Slurry feed line steel with good low-temperature toughness and manufacturing method thereof

A technology of conveying pipeline and low temperature toughness, which is applied to the steel for slurry conveying pipeline and its manufacturing field, can solve the problems of high alloy cost, poor weldability and low temperature toughness, etc., achieve high hardness, good weldability, and ensure product strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

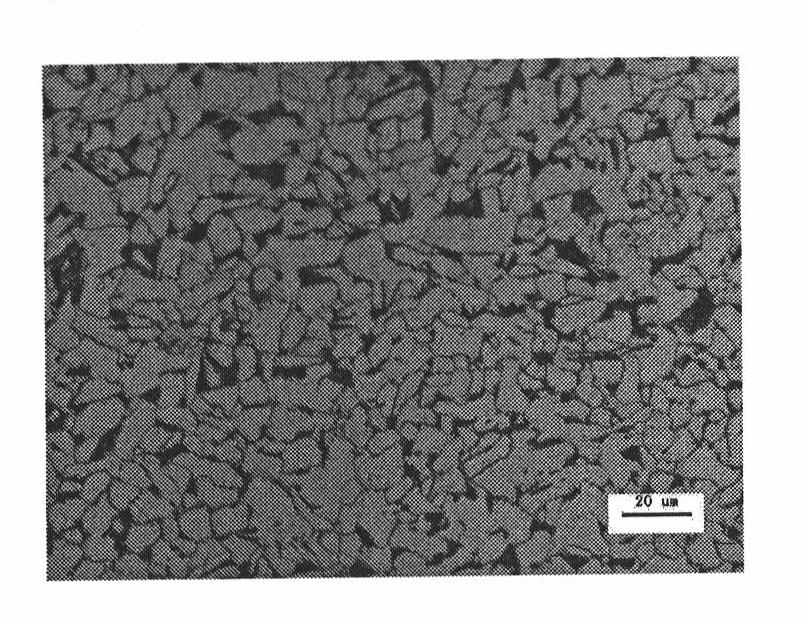

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below by way of examples.

[0061] The chemical composition of the steel in the embodiment of the present invention is shown in Table 8, the rolling process is shown in Table 9, the mechanical properties of the hot-rolled state are shown in Table 10, and the series of temperature shock and drop weight properties are shown in Table 11.

[0062] It can be seen from Table 10 and Table 11 that steel types and processes of the present invention can be used to produce steels that meet the performance requirements of slurry pipelines.

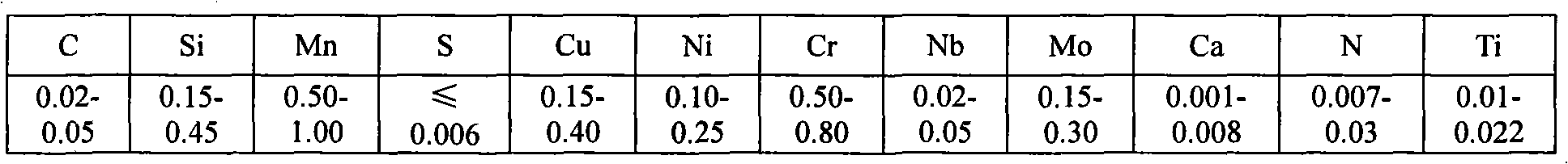

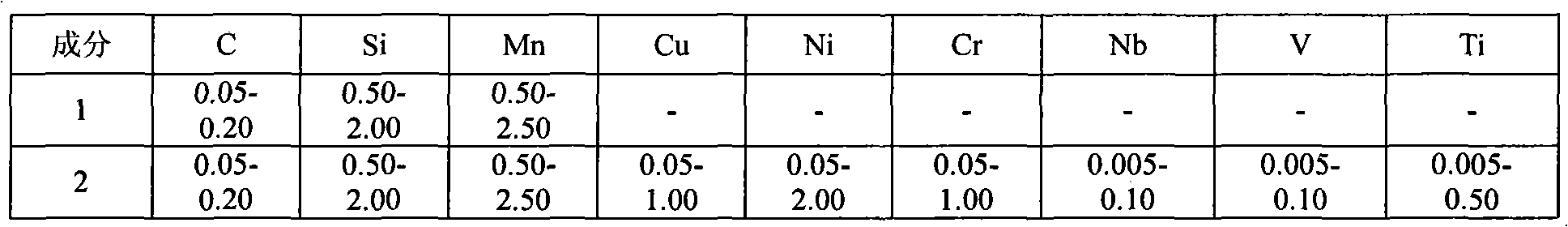

[0063] Table 8 test steel chemical composition (wt,%)

[0064] Example

C

Si

mn

P

S

Ti

als

N

1

0.12

0.15

0.95

0.012

0.002

0.010

0.038

0.0042

2

0.14

0.20

1.05

0.014

0.001

0.019

0.031

0.0044

3

0.14

0.12

1.23

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com