Lithium battery anode material based on lithium ferrite as well as preparation method and application thereof

A negative electrode material, lithium ferrite technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of poor transmission and diffusion performance, poor cycle stability, low rate performance, etc., and achieve excellent long cycle. Effects of stability and rate capability, phase uniformity, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In a lithium battery negative electrode material based on lithium ferrite, the preparation method of its lithium ferrite is:

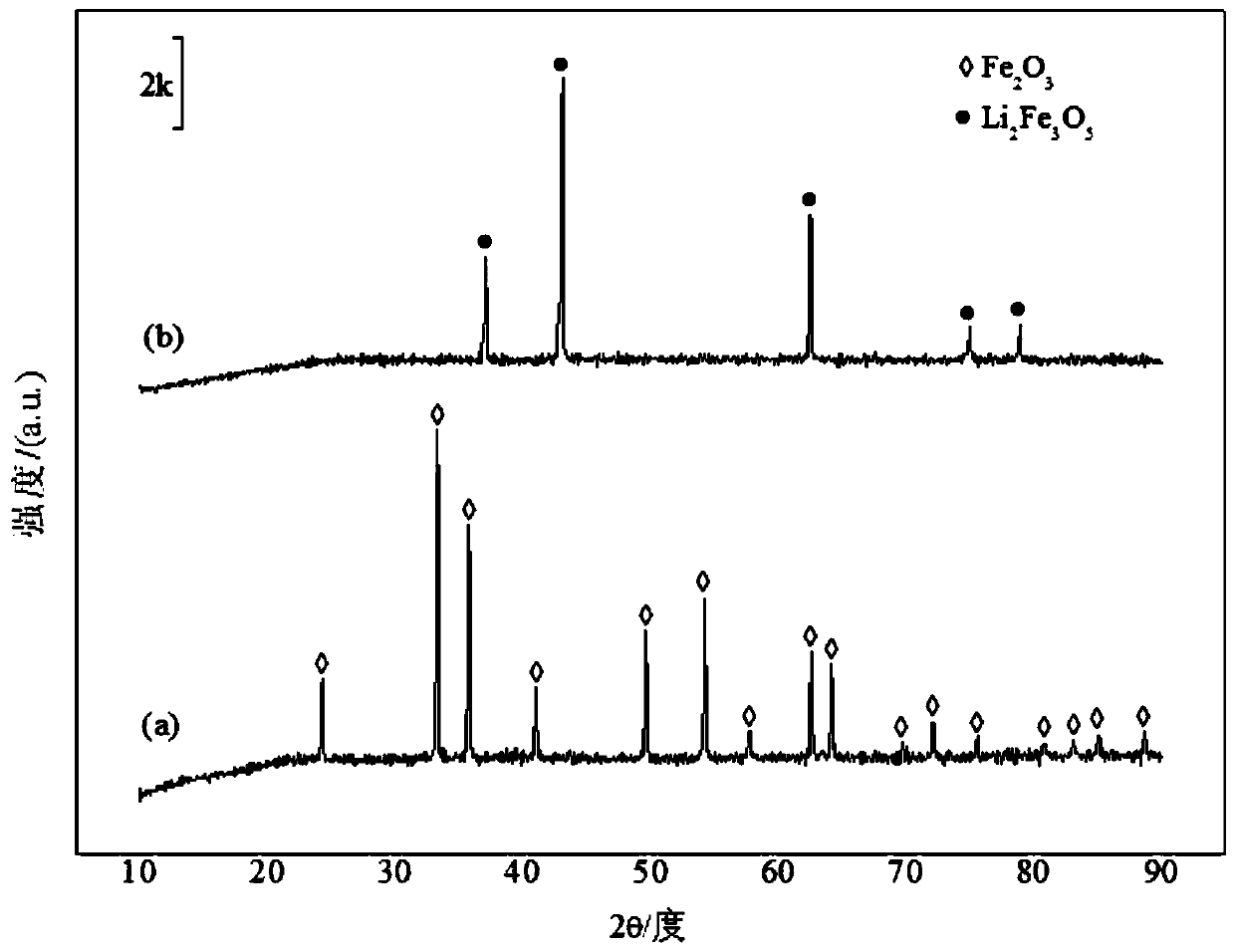

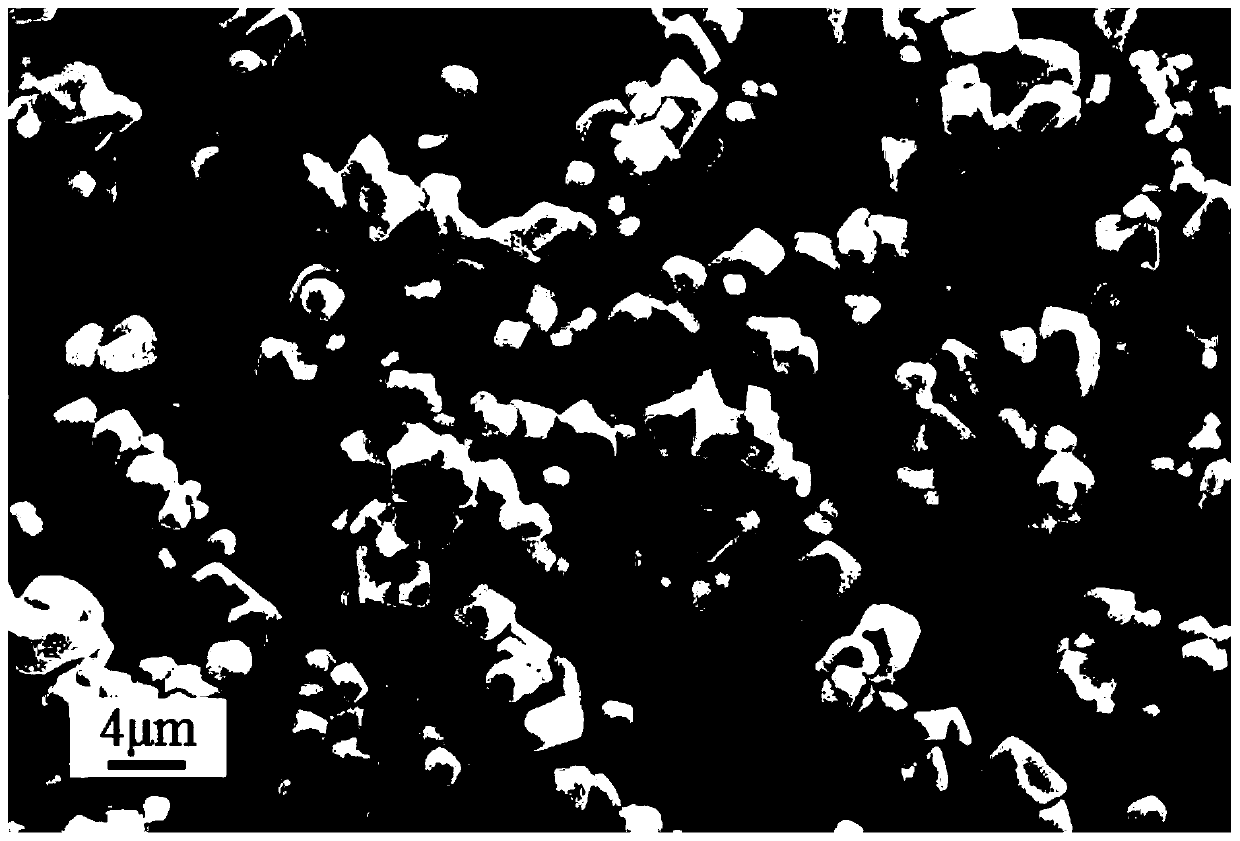

[0047] Direct use of iron oxide (Fe 2 o 3 ) powder (XRD figure see figure 1 (a)) is the working cathode, and graphite is used as the working anode, wherein the electrolyte is LiCl, the electrolysis temperature is 660°C, the electrolysis voltage is 1V, the electrolysis time is 60min, the heating rate before electrolysis and the cooling rate after electrolysis are equal 3°C / min. During the electrolysis process, the argon gas flow into the electrolytic cell is 600mL / min. The electrolytic cell is connected with a U-shaped quartz tube, and the U-shaped quartz tube is filled with deionized water. After the argon gas flows through the U-shaped quartz tube, the moist argon gas flows into the In a sealed reactor, electrolysis is carried out under a protective atmosphere of molten salt containing water vapor. After the electrolysis experiment, the cat...

Embodiment 2

[0059] In a lithium battery negative electrode material based on lithium ferrite, the preparation method of its lithium ferrite is: the same as in Example 1, the difference is:

[0060] (1) The iron oxide powder is pressed (20MPa, holding pressure for 10 minutes), and then sintered at a constant temperature of 800°C for 2 hours to obtain a sheet-shaped cathode;

[0061] (2) The electrolysis voltage is 0.7V, the electrolysis time is 120min, and the electrolysis temperature is 450°C;

[0062] (3) The chemical composition of the electrolyte is LiCl-KCl (wherein LiCl is 59.2 mol%, KCl is 40.8 mol%);

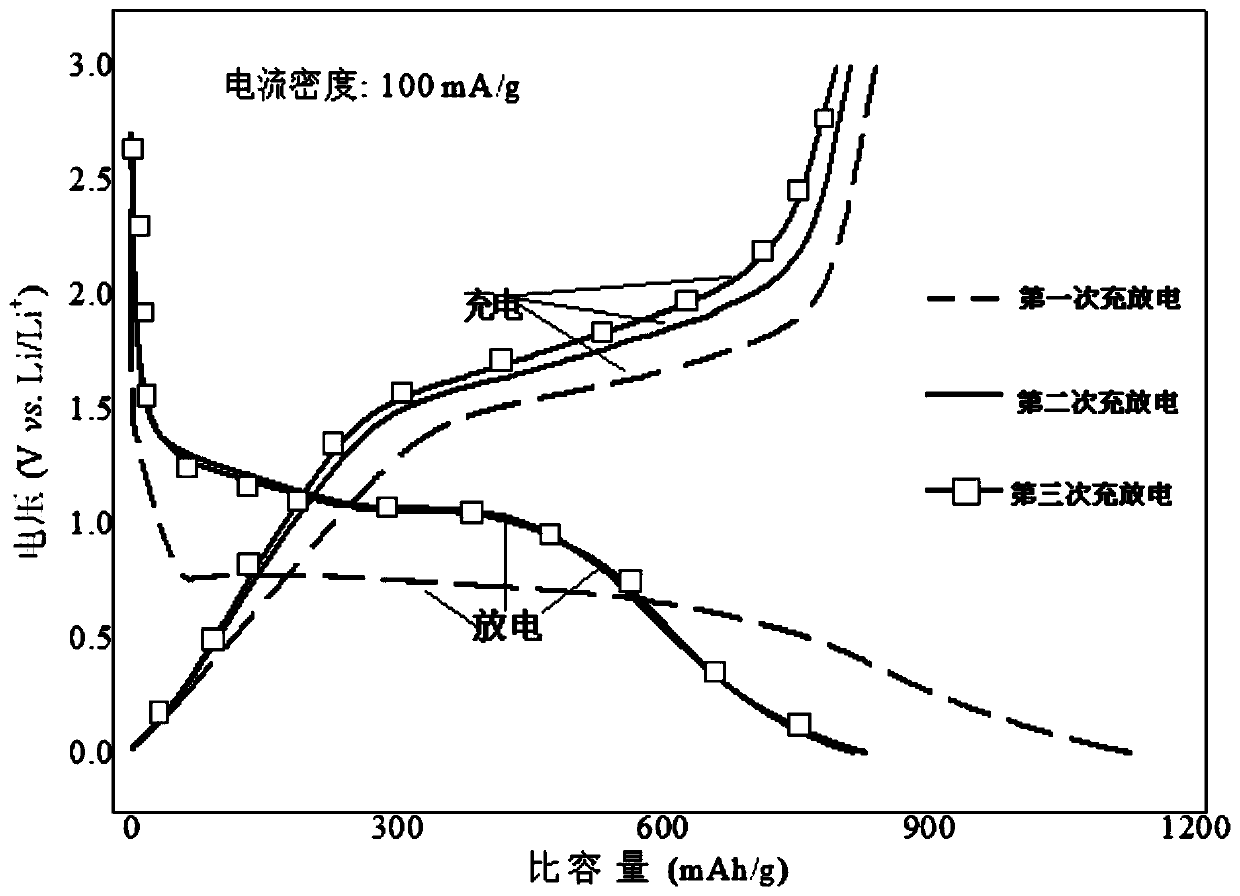

[0063] A lithium battery negative electrode material based on lithium ferrite, including the lithium ferrite prepared above, as well as conductive carbon, binder and solvent; wherein, according to the mass ratio, lithium ferrite: conductive carbon = 2: 1, bonded The added mass of the agent accounts for 11.1% of the total mass of lithium ferrite + conductive carbon, and according to ...

Embodiment 3

[0070] Method is with embodiment 1, and difference is:

[0071] (1) The electrolysis voltage is 0.9V, the electrolysis time is 20min, and the electrolysis temperature is 590°C;

[0072] (2) The chemical composition of the electrolyte is LiCl-SrCl 2 (64.3:35.7mol%);

[0073] (3) Weigh 6 g of lithium ferrite prepared under the conditions, 3 g of conductive carbon and 1 g of binder, mix and grind, add 80 mL of N-methylpyrrolidone, and stir magnetically for 10 h. The adjusted slurry was coated on copper foil to make electrode sheets, which were sliced and pressed and then used as counter electrodes with lithium sheets, and assembled into CR2025 button cells in a glove box. The electrochemical performance test was carried out on a constant current charge-discharge system at a rate of 200mA / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com