Lithium ferrite @PPy supercapacitor electrode material with core-shell structure and preparation method thereof

A supercapacitor, core-shell structure technology, applied in the field of material science, can solve the problems of poor electrical conductivity, small powder particle size, small specific surface area, etc., and achieve the effects of low cost, large specific surface area, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

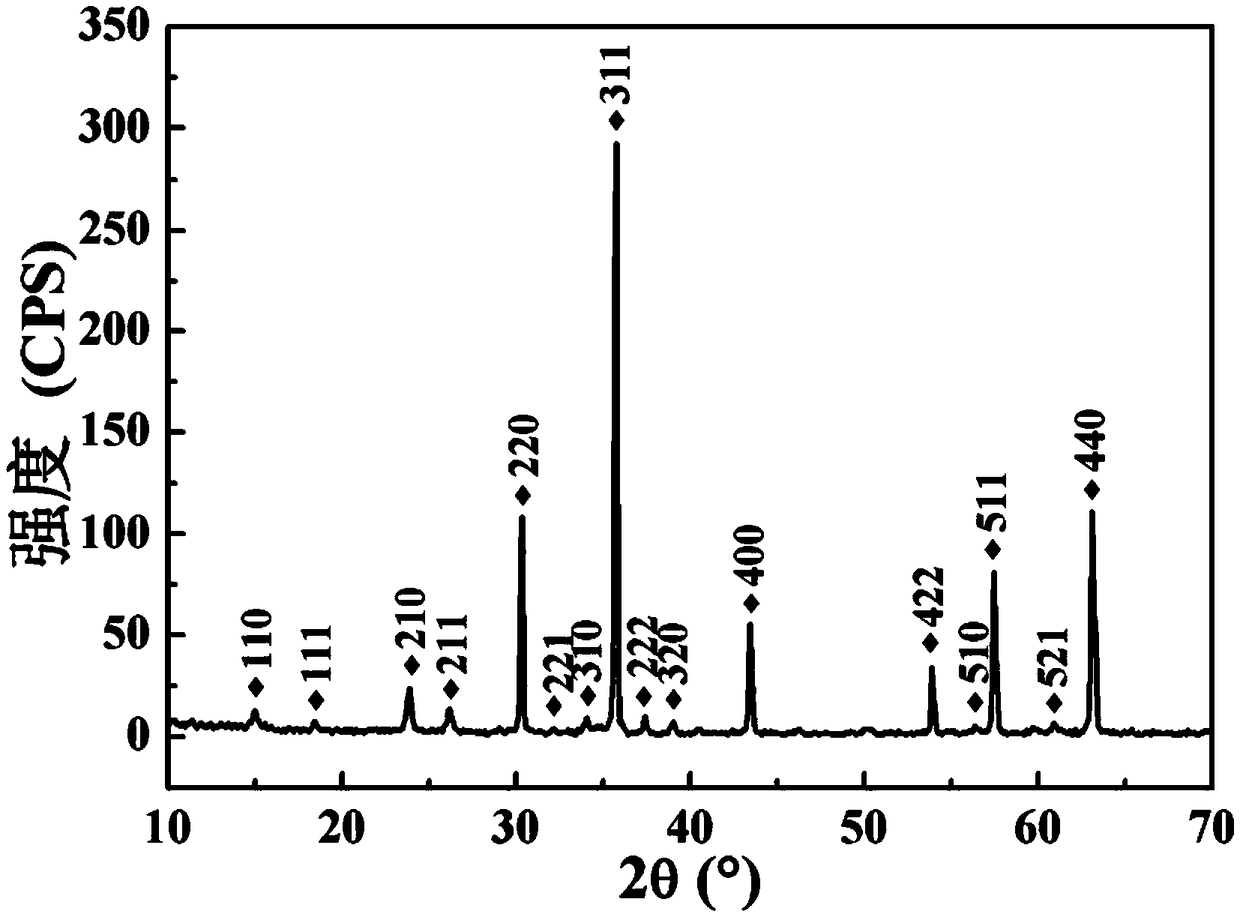

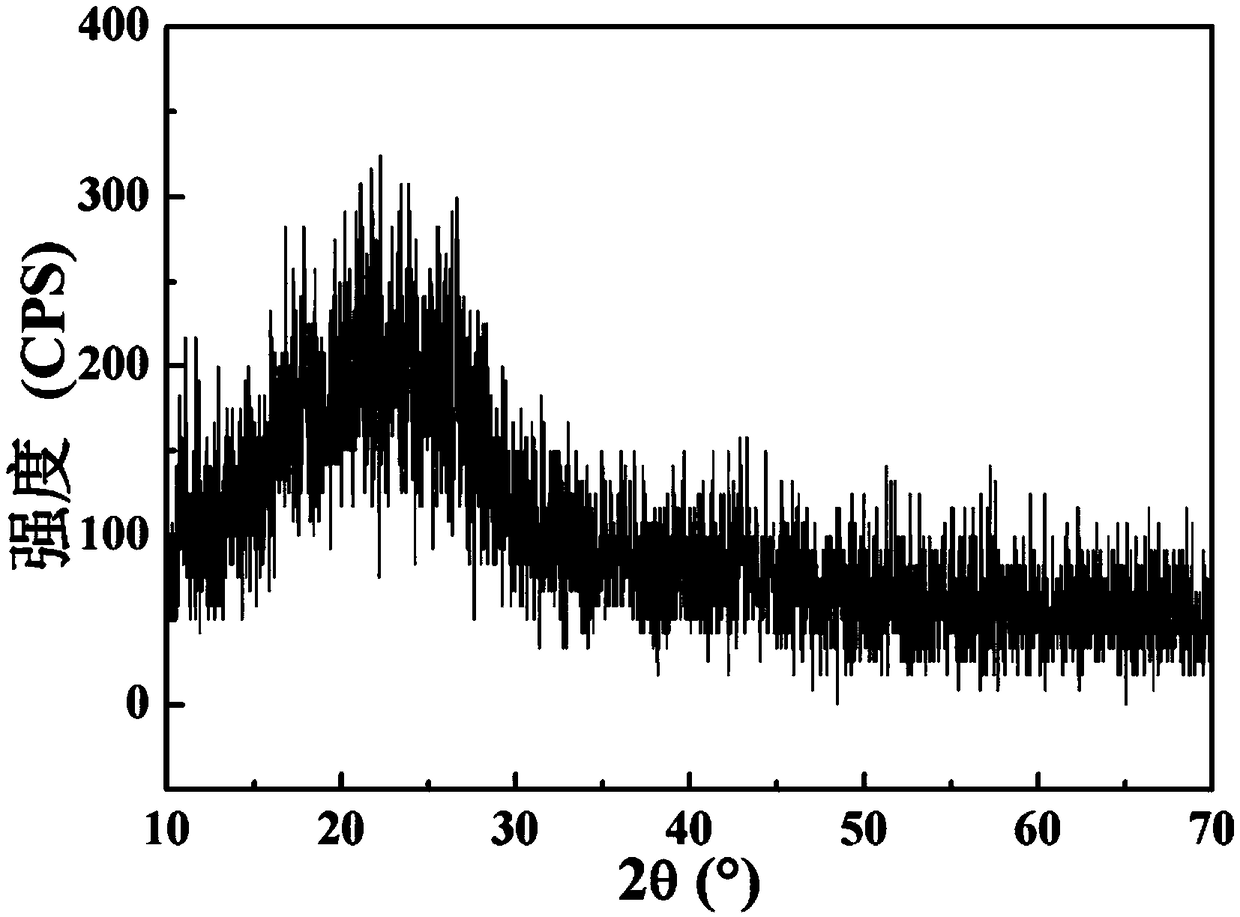

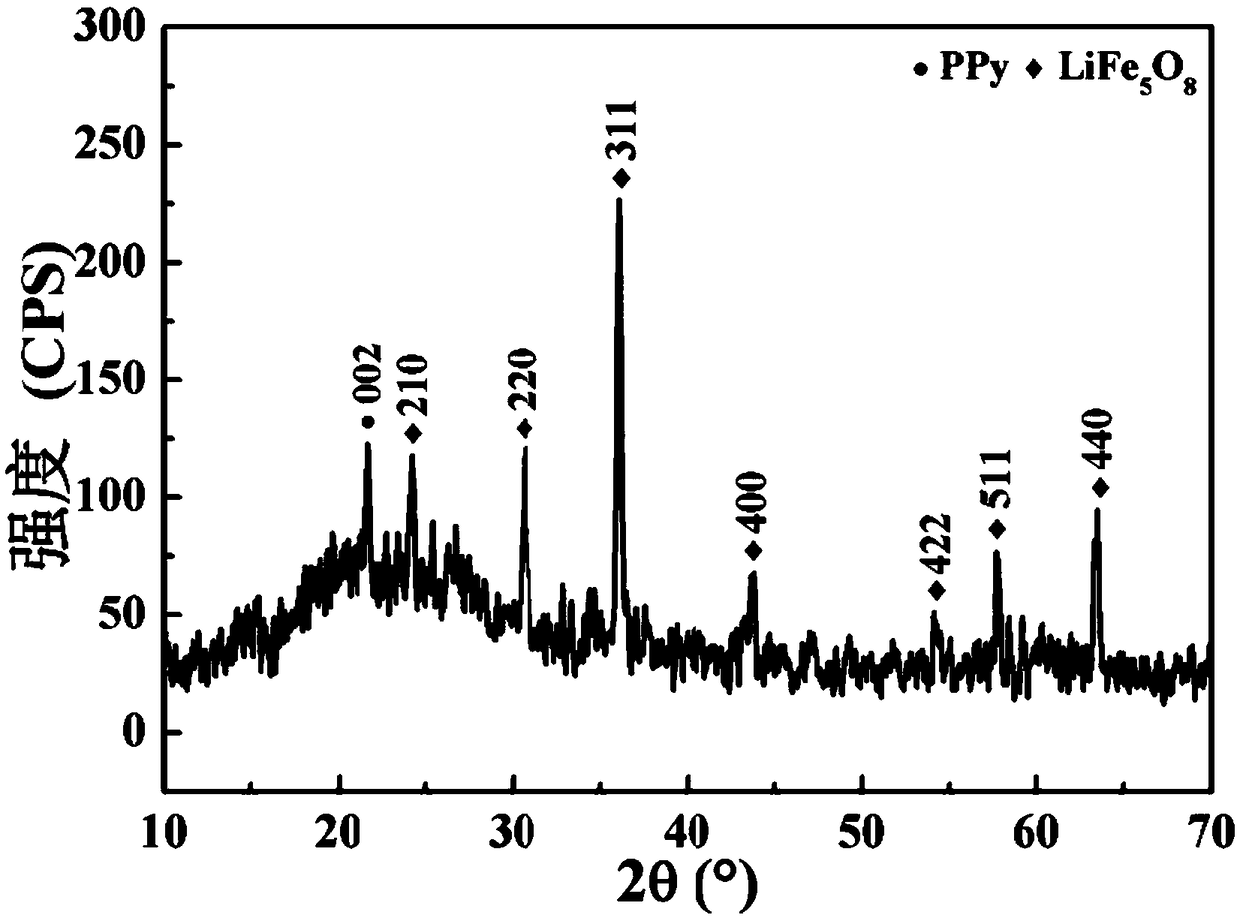

[0044] LiFe with a core-shell structure 5 o 8 The preparation method of @PPy supercapacitor electrode material, comprises the following steps:

[0045] (1) First, 0.01 g of CTAB was added to 100 mL of N,N dimethylformamide to obtain mixed solution A.

[0046] (2) Then 0.1g LiFe 5 o 8 The powder and 0.02 g of PPy nanotubes were added to the mixed solution A, and the mixed solution B was obtained by ultrasonication at 600 W for 4 hours.

[0047] (3) Pour the mixed solution B into a three-necked flask, heat and stir in a water bath at 80°C, and feed nitrogen at the same time;

[0048](4) Add 12.5 mL of hydrazine hydrate and 5 mL of methyl mercaptoacetate dropwise to the mixed solution B, and continue to protect with nitrogen for 30 min. After the reaction is carried out for 45 min, stop the reaction with supercooled ethanol;

[0049] (5) After the precipitate obtained after the reaction was washed three times with absolute ethanol and deionized water, vacuum-dried for 10 h, ...

Embodiment 2

[0051] LiFe with a core-shell structure 5 o 8 The preparation method of @PPy supercapacitor electrode material, comprises the following steps:

[0052] (1) First, 0.01 g of CTAB was added to 100 mL of N,N dimethylformamide to obtain mixed solution A.

[0053] (2) Then 0.1g LiFe 5 o 8 The powder and 0.03g PPy nanotubes were added to the mixed solution A, and the mixed solution B was obtained by ultrasonication at 600W for 5h;

[0054] (3) Pour the mixed solution B into a three-necked flask, heat and stir in a water bath at 80°C, and feed nitrogen at the same time;

[0055] (4) Add 12.5 mL of hydrazine hydrate and 5 mL of methyl mercaptoacetate dropwise to the mixed solution B, and continue to protect with nitrogen for 30 min. After the reaction is carried out for 45 min, stop the reaction with supercooled ethanol;

[0056] (5) After the precipitate obtained after the reaction was washed three times with absolute ethanol and deionized water, vacuum-dried for 10 h, LiFe with...

Embodiment 3

[0067] LiFe with a core-shell structure 5 o 8 The preparation method of @PPy supercapacitor electrode material, comprises the following steps:

[0068] (1) First, add 0.01 g of PVP into 100 mL of N,N dimethylformamide to obtain a mixed solution A.

[0069] (2) Add 0.1g LiFe 5 o 8 The powder and 0.04g PPy nanotubes were added to the mixed solution A, and the mixed solution B was obtained by ultrasonication for 6h;

[0070] (3) Pour the mixed solution B into a three-necked flask, heat and stir in a water bath at 80°C, and feed nitrogen at the same time;

[0071] (4) Add 12.5 mL of hydrazine hydrate and 5 mL of methyl mercaptoacetate dropwise to the mixed solution B, and continue to protect with nitrogen for 30 min. After the reaction is carried out for 45 min, stop the reaction with supercooled ethanol;

[0072] (5) After the precipitate obtained after the reaction was washed three times with absolute ethanol and deionized water, vacuum-dried for 10 h, LiFe with a core-shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com