Patents

Literature

149results about How to "Anti-wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slurry feed line steel with good low-temperature toughness and manufacturing method thereof

InactiveCN102400039AGood welding performanceImprove low temperature impact toughnessTemperature control deviceSlurryPearlite

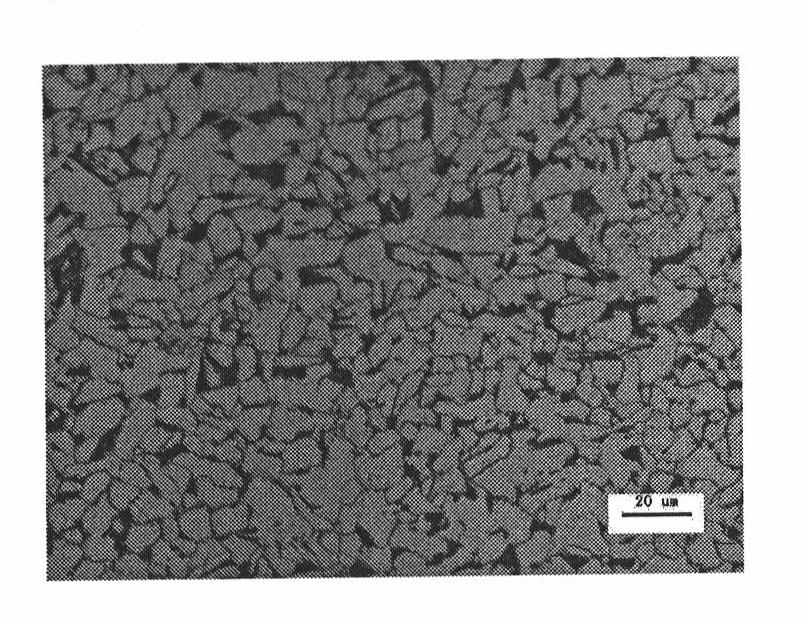

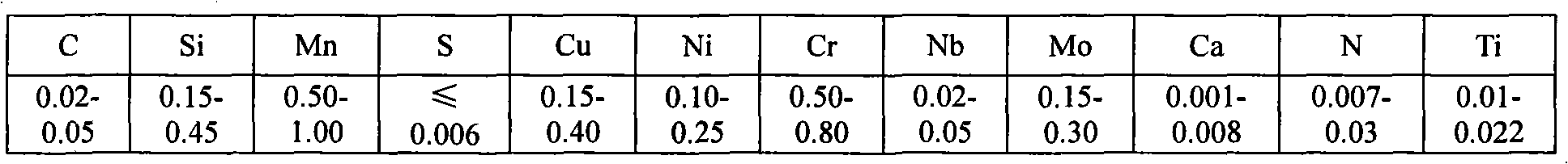

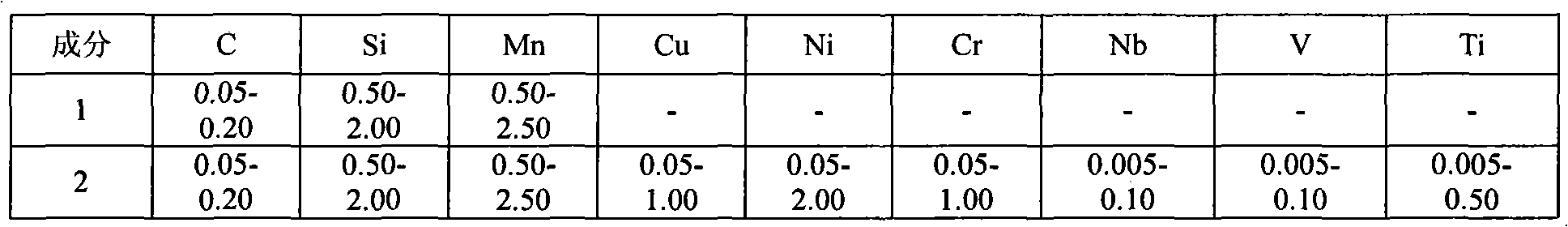

The invention provides slurry feed line steel with good low-temperature toughness and a manufacturing method thereof. The slurry feed line steel with good low-temperature toughness comprises 0.10 to 0.20% of C, 0.10 to 0.30% of Si, 0.80 to 1.50% of Mn, less than or equal to 0.018% of P, less than or equal to 0.004% of S, 0.010 to 0.035% of Ti, 0.02 to 0.05% of Als, less than or equal to 0.006% of N and the balance Fe. The manufacturing method of the slurry feed line steel with good low-temperature toughness comprises smelting, continuous casting and hot rolling. When a plate blank is heated to a temperature of 1160 to 1300 DEG C, the plate blank is subjected to a first-stage controlled rolling and a second-stage controlled rolling, wherein an initial temperature of the first-stage controlled rolling is in a range of 1130 to 1200 DEG C; an end temperature of the first-stage controlled rolling is above 1020 DEG C; an initial temperature of the second-stage controlled rolling is below 1000 DEG C; and an end temperature of the second-stage controlled rolling is in a range of 780 to 880 DEG C. The plate blank subjected to the first-stage controlled rolling and the second-stage controlled rolling is cooled at a speed of 5 to 20 DEG C per second and then is reeled at a temperature of 550 to 680 DEG C. The manufacturing method of the slurry feed line steel with good low-temperature toughness has the advantages that the slurry feed line steel with good low-temperature toughness does not contain precious alloy elements such as Nb, Mo, V and the like so that an alloy cost is low; S content and P content are controlled strictly so that good low-temperature toughness of steel is guaranteed effectively; and a controlled rolling and controlled cooling technology is utilized for crystal particle refinement so that a pearlite microstructure is uniformly distributed and good steel strength matching with toughness is guaranteed.

Owner:ANGANG STEEL CO LTD

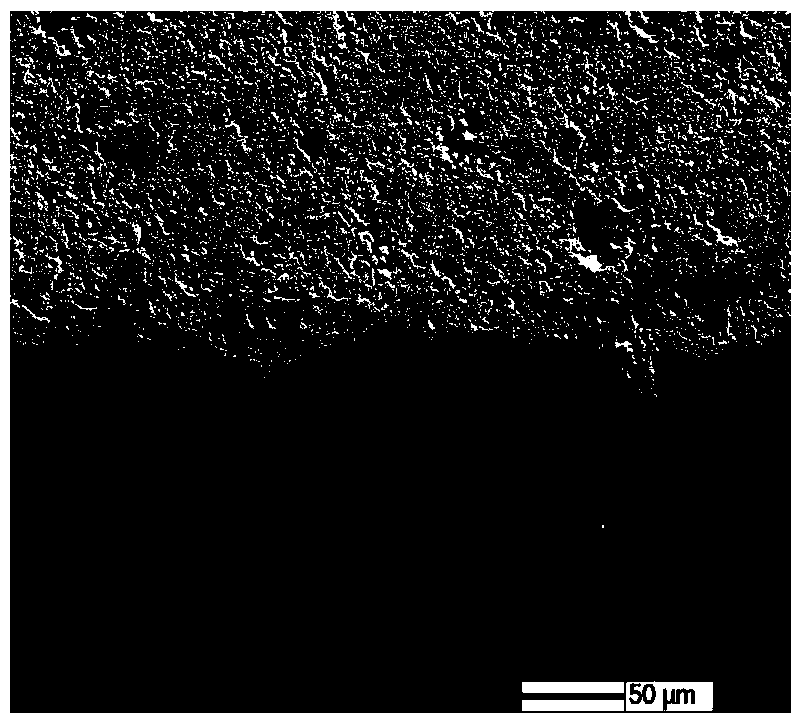

Anti-abrasion and anti-corrosion composite functional coating layer

The invention belongs to the technical field of thermal-sprayed coating layers and relates to a composite functional coating layer capable of resisting abrasion and corrosion. The coating layer consists of the chemical components such as NiCrAlY alloy powder, metallurgical TiC powder and rare-earth oxide La2O3 powder, wherein the adding amount of the NiCrAlY alloy powder accounts for 49.5-80 percent of the weight of the powder of the whole coating layer; the adding amount of the metallurgical TiC powder accounts for 19.5-50 percent of the weight of the materials of the coating layer; the adding amount of the rare-earth oxide La2O3 powder accounts for 0.5-5 percent of the weight of the materials of the coating layer. Metallurgical combination is realized, so that the bonding strength of the coating layer is high, and organization is compact; therefore, compared with the common coating layer, the coating layer has the advantages that the abrasion resistance and the corrosion resistance are greatly improved. The coating layer disclosed by the invention is processed by a plasma composite spraying technology such as laser and atmosphere instead of an independent thermal spraying technology; in order to fulfill the aim of realizing coating layer metallurgical combination, due to the metallurgical combination, the coating layer combining strength can be improved, and the high compactness of the organization of the coating layer is realized; due to the high combining strength and the low porosity, the coating layer is long in service life and high in abrasion resistance and corrosion resistance.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

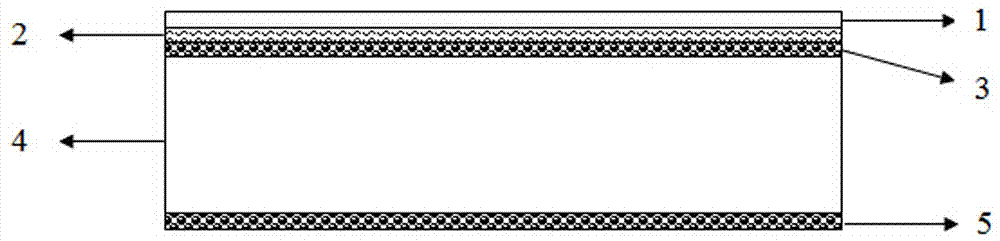

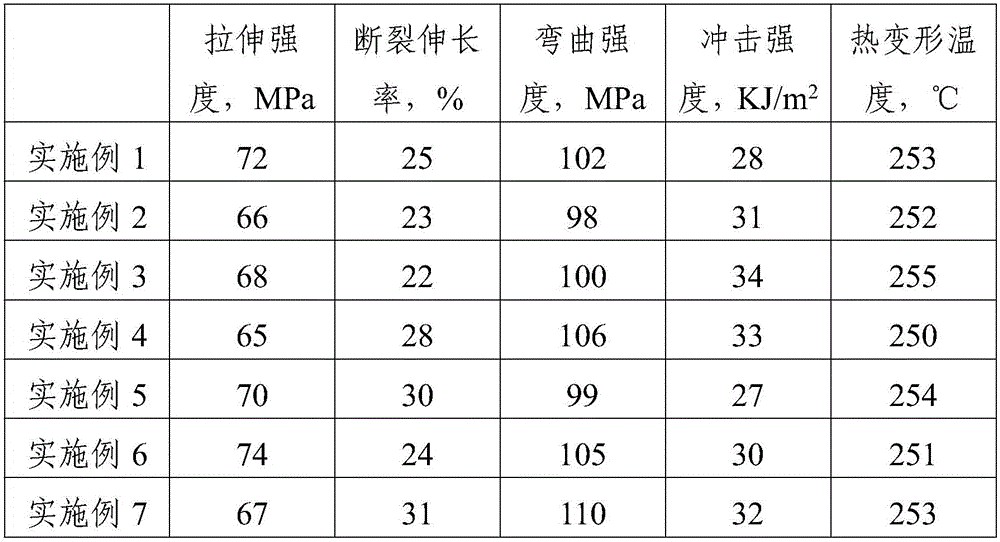

Composite board and preparation method thereof

PendingCN107571577AStrong impact resistanceHigh mechanical strengthLamination ancillary operationsSynthetic resin layered productsSurface layerAdhesive

The invention discloses a composite board, comprising a composite layer, an upper adhesive layer and a lower adhesive layer respectively bonded with the upper and lower surfaces of the composite layerto form an integral body with the composite layer, and a functional surface layer bonded with the upper surface of the upper adhesive layer to form an integral body with the upper adhesive layer. According to the invention, the upper adhesive layer and the lower adhesive layer respectively cover the upper and lower surfaces of the composite layer, and the functional surface layer is laminated with the upper surface of the upper adhesive layer via a film spraying method, so the prepared composite board has excellent impact resistance and the advantages of high mechanical strength, ageing resistance, scratch resistance, etc.; meanwhile, the functional surface layer endows the composite board with unique appearance and functionality; moreover, since one part of the upper adhesive layer is embedded into the upper surface of the composite layer and another part of the upper adhesive layer is embedded into the lower surface of the functional surface layer, such mechanical bonding can improve peeling strength between the functional surface layer and the composite layer; and the lower adhesive layer may be embedded into the lower surface of the composite layer so as to realize bonding between the composite board and other materials.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

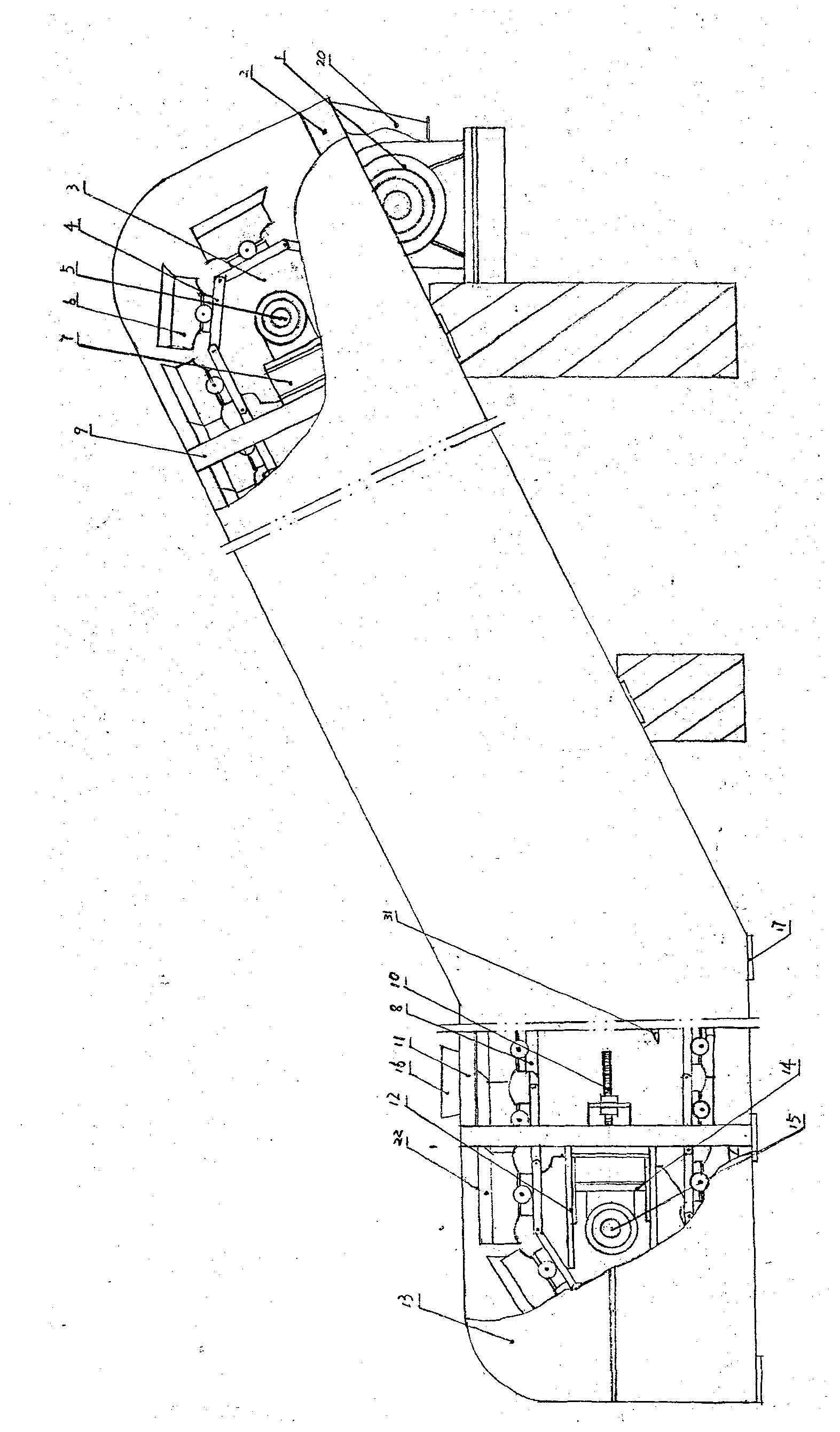

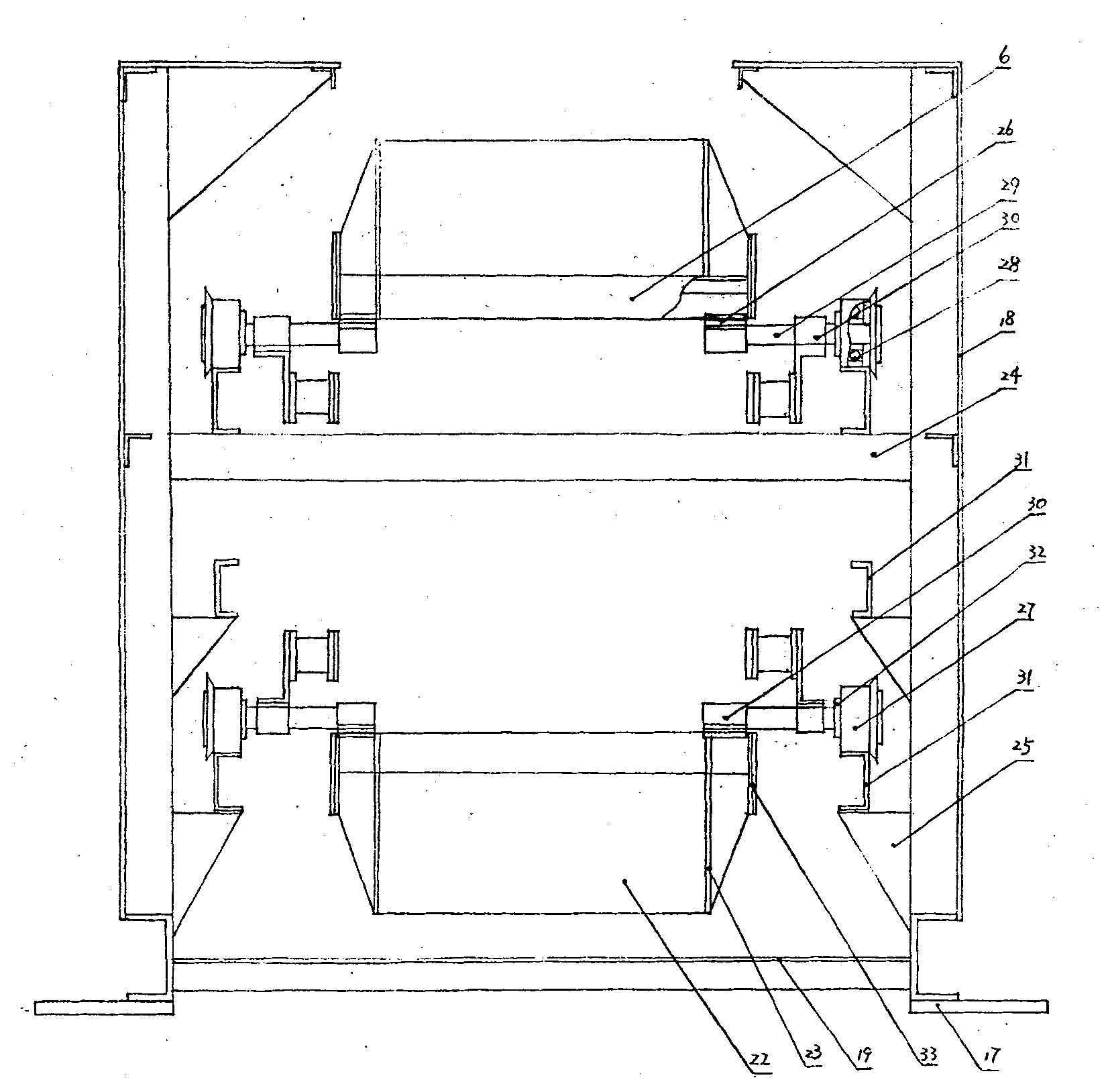

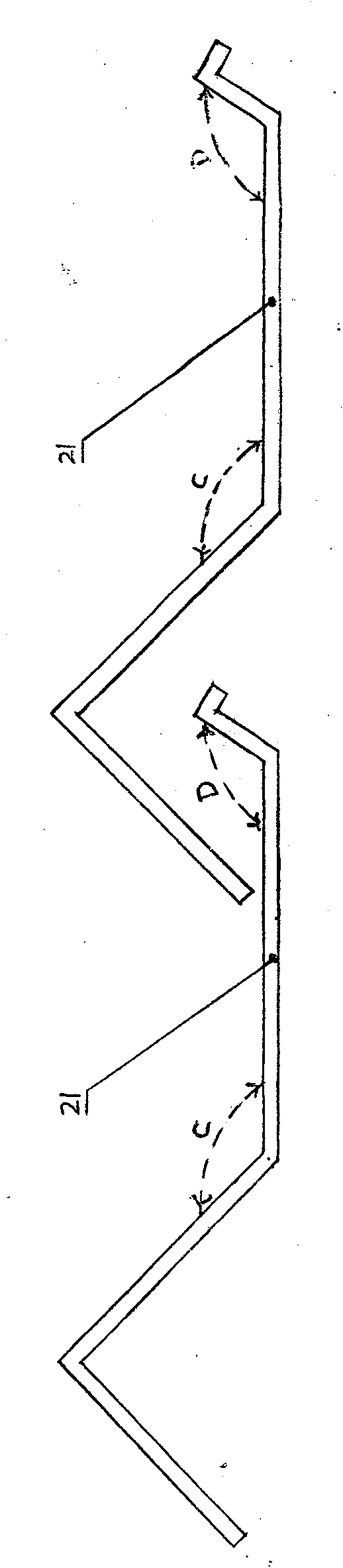

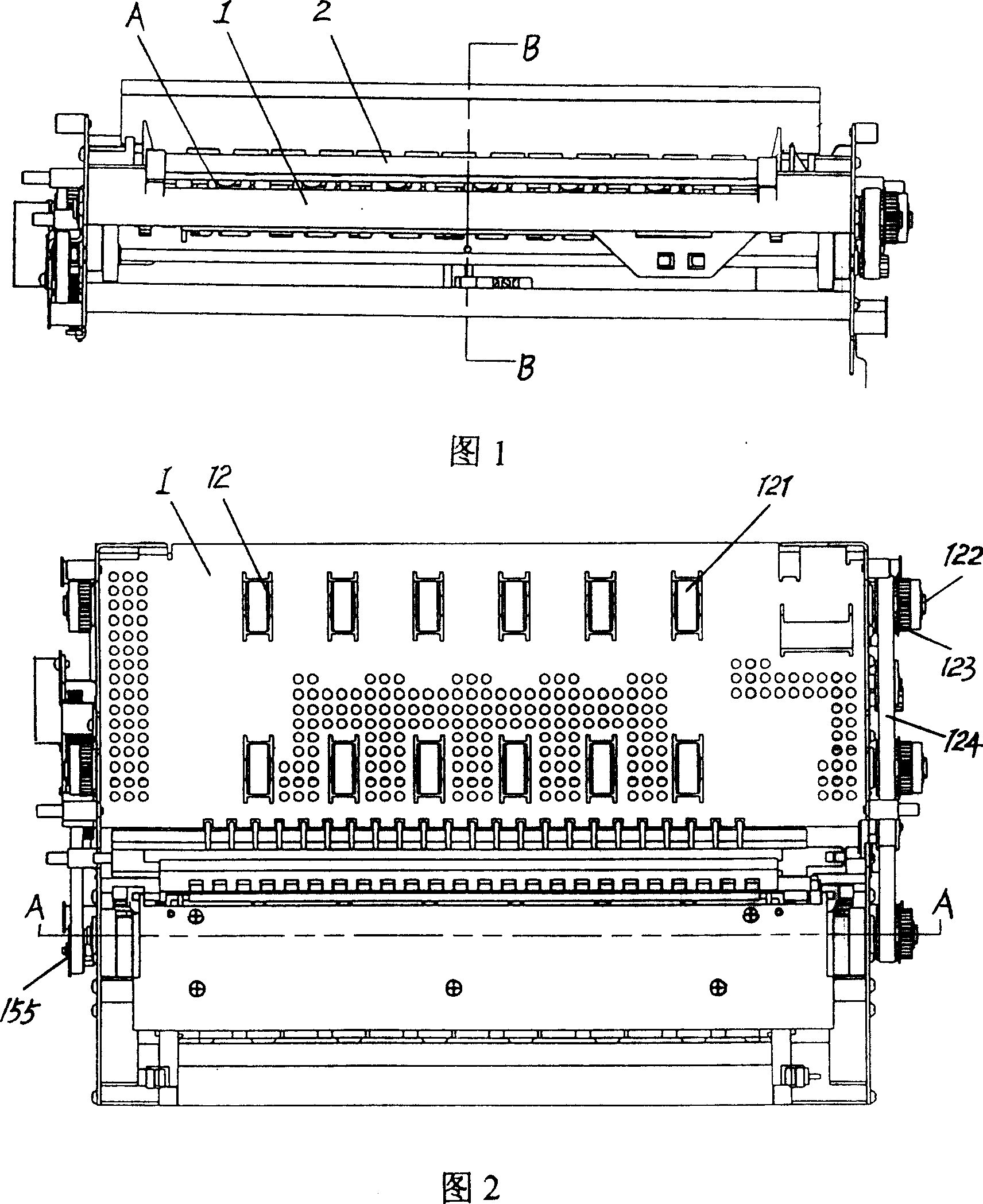

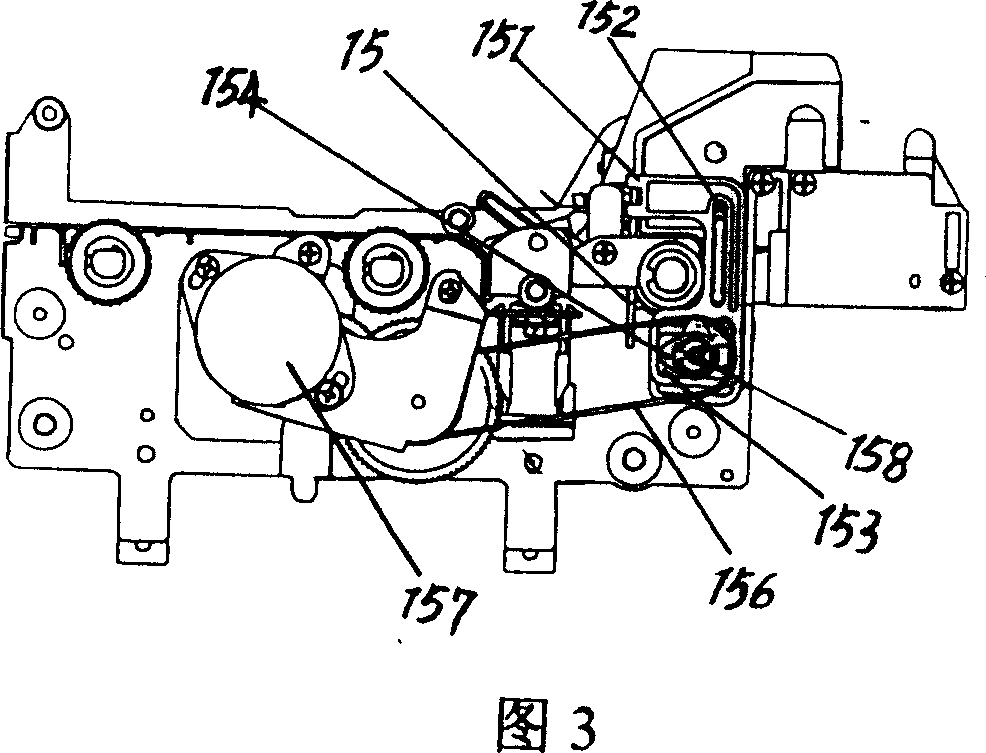

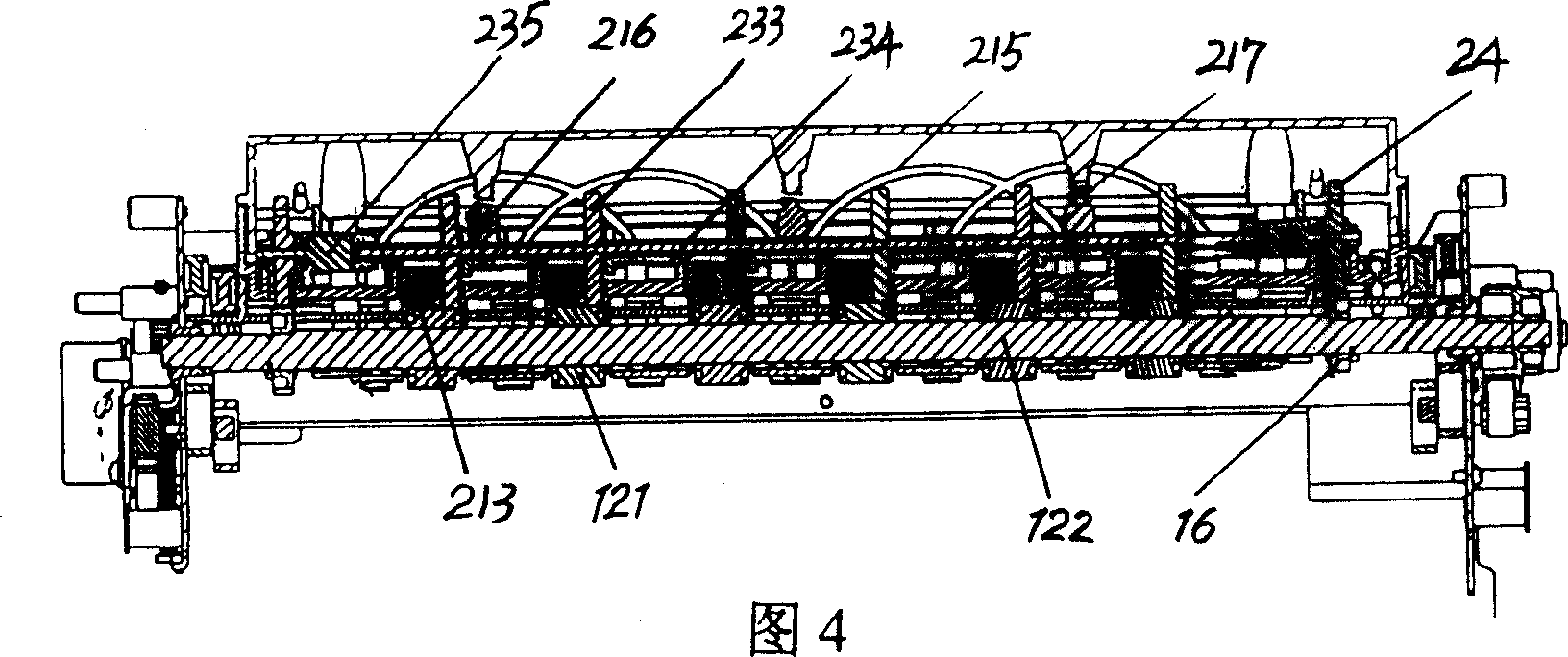

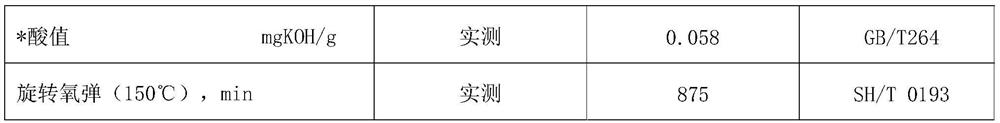

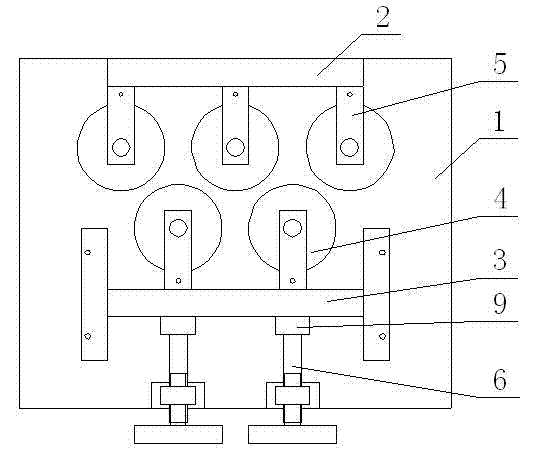

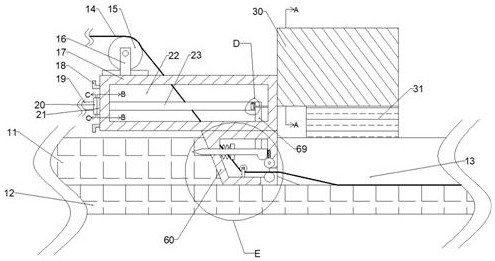

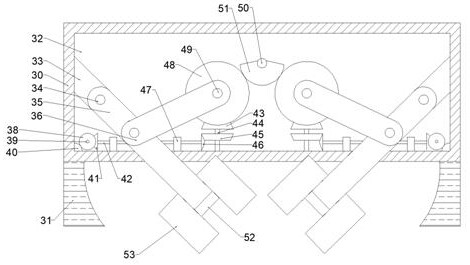

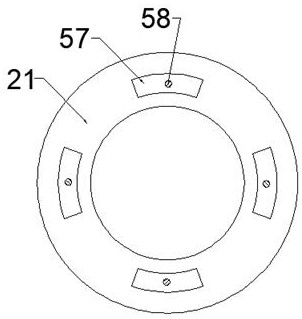

Multi-functional diamond disk material conveying machine

The invention discloses a multi-functional diamond disk material conveying machine, and relates to the technical field of designing and manufacturing of conveying machinery. The multi-functional diamond disk material conveying machine consists of a drive assembly, a bracket frame, a rail, a transmission chain, diamond disks, material bearing frames, a chain adjusting assembly, a shaft, a bearing seat, a feed and discharge hopper, a bearing, a band-edge roller, a protective plate, a pin, a positioning component, a wheel fixing component and a base plate, wherein the diamond disks are installedin the mode of completely covering small uplift bodies by large uplift bodies on the connection positions of two adjacent diamond disks; a conveying transmission mode is bearing and roller transmission; each diamond disk consists of a material blocking plate and a material loading panel, the material bearing frames are arranged on the diamond disks, and the material loading panel is provided withthree construction modes. The material conveying machine has the technical characteristics of wear resistance, heat resistance, jamming resistance, can convey material leakage resistance and strong adaptability, powder materials, bag materials, block materials whose particle sizes are less than 300 mm and multiple materials whose temperature is within 500 DEG C, has the minimum conveying capacityof 10 T / h, and the maximum conveying capacity or over 2000 T / h.

Owner:夏才明

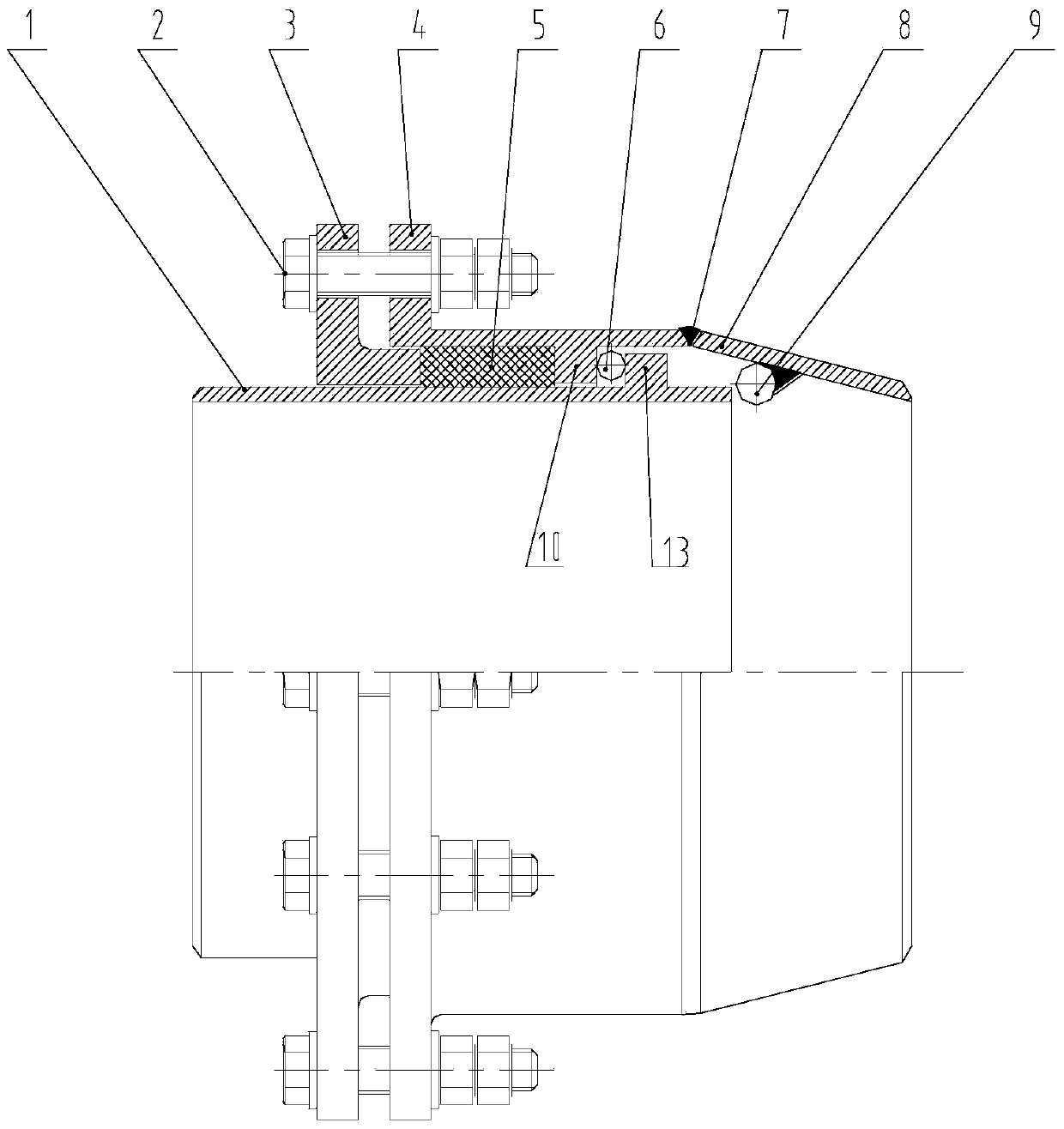

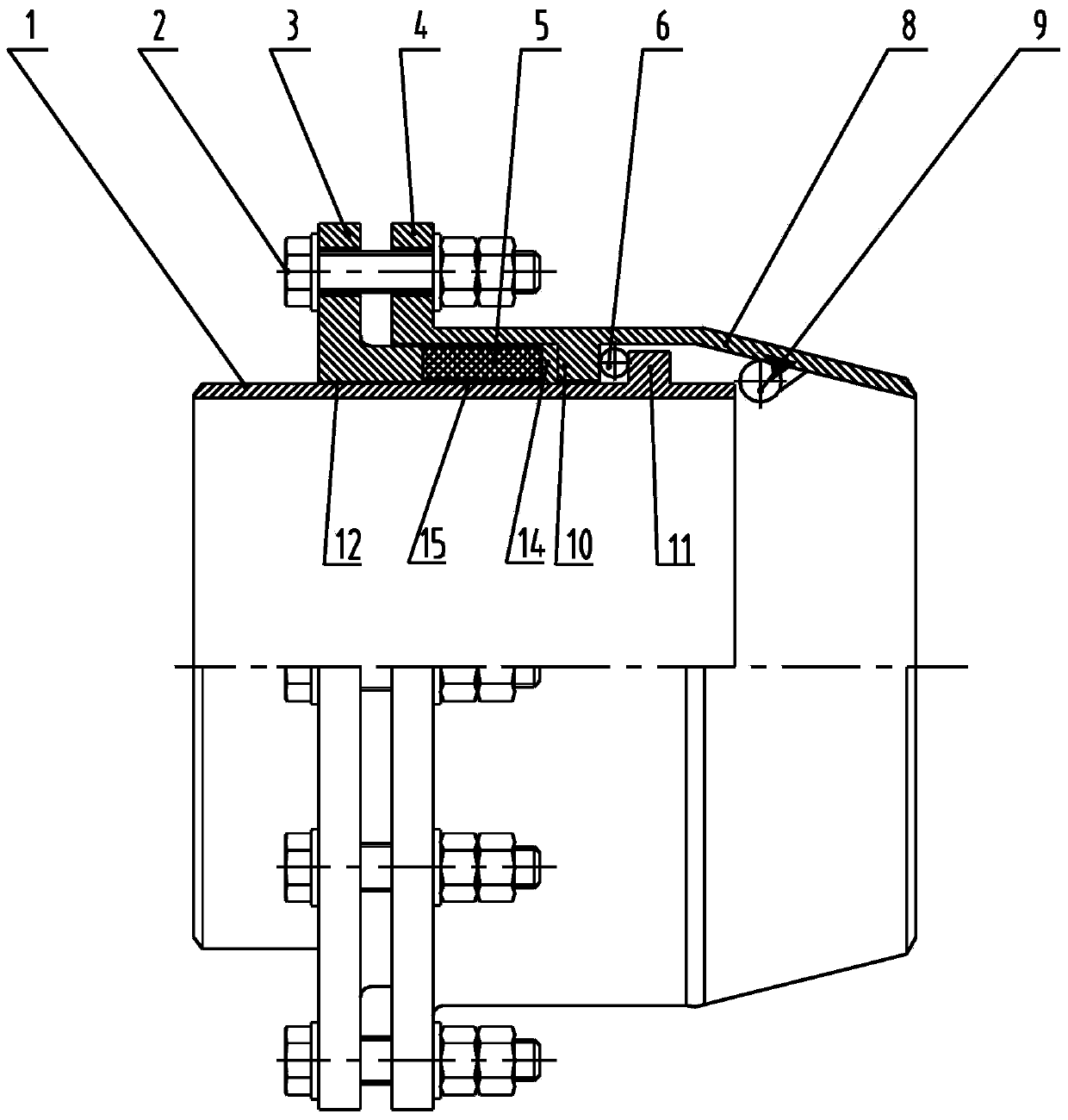

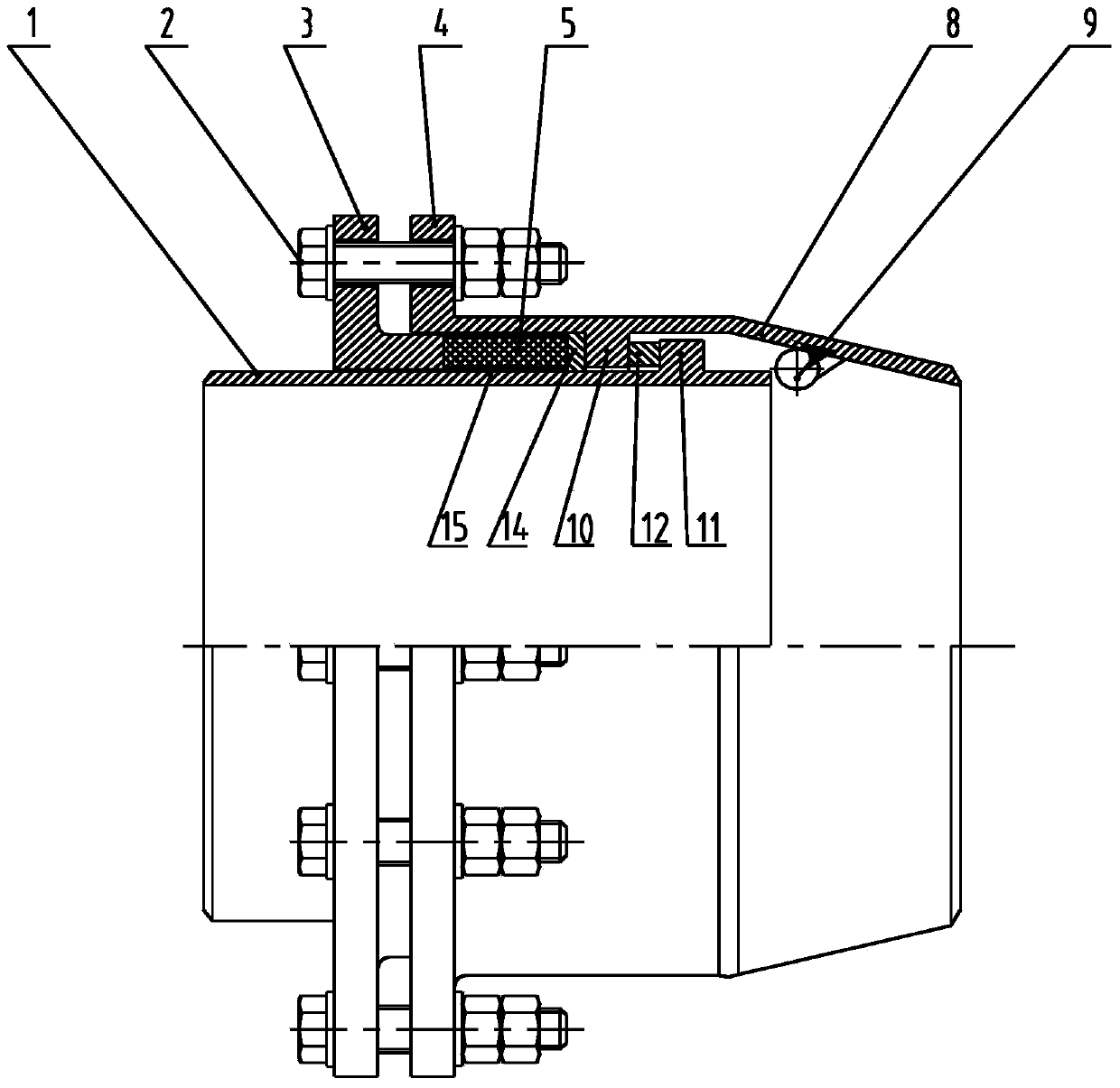

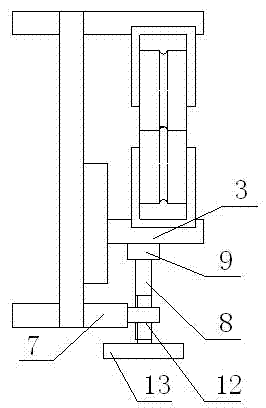

High-pressure-resistant integrated leakage-free rotating compensator

ActiveCN103994296AQuality improvementImprove securitySleeve/socket jointsPipeline expansion-compensationOuter CannulaHigh pressure

The invention relates to a high-pressure-resistant integrated leakage-free rotating compensator. The high-pressure-resistant integrated leakage-free rotating compensator comprises an inner pipe, an outer sleeve, a connecting pipe and a filler flange. The outer sleeve is arranged on the inner pipe in a sleeved mode. One end of the inner pipe penetrates through the outer sleeve to be inserted into the connecting pipe. The filler flange is arranged on the inner pipe in a sleeved mode. One end of the filler flange extends into the outer sleeve. An annular inner boss is arranged on the inner surface of the outer sleeve. The portion between the annular inner boss and the end, extending into the outer sleeve, of the filler flange is arranged on gland packing. The outer sleeve and the connecting pipe are of an integrally-formed integrated structure. An anti-impact plate is arranged between the gland packing and the annular inner boss. An abrasion-resistant carbon fiber layer is arranged between the gland packing and the outer surface of the inner pipe. An abrasion-resistant carbon fiber layer is arranged between the gland packing and the inner surface of the outer sleeve. The high-pressure-resistant integrated leakage-free rotating compensator thoroughly solves the problems that due to an existing welding method, weld joint flaw inspection can be hardly conducted and even can not be detected. Meanwhile, by arranging the abrasion-resistant carbon fiber layers and the anti-impact plate, loss of sealing material can be effectively reduced, and the sealing performance of the whole rotating compensator is improved.

Owner:JIANGSU BT PIPE CO LTD

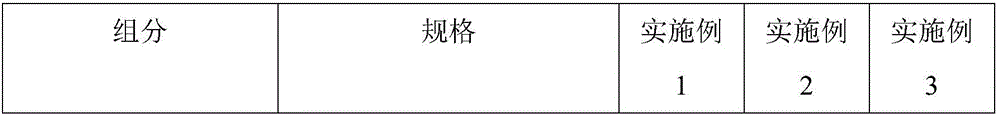

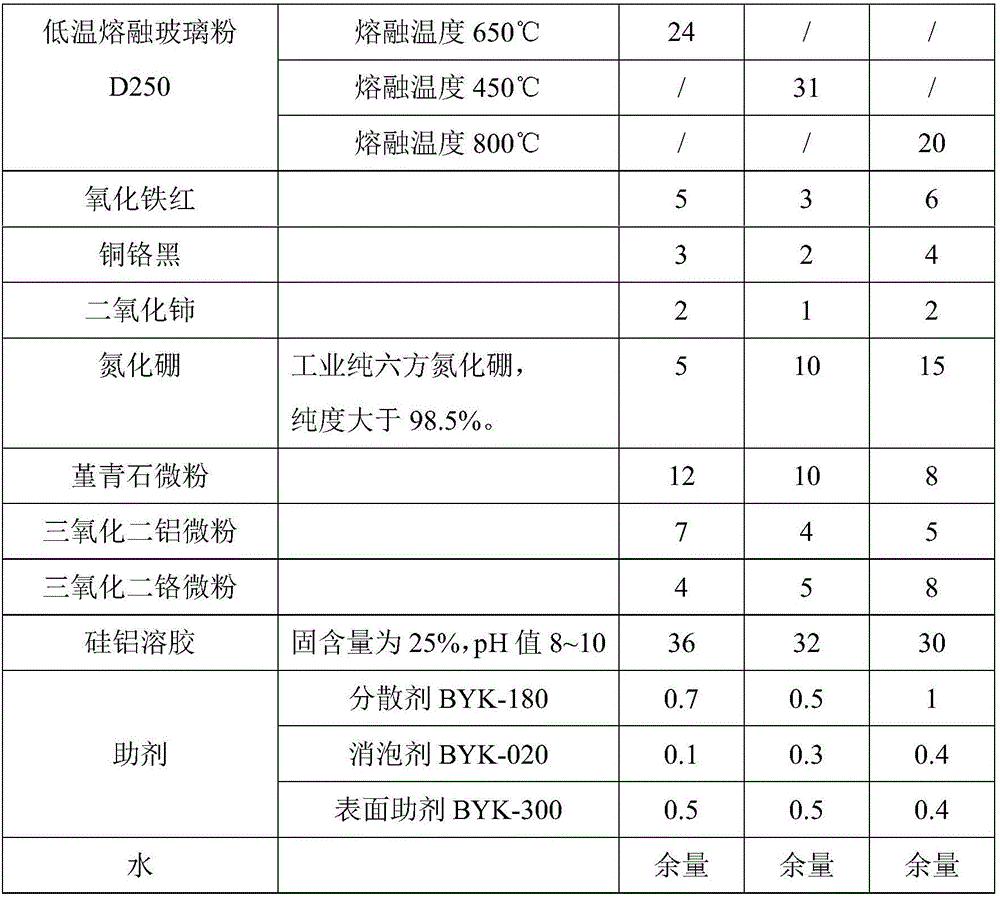

Low-temperature sintering high-heat conduction ceramic paint suitable for metal base material and preparation method and application thereof

The invention discloses a low-temperature sintering high-heat conduction ceramic paint suitable for metal base material and a preparation method and an application thereof. The paint comprises the following raw materials: low-temperature molten glass powder, iron oxide red, copper-chrome black, cerium dioxide, boron nitride, iolite micro powder, alumina micro powder, chromium sesquioxide micro powder, 20-50% of silicon aluminium sol, 0.5-3% of an auxiliary agent, and the balance of water. The method comprises the following steps: a metal matrix is processed, then the surface of the metal matrix is uniformly coated with a paint and dried in shade; and the coated metal matrix is heated at the temperature of 650-900 DEG C to form the low-temperature sintering high-heat conduction ceramic paint. The paint has the advantages of easy acquisition of the raw materials and low cost, is tightly combined with the metal matrix, has effective high temperature oxidation resistance, acid corrosion resistance and abrasion resisting effects of a heating furnace flue heat exchanger on a metal heat exchanger, ceramic coating surface is smooth and clean, slag buildup of the heat exchanger is effectively reduced, the service life of the metal heat exchanger is prolonged, and the heat exchange efficiency effect is increased.

Owner:武汉钢铁有限公司

Lubricating oil composition

One lube oil compound with the quality of oxidation resistance, abrasive resistance, and anti-attrition, based on total weight of the compound, includes the following components: (a) zinc salt, ntoquita nantokite, magnesium salts, calcium salt and barium salt of dialkyl phosphorodithioic acid, the content is 0.1-3.5%; (b) compound antioxidant of amine antioxidant and phenolic ester antioxidant, the content is 0.2-3.0%; (c) molybdenum salt of dialkyl dithioic organic acid, the content is 0.05-1.5%; (d) monohydric or polyhydric alcohol ester with abrasive resistance and anti-attrition produced by monohydric alcohol or diatomic alcohol and alkyl, arene or alkyl phenol in place of carboxylic acid, the content is 0.05-1.5%; (e) zinc salt, sodium salt, magnesium salts, calcium salt and barium salt dialkyl dithiocarbamate or dialkyl dithiobenzoic acid, the content is 0.05-1.5%; (f) grease oil, the residue.

Owner:CHINA PETROLEUM & CHEM CORP +1

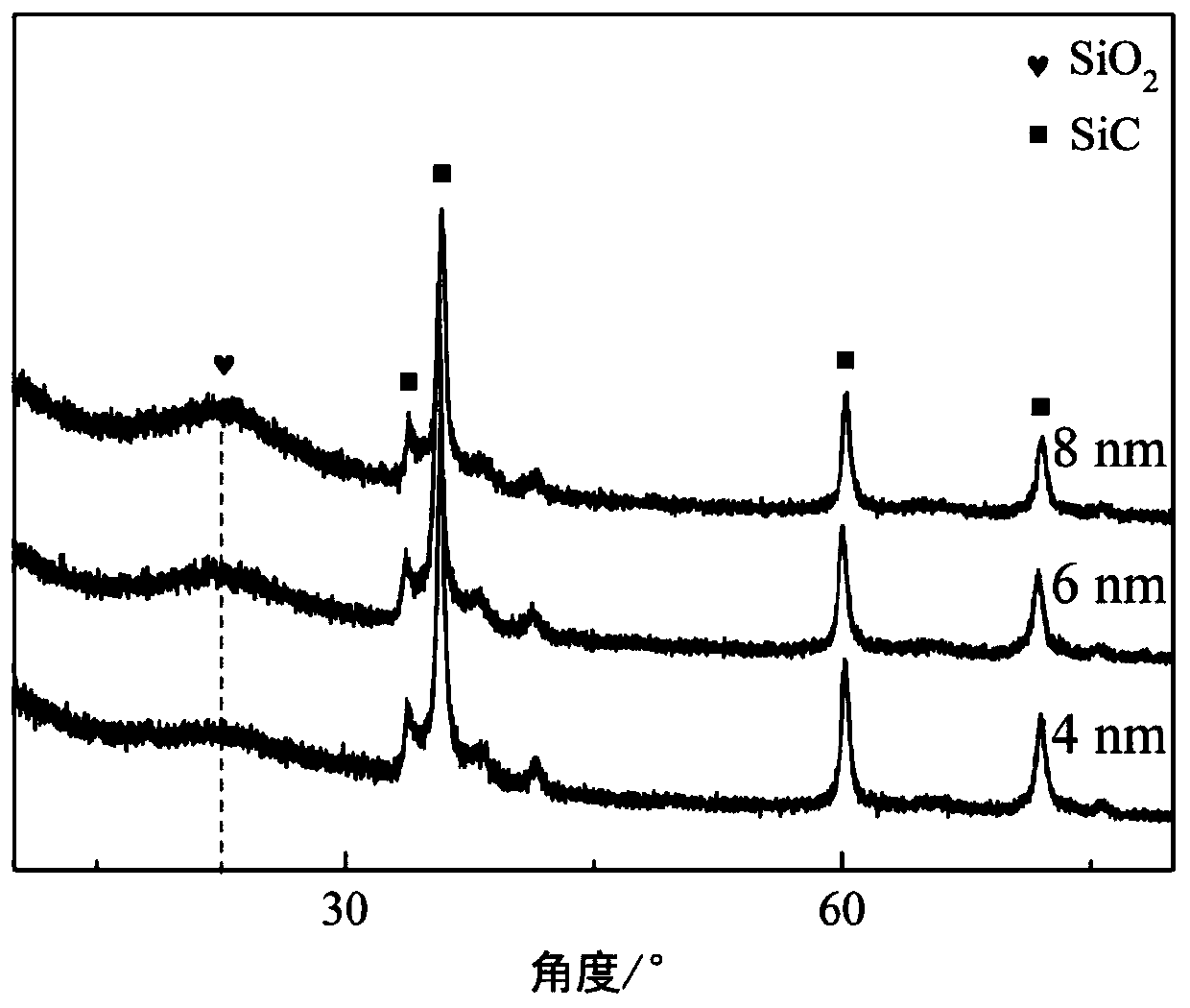

Sic@SiO<2> core-shell-structured nanofiller/epoxy resin-based composite material and preparation method thereof

InactiveCN110938288AGood nonlinear conductance characteristicsExcellent nonlinear conductance characteristicsPlastic/resin/waxes insulatorsEpoxyBreakdown strength

The invention relates to a SiC@SiO2 core-shell-structured nanofiller / epoxy resin-based composite material and a preparation method thereof, belonging to the technical field of high-voltage dielectricinsulating materials. To overcome the problem that a nonlinear insulating material is low in breakdown strength, the invention provides the SiC@SiO2 core-shell-structured nanofiller / epoxy resin-basedcomposite material. The material is doped with 5 wt% of a SiC@SiO2 core-shell-structured nanofiller, wherein the nanofiller uses nanometer SiC particles as a core layer, and the core layer is coated with a SiO2 shell layer with a thickness of 6 nm. According to the invention, the epoxy resin composite material obtained after doping of the core-shell-structured inorganic nanofiller with a low filling amount still has excellent nonlinear conductivity along with the rise of temperature; and moreover, the breakdown strength of the epoxy resin is remarkably improved, so the composite material can work safely under severe conditions, and has wide application prospects in the technical field of high-voltage dielectric insulating materials.

Owner:HARBIN UNIV OF SCI & TECH

Adhesive mortar for ceramic tile

The invention relates to a mortar and provides an adhesive mortar for a ceramic tile. The adhesive mortar for the ceramic tile contains tailings, is high in tensile adhesive strength and low in cost, does not pollute the environment, and has a heat preservation effect. The adhesive mortar for the ceramic tile comprises the following materials in parts by weight: 30-35 parts of ecological cement, 0.5-0.6 part of polyving akohol, 30-50 parts of tailings, 5-10 parts of polypropylene monofilament, 1.3-2.8 parts of a defoamer, 12-17 parts of a water reducer, 17-19 parts of coal ash, 7-9 parts of glass bead, 21-32 parts of ceramic sand, 1.5-2.5 parts of cellulose ether, 4-8 parts of redispersible powder and 70-90 parts of water, wherein the ceramic sand comprises sand grains with the grain diameters of 0.10-2.0 mm and with a plurality of pores not communicated in the surfaces.

Owner:荣达新型建材(福建)集团有限公司

Composite structure coating and spraying method thereof

ActiveCN101613852AAccelerated corrosionImprove high temperature wear resistanceMolten spray coatingStellite alloyFunctional composite

The invention discloses a composite structure coating which is characterized by comprising a stellite alloy layer coated on the surface of a roller body, a MoB / CoCr metal ceramic layer coated on the surface of the stellite alloy layer and a barrier layer arranged on the surface of the MoB / CoCr metal ceramic layer. In the invention, the functional composite structure coating manufactured by the thermal spraying technology and special coating after being subjected to hole sealing can ensure single use time and accumulative service life of a sinking roller and stable roller to be increased by 1-3 times of roller bodies without coatings, so that steel plants improve use efficiency of high value roller bodies, thus improving production efficiency and product quality.

Owner:SHANGHAI JUSN SURFACE TECH ENG +1

Application technology of nano additive for lubricating oil

The invention relates to an application technology of a nano additive for lubricating oil. The nano materials with characteristics of wear resistance, friction resistance and extreme pressure activity such as nano rare earth, metals, a metal oxide and carbon series nano-materials are taken as lubricating oil additives, the tribological property, the energy saving performance and environmental protection performance of different types of nano-materials which are taken as the lubricating oil additives can be researched, thereby 3-5 types of novel composite nano lubricating oil additives with characteristics of good friction resistance, wear resistance, machinery life prolongation, environmental protection and energy saving can be screened.

Owner:李红

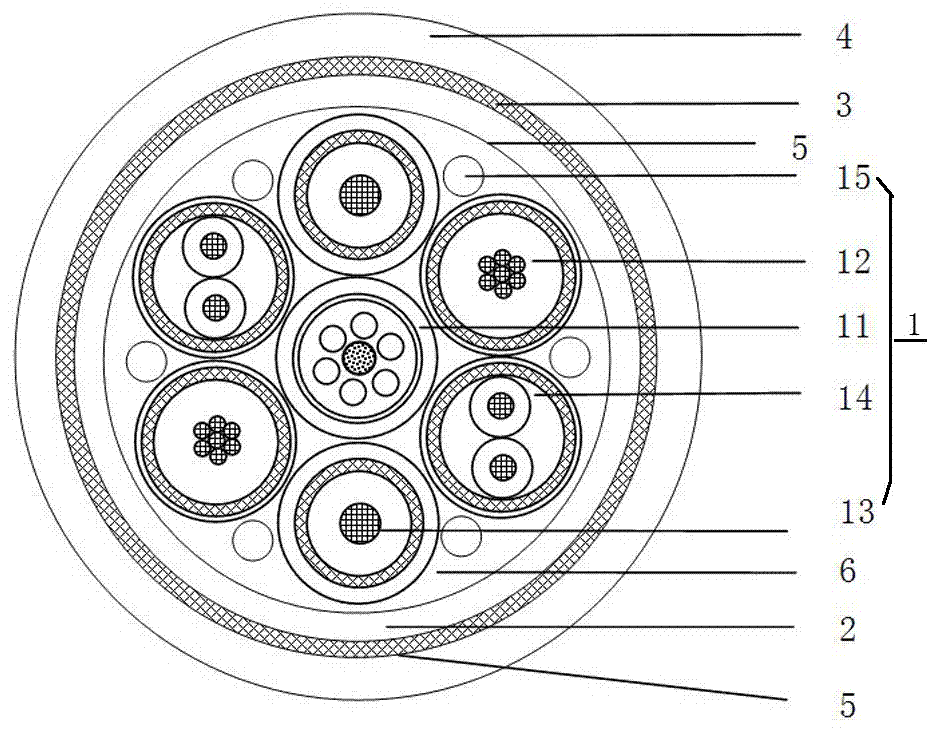

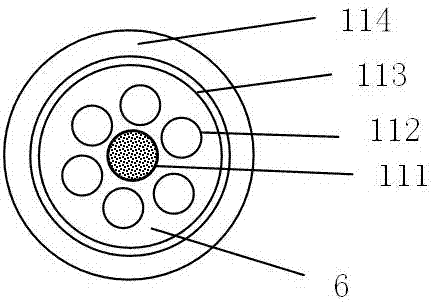

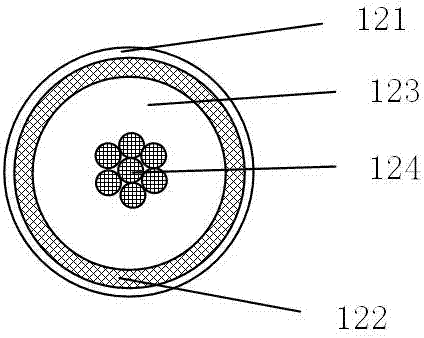

Total cross-section water-stop sealing multi-signal composite cable and preparation technique thereof

PendingCN107958724ARich varietyLarge transmission capacityNon-insulated conductorsInsulated cablesRadio frequencyCoaxial line

The invention discloses a total cross-section water-stop sealing multi-signal composite cable including a cable core, an inner protection layer, a shielding layer and an outer protection layer. The cable core is externally provided with a wrapping tape. The inner protection layer and the outer protection layer are formed outside the wrapping tape through extrusion. The shielding layer is formed ina braiding manner between the outer protection layer and the inner protection layer. A wrapping tape is also arranged between the shielding layer and the outer protection layer. The cable core is formed by twisting an optical unit, a power line, a coaxial line, a twisting pair and a filler rope in a spiral manner. The twisting gap of the cable core and the gap in the shielding layer are both filled with filler glue. Each of the power line, the coaxial line, the twist pair and the outer protection layer in the composite cable is therein provided with a braided shielding layer, water-resistingand wear-resisting chemical material is adopted for a sheath, and the gaps among the different units are filled with water-stop filler glue. Therefore, the composite cable provided by the invention has a capability of total cross-section high pressure resistance and water leakage prevention. In underwater application, the composite cable can provide optical fibers for transmitting optical signalsand can also provide a power line for transmitting control signals, a coaxial line for transmitting radio frequency signals and a twisting pair for transmitting communication signals. Besides, the composite cable provided by the invention is small in product size, diversified in functions and stable in transmission.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

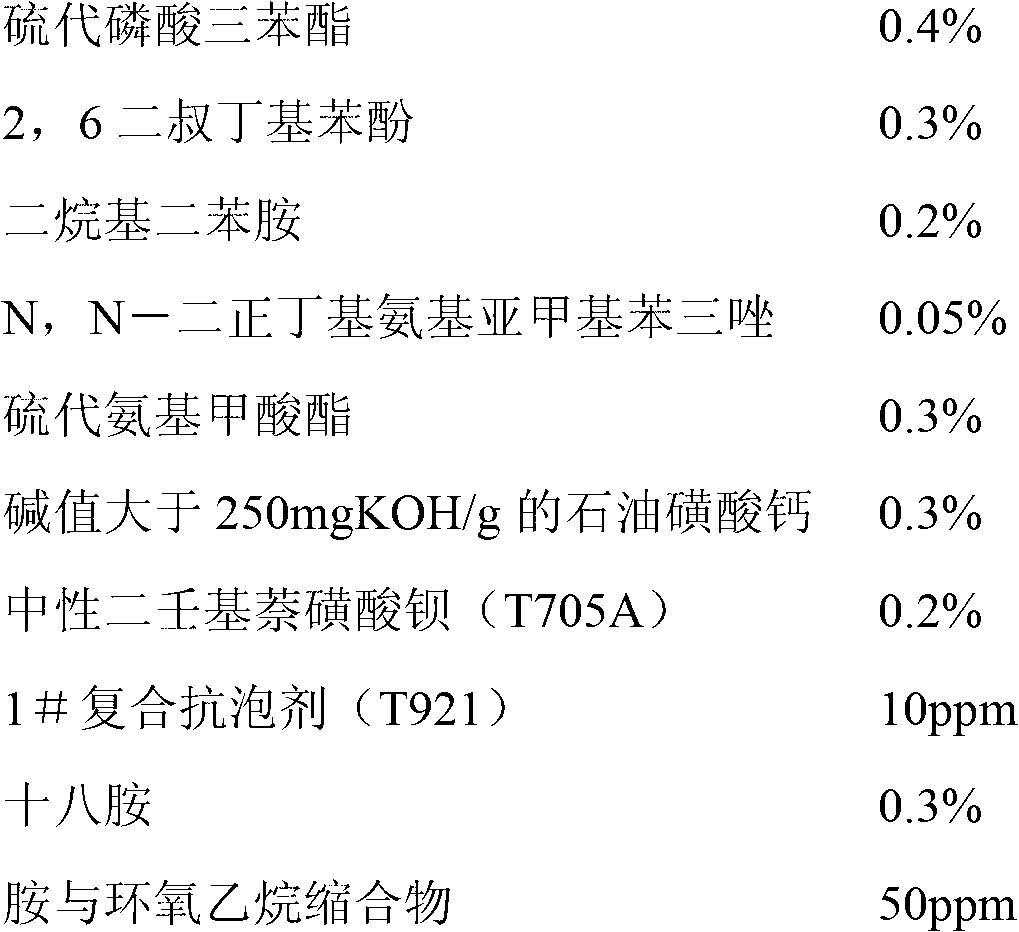

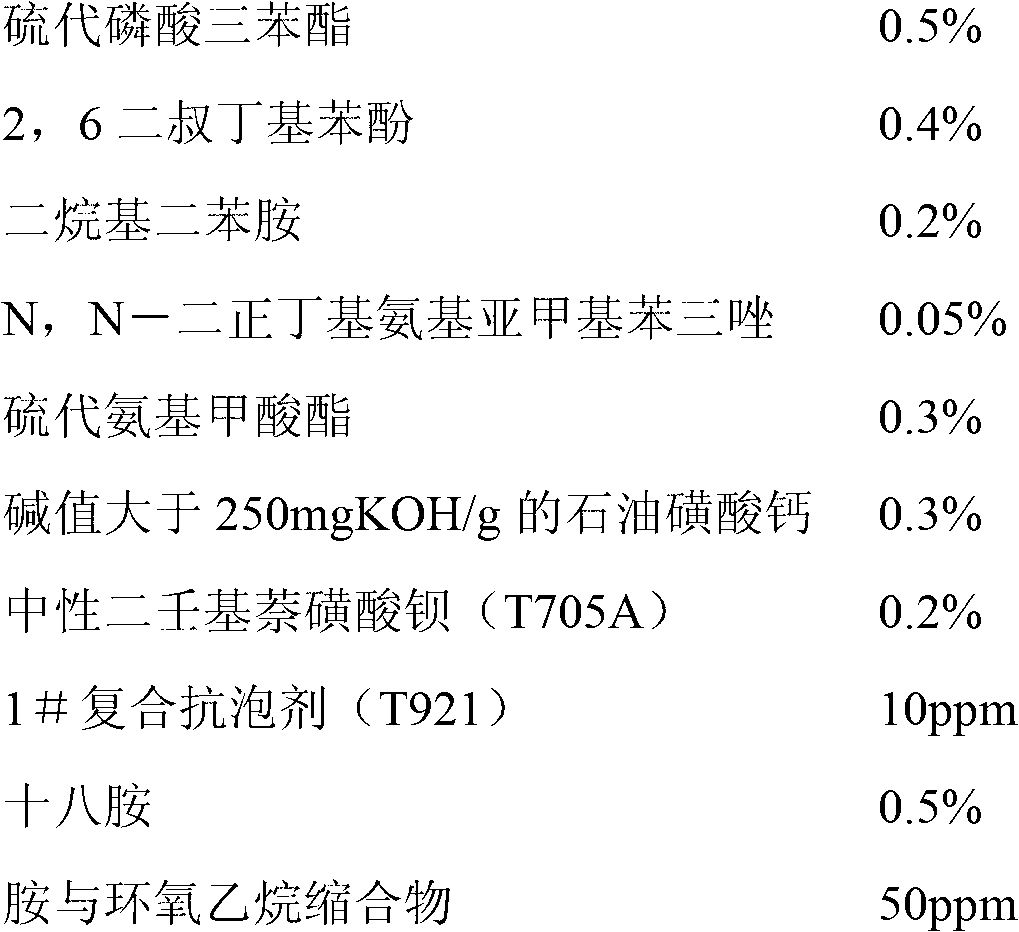

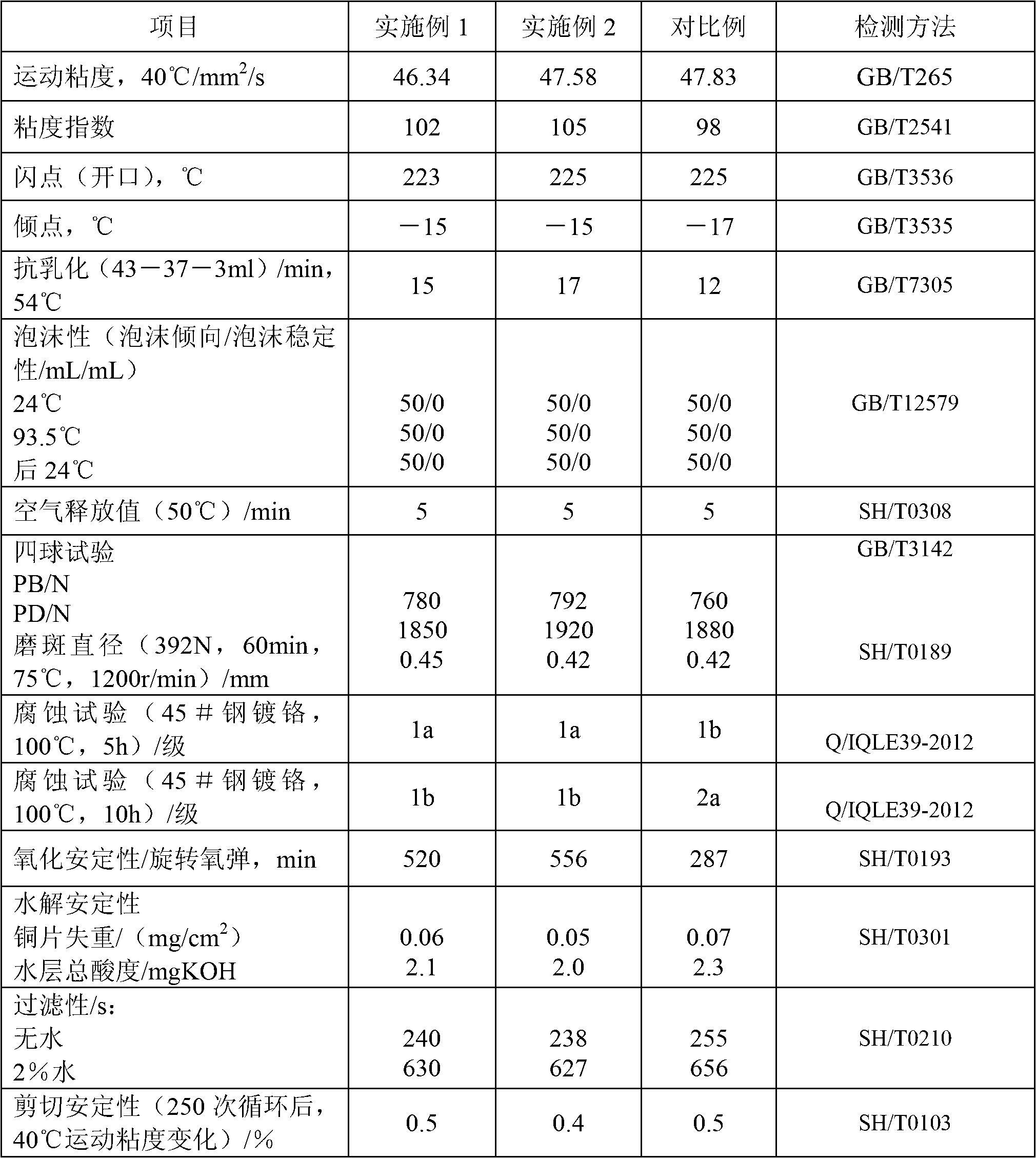

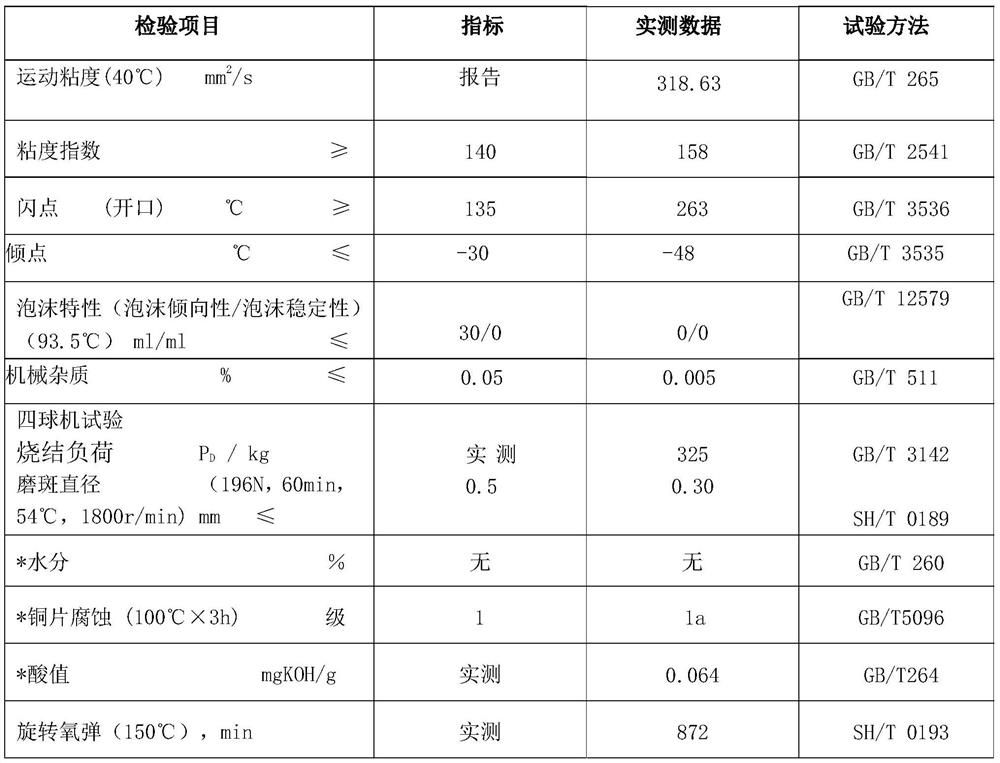

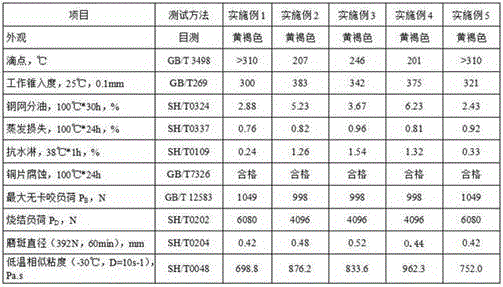

Anti-wear hydraulic oil capable of preventing chromium plated metal from blackening and bluing, as well as preparation method and application thereof

The invention provides anti-wear hydraulic oil capable of preventing chromium plated metal from blackening and bluing, and preparation method thereof. The anti-wear hydraulic oil comprises the following components in weight percent: 0.4%-0.8% of antiwear agent, 0.2%-0.4% of high alkaline petroleum sulfonate, 0.3%-1.2% of antioxygen, 20 ppm-80 ppm of demulsifying agent, 0.2%-0.5% of octadecylamine, 0.1%-0.3% of antirusting agent, 10 ppm-20 ppm of antifoaming agent, and the balance of base oil. The anti-wear hydraulic oil can efficiently avoid the blackening and bluing phenomena frequently occurring during the process that normal anti-wear hydraulic oil is applied onto the piston rod of engineering machinery, and meanwhile has the anti-wear performance; when the anti-wear hydraulic oil is applied, the increase of the acid value along with time is not significant, so that the anti-wear hydraulic oil has excellent antioxidation stability, and can satisfy long-term use by the engineering machinery hydraulic system.

Owner:上海火炬润滑油有限公司

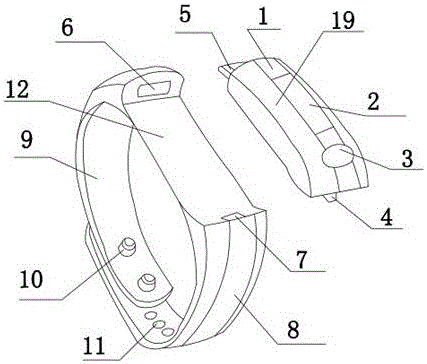

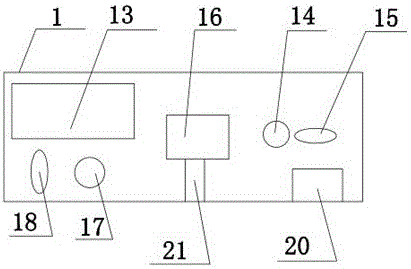

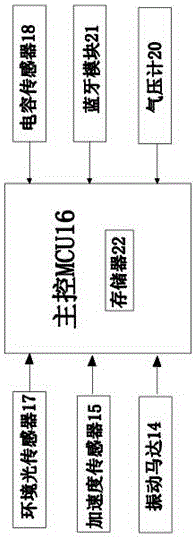

Smart band with anti-collision function

InactiveCN106820480AAvoid collisionEasy to useBraceletsWrist-watch strapsLED displayBiochemical engineering

The invention discloses a smart band with an anti-collision function. The smart band is characterized in that a host is arranged at the upper end of a host base; an anti-collision body is arranged at the outer end of the host, and is in an arch shape; an LED (light emitting diode) display screen is arranged in the middle part of the anti-collision body; a round press button is arranged at one end of the LED display screen; a host buckle is arranged at one end of the host, and is clamped with a host bayonet; the other end of the host is provided with a host charging interface, and the host charging interface is plugged with a wrist band interface; a MCU (main control unit) is arranged in the middle end of the interior of the host; a Bluetooth module is arranged at the lower end of the MCU; a rechargeable battery is arranged at the upper middle end of one end of the MCU; a capacitance sensor and an environment light sensor are respectively arranged at the lower end of the rechargeable battery. The smart band has the advantages that by adopting the arch-shaped structure and arranging the anti-collision body, the collision of the smart band is effectively prevented; the compressive effect is realized, the wearing is convenient, the safety in use is realized, the service life is prolonged, and the smart band is directly used as Bluetooth.

Owner:苏州祥弘源电子科技有限公司

Automatic aligning device of printer

ActiveCN1931593AImprove print quality and accuracyReduce labor intensityOther printing apparatusElectric machineryElectricity

The automatic aligning device of printer includes one printing medium entering passage, one signal receiver set below the passage and with lower paper twisting wheel set and aligning light sensitive tube, one lower platform for the transmitting fiber, one upper paper twisting wheel set, one driving gear in the end of the lower paper twisting wheel set, one power transmitting belt driving the driving gear and one motor. It features the upper paper twisting wheel set on the movable carriage separated from the bottom frame, the balls in the slot on the bottom frame and the movable carriage connected to the elevating paper stopper. The present invention may be used to align and feed various printing mediums of different materials, different sizes and different thickness to ensure high printing quality and precision.

Owner:YUNNAN NANTIAN ELECTRONICS INFORMATION CORP +1

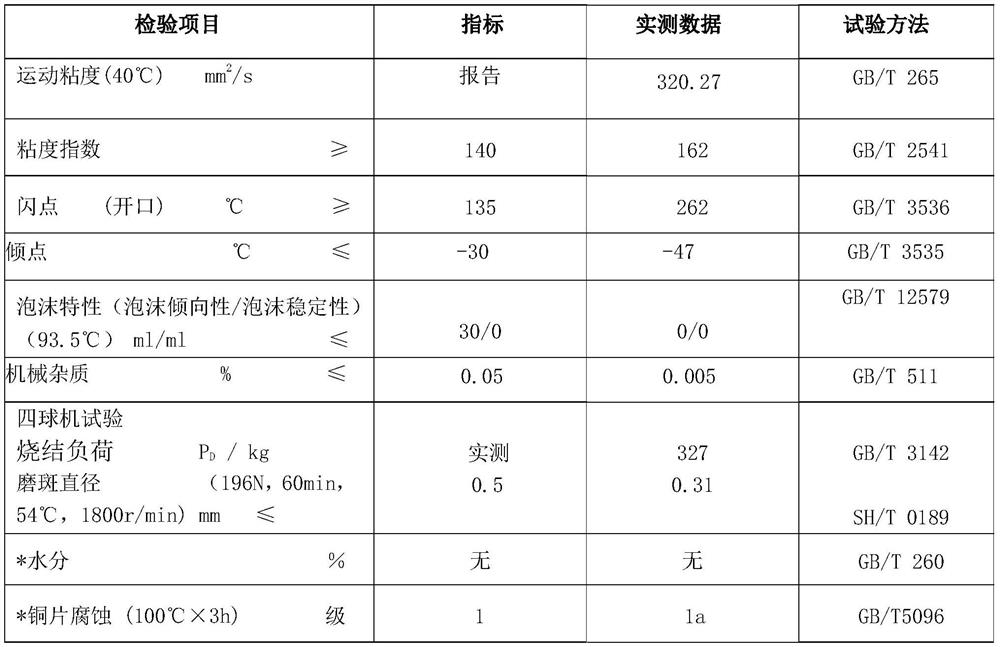

High-performance fully-synthetic wind-power gear oil and preparation method thereof

InactiveCN112011392AGood chemical stabilityImprove the lubrication effectLubricant compositionPolyolesterAntioxidant

The invention discloses high-performance fully-synthetic wind power gear oil. The wind power gear oil comprises base oil and additives, wherein the base oil is polyol ester, and the additives comprisean antioxidant, a demulsifying agent, a pour point depressant, an antirust agent, an extreme-pressure anti-wear agent, a detergent dispersant, a defoaming agent and a metal deactivator. The inventionalso provides a preparation method of the wind power gear oil. The preparation method comprises the following steps: carrying out an esterification reaction on polyol monoester and fatty acid to synthesize polyol ester, blending the polyol ester to obtain the base oil, adding the additives into the base oil, and conducting mixing to obtain the environment-friendly fully-synthetic wind power gearoil. According to the invention, the wind power gear oil has good compatibility with various additives and can be widely applied to a wind power gear oil tank; the gear oil has very long service lifeeven under severe working conditions; the high viscosity index and good shear stability of the gear oil are guaranteed; the lubricating requirement of a gear box used in a very wide viscosity range ismet; pitting corrosion can be effectively avoided or inhibited; and normal operation of a large heavy-duty mechanical gear transmission device is guaranteed.

Owner:上海中孚油品集团有限公司

Steel wire rope rear deformer

InactiveCN102330374AAnti-deformationWon't scratchRope making machinesFixed frameArchitectural engineering

The invention discloses a steel wire rope rear deformer. An upper pressure plate is fixed on a base. A lower pressure plate and the upper pressure plate are arranged in parallel on the base. The opposite lateral surfaces of the upper and lower pressure plates are respectively provided with a row of U-shaped brackets and the two rows of U-shaped brackets are arranged up and down in an adjacent staggered mode. Deformation pulleys are arranged in grooves of the U-shaped brackets and freely rotate. A regulating device drives the lower pressure plate to move up and down along the base. The regulating device comprises a bracket, a regulating rod and a fixed frame. The fixed frame is fixed on the outer lateral surface of the lower pressure plate. The bracket is fixed on the base. The upper end of the bracket is provided with a screwed hole. The regulating rod passes through the screwed hole on the bracket. One end of the regulating rod is arranged in the fixed frame and the other end of the regulating rod is provided with a rotating handle. The regulating rod is vertical to the lower pressure plate. The position on the regulating rod, which corresponds to the bracket, is provided with an external screw thread which is matched with the screwed hole. The steel wire rope rear deformer disclosed by the invention has a simple structure, is convenient to regulate and has wear resistance and deformation resistance. Moreover, a steel wire rope for decoration cannot be scratched.

Owner:江苏宏泰不锈钢丝绳有限公司

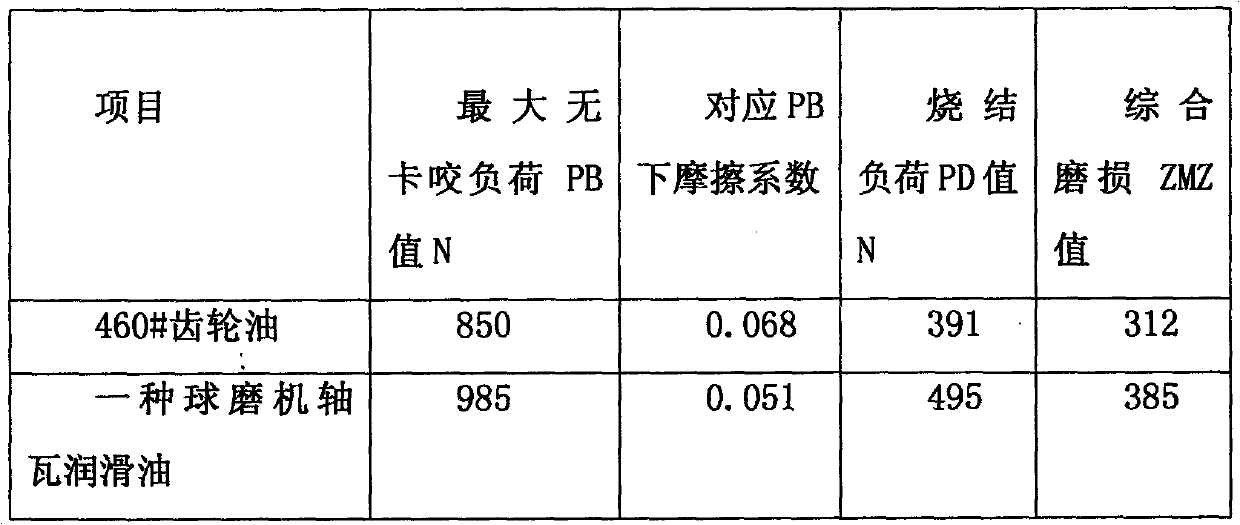

Ball grinding mill bearing bush lubricating oil and manufacturing method thereof

ActiveCN102559347AImprove the lubrication effectReduce the temperatureBase-materialsPolyesterEngineering

Ball grinding mill bearing bush lubricating oil and a manufacturing method thereof solve the problem that a ball grinding mill bearing bush is poor in lubrication in the severe environment. The ball grinding mill bearing bush lubricating oil is formed by using synthetic oil as base oil and refining multiple added efficient composite additives, has the advantages of being abrasion-resisting, high-temperature-resisting, oxidation-resisting, firm in formed film and the like, and can repair wire drawing and reduce abrasion and bearing bush temperature at fastest speed. The work efficiency and the product quality are improved obviously, the repair and maintenance costs are reduced, the service life of a device is prolonged, and energy consumption is reduced greatly. The ball grinding mill bearing bush lubricating oil is composed of, by mass, mineral lubricating oil 49%-69%, polyester synthetic oil 20%-40%, thickening agent 0.05%-0.15%, organic molybdenum composite additive 2.5%-4.5%, T306 additive 1%-3%, T202 antioxygen 0.4%-0.6%, T551 metal deactivator 0.7%-0.9% and T704 antirust additive 0.6%-0.8%, wherein the summation of the components is a hundred percent.

Owner:洛阳正本润滑材料有限公司

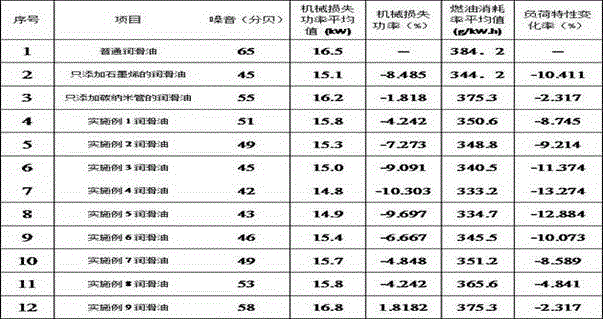

Method for preparing lubricating oil containing carbon nano tube and graphene

InactiveCN106381206AImprove the lubrication effectReduce consumptionAdditivesCarbon nanotubeFuel oil

The invention provides a method for preparing lubricating oil containing carbon nano tube and graphene, which solves the technical defects of large wearing degree on an engine by common lubricating oil, non-ideal antiwear effect, large noise, and large fuel oil consumption in the prior art. The preparation method comprises fatty acid and acidifying processing of carbon nano tube, ultrasonic dispersion of graphene, and addition of the processed materials in the lubricating oil; wherein according to the mass percentage, carbon nanotube accounts for 0.005-2%, graphene accounts for 0.005-3%, a dispersant accounts for 0.01-2%, and an emulsifier accounts for 0.01-1%. The performance detection experiment shows that the prepared lubricating oil can reduce friction, reduces wearing, reduces noise of the engine, and obviously saves fuel oil consumption, because sheet layer sliding and self lubricating effects of graphene as well as nano rolling effect of the carbon nano tube are combined, the lubrication effect is provided, and at the same time, antiwear effect is provided.

Owner:SICHUAN CARBON WORLD TECH CO LTD

Preparation process of a self-lubricating ceramic material cutting tool

The invention relates to the technical field of cutting tools, in particular to a preparation process of self-lubricating ceramic material cutting tools, which is characterized in that the process steps are: (1) Nano-thulium zirconium ceramic powder prepared by hydrothermal precipitation method, its composition The content and mass percentage are: 7% to 38% of thulium oxide, 62% to 93% of zirconia, (2) after adding TiC composite, ball milling, (3) adding solid lubricant, the radius of the solid lubricant particle ceramic composite material The ratio is 0.225≤r / R≤0.419, (4) mixed after ball milling, (5) vacuum dried, (6) put into graphite mold, (7) prepared by hot pressing sintering process, and the sintering temperature is 1500°C-1700°C , holding time 40 minutes. Compared with the prior art, the present invention has a simple technological process, and the self-lubricating ceramic tool has the functions of anti-friction, anti-wear and lubrication, saves the cooling and lubrication system, reduces equipment investment, avoids environmental pollution caused by cutting fluid, and realizes clean production. reduce manufacturing cost.

Owner:上海景文材料科技发展有限公司

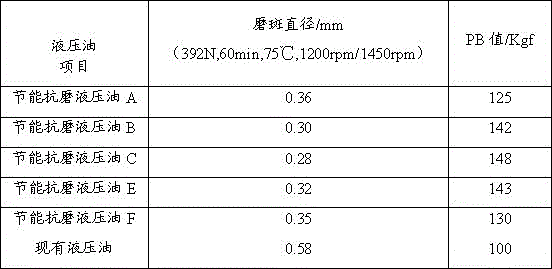

Preparation of dimer acid lanthanum extreme pressure anti-wear additive and energy-saving anti-wear hydraulic oil including dimer acid lanthanum extreme pressure anti-wear additive

InactiveCN106187743AReduce coefficient of frictionImprove wear resistanceOrganic compound preparationChemical industryRare-earth elementAntioxidant

The invention belongs to the field of hydraulic oil and particularly relates to preparation of a dimer acid lanthanum extreme pressure anti-wear additive and an energy-saving anti-wear hydraulic oil including the dimer acid lanthanum extreme pressure anti-wear additive. The preparation of the dimer acid lanthanum extreme pressure anti-wear additive comprises the steps that a La(NO3)3 solution is dropwise added into a specially-made alkali solution, and after a complete reaction, standing filtering and drying are carried out for use. The energy-saving anti-wear hydraulic oil is prepared from basic oil, the dimer acid lanthanum extreme pressure anti-wear additive, an antioxidant, an anti-rusting agent, a viscosity index improving agent, a pour point reducer and a defoaming agent. Carboxyl of dimer acid lanthanum (the dimer acid lanthanum extreme pressure anti-wear additive) can be effectively adsorbed to the surface of a friction pair, and the friction coefficient of the surface of the friction pair is reduced; in the friction process, rare earth elements rub the surface to diffuse to a matrix to form a permeation layer, the anti-wear property and the friction coefficient of the material surface are improved, and the anti-wear effect and the energy-saving effect are achieved; the dimer acid lanthanum extreme pressure anti-wear additive has a good anti-wear property, a good anti-rusting property, a good anti-corrosion property and the like; the rare earth compound dimer acid lanthanum is applied to hydraulic oil, and thus the hydraulic oil can have the excellent properties.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Dragging type optical cable laying plough for laying optical cables in shallow soil layer

InactiveCN111708141AAnti-wearImprove compatibilityOptical fibre/cable installationForeign matterSoil science

The invention discloses a dragging type optical cable laying plough for laying an optical cable in a shallow soil layer. The plough comprises soil to be ploughed, a laying space is formed in the rightside of soil to be ploughed; the right side of the soil to be ploughed is abutted against a laying plough stress shell. A laying plough internal space is formed in the laying plough stress shell; theupper side face of the laying plough stress shell is fixedly connected with a pulling shell. The plough is high in compatibility, the plough can be pulled by an existing carrier, laying can be suspended when foreign matter exists on a preset laying path by setting protection measures, abrasion of the foreign matter to the optical cable is prevented, the service life is shortened, a manual buryinglink is omitted by setting a burying device, and the labor cost is saved.

Owner:武汉长恒如工艺品有限公司

Automobile seat sliding rail lubrication grease and preparation method thereof

The invention discloses an automobile seat sliding rail lubrication grease. The lubrication grease is prepared from the following components in percentage by weight: 52%-65% of base oil, 26%-33% of sulfonate, 6%-10% of a structure improving agent and 3%-5% of a thickening agent. The lubrication grease adopts food-grade base oil, is free of smell, free of damage to human body and excellent in high-and-low temperature performance, and can meet the application of an automobile seat sliding rail in extreme environment; the high-alkali synthetic calcium sulphonate has excellent extreme-pressure antiwear property and is free of damage to human body; the effects of resisting wearing, reducing friction and reducing noise can be achieved by not adding high-cost solid lubricant; the structure improving agent is capable of effectively improving the thickening capability of the product and shortening the production time; the thickening agent is capable of greatly improving the antiwear property and the antifriction property of the product and also has excellent pumpability; the raw materials are cheap and easily available; the preparation method is simple and easily controllable; the production efficiency of the product is greatly improved.

Owner:NATOR LUBRICATION TECH JIANGSU CO LTD

Heat-resistant high-toughness polystyrene resin expanded plastic

The invention provides heat-resistant high-toughness polystyrene resin expanded plastic, which is prepared from the following raw materials in parts by mass: 40 to 60 parts of polystyrene resin, 20 to 25 parts of polyimide resin, 16 to 22 parts of polysulfone, 6 to 10 parts of nanometer hydrotalcite, 2 to 7 parts of PBO fiber, 1 to 3 parts of glycerin monostearate, 7 to 10 parts of chlorinated paraffin, 6 to 14 parts of nano-montmorillonite, 2 to 6 parts of rutile powder, 4 to 6 parts of aluminum borate whisker and 2 to 6 parts of coupling agent. The heat-resistant high-toughness polystyrene resin expanded plastic provided by the invention has excellent high / low temperature resistant performance and mechanical property, the fire resistance is good, and the strength and toughness are both obviously improved.

Owner:揭阳市越兴塑胶制品有限公司

Self-lubricating fluorinated silicone rubber seal ring

A self-lubricating fluorinated silicone rubber seal ring relates to the technical field of seal rings, and is characterized by comprising fluorinated silicone rubber, and a PTFE (Polytetrafluoroethylene) thin film arranged on the surface layer of the fluorinated silicone rubber. The invention further provides a production method of the fluorinated silicone rubber seal ring. The production method is characterized by comprising the following steps: injection molding, bonding, hot-forming, cutting and punching. The self-lubricating fluorinated silicone rubber seal ring has the excellent properties of abrasion resistance, pressure resistance and the like, and can be used in complex or bad environments requiring relatively high requirements. The production method has the advantages that the problem of difficulty in bonding polytetrafluoroethylene with fluorinated silicone rubber is solved; the production speed is fast; the machining quality is high.

Owner:宁国市格斯特密封件有限公司

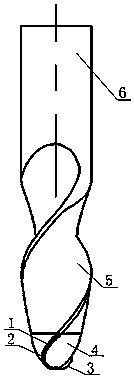

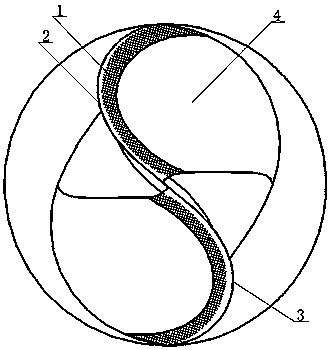

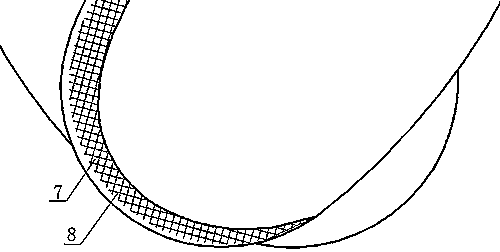

Special bulb milling cutter for milling titanium alloy thin-wall parts

InactiveCN108580999AReduce coefficient of frictionIncrease cooling areaMilling cuttersMilling cutterCutting force

The invention discloses a special bulb milling cutter for milling titanium alloy thin-wall parts. The bulb milling cutter comprises a tool bit consisting of a first cutting edge and a second cutting edge, and a back cutter surface connected with the cutting edges; the back cutter surface is a surface provided with a 60-degree cross texture structure; the problem of difficult machining of a titanium alloy material is the difficulty in the traditional manufacturing industry, and the problems of high cutting temperature, high cutting force, bad cutter wear, low machining precision, low machiningsurface quality and the like in the cutting process are generated; and the special bulb milling cutter for milling the titanium alloy thin-wall parts achieves excellent cutting performances of wear reduction, wear resistance, reduction of the cutting temperature, reduction of the cutting force, improvement of the machining surface quality and prolonging of the cutter service life through innovative design.

Owner:HARBIN UNIV OF SCI & TECH

Composite membrane for portable electronic product housing

The invention relates to a composite membrane for a portable electronic product housing and belongs to the field of composite materials. The composite membrane for the portable electronic product housing comprises, by mass, 20-30 parts of polyether-ether-ketone, 50-100 parts of high density polyethylene, 10-20 parts of polyethylene glycol, 1-5 parts of a surfactant, 2-10 parts of a polymerization initiator, 0-5 parts of a pigment, 3-15 parts of composite antibacterial powder, 2-10 parts of expandable graphite and 0-10 parts of alumina powder. The composite membrane has light specific gravity and good antibiosis and flame retardation effects and is especially suitable for a housing material of a tablet personal computer.

Owner:DALIAN OLYMPIC ELECTRONICS CITY ZIXIN FIRM

Preparation method of carbon nanotube and graphene compounded lubricating oil

InactiveCN106398803AImprove the lubrication effectReduce consumptionAdditivesCarbon nanotubeCvd graphene

The invention provides a preparation method of a carbon nanotube and graphene compounded lubricating oil, and solves the technical problem in the prior art that the conventional lubricating oil is relatively large is wear degree for engines, not ideal in anti-wear effect, large in noise and large in fuel consumption. The preparation method comprises the steps of subjecting a carbon nanotube to fatty acid treatment and acidification treatment, and adding graphene into the lubricating oil after the ultrasonic dispersion treatment of graphene. Counted in weight percentage, the lubricating oil comprises 0.004-2.2% of carbon nanotube, 0.004-3.2% of graphene, 0.02-2.2% of dispersing agent, and 0.02-1.2% of emulsifier. The results of performance detection experiments show that, the lubricating oil can reduce the friction, relieve the wear condition, reduce the noise of an engine and save the fuel consumption.

Owner:SICHUAN CARBON WORLD TECH CO LTD

SCR denitration catalyst end face hardening hydrosol and preparation method therefor

ActiveCN105413756AExtended service lifeImprove adsorption capacityGas treatmentCatalyst protectionOXALIC ACID DIHYDRATEPtru catalyst

The invention provides SCR denitration catalyst end face hardening hydrosol and a preparation method therefor. The SCR denitration catalyst end face hardening hydrosol comprises the following components: an aluminum sulfate solution with a concentration of 20%-27%, an oxalic acid solution with a concentration of 25%-50% and an ammonium metavanadate solution with a concentration of 33%-66%, wherein, the weight part ratio of the oxalic acid solution to the ammonium metavanadate solution is (0.6-1):1, the oxalic acid solution and the ammonium metavanadate solution are mixed and a mixed solution is prepared, the weight part ratio of the aluminum sulfate solution, the mixed solution and polyvinyl alcohol is 1:(0.1-0.2):0.02. SCR denitration catalysts can be immersed in the SCR denitration catalyst end face hardening hydrosol, thus the load capacity of the SCR denitration catalysts is raised and the service life of the SCR denitration catalysts is prolonged.

Owner:HUADIAN QINGDAO ENVIRONMENTAL TECHNOLOCY CO LTD

Cleaning agent for engine lubrication system without disassembly

ActiveCN108546583AEasy to cleanImprove adsorption capacityLubricant compositionOil sludgeCarbon deposit

Owner:杭州维客泰美品牌管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com