Ia32 image analysis software.

[0037] The bonding strength of the coating and the substrate was measured on a universal testing machine by the bonding tensile method, and the bonding strength of the coating was measured to be 28.8Mpa by stretching at a tensile speed of 1mm per minute.

[0038] The electrical resistance of the coating was tested by the two-terminal method and the resistivity was calculated. In order...

example 3

[0041] Oxygen-acetylene flame spraying is adopted, and the metal bonding primer and the ferrite layer respectively adopt the bonding primer shown in Table 1 and Example 3: The spraying process parameters of the ferrite layer, and the bonding primer with a particle size of 20 to 100 μm is used. and ferrite spraying powder materials are sprayed successively on the Q235 steel substrate that has been cleaned and sandblasted, the bonding bottom layer is 0.12mm, and the ferrite coating is 0.21mm.

[0042] The average porosity of the ferrite coating was calculated to be 3.0% by Ia32 image analysis software.

[0043] The bonding strength of the coating and the substrate was measured on a universal testing machine by the bonding tensile method, and the bonding strength of the coating was measured to be 26.2Mpa by stretching at a tensile speed of 1mm per minute.

[0044] The electrical resistance of the coating was tested by the two-terminal method and the resistivity was calculated. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com