Production for positive electrode piece of cylindrical winding lithium-ferrite disulfide battery

A technology of iron disulfide battery and positive electrode sheet, which is applied in the direction of electrode manufacturing, etc., to achieve the effect of high capacity, low cost and excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

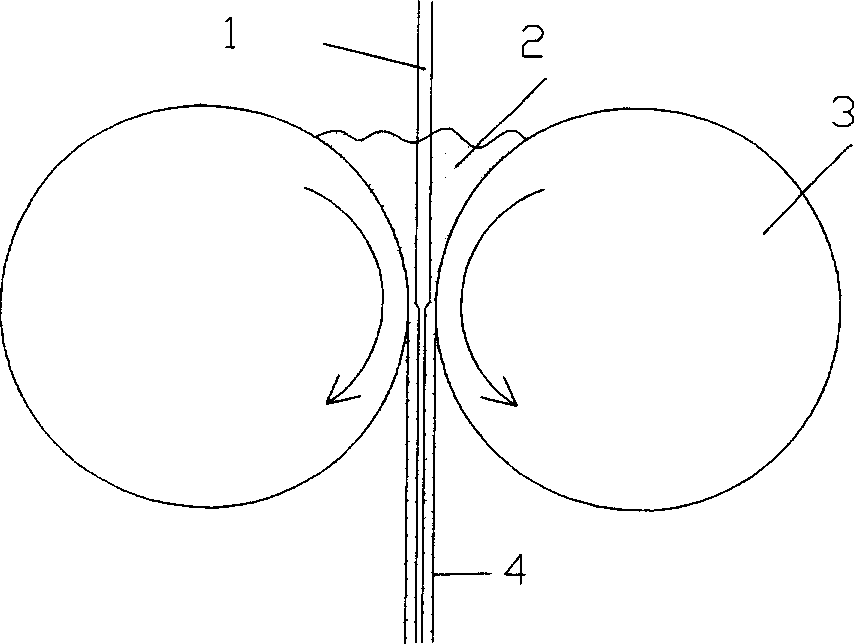

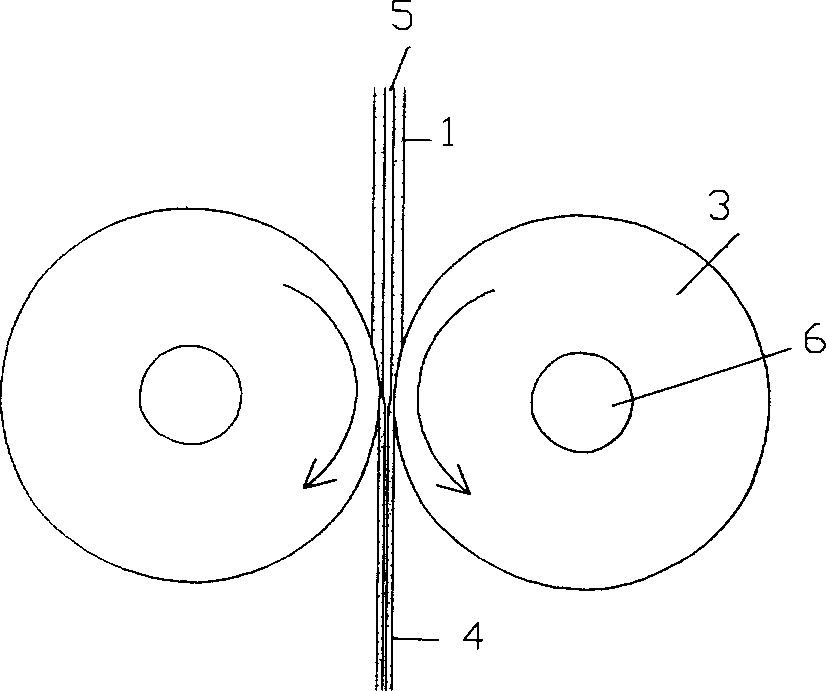

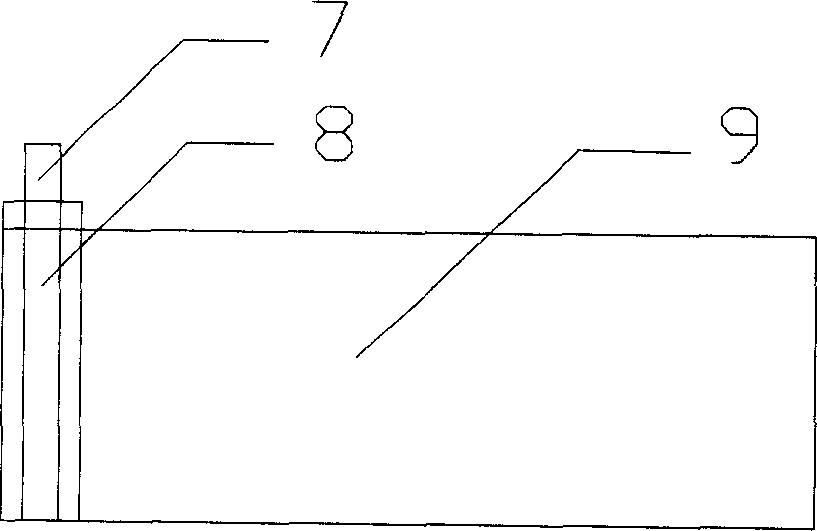

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0032] The positive electrode active material of the lithium-iron disulfide battery in this example is natural pyrite, which is crushed and sieved to make the particle size about 200 mesh, and baked in a high-temperature oven at 350°C with nitrogen for 10 hours , and then naturally cooled to below 50°C under the protection of nitrogen. Mix commercially available acetylene black (its apparent specific volume is about 11-16ml / g) with denatured alcohol at a ratio of 1:1, roll it on a double-roller machine to form a sheet, and then pass it through a 60-mesh mechanical vibrating sieve. The apparent specific volume reaches about 4ml / g. The above treated pyrite, acetylene black, graphite and additives were ball milled in a ball mill for 3 hours to form a uniformly mixed powder. Pour 37% industrial alcohol and 60% polytetrafluoroethylene emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com