Patents

Literature

71 results about "Lithium ferrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

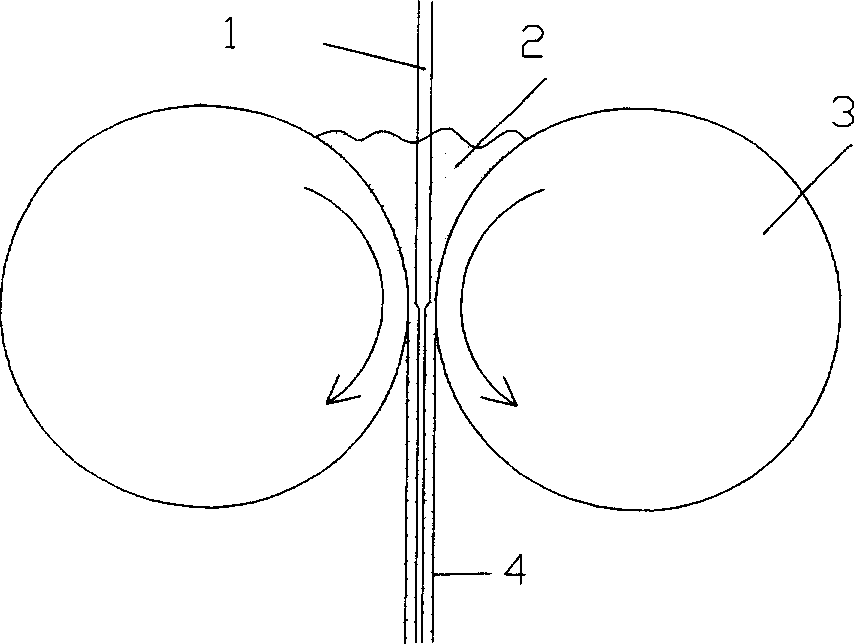

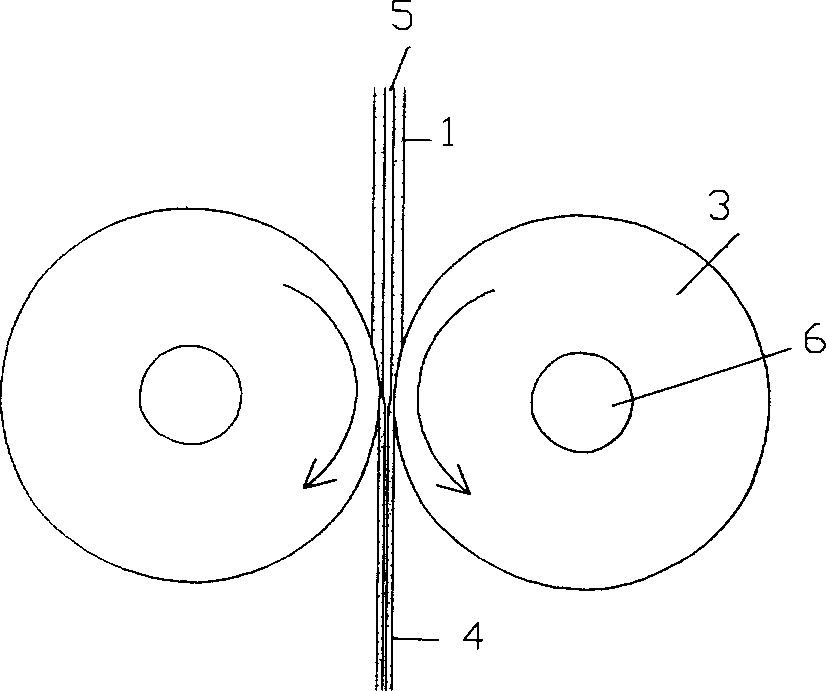

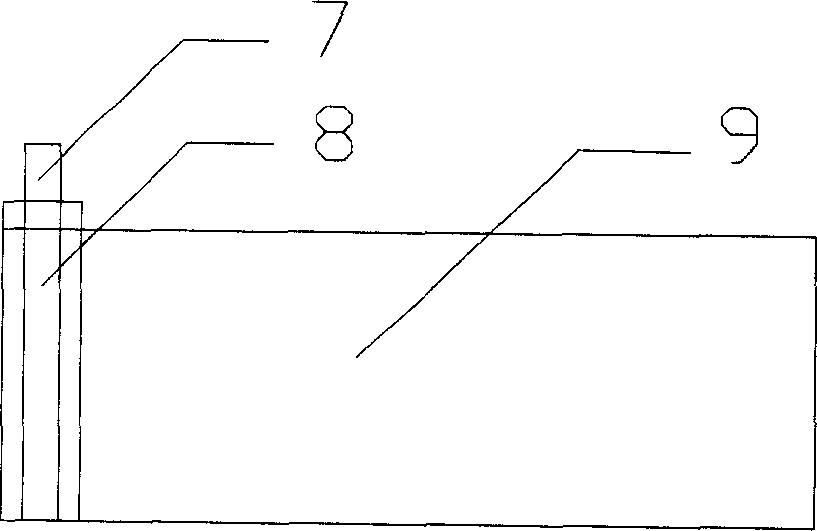

Production for positive electrode piece of cylindrical winding lithium-ferrite disulfide battery

InactiveCN1645650ALow costSimple production processElectrode manufacturing processesPyritePole piece

The pole piece of anode is composed of pyrite, acetylene black, black lead, binding agent and additive. After the pyrite is taken by heat treatment, it mixes with compression-treated acetylene black, black lead and additive. Two methods are used in making the anode powder piece. One is slurry method: after the anode powder mixes with deionized water and industrial spirit, the Teflon liquid cream is added to form a cream; first pressing it to form film and then making it into piece. The second method is rolling forming: after the industrial spirit, Teflon liquid cream are added into the anode powder, first pressing it into film; then making it into pieces; the pieces are put into bake oven to remove water and then put into vacuum case for drying.

Owner:惠州德赛能源科技有限公司

Lithium ferrite material applied to C waveband phase shifter

The invention relates to the field of ferrite materials, discloses a lithium ferrite material applied to C waveband phase shifter, composed of the following ingredients in weight ratio: 10-12 % of Li [2] CO [3], 3-5% of MgO, 18-20% of TiO [2], 1-2% of ZnO, 0.1-0.3% of Bi [2] O [3], 0.6-0. 8% of NiO, 4-6% of MnCO [3], 0.4-0.6% of Al (OH) [3], 0.4-0.6% of Nb [2] O [5], and 55-59% of Fe [2] O [3]. The phase shifter prepared by the inventive lithium ferrite material has advantage of small insertion loss and highly moisture-proof ability.

Owner:HUAYANG TECH DEV

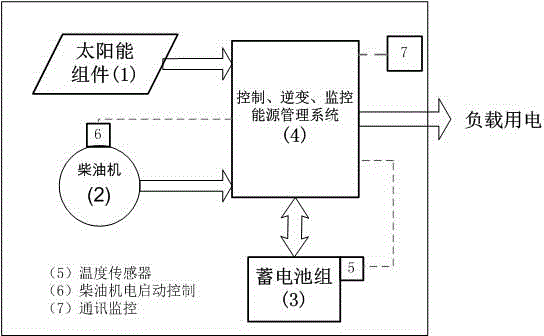

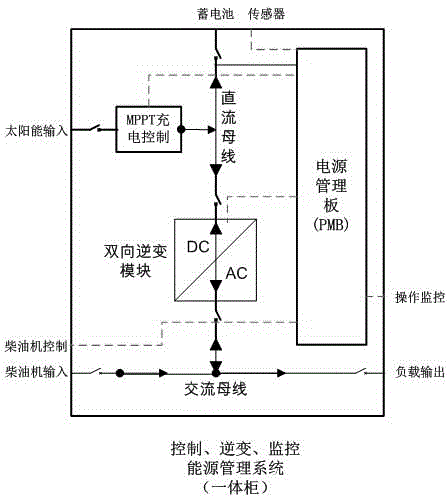

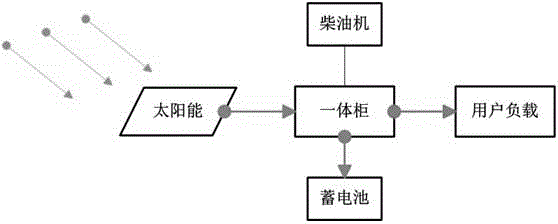

Novel solar and diesel hybrid power generation system

InactiveCN104953927AReduce usageReduce high costPV power plantsSingle network parallel feeding arrangementsNew energySolar power

The invention provides a new energy hybrid power generation technology formed by mutually complementing a solar power generation technology with a diesel power generation technology, and composed of a storage battery (plumbic acid or lithium ferrite) energy storage technology. The new energy hybrid power generation technology provides a new energy solution for remote areas, islands and the like, and is an important alternative scheme for the existing diesel power generation scheme in some districts. According to the new energy hybrid power generation technology, solar energy is used for supplying power and charging a storage battery in case of sufficient solar energy; the storage battery provides a discharge support load in the case that the solar energy cannot be met; the capacity of the storage battery is detected, and a diesel power generator is automatically started up to supply power in the case that the capacity of the storage battery is insufficient; the diesel power generator is automatically turned off when it is detected that the capacity of the storage battery is recovered to a certain extent. The system overcomes the problems of a high use cost, a high noise pollution and the like of a pure diesel power generator, and also avoids the problems of a too high initial investment and a low system reliability in extreme weather of a pure solar power generator. The power supply system generates power mainly by virtue of the solar energy, uses the diesel for standby, and is capable of intelligently control, contravariant and management to increase energy conversion and use efficiency; the overall system provided by the invention provides a cheap and reliable energy solution.

Owner:SHANGHAI GFSOLAR ENERGY TECH CO LTD

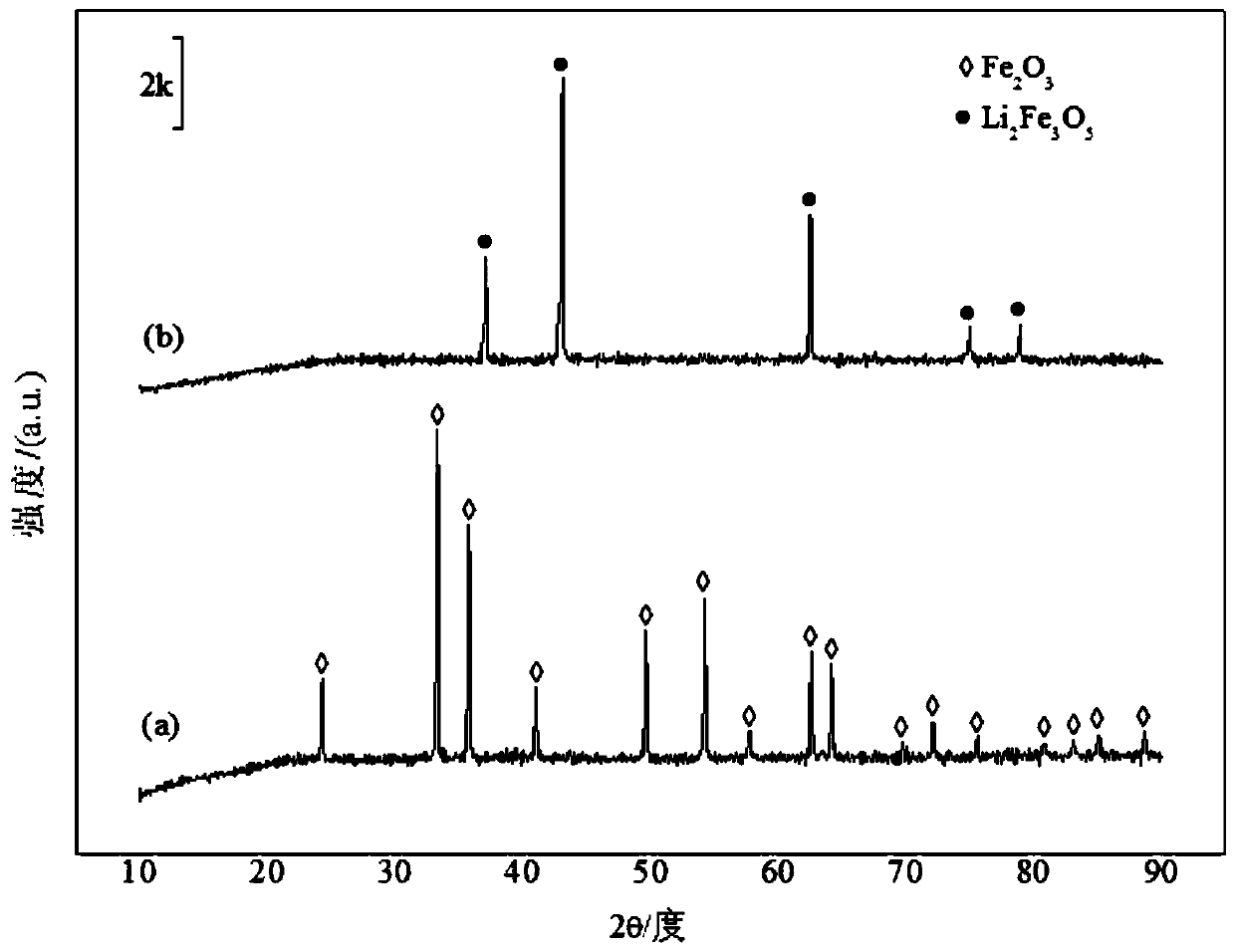

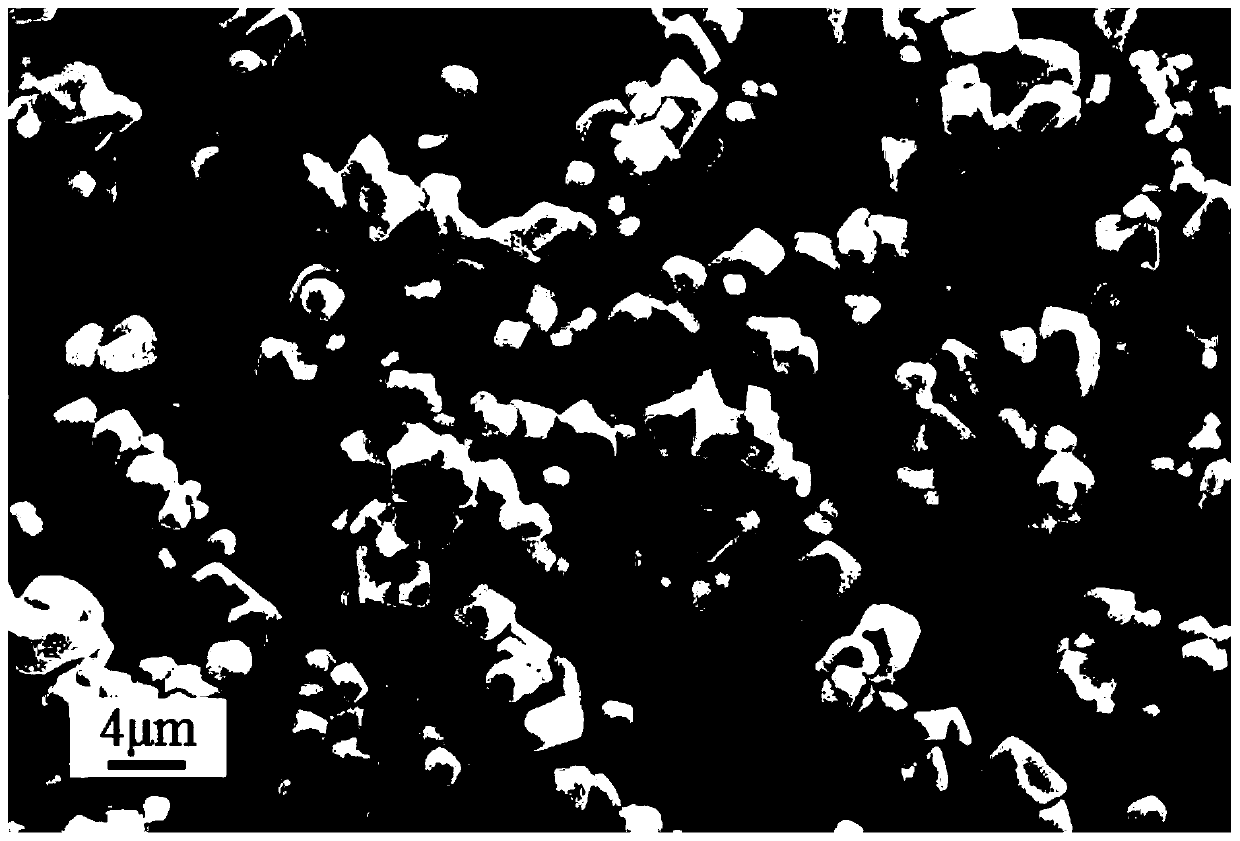

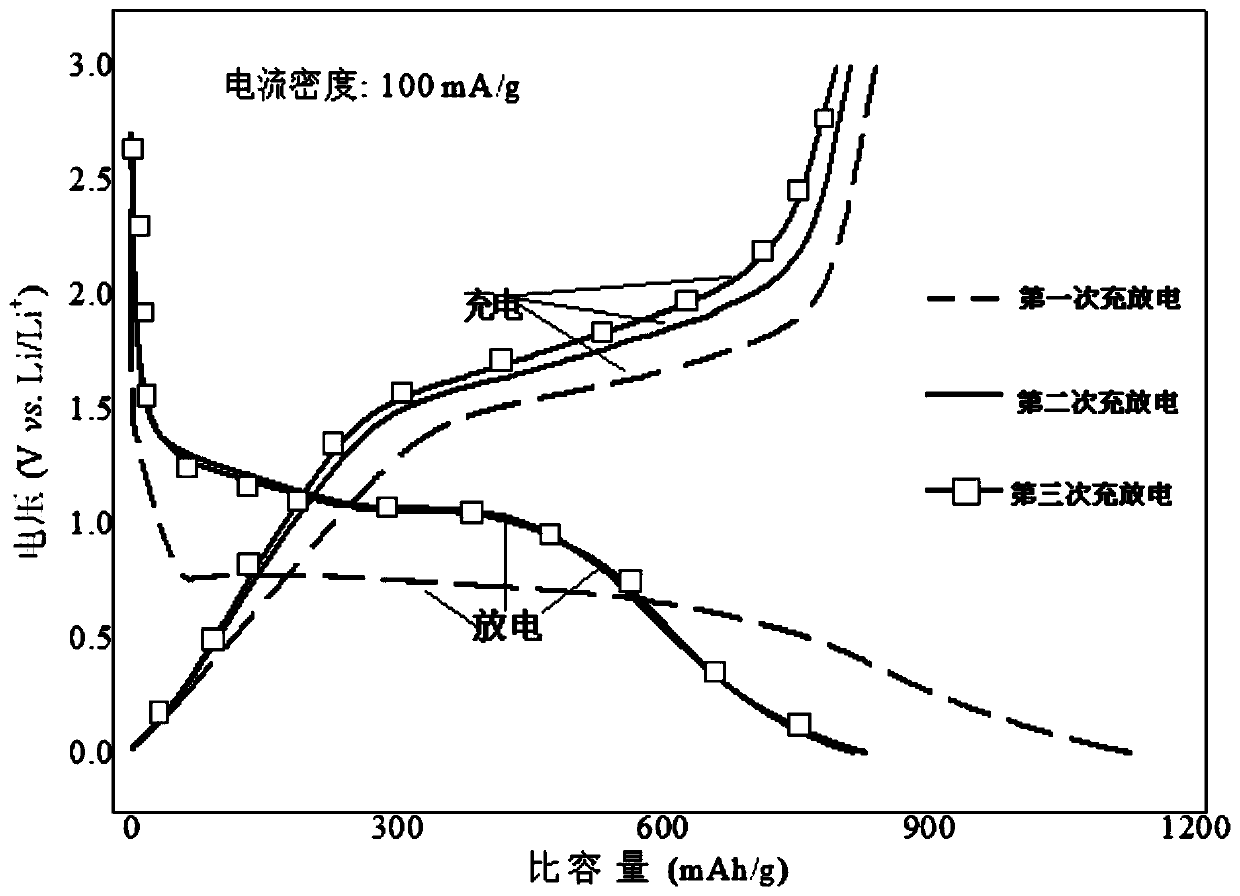

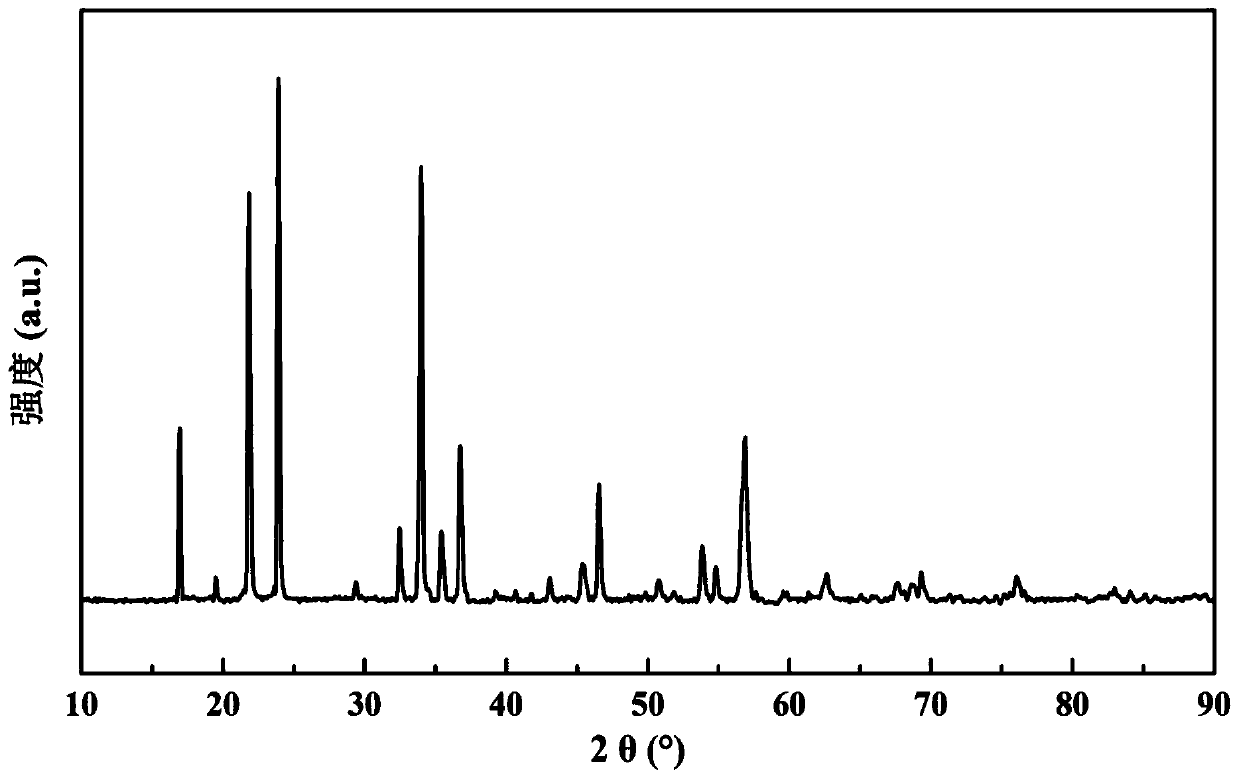

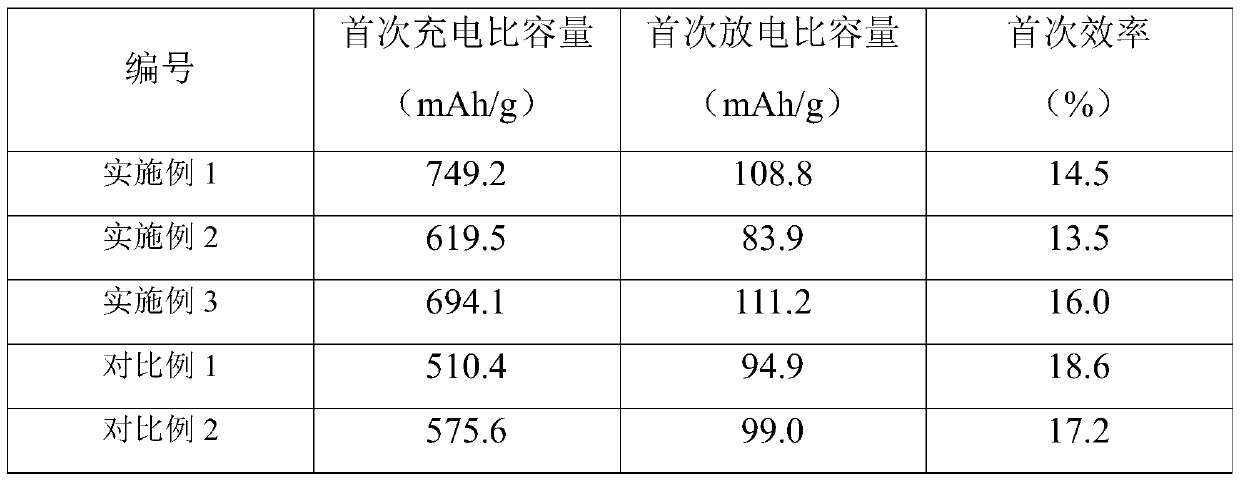

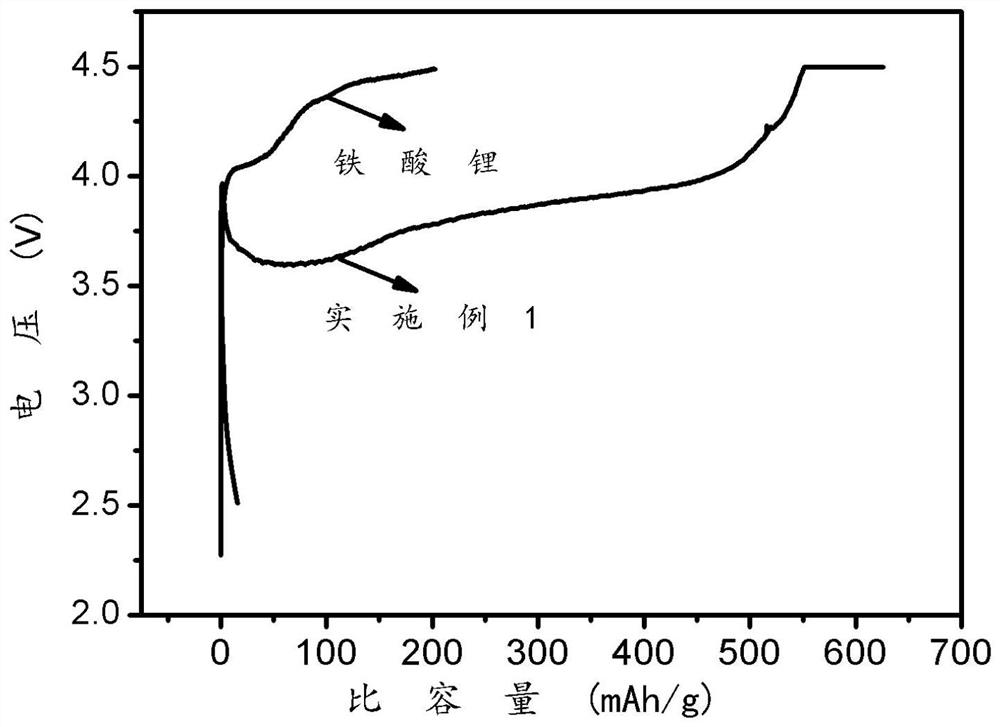

Lithium battery anode material based on lithium ferrite as well as preparation method and application thereof

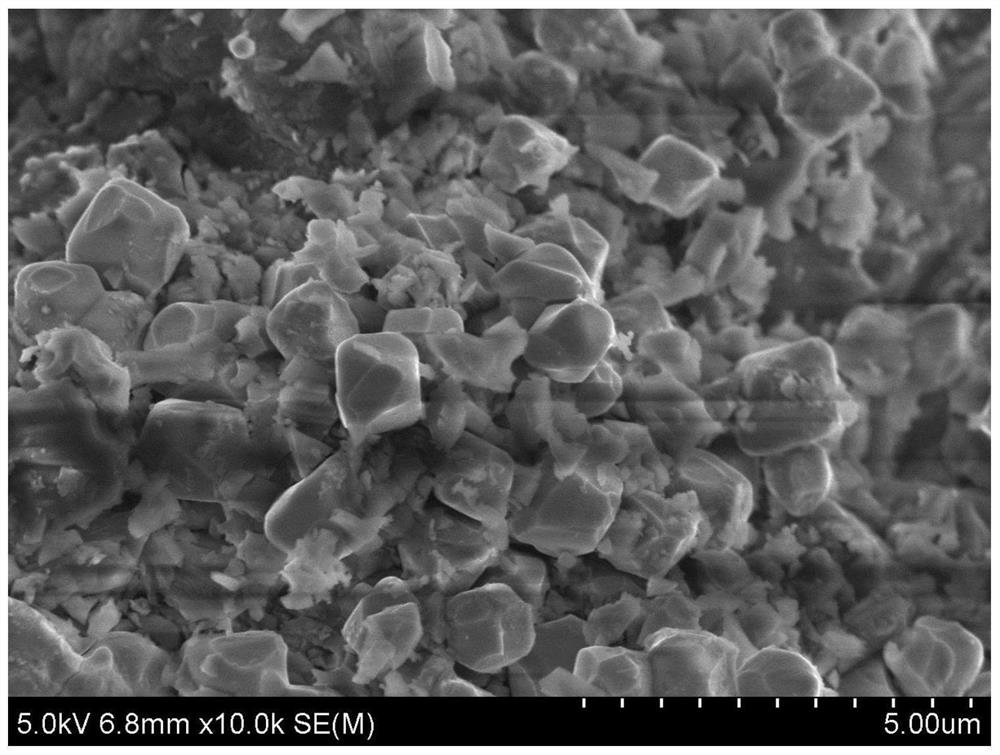

ActiveCN109755471ARegulatory TopographyRegulatory granularitySecondary cellsNon-aqueous electrolyte accumulator electrodesGraphiteSolvent

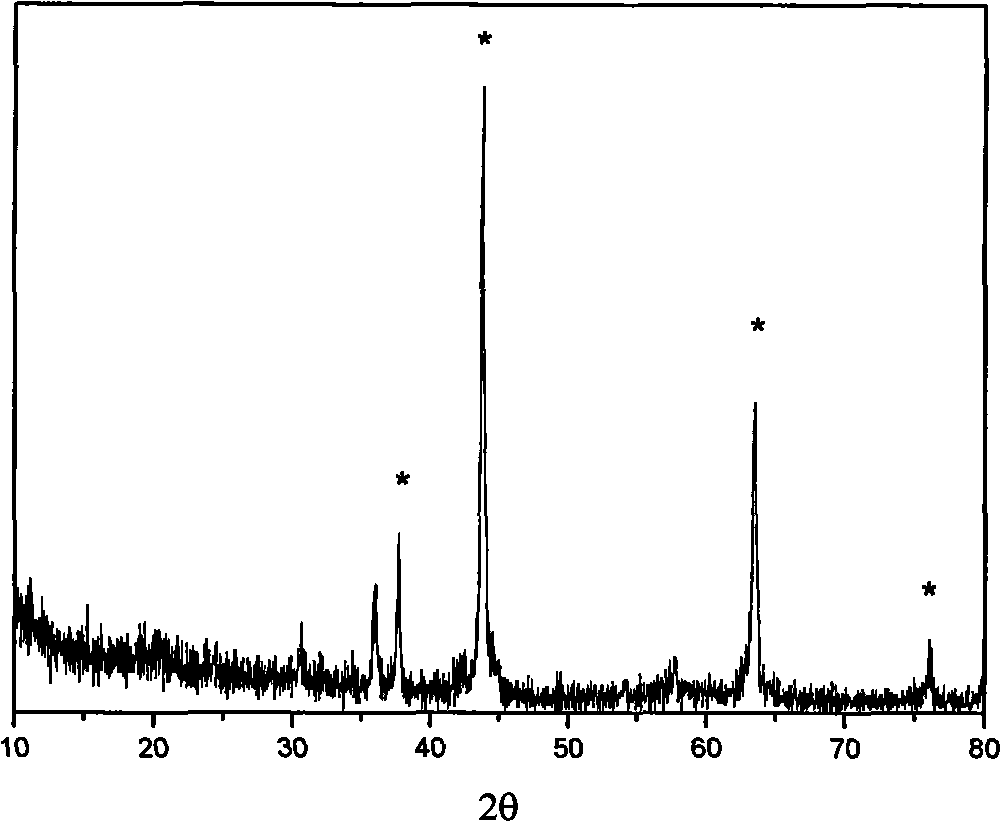

The invention relates to a lithium battery anode material based on lithium ferrite as well as a preparation method and application thereof and belongs to the field of preparation and application of lithium ion battery electrode materials. The lithium battery anode material based on lithium ferrite comprises lithium ferrite as well as conductive carbon, a binder and a solvent, wherein a chemical formula of lithium ferrite is Li2Fe3O5, morphology of lithium ferrite is particles of an octahedral structure, and particle size is 0.2-10[mu]m. The preparation method of the lithium battery anode material comprises the following steps: mixing all the substances, and stirring, so that the lithium battery anode material is obtained. A lithium battery can be prepared by adopting the anode material. The method provided by the invention prepares a lithium ion anode material on the basis of a lithium ferrite material of the octahedral structure, not only conductivity is improved, but also great volume change of lithium ions in intercalation and deintercalation processes is alleviated, so that electrochemical stability of the lithium ion anode material is improved, the problem that graphite has relatively low theoretical specific capacity when being taken as the traditional lithium ion battery anode material can be thoroughly solved, and the development obstacle that specific capacity of a lithium ion battery is relatively low is overcome.

Owner:NORTHEASTERN UNIV

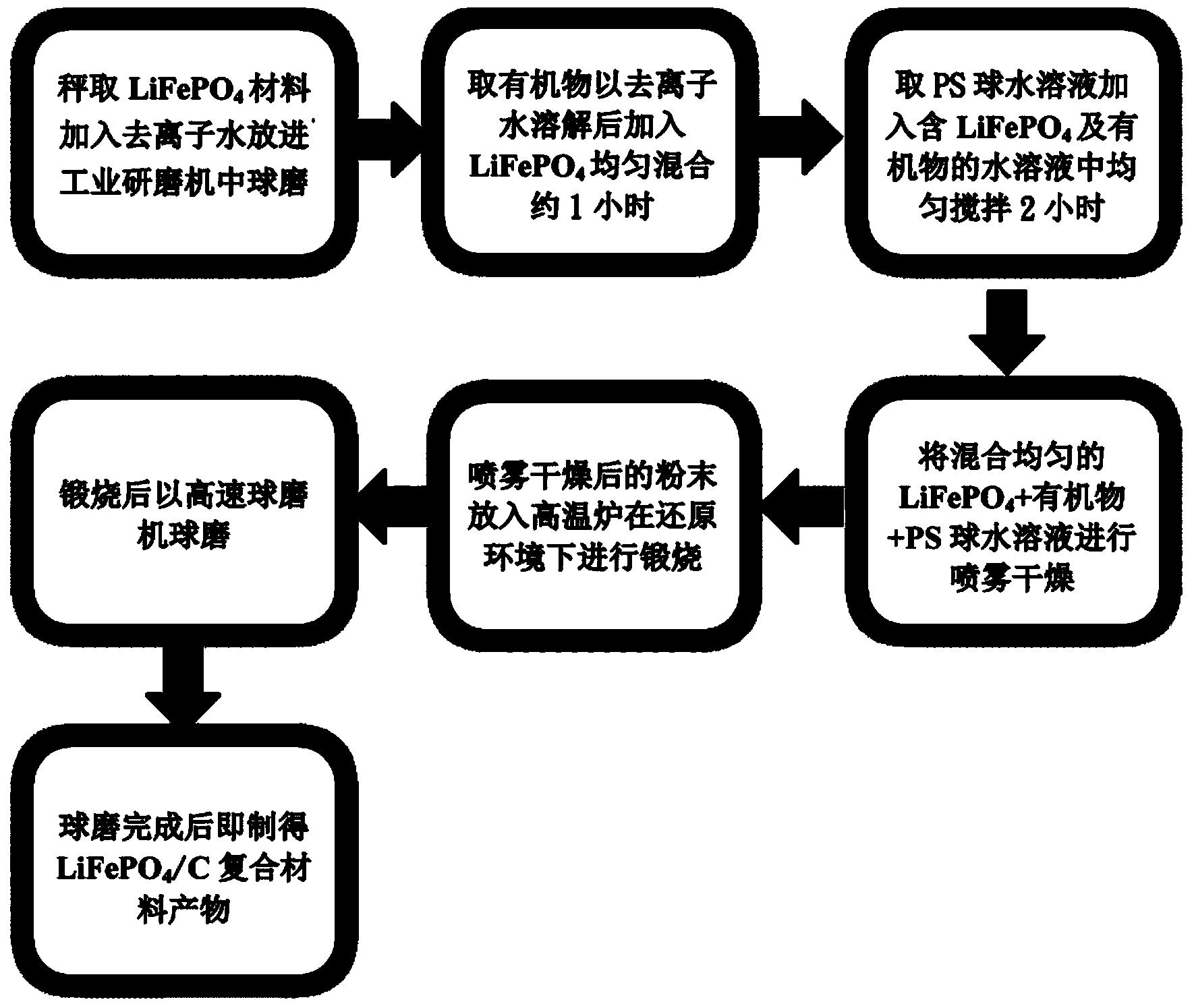

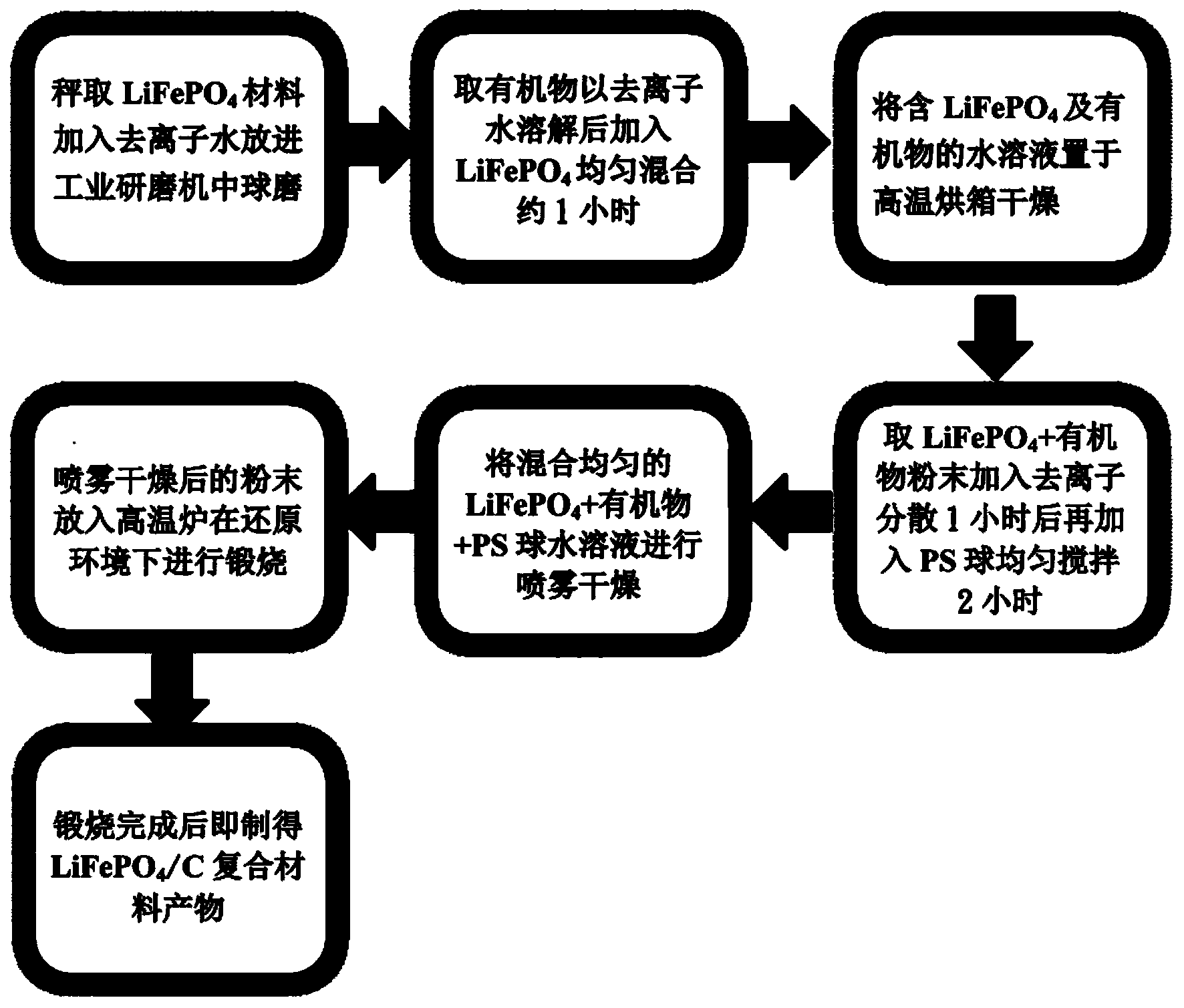

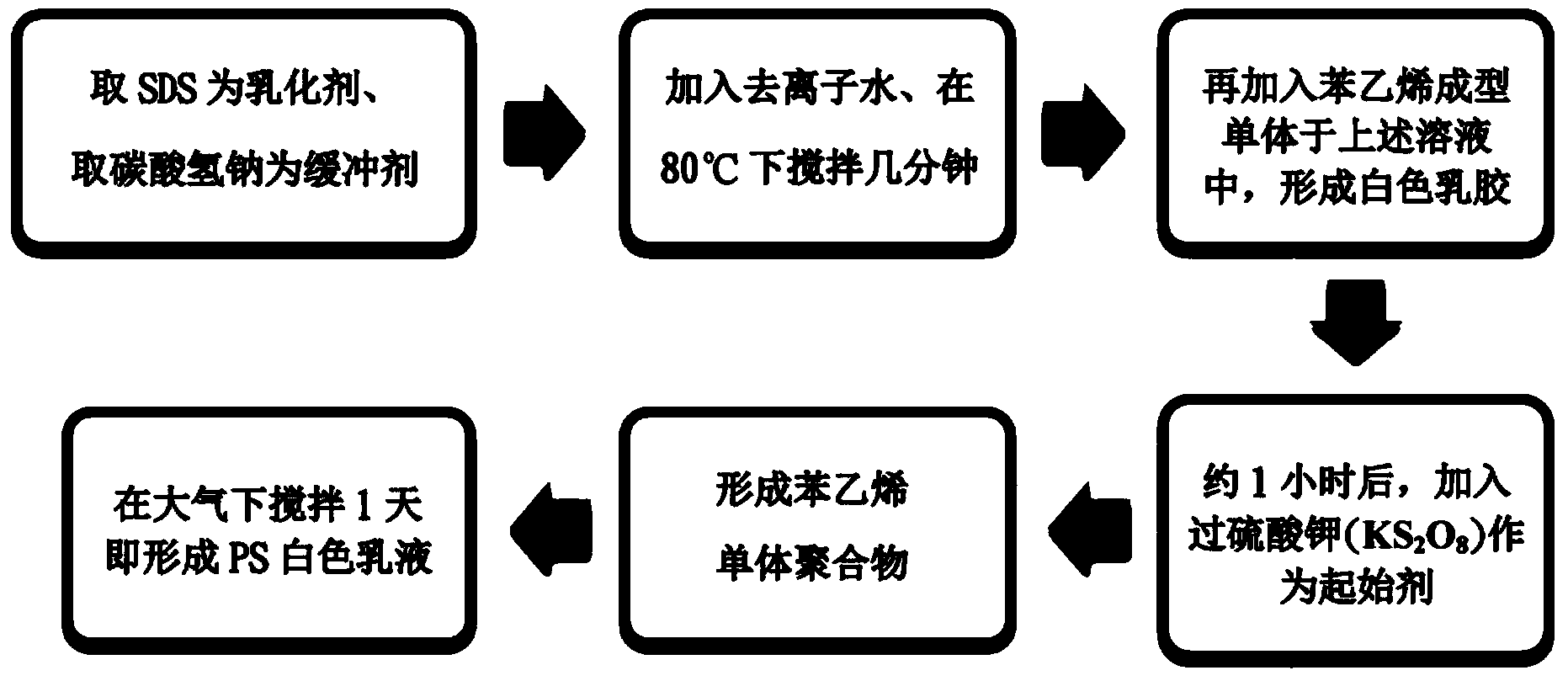

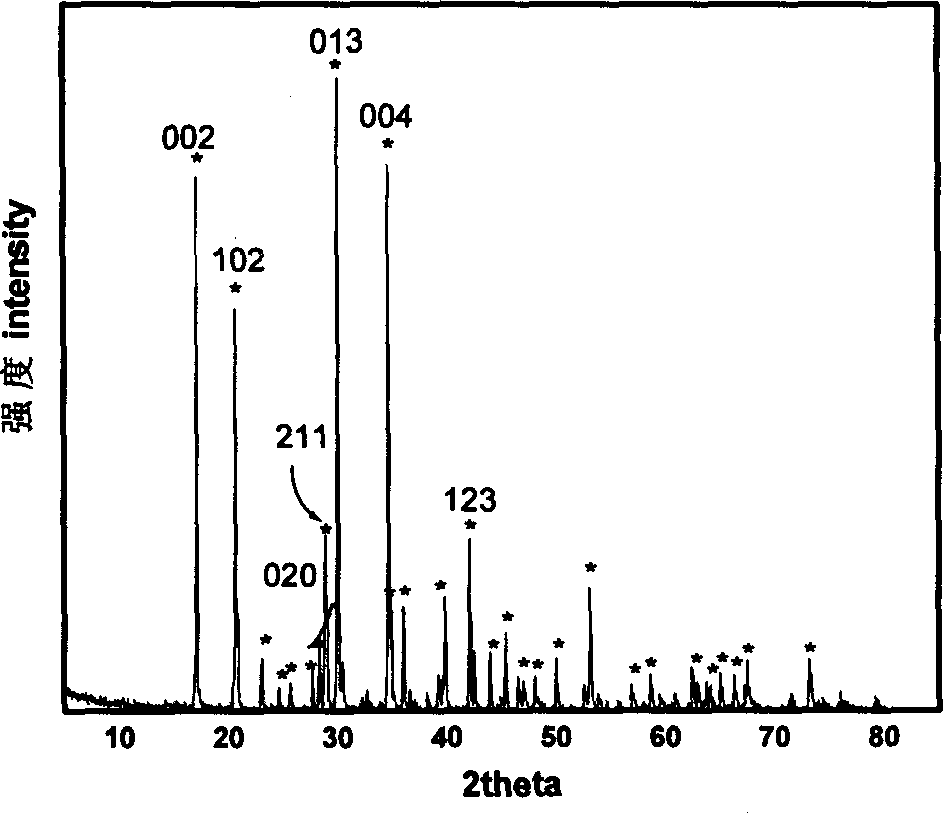

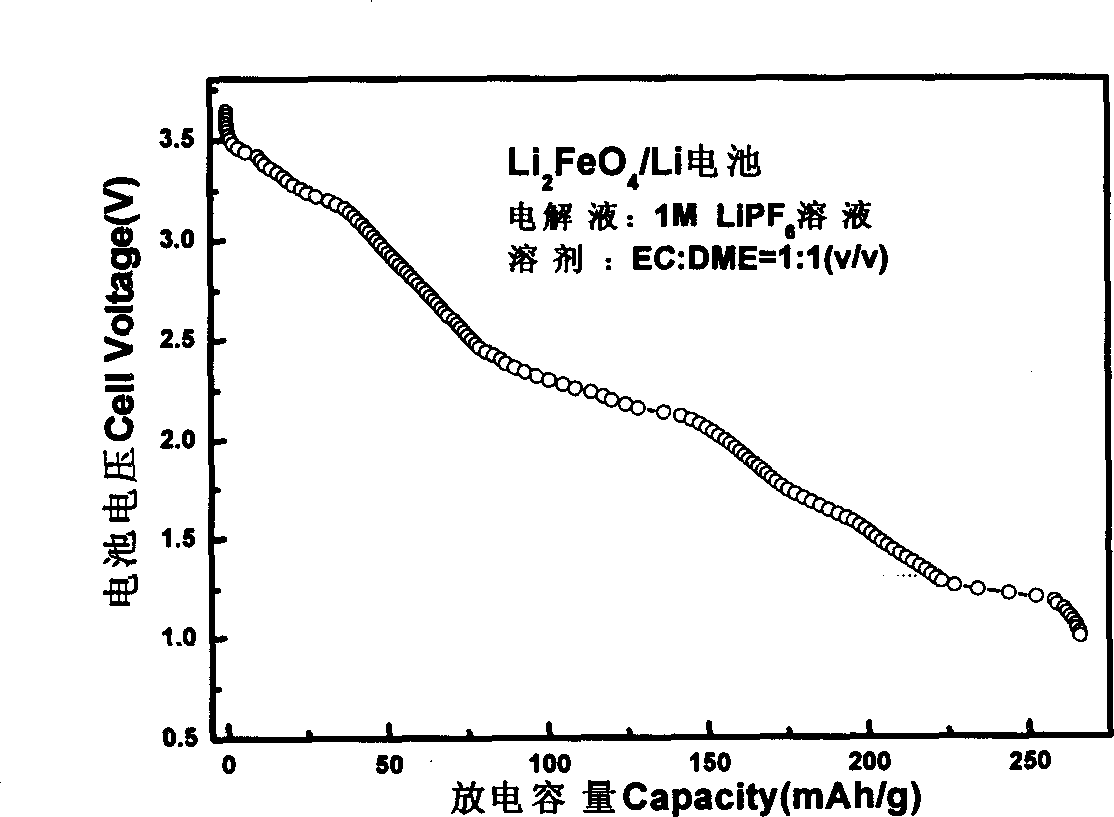

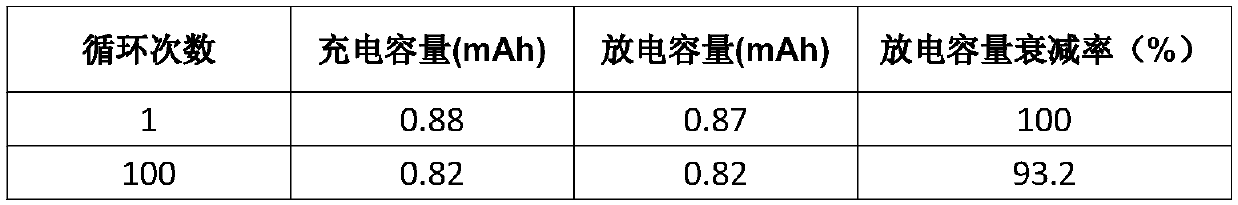

Preparation method and application of spherical lithium ferrite material/carbon cathode material composite

The invention provides a preparation method and application of spherical lithium ferrite material / carbon cathode material composite. Spherical lithium ferrite phosphate / carbon (LFP / C) cathode material or lithium ferrite phosphorous oxide / carbon (LFPO / C) cathode material is synthesized through spray drying, and particularly the prepared LFP / C cathode material or the LFPO / C cathode material has a 3D spherical structure with many pores, so the electrical conductivity of active material of the lithium ferrite material can be greatly improved. Except the problem that the lithium ferrite material is low in electrical conductivity, the prepared lithium ferrite material / carbon cathode material has high power characteristic and stable cycle life of charging / discharging, so the spherical lithium ferrite material / carbon cathode material composite can be used for the cathode of a lithium-Ion Secondary battery.

Owner:FORMOSA BIOMEDICAL TECH CORP

Chemical compound batteries with embedded lithium ferrate-lithium

InactiveCN1416190AHigh purityIncrease specific energyCell electrodesFinal product manufactureLithium oxideNitrate

The invention relates to the method for manufacturing the secondary battery, especially, for composing lithium ferrate used as the material of positive electrode in the lithium ion battery. The admixture of the lithium oxide and the oxide of iron or nitrate being as the initiator are put in the ball mill throug hthe mechanical ball milling so as to obtain the lithium ferrate with purity 85%-99%, the grain size 30 nano to 100 micros. The mechanical ball milling condition is as following: the mass ratio between the balls and the materials 1.5:1-2.5:1, the rotation speed 200-400 rmp / min, the time 10-50 hours, then keeping the constant temp 5-20 hours in 400 deg.C-800 deg.C under oxygen atmosphere. The invention features simple technical procedures and equipment, the high purity.

Owner:NANKAI UNIV

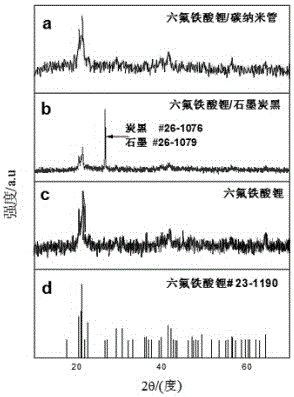

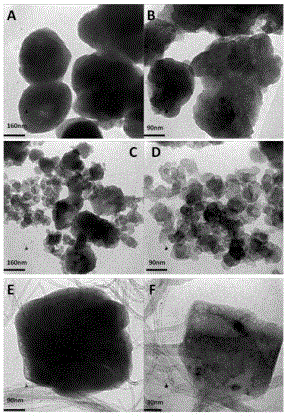

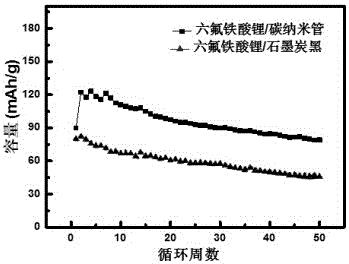

Method for preparing hexa-fluorine lithium ferrite and carbon nano-tube composite materials

The invention discloses a method for preparing a xa-fluorine lithium ferrite and carbon nano-tube composite material. The method includes dissolving 20 grams of iron nitrate nonahydrate in 200 milliliters of deionized water, adding 5 milligrams of cetyl trimethyl ammonium bromide into the deionized water and continuously stirring the cetyl trimethyl ammonium bromide in the deionized water for 3 hours to obtain saturated solution; adding 0.1 gram of carbon nano-tubes into 20 milliliters of 1 mole / liter sodium hydroxide solution, stirring the carbon nano-tubes in the sodium hydroxide solution, cleaning the carbon-tubes by the aid of deionized water until the carbon nano-tubes is neutral and carrying out centrifugal suction filtration on the carbon nano-tubes; adding the treated carbon nano-tubes into 20 milliliters of 40% hydrofluoric acid solution, stirring the carbon nano-tubes in the hydrofluoric acid solution to obtain uniformly dispersed carbon nano-tube-hydrofluoric acid solution; adding the obtained carbon nano-tube-hydrofluoric acid solution and 5.6 grams of lithium carbonate powder into iron nitrate-cetyl trimethyl ammonium bromide solution and continuously stirring the obtained carbon nano-tube-hydrofluoric acid solution and the lithium carbonate powder in the iron nitrate-cetyl trimethyl ammonium bromide solution to obtain black precipitates; cleaning and centrifuging the obtained black precipitates by the aid of isopropyl alcohol by four times and then drying the black precipitates in an air blast drying oven at the temperature of 80 DEG C for 10 hours to obtain the hexa-fluorine lithium ferrite and carbon nano-tube composite material. The method has the advantage that the hexa-fluorine lithium ferrite and carbon nano-tube composite material is excellent in electric conductivity and can be used as an anode material for lithium ion batteries.

Owner:CHINA UNIV OF MINING & TECH

Lithium iron oxide material and preparation method thereof

InactiveCN110498449AImprove electrical performanceImprove playbackCell electrodesIron compoundsCarbon coatingElectrical battery

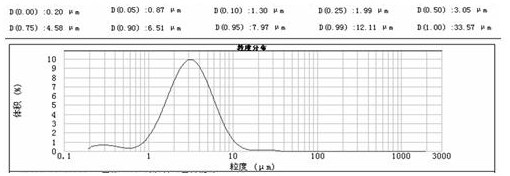

The invention belongs to the field of electrochemistry, and discloses a lithium iron oxide material, and a preparation method thereof. The preparation method comprises following steps: 1, an iron source, a lithium source, a carbon source, and deionized water are mixed to obtain a mixed solution; 2, the mixed solution is subjected to grinding to control the particle size of solid particles in the mixed solution to be 0.4<mu>m or lower; 3, after grinding, the mixed solution is subjected to spray drying to obtain a lithium iron oxide precursor; and 4, the lithium iron oxide precursor is subjectedto sintering, and crushing so as to obtain the lithium iron oxide material. The using amount of the carbon source is controlled so that the carbon coating layer content in the lithium iron oxide material accounts for 0.5 to 15wt%; the molar ratio of the lithium in the lithium source to the iron in the iron source is controlled to be (5-25) : 1. The prepared lithium iron oxide material possesses excellent irreversibility and excellent capacity performance, so that battery energy density can be increased.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

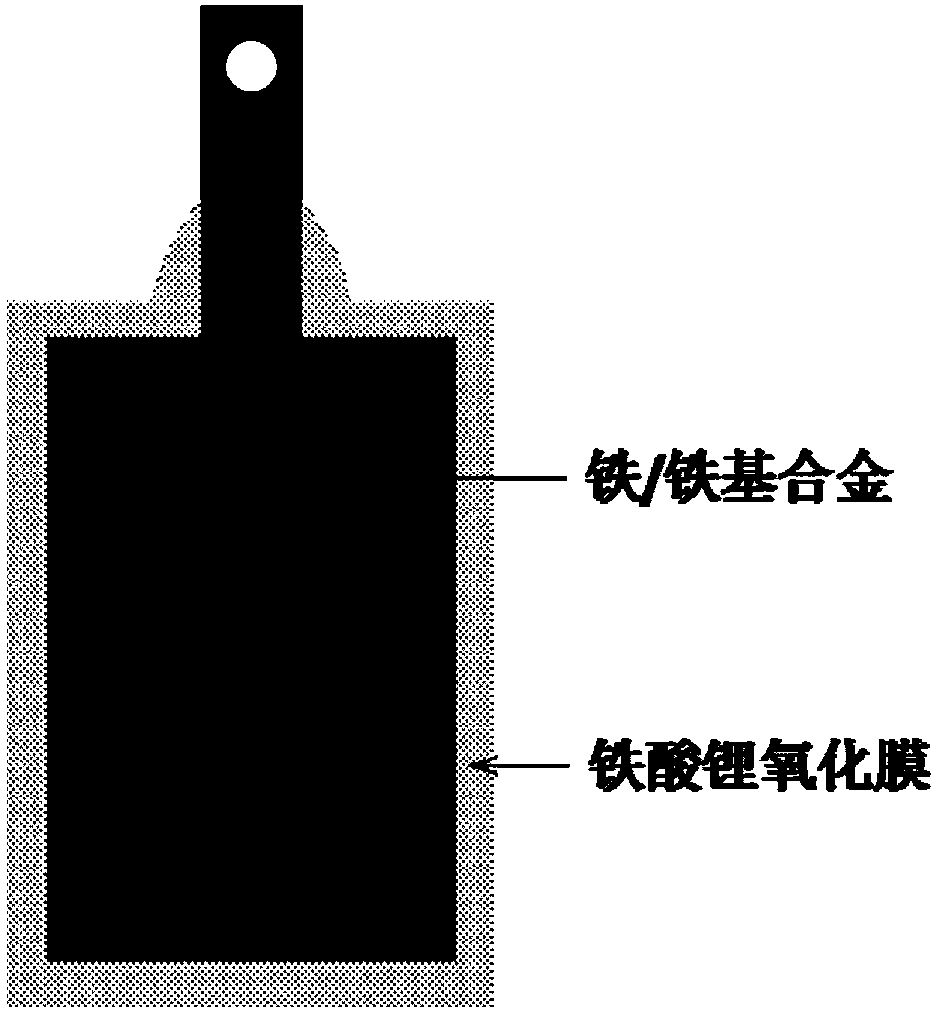

Iron-based inert anode with lithium ferrite protective film and preparation method and application of iron-based inert anode

ActiveCN107740143AImprove electronic conductivityImprove thermal shock resistanceAnodisationElectrodesElectrolysisElectrochemical anodization

The invention relates to an iron-based inert anode with a lithium ferrite protective film and a preparation method and application of the iron-based inert anode. The inner layer of the iron-based inert anode is pure iron or an iron-based alloy, the outer layer of the iron-based inert anode is a lithium ferrite oxide layer, and the pure iron or the iron-based alloy undergoes electrochemical anodicoxidation in lithium-containing molten carbonate to obtain the iron-based inert anode. The iron-based inert anode has good electronic conductivity, excellent oxygen evolution catalytic performance, high stability and good thermal shock resistance; and the iron-based inert anode is low in cost and easy to process and can be used as a stable oxygen evolution inert anode in a high-temperature moltensalt electrolysis system taking carbonate as a main component.

Owner:WUHAN UNIV

Preparation method of lithium iron phosphate coated with lithium iron oxide

ActiveCN109950514APlay conductivityPlay the role of conductivityCell electrodesSecondary cellsLithium hydroxidePhosphate

The invention discloses a preparation method of lithium iron phosphate coated with lithium ferrite. According to the method, the ferrous sulfate solution, the lithium hydroxide solution, the ammoniumdihydrogen phosphate solution and the titanyl sulfate solution are added into a high-pressure reaction kettle together, and then the hydrothermal reaction is carried out to obtain the slurry. A dispersing agent is added into the slurry, and a ferric chloride solution, an ammonium bicarbonate solution and a lithium hydroxide solution are merged and added into a base solution in a parallel flow manner. After the adding of above materials, the carbon dioxide is introduced and then the filtering is carried out. Obtained filter residues are heated and washed with pure water. A precursor is obtainedthrough drying and screening the residues and removing iron in the residues. The obtained precursor is calcined in an inert atmosphere, and the calcined material is subjected to smashing, screening and iron removing through the air flow to obtain lithium iron phosphate coated with lithium iron oxide. The method is simple and low in cost. The amorphous titanium-doped lithium iron phosphate is prepared through the hydrothermal method. After that, lithium iron phosphate coated with lithium iron oxide is obtained through precipitation. Finally, the lithium iron phosphate coated with lithium ironoxide is obtained through calcination. The obtained lithium iron phosphate is high in capacity and high in compaction density.

Owner:SICHUAN LOMON PHOSPHORUS CHEM

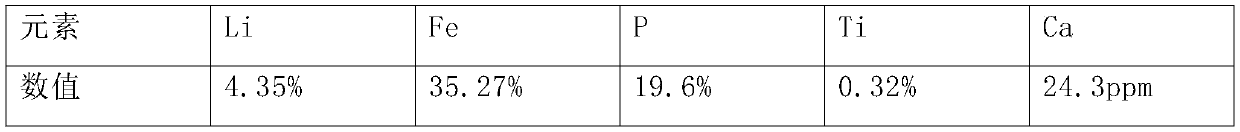

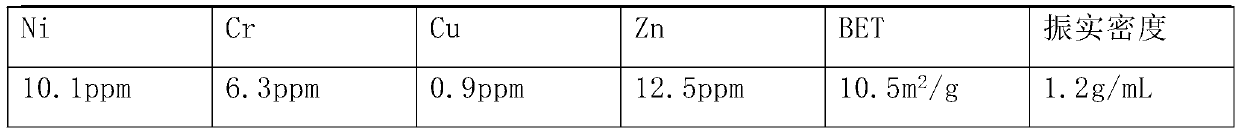

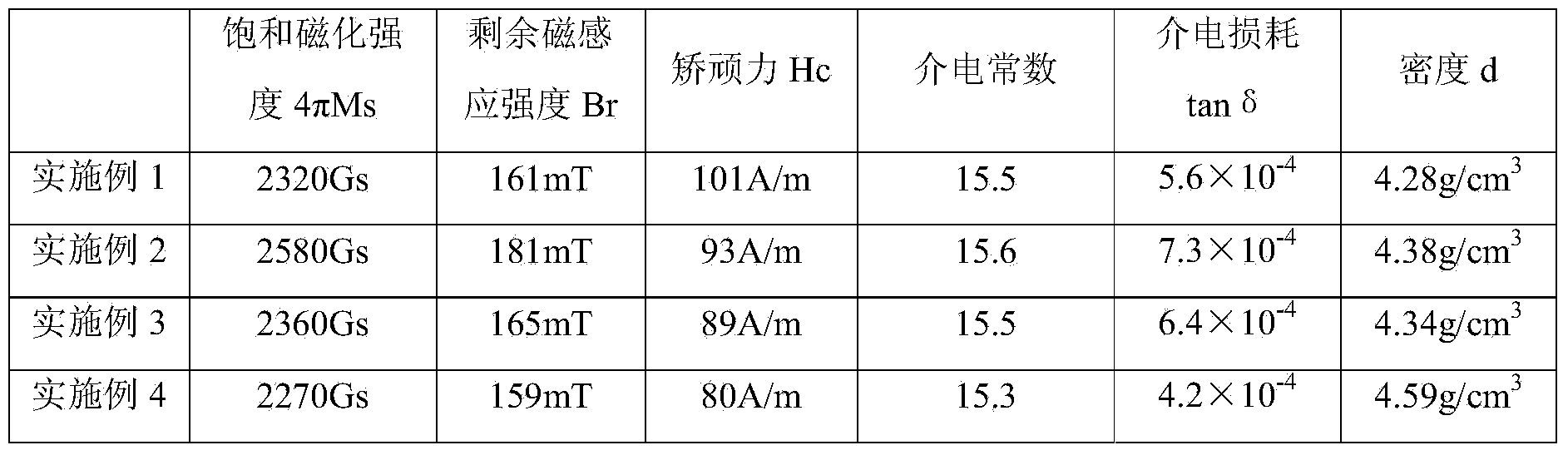

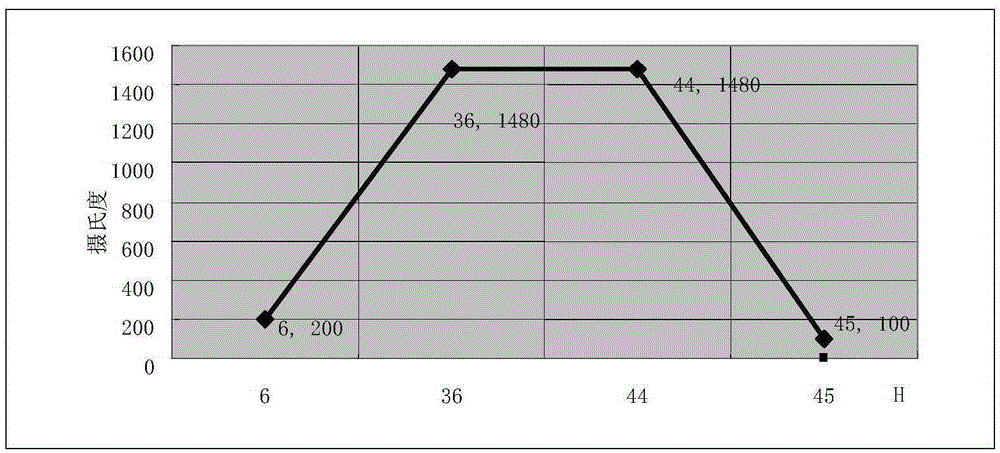

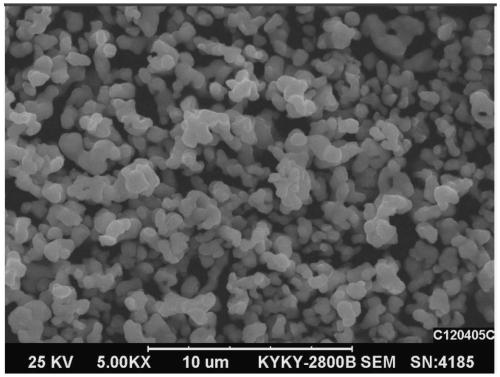

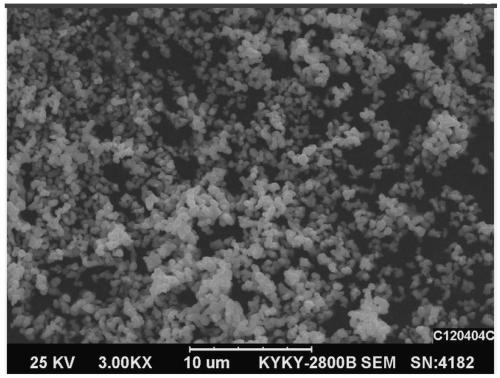

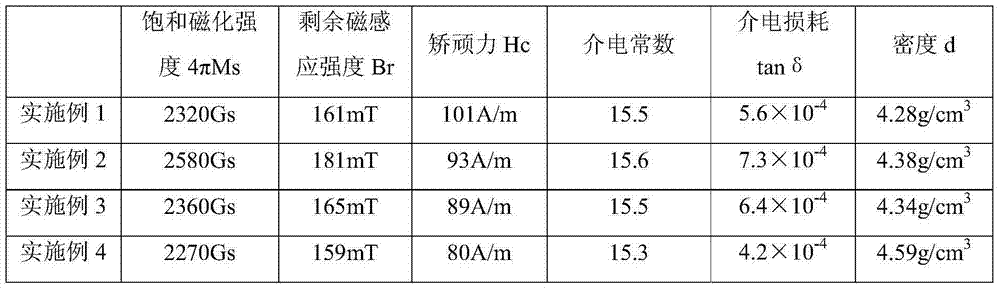

High-performance high-compaction lithium ferrite material for phase shifter, and preparation method thereof

The invention discloses a high-performance high-compaction lithium ferrite material for a phase shifter, and a preparation method thereof, belonging to the technical field of an electronic material. The lithium ferrite material comprises main components and an additive, wherein the main components include the following substances in parts by weight: 65-75 parts of Fe2O3, 9-12 parts of Li2CO3, 8-14 parts of TiO2, 3-4 parts of ZnO, 1-6 parts of MnCO3 and 0.1-1 part of Bi2O3; and the additive is 0.2-3wt% of the main components. The preparation method comprises the following steps: ball-milling and grinding all the components, drying and calcining, performing secondary ball-milling and grinding the calcinated components, and then granulating through a spray granulator; performing compression moulding to the obtained granules through a dry powder press, and then pressing into blanks through an isostatic press and finally putting the blanks into a furnace for sintering. The lithium ferrite material for the phase shifter, prepared by adopting the method has excellent performances of low coercivity, low dielectric loss, high compaction and the like.

Owner:南京国睿微波器件有限公司

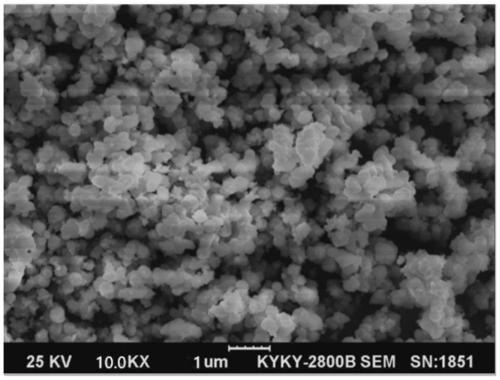

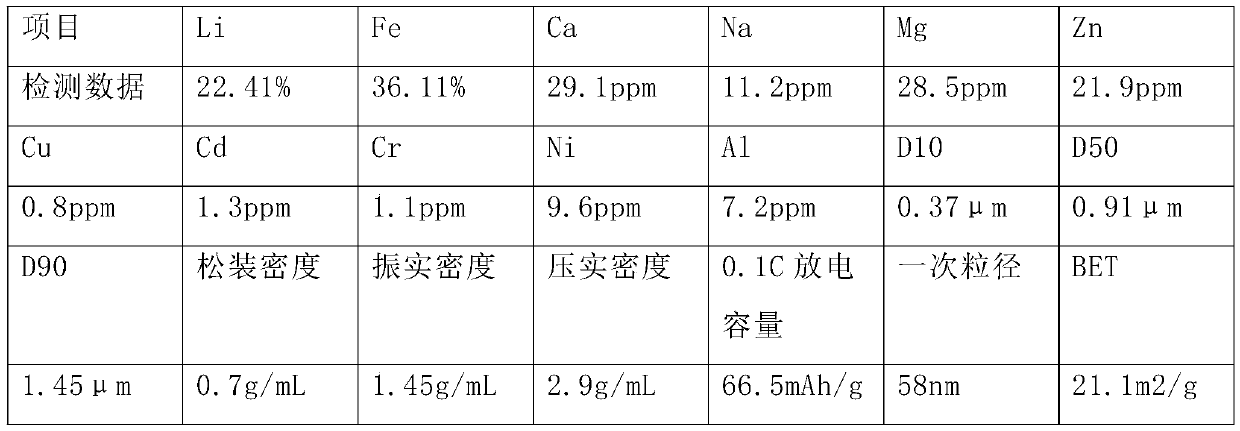

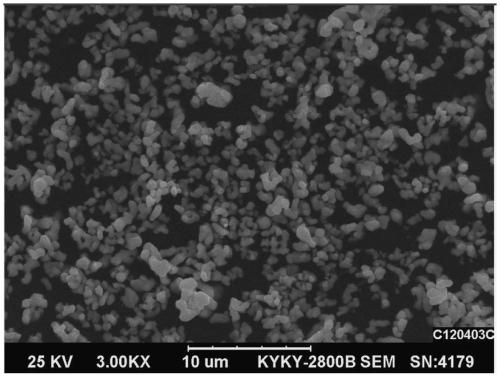

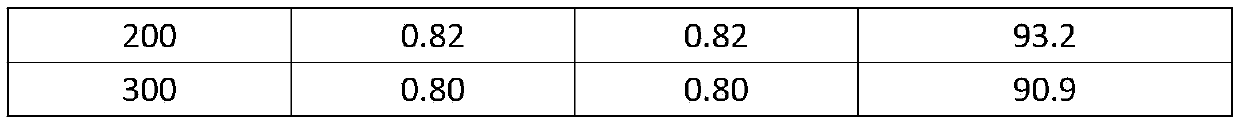

Preparation method of nano lithium ferrite

The invention discloses a preparation method of nano lithium ferrite. The preparation method comprises: preparing a ferrous solution and a lithium bicarbonate solution; adding a base solution into a reaction kettle; adding the ferrous solution, the lithium bicarbonate solution and an acid-base regulator into the reaction kettle, and reacting to obtain slurry; transferring the slurry into a high-pressure reaction kettle, stirring reaction for 3-5 min at the temperature of 220-250 DEG C under pressure of 0.6-0.9 MPa, after cooling and pressure relief, taking out the material, filtering, and washing to obtain a precipitate; putting the precipitate into a roller bed furnace, calcining for 5-8 h at the temperature of 400-500 DEG C, introducing air in the calcining process, and maintaining the flow velocity of gas in the calcining furnace at 2-3 m / S, and then cooling the calcined material, carrying out air flow crushing, carrying out grading by virtue of a grading wheel, and screening to remove iron, so as to obtain the nano lithium ferrite. The preparation method is simple in process and low in cost, and the obtained nano lithium ferrite is large in specific surface area and uniform inparticle size distribution.

Owner:王柯娜

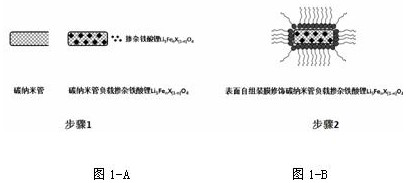

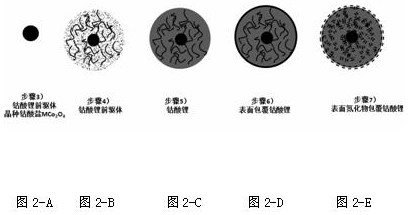

Preparation method and application of lithium cobalt oxide with pre-lithiated core-shell structure

InactiveCN114084913APrevent hydrolysis reactionImprove first-time efficiencyNitrogen compoundsCell electrodesModified carbonTitanium nitride

The invention provides a preparation method and application of lithium cobalt oxide with a pre-lithiated core-shell structure. The method comprises the following steps: (1) preparing carbon nanotube loaded doped lithium ferrite Li5FenX(1-n)O4; (2) preparing surface self-assembled film modified carbon nanotube loaded doped lithium ferrite Li5FenX(1-n)O4; (3) preparing a lithium cobalt oxide precursor crystal seed cobaltate MCo2O4; (4) preparing a lithium cobalt oxide precursor; (5) preparing lithium cobalt oxide; (6) preparing surface coated lithium cobalt oxide; and (7) preparing surface nitride coated lithium cobalt oxide. According to the lithium cobalt oxide with the pre-lithiated core-shell structure, the cobaltate is adopted as a seed crystal, and the lithium cobalt oxide precursor is prepared and generated in an aqueous solution in a carbon nanotube loaded pre-lithiated positive electrode material doped lithium ferrite self-assembly mode; and a titanium-containing oxide coating layer is prepared, and nitridation reaction is carried out to generate coated lithium cobalt oxide containing titanium nitride and oxide.

Owner:TIANJIN B&M SCI & TECH

All-solid-state film battery with high energy density and preparation method thereof

ActiveCN106099201AEasy to controlImprove electrochemical performanceFinal product manufactureCell electrodesComposite filmHigh energy

The invention discloses an all-solid-state film battery with high energy density. The all-solid-state film battery comprises a substrate material layer, a metal current collecting layer I, an anode active material layer, an electrolyte film layer, a cathode active material layer and a metal current collecting layer II, wherein the anode active material layer and the cathode active material layer are composed of a plurality of layers of composite films respectively, and are alternately grown through the vacuum deposition technology; the anode active material is formed by mixing lithium titanate with lithium ferrite; the cathode active material is formed by mixing lithium cobaltate with lithium manganate. The invention also discloses a preparation method of the all-solid-state film battery. The prepared all-solid-state film battery is high in energy density, good in stability and long in service life.

Owner:江华邦能电子科技有限公司

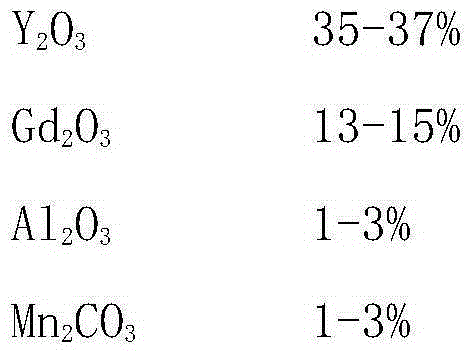

Garnet ferrite material applied to high-power phase shifter and preparing method thereof

The invention relates to a garnet ferrite material applied to a high-power phase shifter and a preparing method thereof. The garnet ferrite material is prepared from, by weight, 35-37% of Y2O3, 13-15% of Gd2O3, 1-3% of Al2O3, 1-3% of Mn2CO3 and 45-47% of Fe2O3; the method comprises the steps of weighing and mixing according to the weight ratio, primary ball milling, drying, screening, presintering, secondary ball milling, drying, pelletizing, pressing forming and sintering. Compared with a lithium ferrite material, the garnet ferrite material prepared by utilizing the method has the advantages of being high in density, small in porosity and small in effective line width and the like.

Owner:南京国睿微波器件有限公司

Preparation method of phosphorus-doped lithium nickel cobalt ferrite

ActiveCN111533184AHigh reactivityImprove compactnessCell electrodesLi-accumulatorsAir atmosphereO-Phosphoric Acid

The invention discloses a preparation method of phosphorus-doped lithium nickel cobalt ferrite. The preparation method comprises the steps: adding a nickel-cobalt solution into an ammonium bicarbonatesolution, reacting, filtering and washing to obtain nickel-cobalt carbonate precipitate; adding the nickel-cobalt carbonate precipitate into a phosphoric acid solution, and stirring for reaction to obtain a phosphate radical doped nickel-cobalt precipitate; adding the phosphate radical doped nickel-cobalt precipitate into a polyethylene glycol solution and a lithium bicarbonate solution, stirring, slurrying, carrying out spray drying, and carrying out primary calcination to obtain a primary calcined material; adding ferrous salt and lithium salt into the primary calcined material, then addingwater, adding an ammonium carbonate solution and an acid solution after grinding and levigating are conducted, filtering, washing and drying, and obtaining a reaction material; and carrying out high-temperature calcination on the reaction material in an air atmosphere to obtain a secondary calcined material, carrying out jet milling on the secondary calcined material, screening to remove iron, and carrying out vacuum packaging to obtain the phosphorus-doped lithium nickel cobalt ferrite. The conductivity can be improved through phosphorus-doped lithium nickel cobalt oxide so that the structure stability is better, and the product capacity and the cycle performance are excellent.

Owner:蒋达金

Preparation method of lithium ferrite

ActiveCN112117433AThe manufacturing method steps are simpleSmall particle sizeElectrode thermal treatmentSecondary cellsFerric hydroxideOrganic acid

The invention belongs to the technical field of lithium supplementing materials of lithium ion batteries, and particularly relates to a preparation method of lithium ferrite. By adopting a solvent method, an iron source, a lithium source and organic acid are mixed in a water-containing solvent to obtain ferric hydroxide colloid with smaller particle size. Meanwhile, the organic acid reacts with alithium source to generate a lithium salt, and the lithium salt and the ferric hydroxide colloid can be attached to the surface of the ferric hydroxide colloid after being heated to form a precursor solution with higher activity. And after the obtained precursor solution is dried, lithium ferrite with relatively high purity can be obtained only by once sintering, so the problems of repeated sintering, insufficient sintering reaction, long sintering time and high impurity content of a conventional solid-phase method are solved.

Owner:SHENZHEN DYNANONIC INNOVAZONE NEW ENERGY TECH CO LTD +2

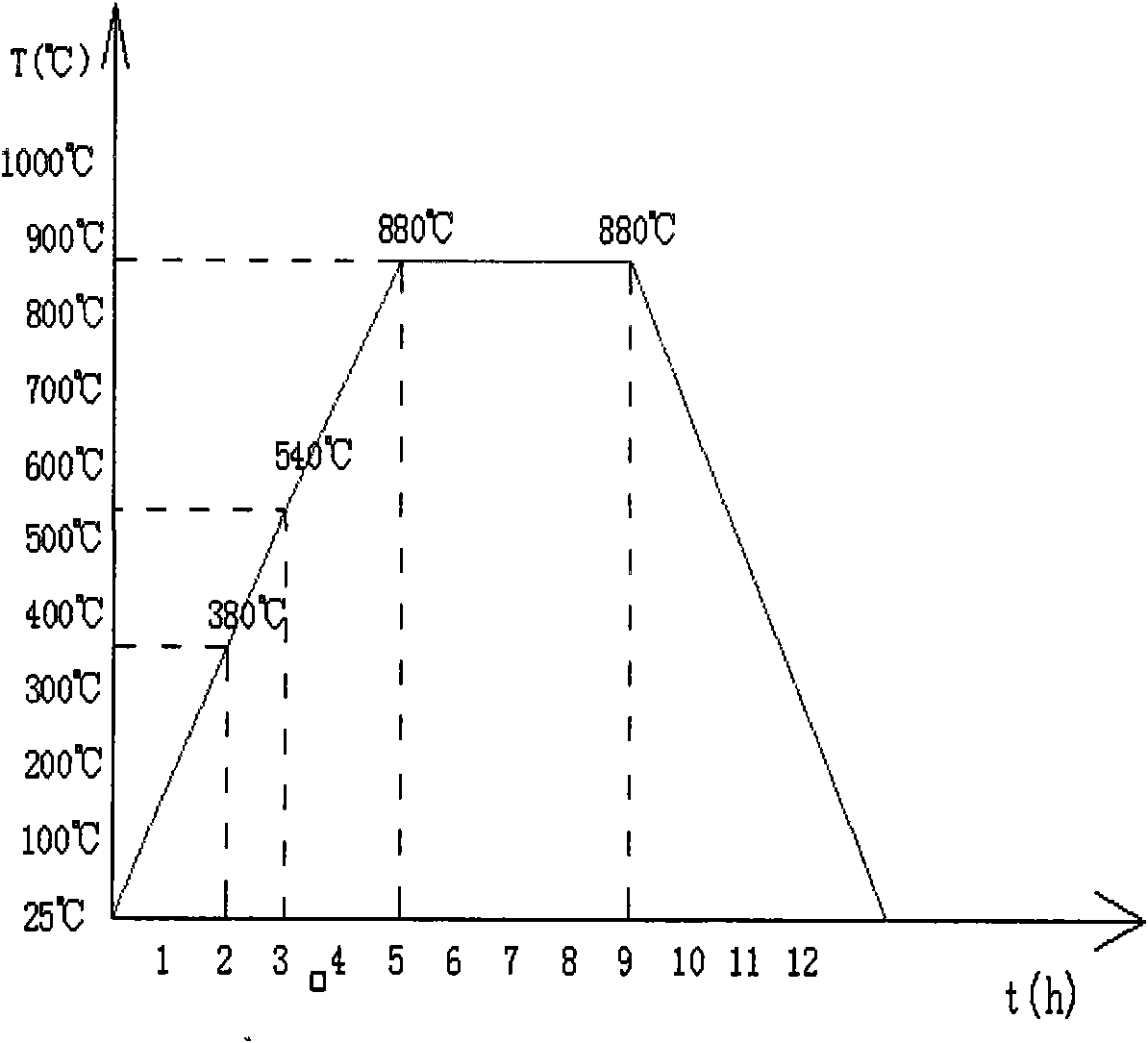

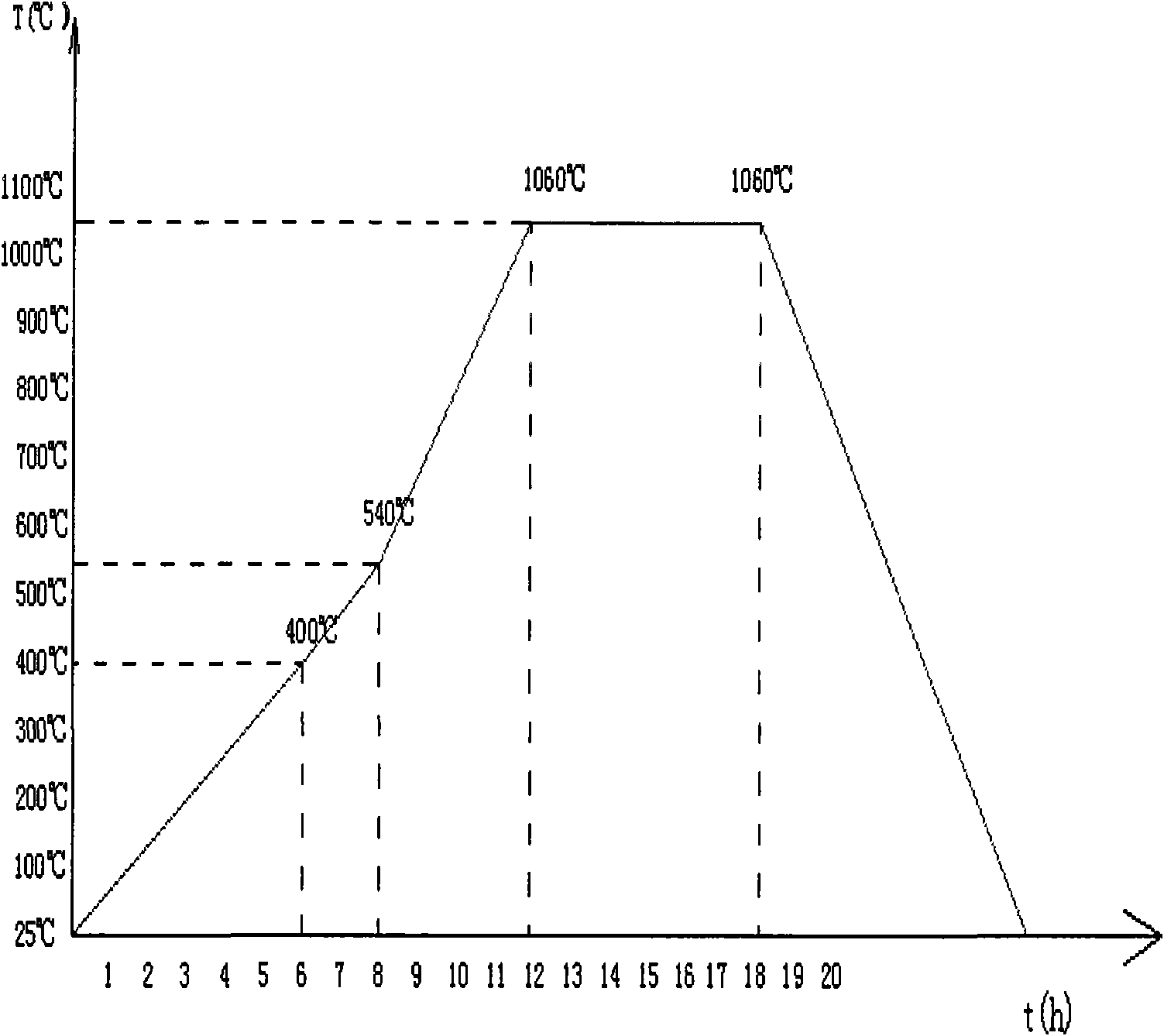

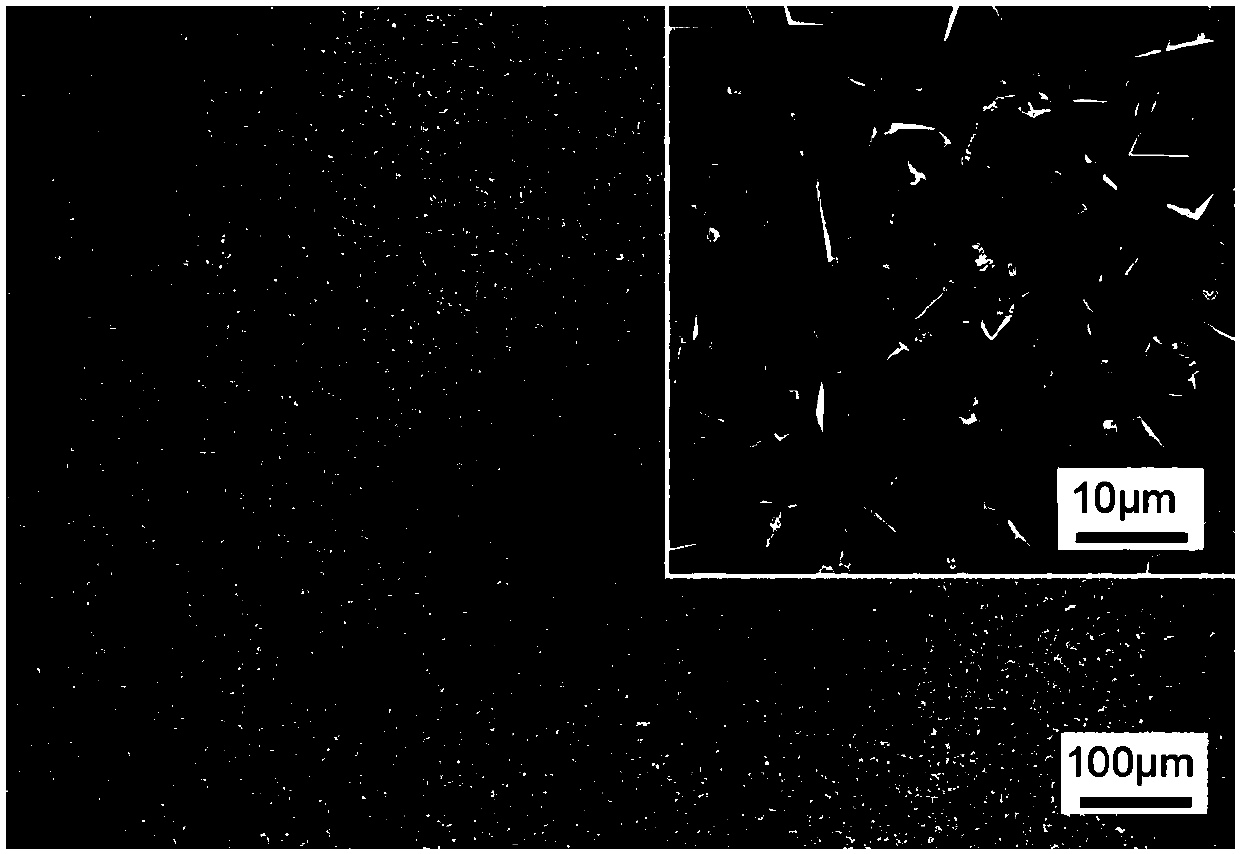

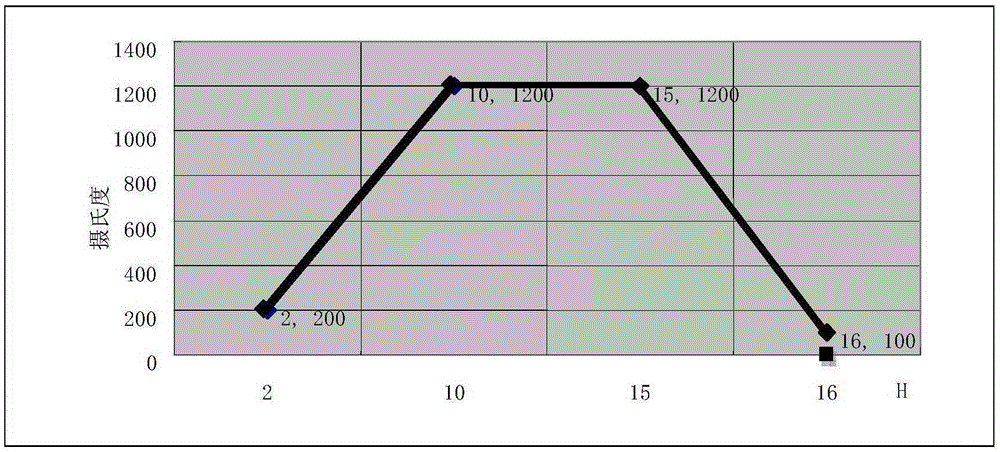

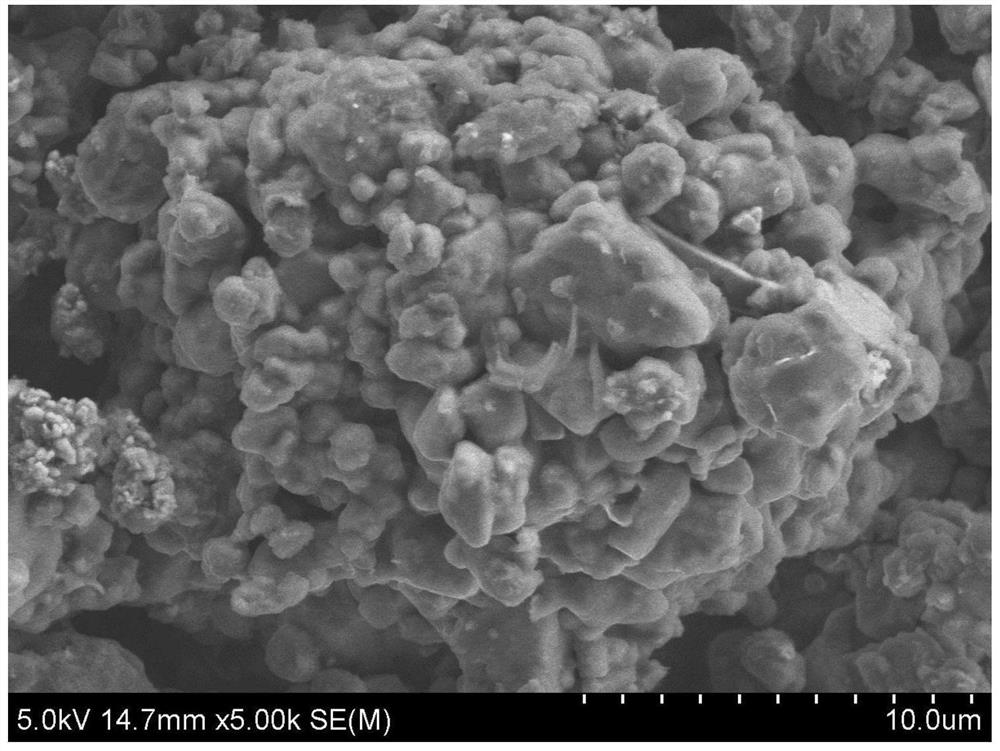

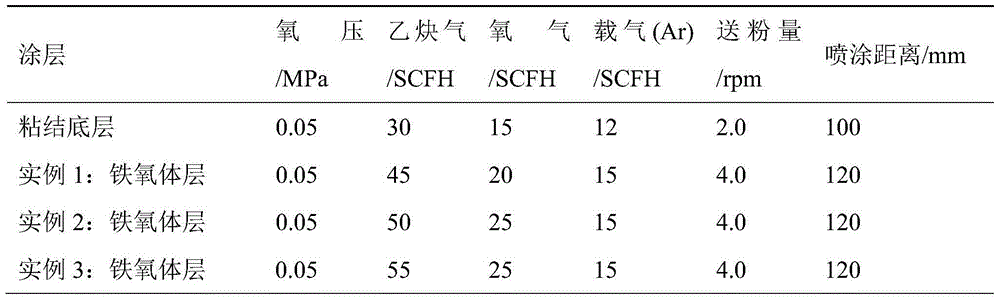

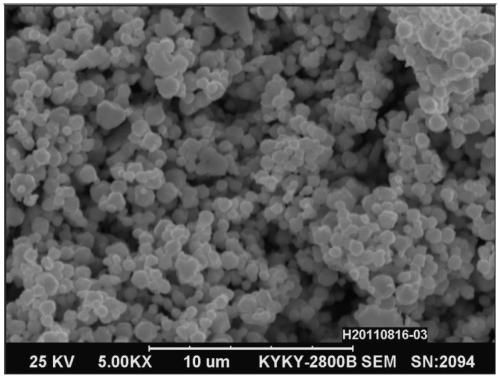

Method for preparing lithium ferrite thermal spraying powder used for conductive coating

The invention provides a method for preparing lithium ferrite thermal spraying powder used for conductive coating. The method includes the following steps: (1) mixing the materials and jolt-ramming; (2) pelletizing and drying; (3) calcinating and crushing; (4) agglomerating; (5) carrying out spray granulation; (6) carrying out heat treatment. The lithium ferrite thermal spraying powder prepared by using the method provided by the invention is high in crystallinity, good in sphericity retaining capability and fluidity; the lithium ferrite coating prepared by using the thermal spraying powder is good in conductivity, bonding strength and corrosion resistance; the process and device of the invention are simple and controllable, convenient to operate, low in cost, short in production period, and good in repeatability; the powder yield is as high as 75% or above; demands for scale production of thermal spraying powder used for Li0.5Fe2.5O4-x conductive coating are met.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +5

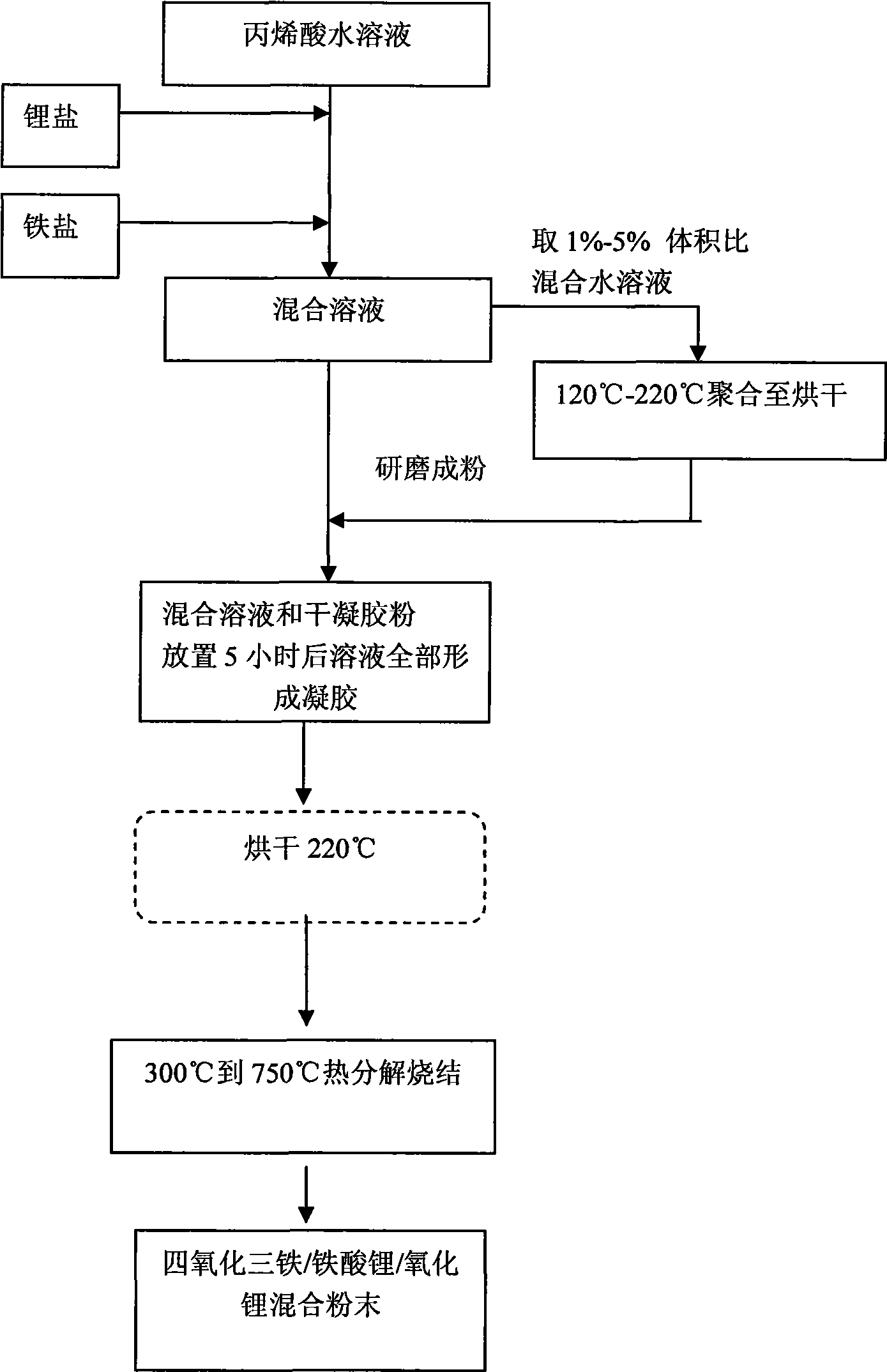

Lithium ion battery cathode material and preparation method

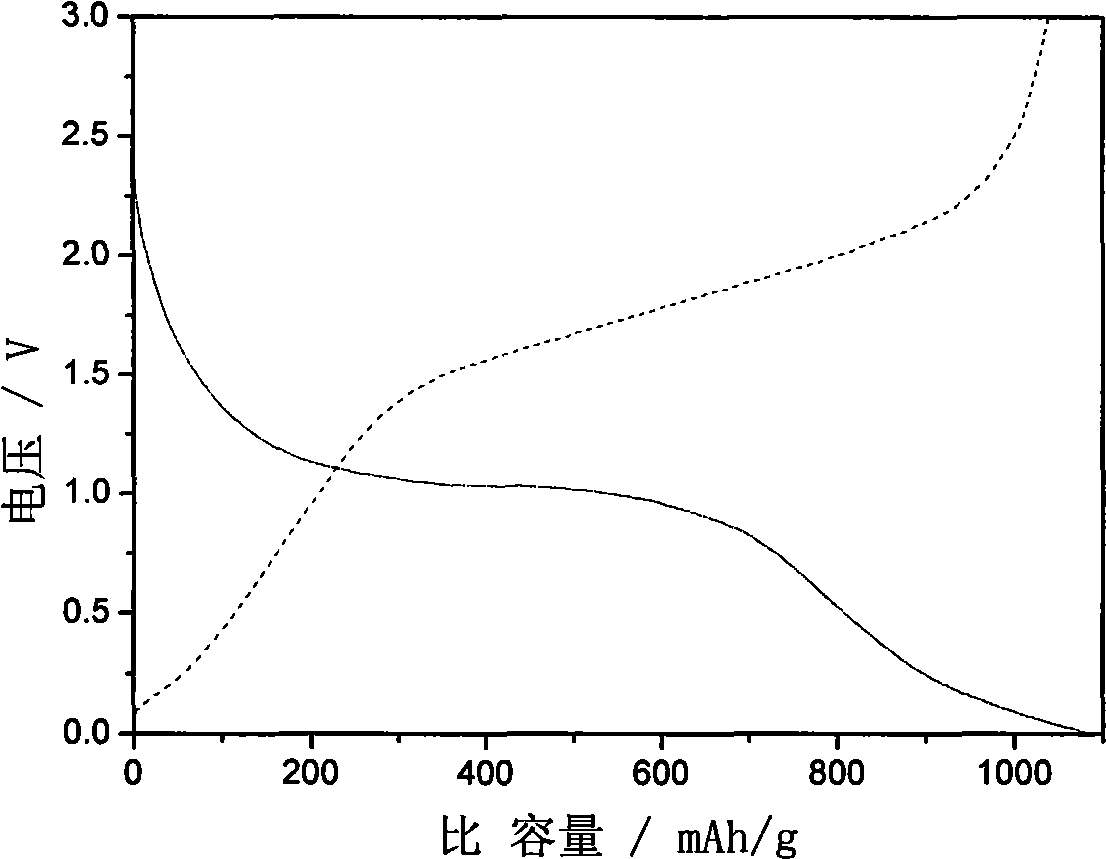

InactiveCN101533910AHigh specific capacityReduce the first irreversible capacity lossElectrode manufacturing processesLithium oxideRoom temperature

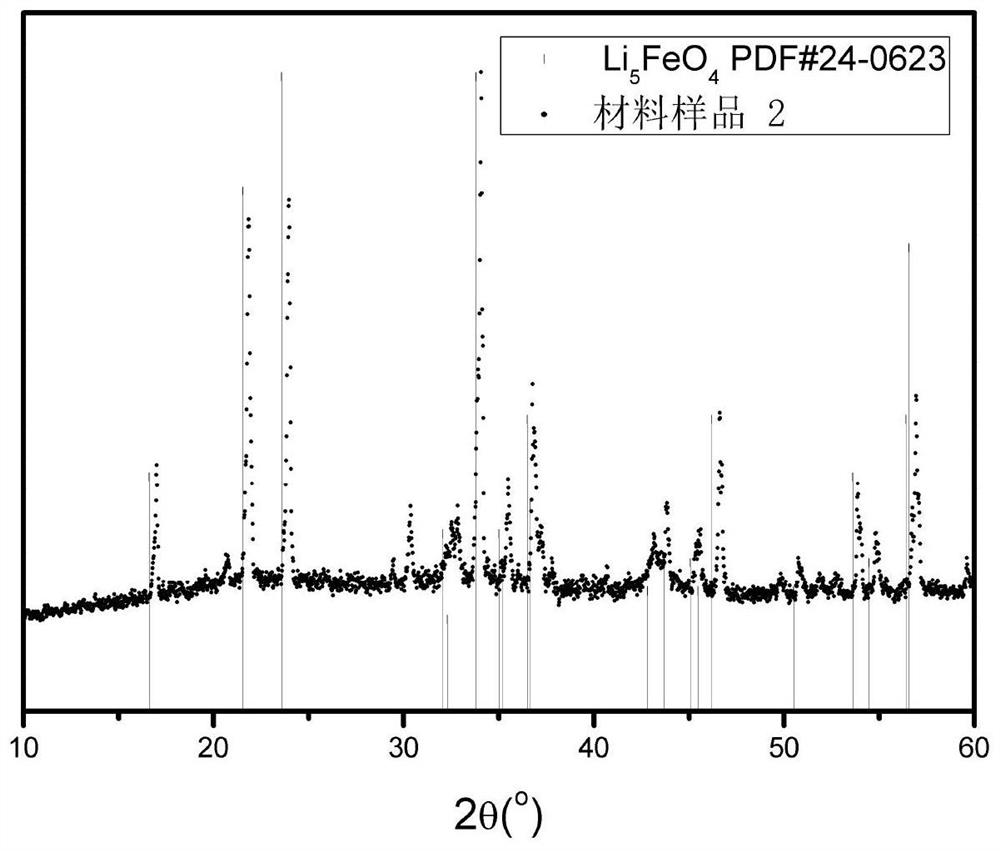

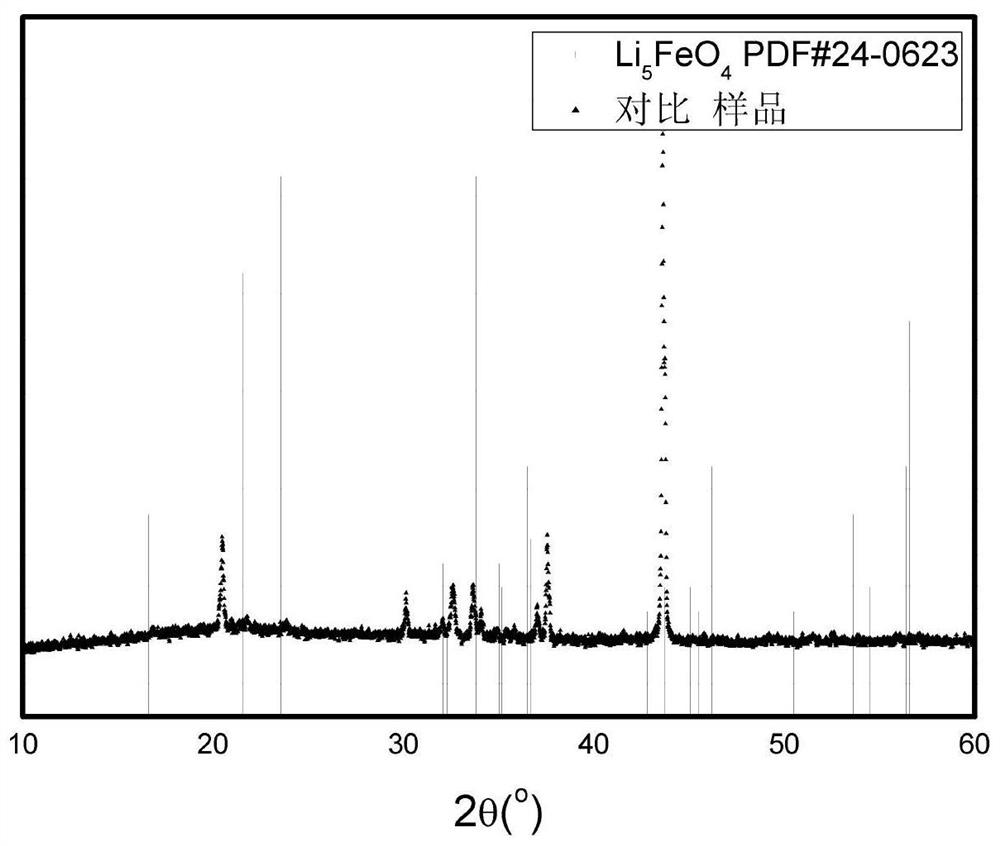

The invention relates to a lithium ion battery cathode material and a preparation method, and solves problem of further increasing integral capacity of battery. The lithium ion battery cathode material of the invention is ferroferric oxide / lithium ferrate / lithium oxide composite powder, which is prepared by adding prefabricated xerogel powder into solution to initiate polymer monomer polymerization to obtain macromolecular gel, and carrying out thermal decomposition of the obtained gel to obtain the composite powder with uniformly distributed particle size and stable performance. The lithium ion battery cathode can be prepared from the composite powder or mixture of the composite powder and graphite. The invention has high specific capacity which is more than 1000mAh / g and is about three times of that of existing graphite cathode (theoretical capacity is 372mAh / g, and practical capacity is 340mAh / g), and simple method, is easy for large scale production, can form gel at room temperature, and can initiate polymerization without additional initiator, heat source and radiation source.

Owner:UNIV OF SCI & TECH OF CHINA +1

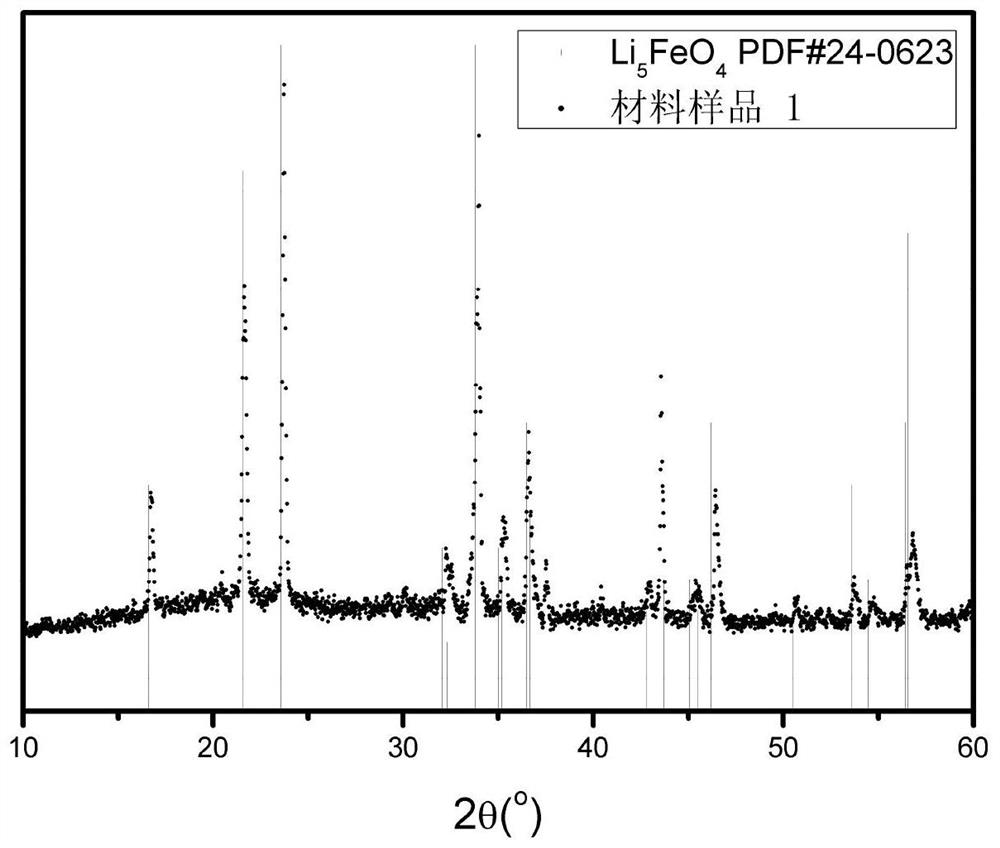

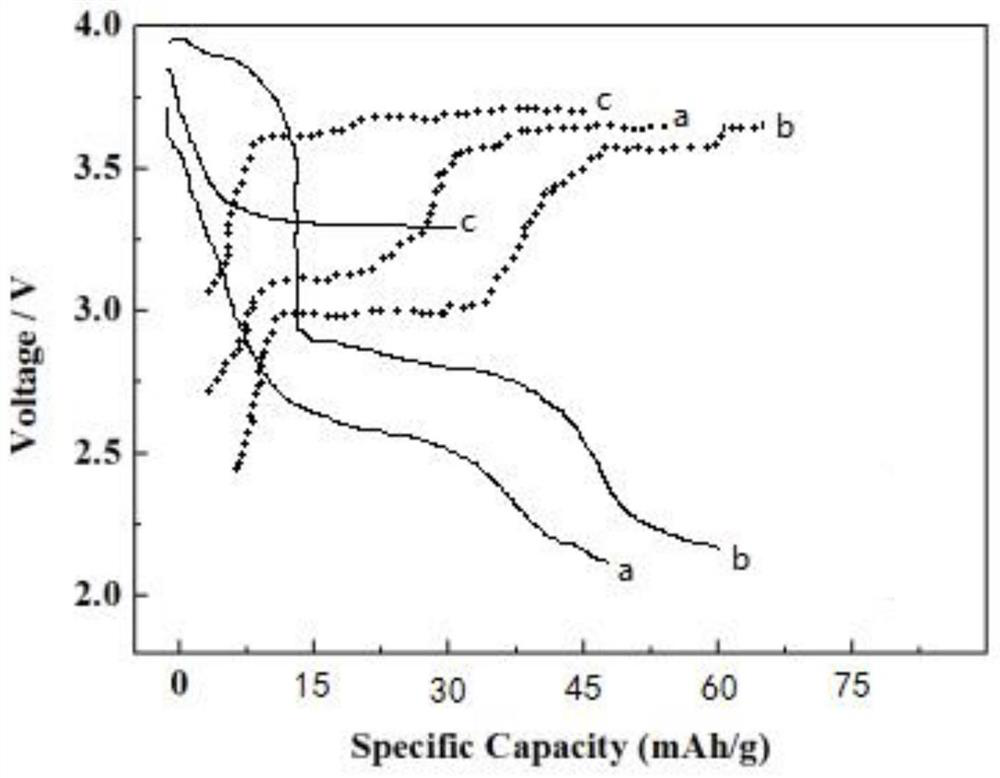

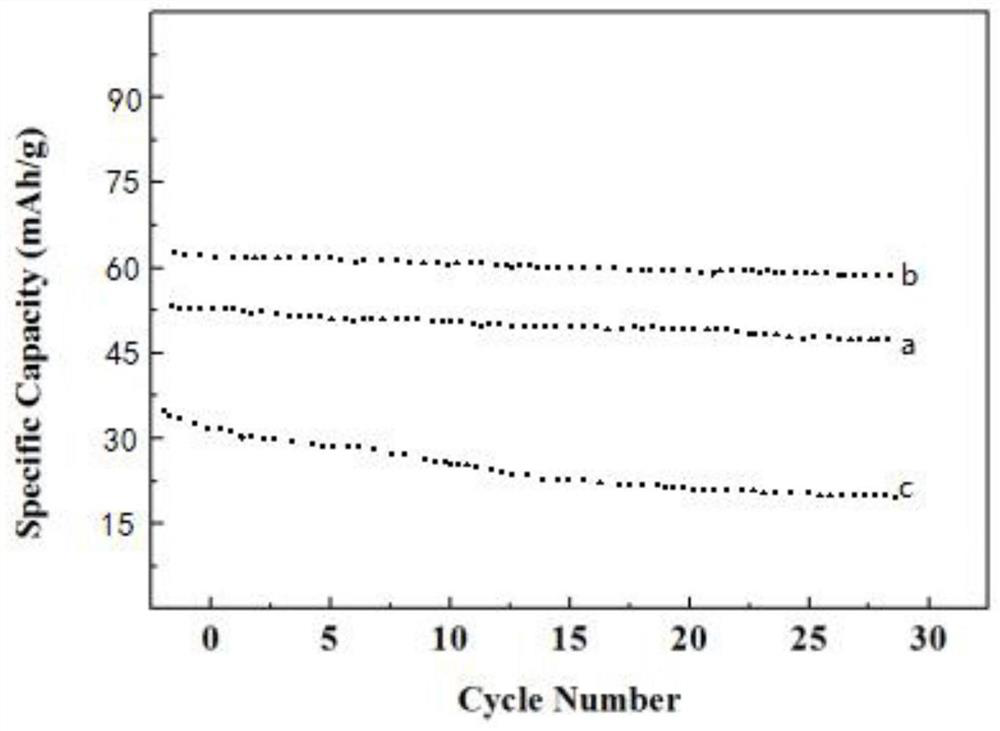

Modified lithium ferrite positive electrode material, preparation method thereof and positive plate

InactiveCN112186143AReduces electrode polarization effectsHigh specific capacitySecondary cellsPositive electrodesElectrical batteryManganese

The invention discloses a preparation method of a modified lithium ferrite positive electrode material. The method comprises the following steps: step 1, mixing LiOH.H2O, Fe (NO3)3.9 H2O and Mn(CH3COOH) 2.4H2O as raw materials, and drying the mixture in an environment of 100 DEG C for 8 hours to obtain a mixture A, wherein the molar ratio of Li to Fe to Mn in the raw materials of LiOH.H2O, Fe (NO3)3.9H2O and Mn(CH3COOH)2.4H2O is 5: 0.95: 0.05-5: 0.85: 0.15; 2, grinding the mixture A, and roasting the ground mixture A in an environment with the temperature of 450-490 DEG C for 8-12 hours to obtain a mixture B containing Li5FeO4; and 3, oxidizing and roasting the mixture B in an environment of 700-800 DEG C for 24 hours, standing at room temperature, cooling, grinding and sieving to obtain the Li5Fe1-xMnxO4 positive electrode material, wherein x is any one of 0.05, 0.10 and 0.15. According to the invention, the Li5FeO4 is doped with manganese metal according to a new lithium-iron-manganese ratio, so that the crystal form of the Li5FeO4 is more complete and orderly, and the resistance of charge transfer of the positive electrode material is reduced; and meanwhile, the electrode polarization effect of the lithium battery prepared from the positive electrode material under high current is reduced, so that the specific capacity of a battery is improved.

Owner:安徽德亚电池有限公司

Polymer-coated lithium battery positive electrode material and preparation method thereof

ActiveCN112820873AReduce energy consumptionReduced activityPositive electrodesSecondary cells servicing/maintenanceCarbon coatingOrganic solvent

The invention provides a polymer-coated lithium battery positive electrode material and a preparation method thereof. The preparation method comprises the following steps: a lithium battery positive electrode material and a polymer solution are uniformly mixed, and a solvent of the polymer solution is an organic solvent; heating and pressurizing reaction is carried out, so that the surface of the lithium battery positive electrode material is coated with the polymer, solid-liquid separation is carried out, an obtained solid is sintered in an inert atmosphere at 80-300 DEG C, and the polymer-coated lithium battery positive electrode material is obtained. According to the preparation method provided by the invention, the lithium battery positive electrode material is not in contact with water and carbon dioxide in the whole process, and a carbonization layer is not formed finally, so that compared with the existing high-temperature carbon coating, the preparation method provided by the invention is beneficial to ensuring the stability of lithium ferrite and other lithium battery positive electrode materials which are easy to react with water and carbon dioxide and are easy to reduce, and the energy consumption is lower.

Owner:SHENZHEN DYNANONIC INNOVAZONE NEW ENERGY TECH CO LTD +2

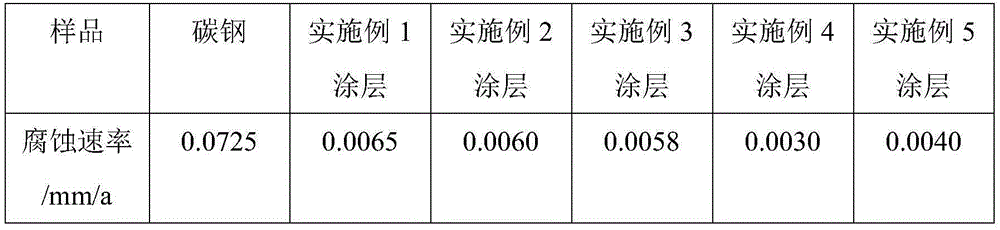

Method for preparing lithium ferrite anticorrosive coatings by flame spraying

ActiveCN103981477AHigh bonding strengthAccelerated corrosionMolten spray coatingConductive coatingOxygen

The invention relates to a method for preparing lithium ferrite anticorrosive coatings by flame spraying. Lithium ferrite conductive anticorrosive coating materials, prepared by adopting a manipulator through optimizing the technological parameters of oxygen-acetylene flame spraying, have excellent corrosion resistance and conductivity. The preparation method, provided by the invention, has the advantages of simple process, high deposition rate, strong repeatability and low facility request, can directly implement the spraying construction on site so as to meet the construction and repair requirements of actual grounding network engineering, and can be applied to metallic matrix surfaces with different shapes or different sizes; in particular, the preparation method has more advantages when preparing large-area anticorrosive conductive coatings for practical application; and meanwhile, the maintenance is simple in the workpiece service process, so that the preparation method is suitable for industrial popularization and application.

Owner:STATE GRID CORP OF CHINA +1

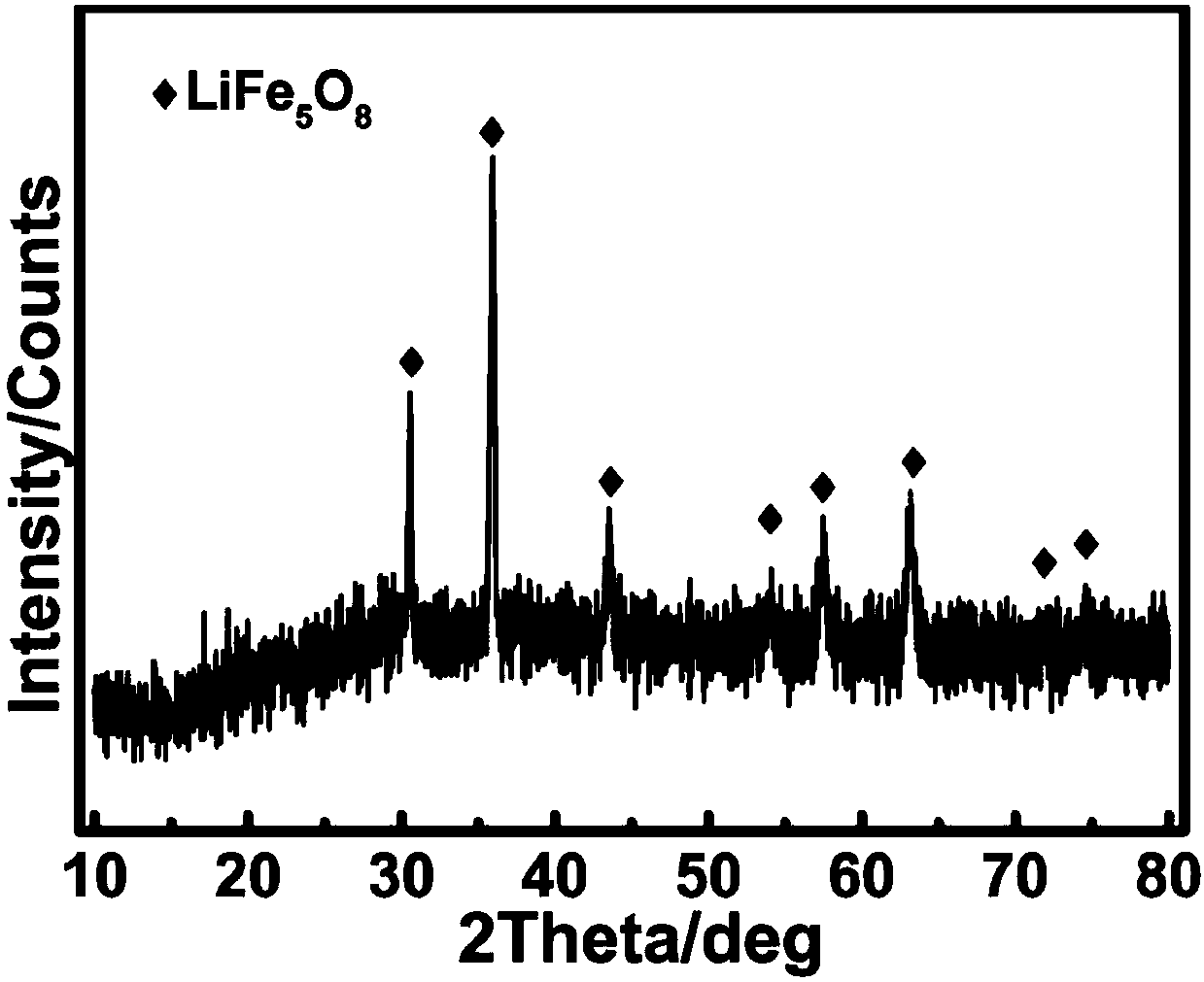

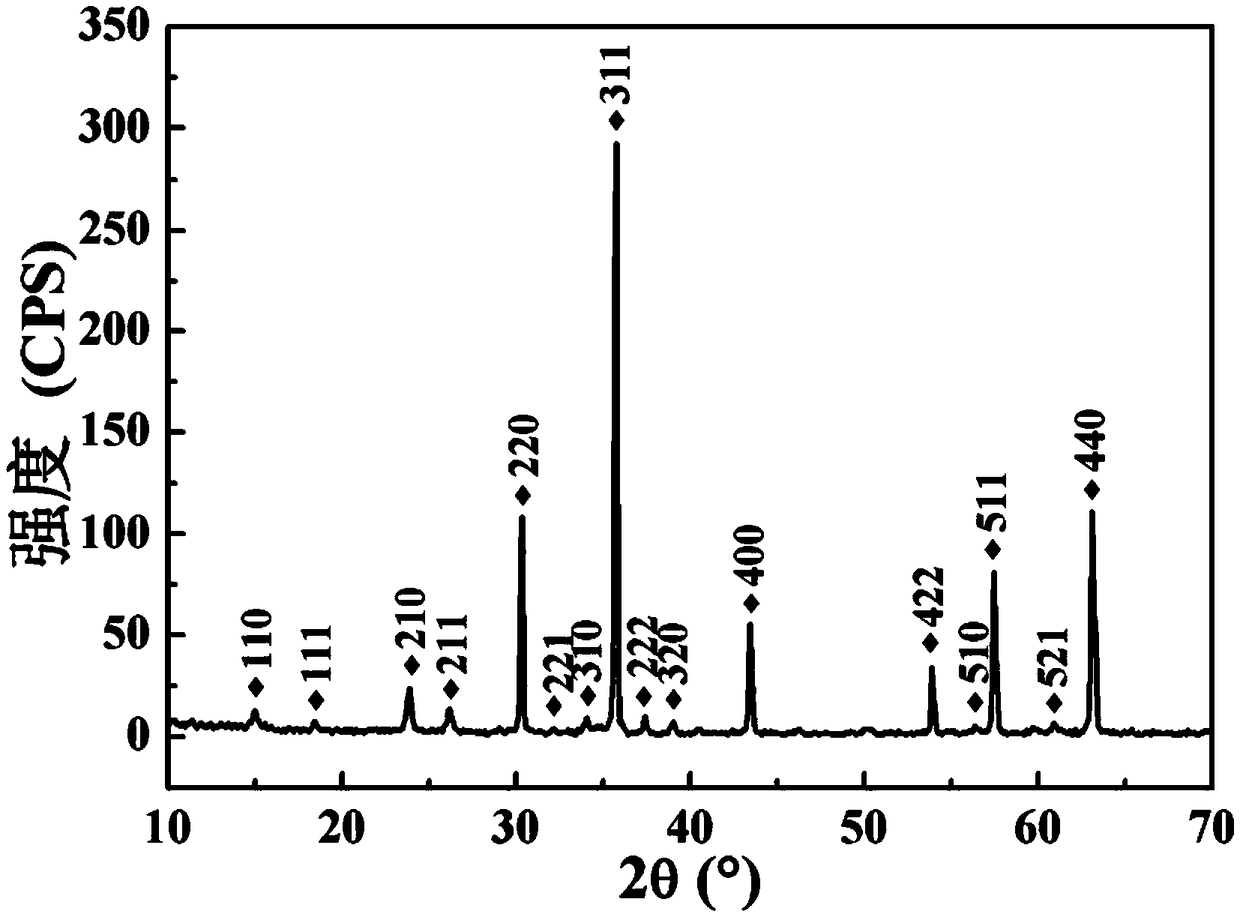

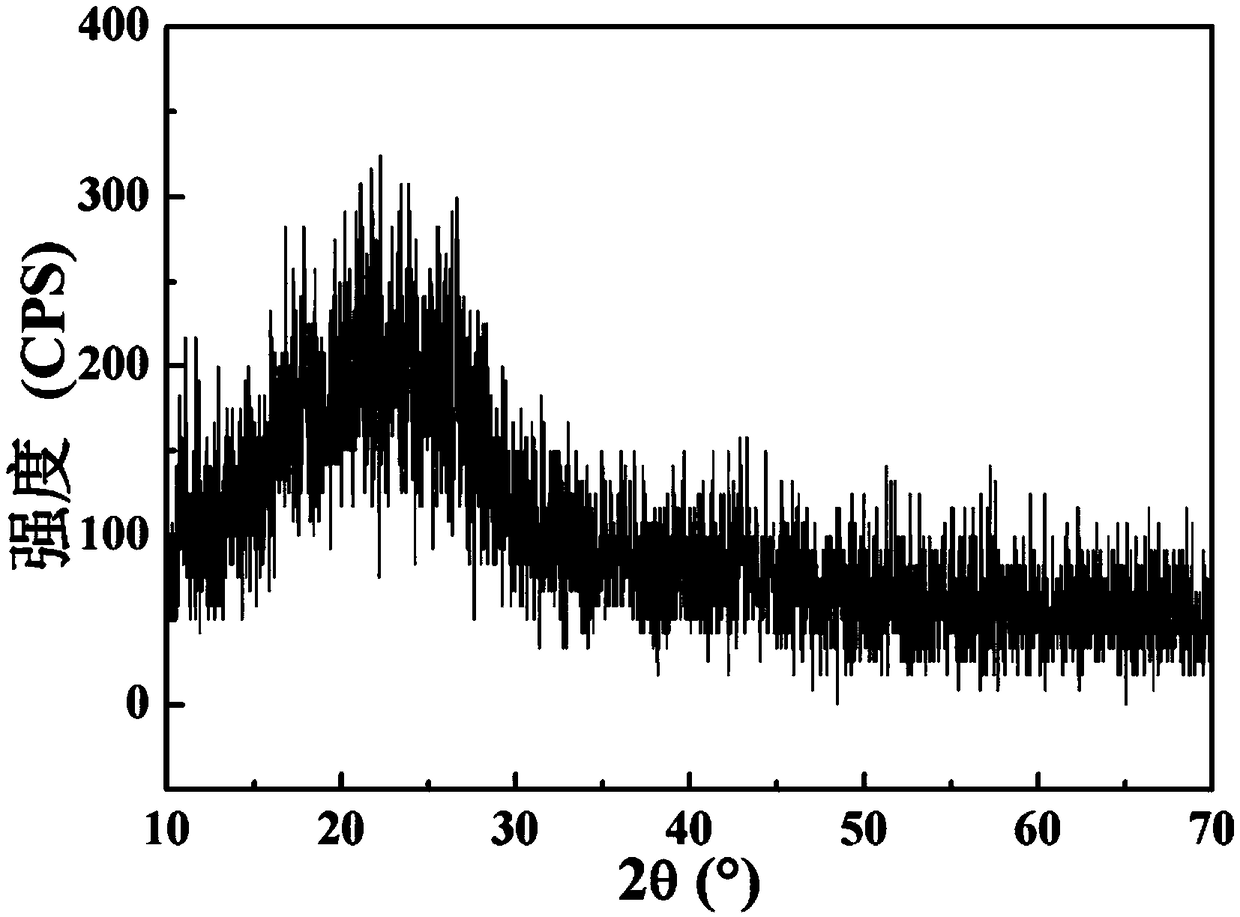

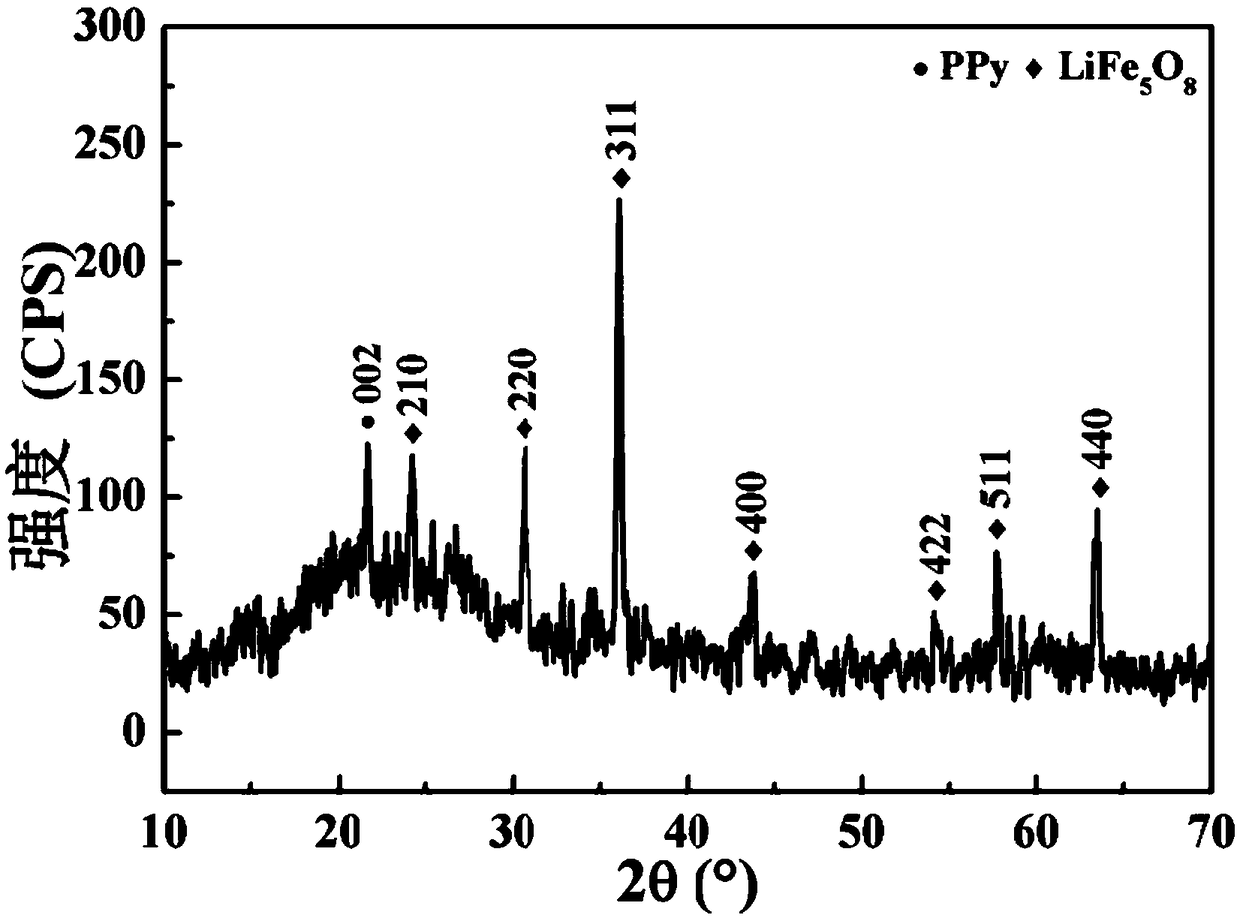

Lithium ferrite @PPy supercapacitor electrode material with core-shell structure and preparation method thereof

ActiveCN108766780ANoveltyEasy to controlMaterial nanotechnologyHybrid capacitor electrodesCapacitanceN dimethylformamide

Disclosed is a preparation method of a lithium ferrite @PPy supercapacitor electrode material with a core-shell structure; the preparation method comprises the steps of firstly, adding a surfactant into N, N dimethylformamide to obtain a mixed solution A; then adding LiFe<5>O<8> powder and PPy nanotubes into the mixed solution A, and performing uniform ultrasonic mixing to obtain a mixed solutionB; and pumping nitrogen to the mixed solution B and performing heating to a temperature of 75-85 DEG C, and next, dropwise adding a mixture of hydrazine hydrate and methyl mercaptoacetate, and performing reacting for 15-45min, and carrying out water washing and drying to obtain the lithium ferrite @PPy supercapacitor electrode material with the core-shell structure. The preparation process is simple, short in period, low in cost and low in energy consumption; and the prepared nano composite material has a relatively large specific surface area, high capacitance characteristic and electrochemical stability and high application prospect in the aspect of energy storage.

Owner:SHAANXI UNIV OF SCI & TECH

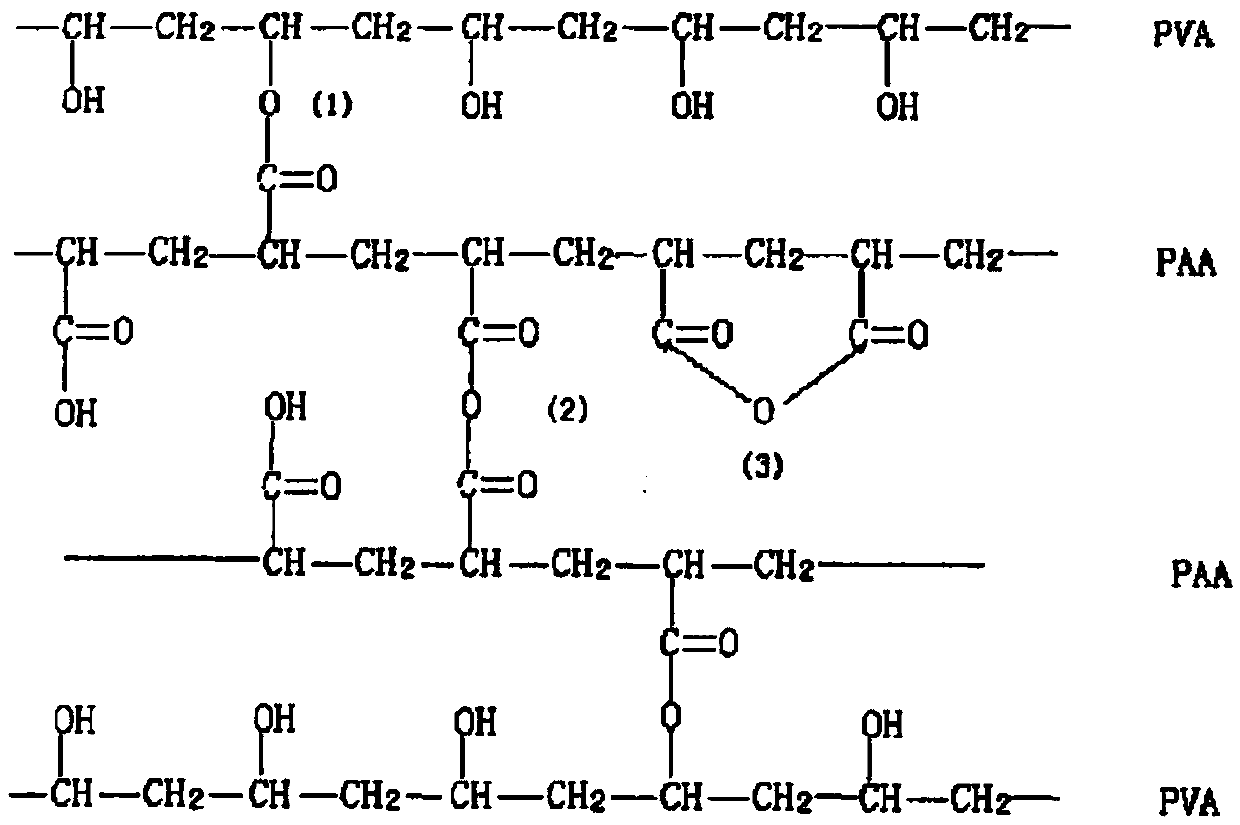

Positive paste, preparation method, anode piece and lithium ion battery

ActiveCN109638291AGood chemical stabilityImprove cycle lifeCell electrodesSecondary cellsSodium-ion batteryChemical stability

A positive paste comprises a positive active material and a PEDOT-doped gel material. The PEDOT-doped gel material is a gel polymer compound obtained through polymerization by a solution system I under a heating state, and PEDOT powder in an oxidized state is uniformly distributed on the gel polymer compound; a polymerized monomer is acrylic acid capable of ring opening polymerization and derivatives thereof; the positive active material comprises a first positive active material and a second positive active material; the first positive active material is a ternary material NixCoyMnzO2, and x+y+z=1; the second positive active material is one or several selected from lithium cobalt oxide, lithium manganate, lithium iron phosphate, lithium nickel manganate, lithium iron manganese phosphate and lithium ferrite; and the weight ratio of the first positive active material to the second positive active material is 1-3 to 3-1. The positive paste of a lithium ion battery has good chemical stability, high safety performance and long cycle life.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

Preparation method of doped lithium iron oxide

InactiveCN110422884AInhibition of segregationEvenly distributedPositive electrodesIron compoundsLithiumAmmonium ferrous sulfate

The invention discloses a preparation method of doped lithium iron oxide, and belongs to the technical field of new energy. The preparation method comprises following steps: a lithium hydrogencarbonate solution, an ammonium ferrous sulfate solution, a titanyl sulfate solution, and an acidifying or alkalizing agent are mixed, and are added into a base solution, wherein in the adding process, the pHvalue is maintained to be 7 to 7.5, the temperature is controlled to be 50 to 60 DEG C, and the stirring speed is controlled to be 300 to 400r / min; after material adding, the temperature is increasedto 90 to 95 DEG C, stirring reaction is carried out for 30 to 60min, and filtering washing are carried out to obtain a precipitate; the precipitate is subjected to drying, is introduced into a rotarykiln for calcining at 700 to 900 DEG C for 8 to 10h to obtain a calcined product, wherein air is introduced in calcining; and the calcined product is subjected to crushing, sieving, and removing of iron to obtain the doped lithium iron oxide. According to the preparation method, preparation of the doped lithium iron oxide can be realized, the surface area is large, the activity is high, and the surface is of a porous structure.

Owner:李旭意

Preparation method of photocatalytic lithium ferrite-titanium oxide composite block and composite block

The invention discloses a preparation method of a photocatalytic lithium ferrite-titanium oxide composite block which is prepared from lithium ferrite battery waste. The preparation method comprises the following steps: step 1, crushing and sieving a positive pole piece of the lithium ferrite battery waste to enable the particle size to be not greater than 70 meshes, and roasting at 400-600 DEG Cfor not less than 1 hour to obtain lithium ferrite positive pole powder; step 2, granulating the lithium ferrite positive electrode powder, pressing into a block, and sintering at 900-1200 DEG C for 4-6 hours to obtain a lithium ferrite block; step 3, carrying out chemical vapor deposition on the lithium ferrite block to obtain the titanium oxide coating; and step 4, carrying out heat preservationat 350-400 DEG C in an air atmosphere for 2-3 h to obtain the photocatalytic lithium ferrite-titanium oxide composite block. The invention also discloses the photocatalytic lithium ferrite-titanium oxide composite block prepared by the method. According to the method, the photocatalytic lithium ferrite-titanium oxide composite block is prepared by taking the lithium ferrite battery waste as a rawmaterial, and an aluminum matrix is taken as a sintering agent so that the reaction is more thorough, and more energy is saved. The internal microstructure of the photocatalytic lithium ferrite-titanium oxide composite block prepared by the method is loose and porous, and the photocatalytic activity is high.

Owner:河南中顺过滤研究院有限公司

High-performance high-compaction lithium ferrite material for phase shifter, and preparation method thereof

Owner:南京国睿微波器件有限公司

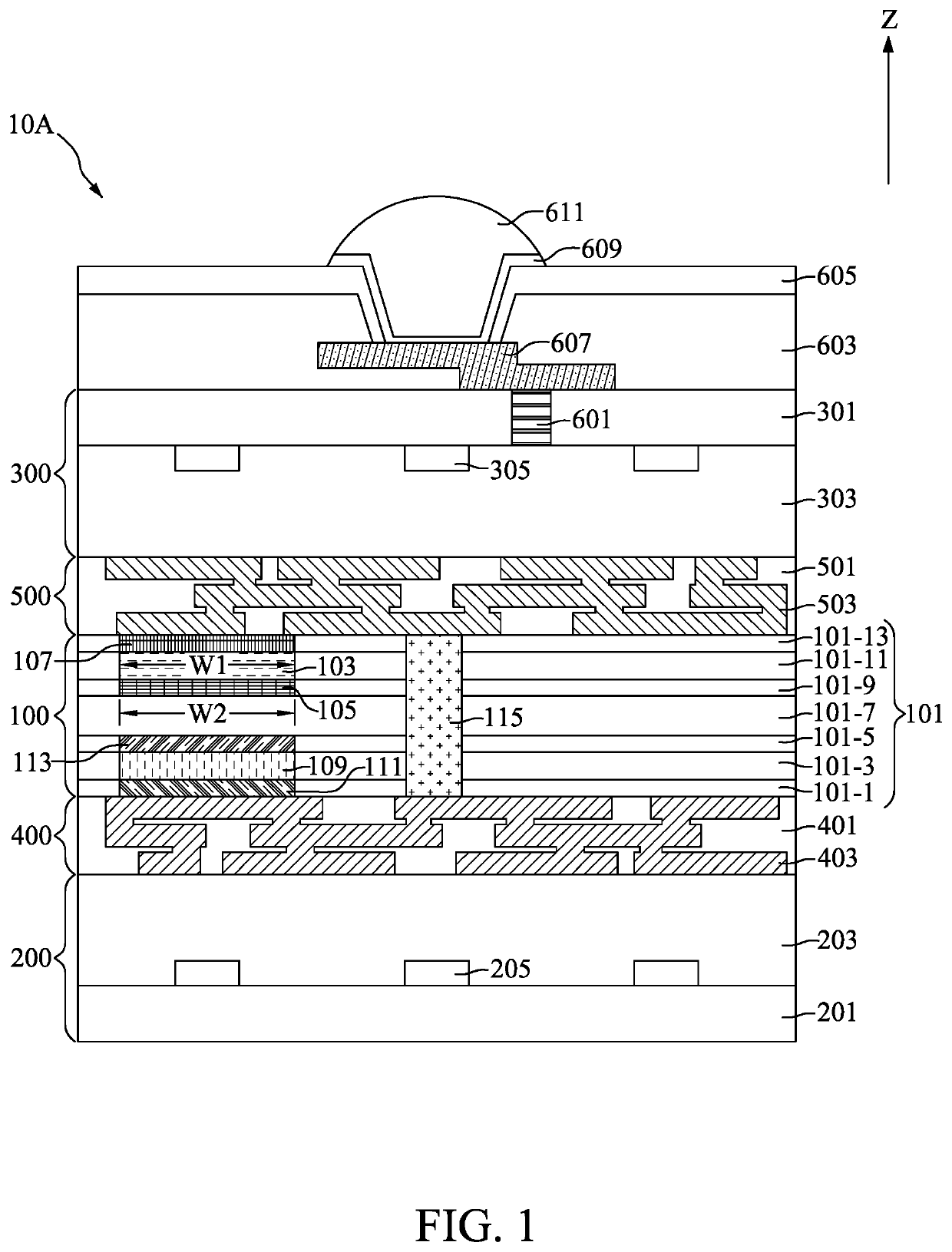

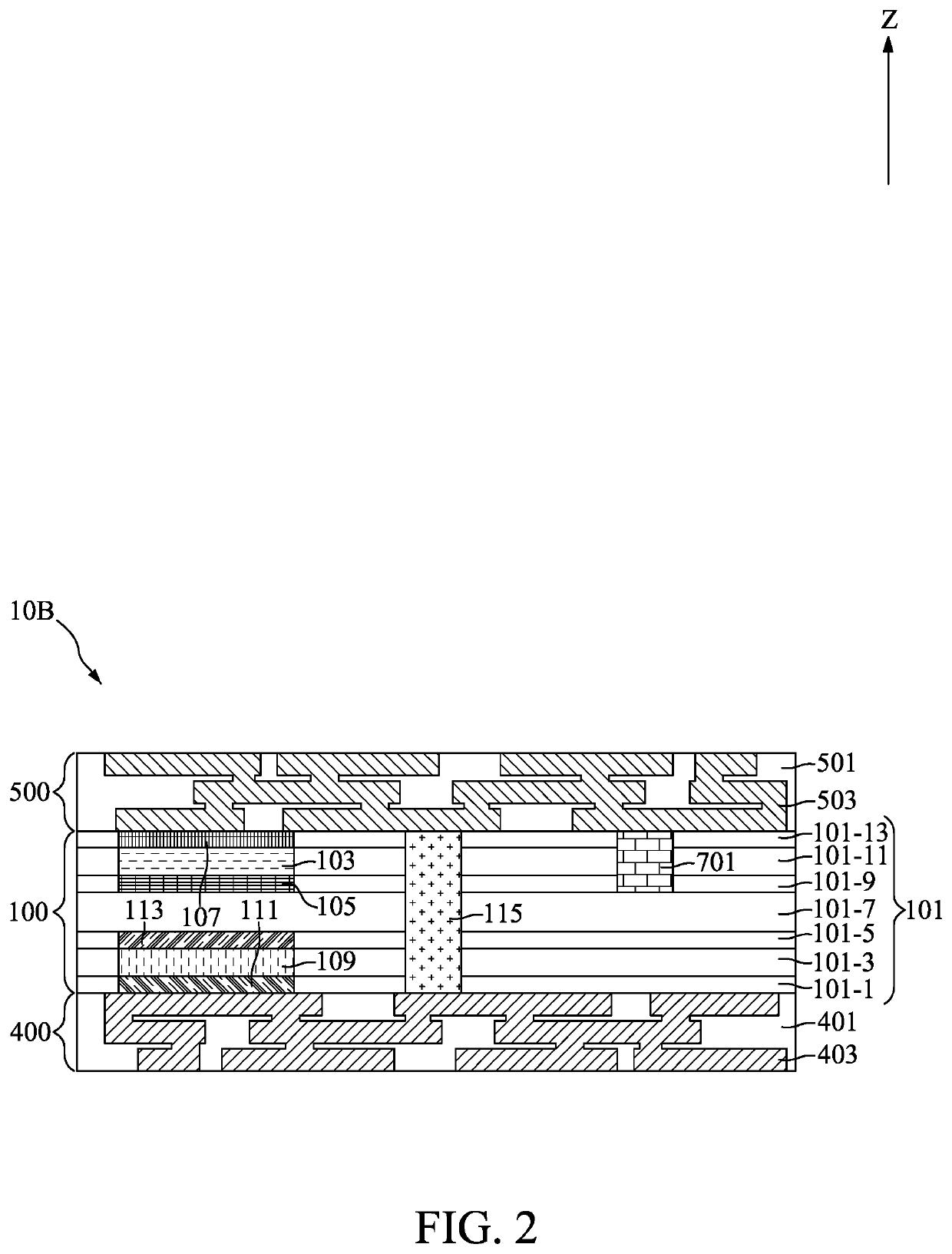

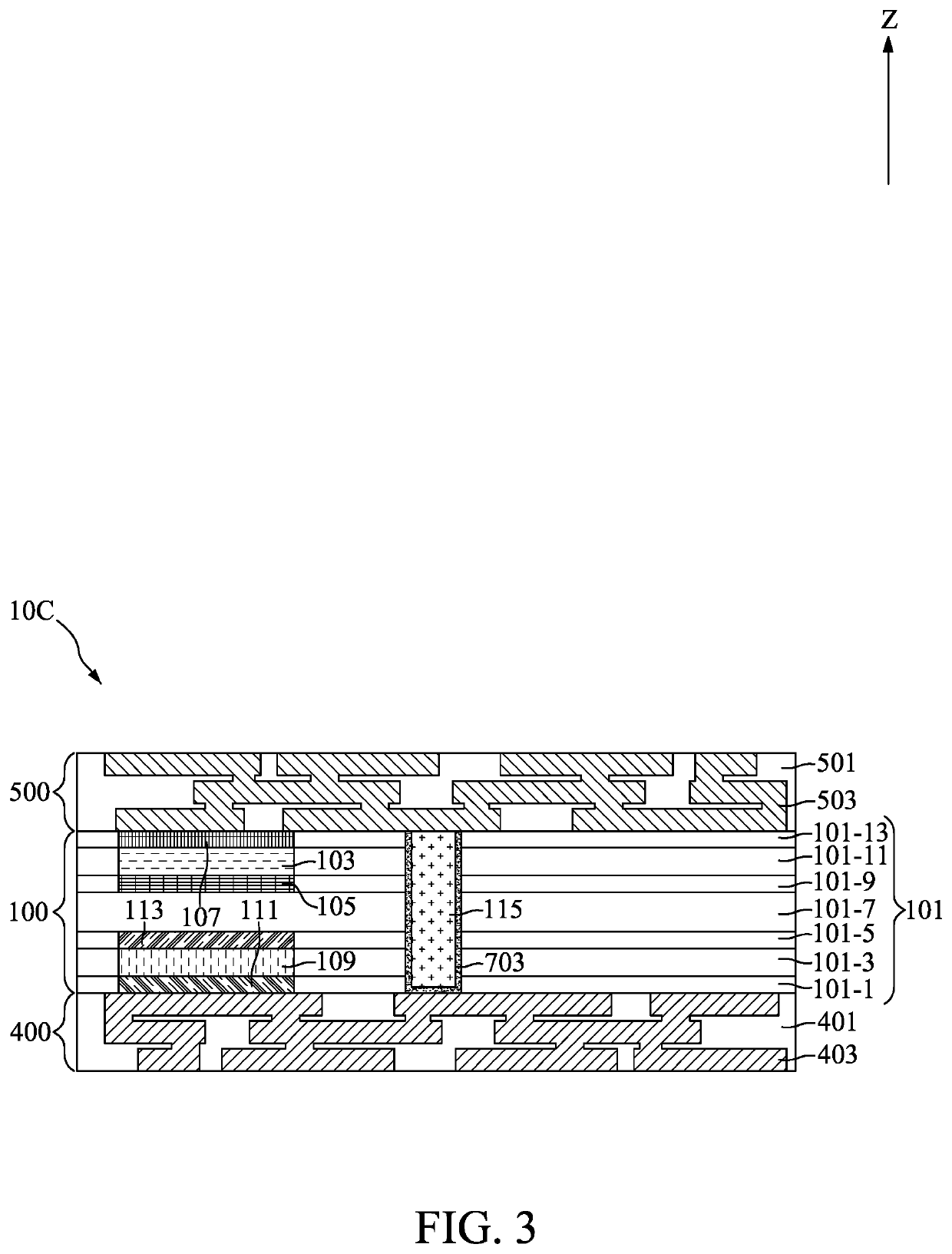

Semiconductor device with EMI protection liners and method for fabricating the same

ActiveUS11037878B1Reduce parasitic capacitanceReduce electromagnetic interferenceSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

The present application discloses a semiconductor device and a method for fabricating the semiconductor device. The semiconductor device includes a plurality of semiconductor memory dies vertically stacked through a plurality of microbumps; a plurality of through silicon vias positioned in the plurality of semiconductor dies and electrically coupled through the plurality of microbumps; and a plurality of protection liners positioned on sides of the plurality of through silicon vias; wherein the plurality of protection liners are formed of manganese-zinc ferrite, nickel-zinc ferrite, cobalt ferrite, strontium ferrite, barium ferrite, lithium ferrite, lithium-zinc ferrite, single crystal yttrium iron garnet, or gallium substituted single crystal yttrium iron garnet.

Owner:NAN YA TECH

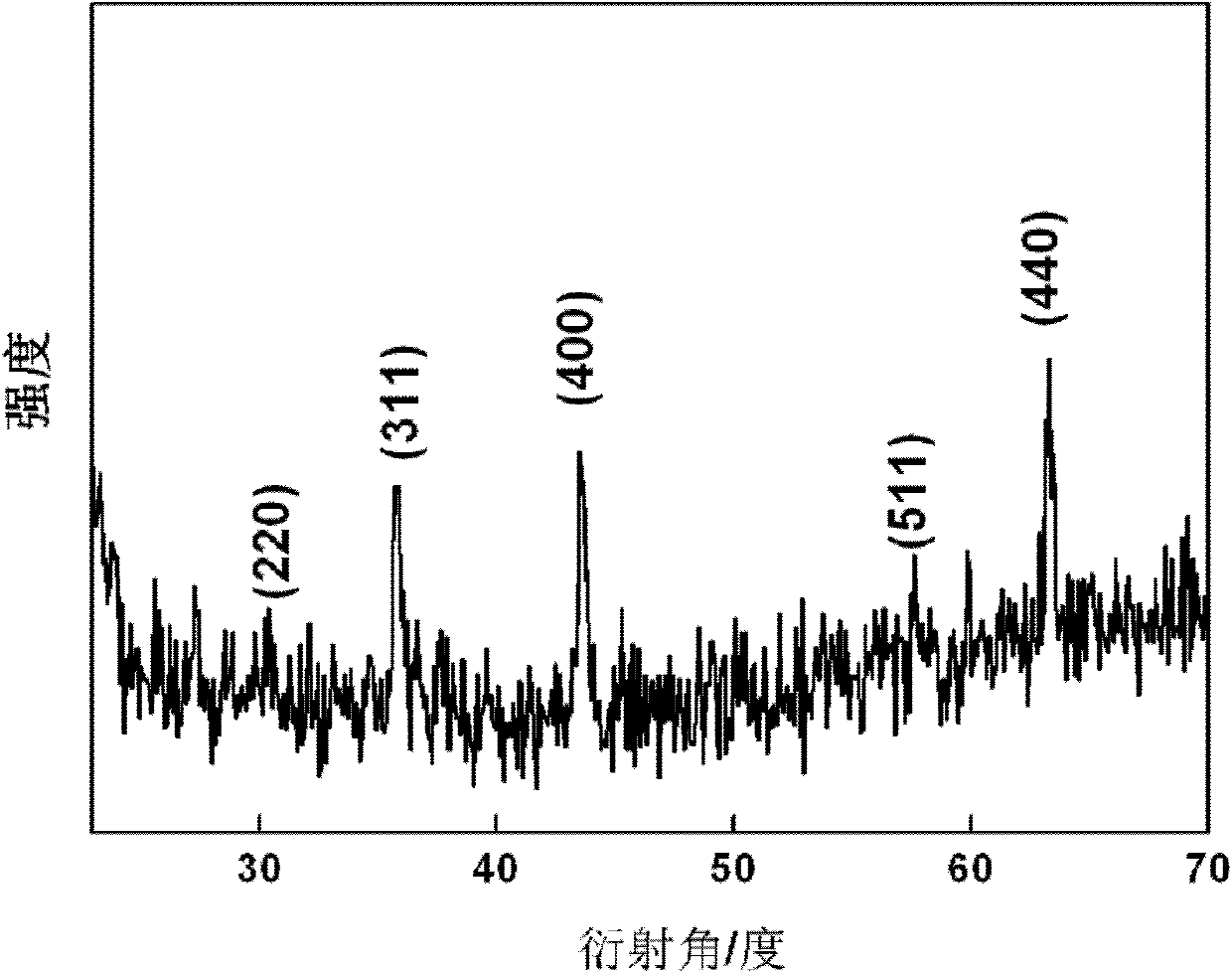

A kind of lithium-supplementing cathode material containing CO-doped lithium ferrate and its preparation and application

ActiveCN110518298BSmall particle sizeHigh activityCell electrodesSecondary cells servicing/maintenanceLithium-ion batteryLithium ferrite

The invention belongs to the field of lithium ion battery materials, and particularly discloses a lithium supplementing cathode material containing Co-doped lithium ferrate. The lithium supplementingcathode material comprises a cathode active material and a lithium supplementing additive, wherein the lithium supplementing additive is Co-doped lithium ferrate or a composite lithium supplementing material formed by the Co-doped lithium ferrate and a carbon material; the chemical formula of the Co-doped lithium ferrate is Li5Fe1-xCoxO4, wherein x ranges from 0.05 to 0.1. The invention also provides a preparation method of the lithium supplementing additive. The method comprises the following steps of: dispersing an iron source, a cobalt source and a lithium source in a stoichiometric ratio in a solution dissolved with citric acid, performing stirring to react to obtain gel, performing drying, and performing ball milling to obtain a precursor; and sintering the precursor in a protective atmosphere at a temperature of 600-900 DEG C to obtain a catalyst. According to the invention, the lithium supplementing additive and the cathode active material are found to have synergism, and in addition, the invention also provides a preparation method which is simple to operate, short in preparation period and high in product activity.

Owner:CENT SOUTH UNIV

Method for preparing carbon-hybridized nickel lithium ferrite nano-catalyst

InactiveCN102343267AEasy to operateRaw materials are cheap and easy to getCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystNitrate

The invention relates to a method for preparing a carbon-hybridized nickel lithium ferrite nano-catalyst. The method is characterized by comprising the following steps of: (1) dissolving lithium nitrate, nickel nitrate, iron nitrate and citric acid into water in the molar ratio of 1:0.5:2:3.5, and stirring to form a settled solution; (2) making the settled solution react at the temperature of 160-200 DEG C for 6-8 hours to obtain a foamed intermediate; (3) calcining the intermediate at the temperature of 550-600 DEG C for 3 hours to obtain nickel lithium ferrite; and (4) putting the nickel lithium ferrite and glucose into a high-pressure reaction kettle in the mass ratio of 1-2:1, reacting at the temperature of 160-200 DEG C for 12 hours, washing and drying to obtain the carbon-hybridizednickel lithium ferrite nano-catalyst. The method has the advantages of easiness for operating, cheap and readily-available raw materials, low cost, high yield, no need of purification treatment, no need of large-size special equipment in the reaction process and easiness for realizing large-scale industrial production.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com