Preparation method of doped lithium iron oxide

A lithium ferrite, doped technology, applied in the direction of chemical instruments and methods, iron compounds, active material electrodes, etc., can solve the problems of small specific surface area and low activity of materials, and achieve uniform distribution of iron, good activity, crystallization high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

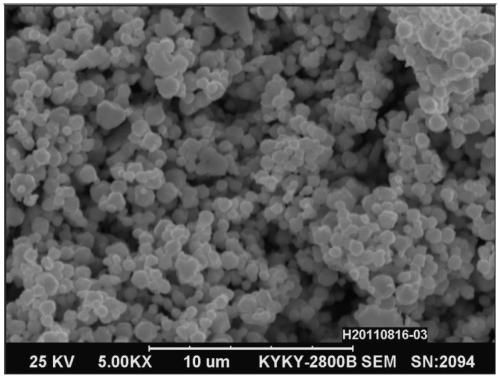

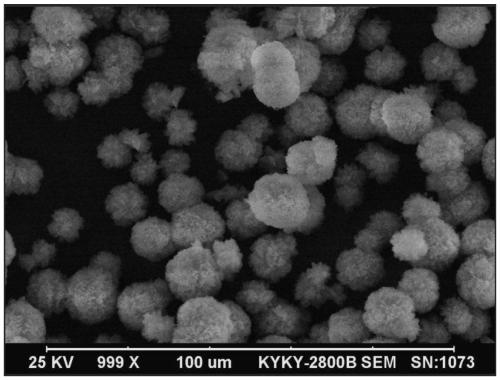

Image

Examples

Embodiment 1

[0035] A preparation method of doped lithium ferrite,

[0036] After the battery-grade lithium carbonate is slurried, carbon dioxide is introduced to completely dissolve and clarify it, and a ceramic membrane is used for precision filtration to obtain a lithium bicarbonate solution; the reagent pure ferrous ammonium sulfate is added to pure water for dissolution, and a ceramic membrane is used for precision filtration , to obtain ferrous ammonium sulfate solution; add reagent pure titanyl sulfate to pure water to dissolve, and use ceramic membrane to carry out fine filtration to obtain titanyl sulfate solution; prepare a mixed solution of ammonium sulfate and hydrazine hydrate, and then add polyethylene glycol, Stir and dissolve to obtain the bottom solution; the acid-base regulator is ammonium bicarbonate solution.

[0037] The detection data of lithium bicarbonate solution, ferrous ammonium sulfate solution, titanyl sulfate solution and bottom liquid are as follows:

[0038...

Embodiment 2

[0049] A kind of preparation method of doped type lithium ferrite, it adds lithium bicarbonate solution, ferrous ammonium sulfate solution, titanium oxysulfate solution and acid-base regulator into the end solution in parallel, maintains the pH of the process to be 7.4, and the temperature is 50°C, the stirring speed is 300r / min, after the feeding is completed, the temperature is raised to 95°C, and after stirring and reacting for 40min, the precipitate is obtained by filtration and washing;

[0050] After the obtained precipitate was dried, it was put into a rotary kiln for calcination, the calcination temperature was 825°C, air was introduced during the calcination process, and the calcination time was 9 hours to obtain the calcined material;

[0051] The calcined material is crushed and then sieved to remove iron to obtain doped lithium ferrite.

[0052] After the battery-grade lithium carbonate is slurried, carbon dioxide is introduced to completely dissolve and clarify it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com