Method of one-step synthesis of cluster type palladium-copper nano particles and application of cluster type palladium-copper nano particles

A nanoparticle and cluster technology, applied in nanotechnology, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the complex process of core-shell growth method, uneven particle size, nanoparticle Small particle size and other problems, to achieve the effect of improving the oxidation activity and stability of formic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

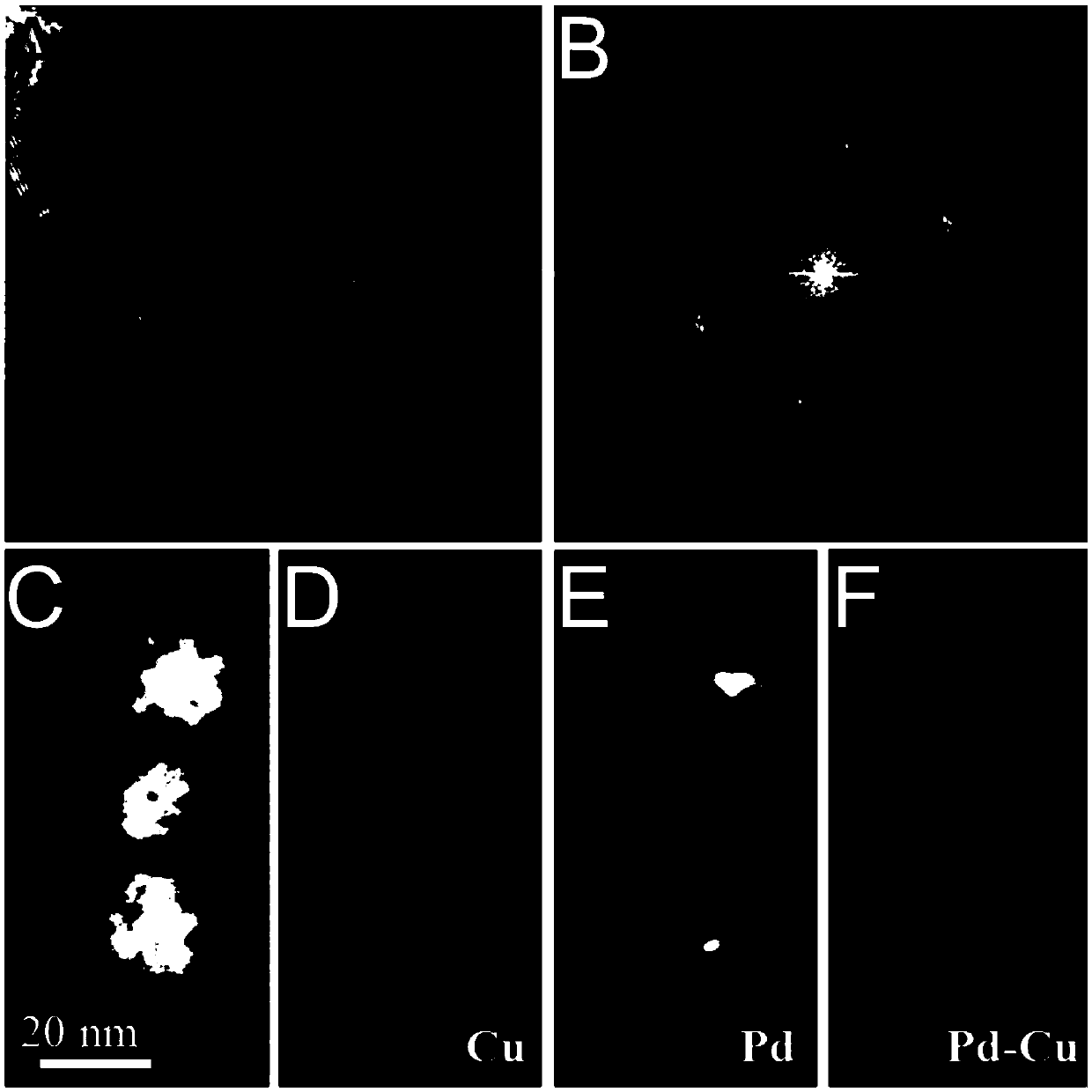

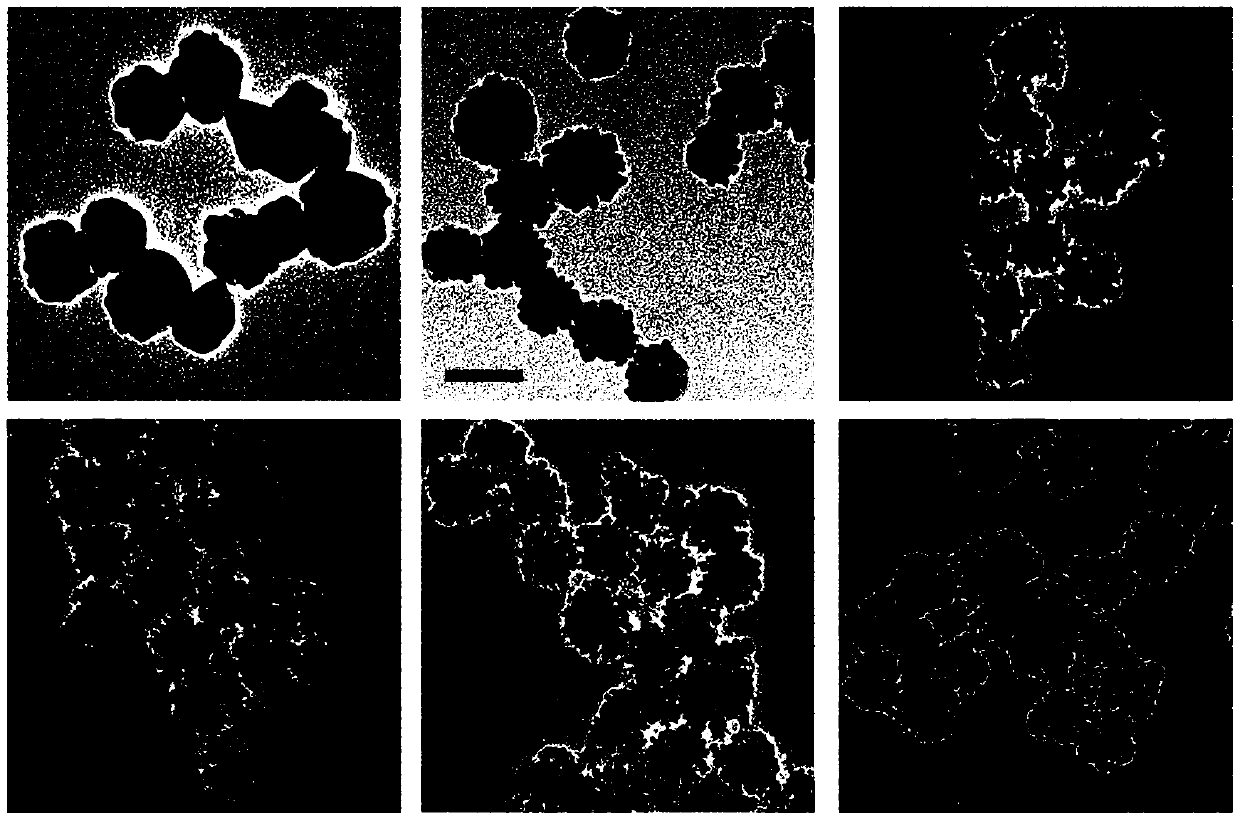

[0019] The present embodiment provides a method for synthesizing cluster-type palladium-copper nanoparticles in one step, which comprises the following steps:

[0020] Put a magnetic stir bar into the round bottom flask, add 40ml DMF (N,N-dimethylformamide), then add 0.1g PVP (polyvinylpyrrolidone, commercially available), start stirring to dissolve; add 0.03g Pd(acac) 2 , 0.005g Cu(acac) 2 Make the solution change from colorless to yellow-green. At this time, install a condenser, open the circulating condensed water, and stir fully to fully dissolve and mix evenly;

[0021] Immerse the round-bottomed flask in an oil bath and heat it to 100°C for reaction, keeping it for 10-18 hours (during this process, it can be observed that the color of the solution gradually becomes darker and finally turns black); after 18 hours, stop heating and stirring, and place the round-bottomed flask in a It can be cooled at room temperature; the obtained cluster type palladium copper nanopartic...

Embodiment 2

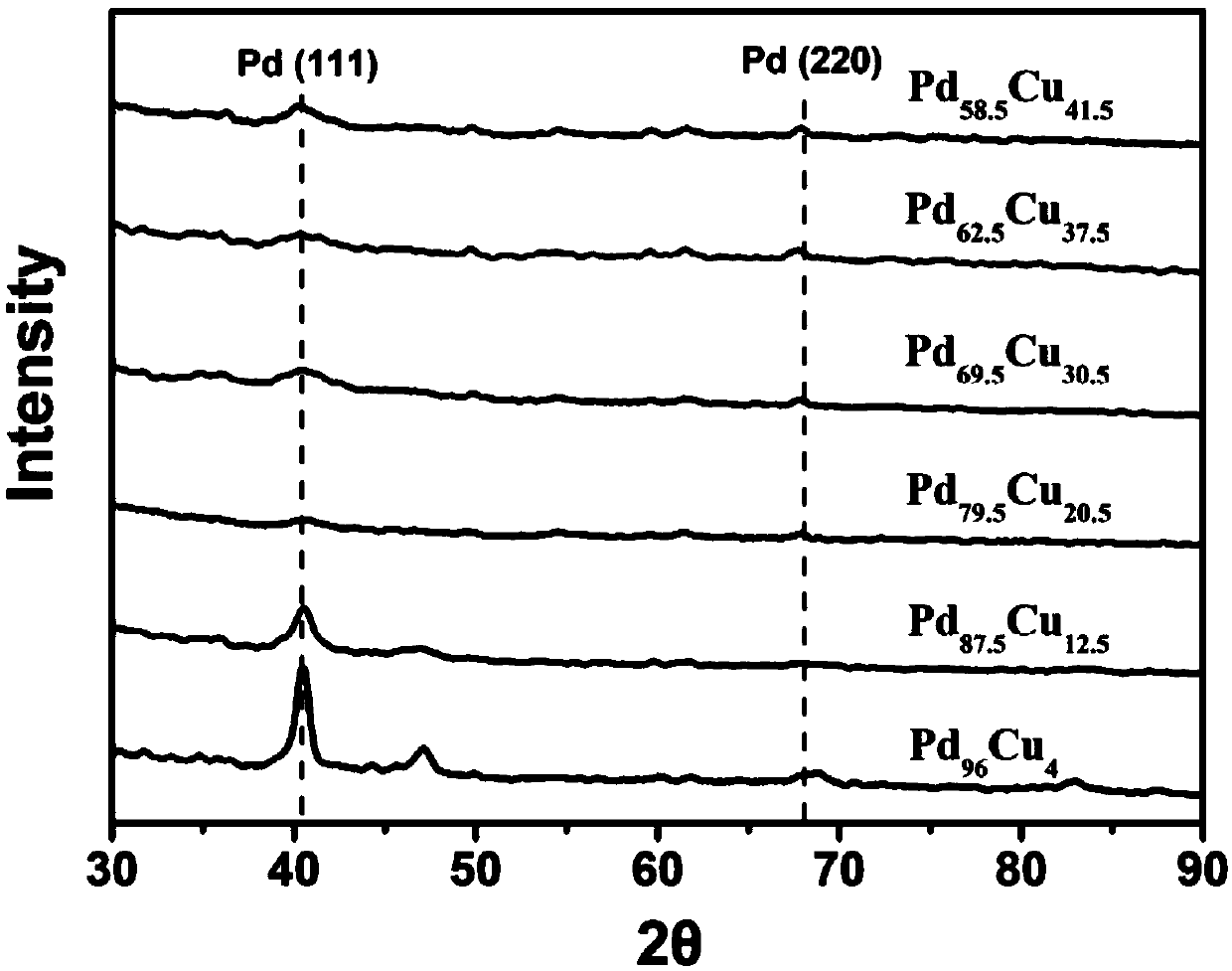

[0023] This embodiment provides a method for synthesizing cluster-type palladium-copper nanoparticles in one step, which is basically the same as that in Example 1, except that 0.03g Pd(acac) is added 2 and 0.015g Cu(acac) 2 .

Embodiment 3

[0025] This embodiment provides a method for synthesizing cluster-type palladium-copper nanoparticles in one step, which is basically the same as that in Example 1, except that 0.03g Pd(acac) is added 2 and 0.03g Cu(acac) 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com