Photocatalytic coating having zinc oxide/titanium dioxide heterostructure and preparation method and application of photocatalytic coating with zinc oxide/titanium dioxide heterostructure

A heterogeneous structure, nano-titanium dioxide technology, applied in the field of photocatalytic materials, can solve the problems of poor controllability of reaction conditions, achieve effective control of morphology and microscopic size, large spectral absorption range, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

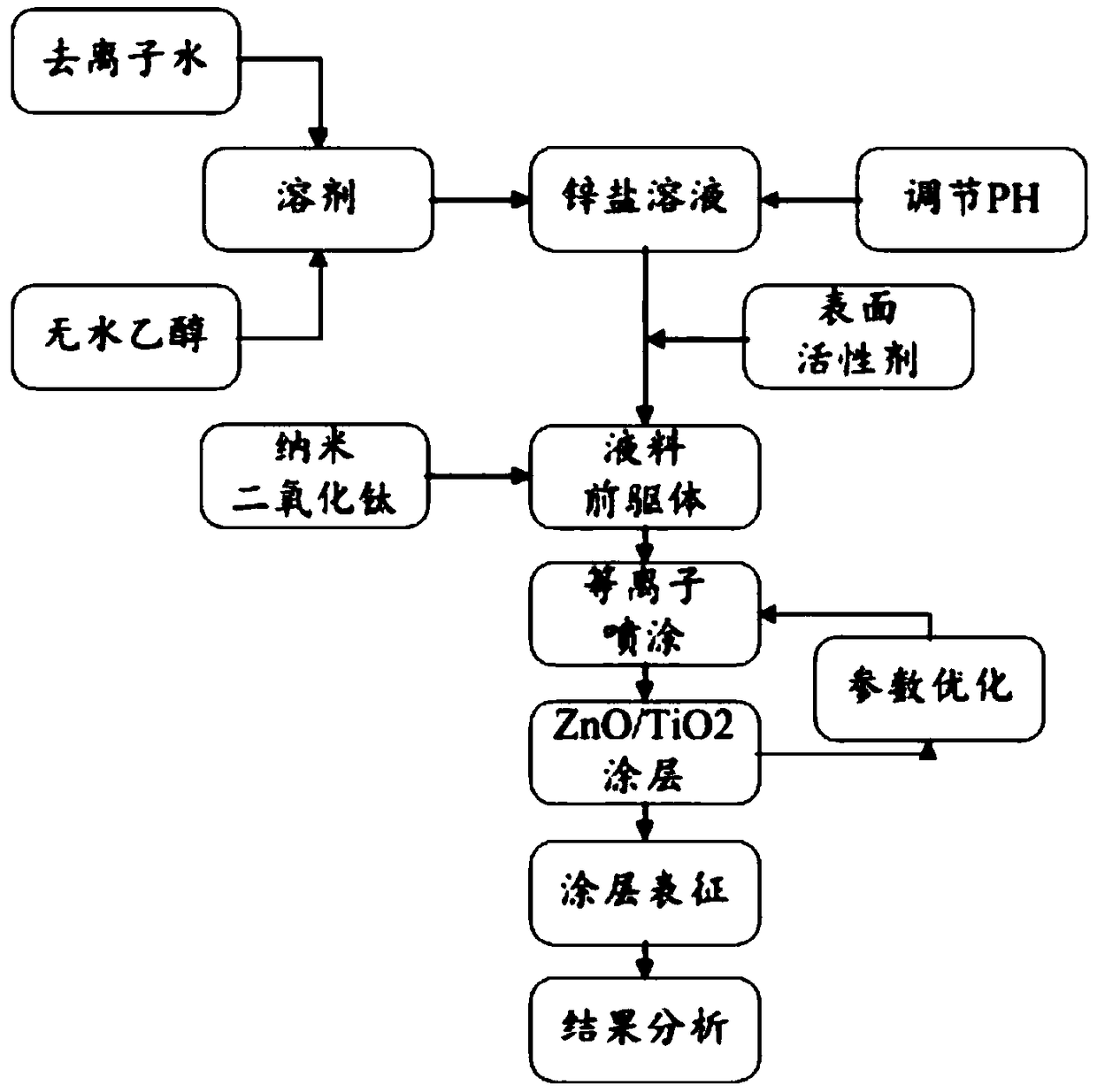

Embodiment 1

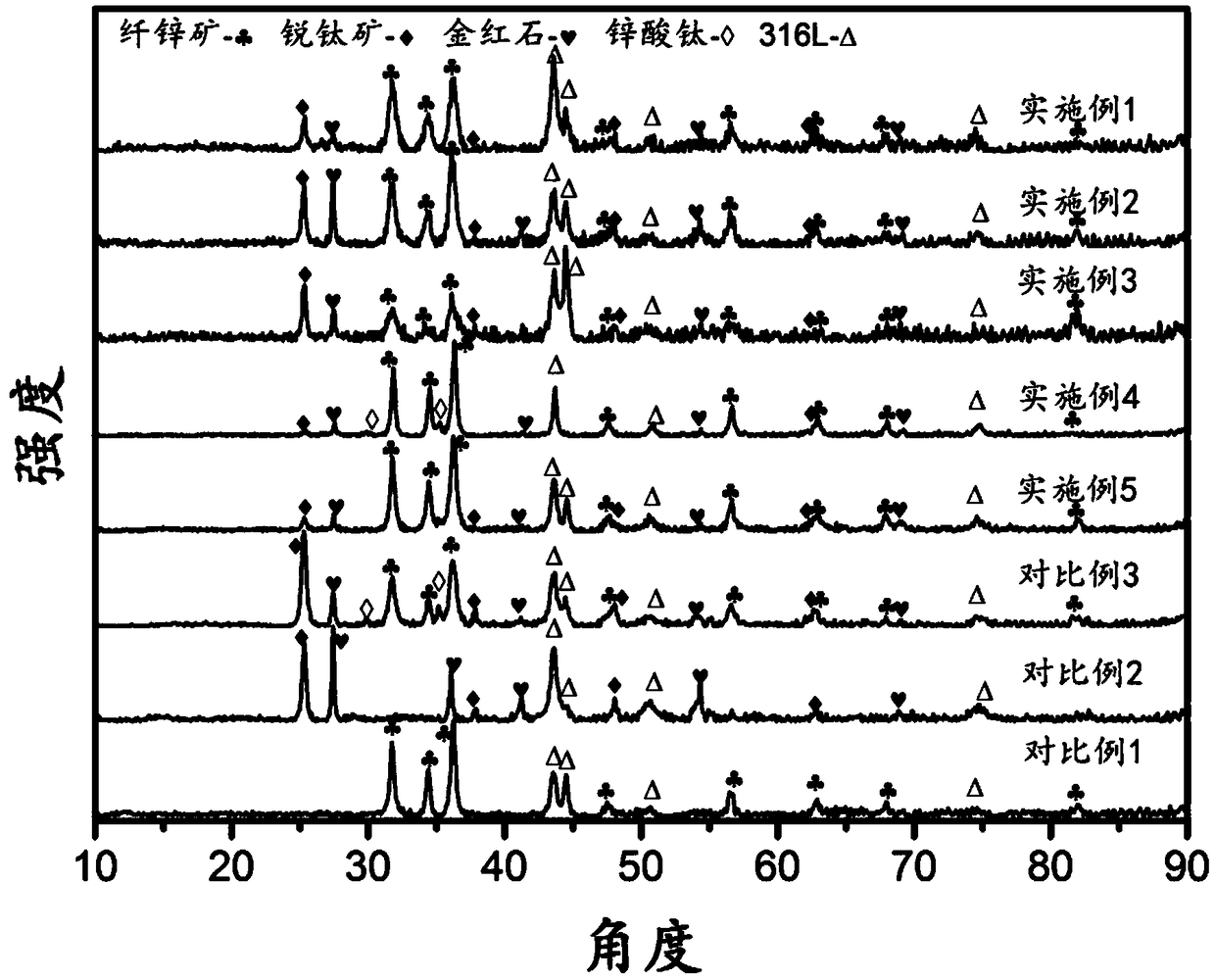

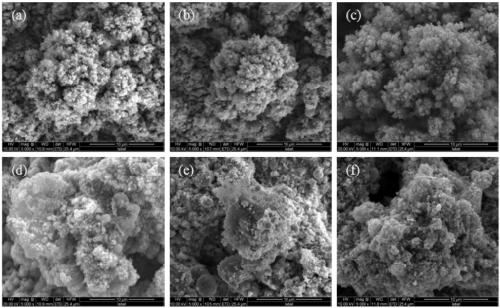

[0053] In this embodiment, the base material is selected as a 316L stainless steel sheet with a thickness of about 2mm, and the ZnO / TiO 2 The thickness of the composite coating is about 5 μm, where TiO 2 The mass ratio of ZnO to ZnO is 1:20, and the coating is a loose surface covered by stacking of ZnO crystal grains and P25 particles. In this example, using P25 as the raw material, after the plasma spraying process, the titanium dioxide particles in the coating are uniformly dispersed nanoparticles, accompanied by a small amount of submicron-sized particles obtained by heating, melting and sintering. The composite micro-nanostructured ZnO / TiO 2 The coating preparation process is as follows figure 1 As shown, the specific preparation method is as follows:

[0054] 1. First, commercially available Zn(CH 3 COO) 2 2H 2 O is added in dehydrated alcohol and deionized water equivolume ratio solvent, stir, be made into the zinc acetate solution of 0.5mol / L, adjust the pH value ...

Embodiment 2

[0060] In this embodiment, the base material is selected as a 316L stainless steel sheet with a thickness of about 2mm, and the ZnO / TiO 2 The thickness of the composite coating is about 5 μm, where TiO 2 The mass ratio of ZnO to ZnO is 1:10, and the coating is a loose surface formed by stacking ZnO grains and P25 particles, wherein the ZnO grain size ranges from 10 to 50nm. The composite micro-nanostructured ZnO / TiO 2 The specific preparation method is as follows:

[0061] 1. First, commercially available Zn(CH 3 COO) 2 2H 2 O is added to absolute ethanol and deionized water in equal volume ratio solvents, stirred evenly, and made into a 0.5mol / L zinc acetate solution, and the pH value of the above solution is adjusted to about 6 with glacial acetic acid. After the solution is clarified, the The tensio-active agent polyethylene glycol (PEG400) of zinc salt quality 0.18wt% joins in the solution, stirs, and Zn(CH 3 COO) 2 2H 2 O mass ratio is 3.6wt% nano titanium dioxide...

Embodiment 3

[0065] In this embodiment, the base material is selected as a 316L stainless steel sheet with a thickness of about 2mm, and the ZnO / TiO 2 The thickness of the composite coating is about 5 μm, where TiO 2 The mass ratio of ZnO to ZnO is 1:5, and the coating is a loose surface formed by stacking ZnO grains and P25 particles, wherein the ZnO grain size ranges from 10 to 50nm. The composite micro-nanostructured ZnO / TiO 2 The specific preparation method is as follows:

[0066] 1. First, commercially available Zn(CH 3 COO) 2 2H 2 O was added to solvents with an equal volume ratio of absolute ethanol and deionized water, stirred evenly, and made into a 0.5mol / L zinc acetate solution, and the pH value of the above solution was adjusted to 6 with glacial acetic acid. After the solution was clarified, zinc The surfactant polyethylene glycol (PEG400) of salt quality 0.36wt% joins in the solution, stirs, and Zn(CH 3 COO) 2 2H 2 The nano-titanium dioxide powder (P25) with a mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com