Preparation method of lithium iron phosphate coated with lithium iron oxide

A technology of coating lithium iron phosphate and lithium ferrite, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of poor conductivity and low compaction density of lithium iron phosphate, and achieve high compaction density, The effect of low cost and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

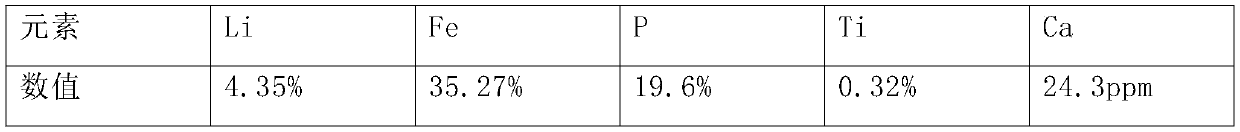

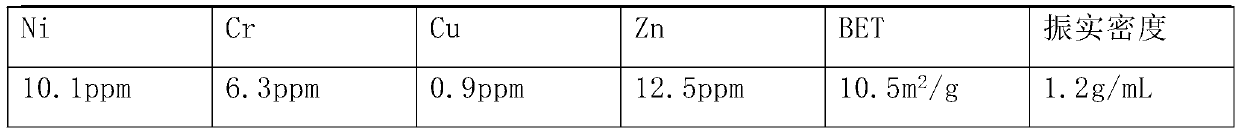

Embodiment 1

[0034] A preparation method for lithium iron phosphate coated lithium iron phosphate, comprising the following steps:

[0035] Add ferrous sulfate solution, lithium hydroxide solution, ammonium monohydrogen phosphate solution, and titanyl sulfate solution together into the high-pressure reactor, and under stirring conditions, hydrothermal reaction is carried out. The hydrothermal reaction temperature is 285°C and the pressure is 0.45MPa. The reaction was carried out for 5.5 hours, then the pressure was released and cooled, and the slurry was poured out; the concentrations of ferrous sulfate solution, lithium hydroxide solution, ammonium monohydrogen phosphate solution, and titanyl sulfate solution were 1.8mol / L, 1.5mol / L, 2.5mol / L and 0.8mol / L, ferrous sulfate and lithium hydroxide are battery grade, ammonium monohydrogen phosphate is food grade, titanyl sulfate is reagent pure, ferrous sulfate, lithium hydroxide, ammonium monohydrogen phosphate and The molar ratio of titanyl ...

Embodiment 2

[0050] A preparation method for lithium iron phosphate coated lithium iron phosphate, comprising the following steps:

[0051] (1) Add ferrous sulfate solution, lithium hydroxide solution, ammonium monohydrogen phosphate solution, and titanyl sulfate solution together into the autoclave, and conduct hydrothermal reaction under stirring conditions. The hydrothermal reaction temperature is 280°C and the pressure React at 0.5MPa for 6h, then release the pressure and cool, and pour out the slurry;

[0052] (2) Add the slurry obtained in step (1) into a dispersant, stir for 20 minutes, and use it as a bottom liquid, then prepare ferric chloride solution, ammonium bicarbonate solution and lithium hydroxide solution, and mix ferric chloride solution, ammonium bicarbonate solution and lithium hydroxide solution were added to the bottom solution in parallel, the pH of the feeding process was maintained at 7.5, the temperature was 50°C, and the feeding time was 3 hours. The lithium con...

Embodiment 3

[0063] A preparation method for lithium iron phosphate coated lithium iron phosphate, comprising the following steps:

[0064] (1) Add ferrous sulfate solution, lithium hydroxide solution, ammonium monohydrogen phosphate solution, and titanyl sulfate solution together into the autoclave, and perform hydrothermal reaction under stirring conditions. The hydrothermal reaction temperature is 295°C and the pressure React at 0.5MPa for 5.5h, then release the pressure and cool, and pour out the slurry;

[0065] (2) Add the slurry obtained in step (1) into a dispersant, stir for 25 minutes, and use it as the bottom liquid, then prepare ferric chloride solution, ammonium bicarbonate solution and lithium hydroxide solution, and under stirring conditions, ferric chloride Solution, ammonium bicarbonate solution and lithium hydroxide solution were added to the bottom solution in parallel, the pH of the feeding process was maintained at 7.3, the temperature was 50°C, and the feeding time wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com