Sic@SiO<2> core-shell-structured nanofiller/epoxy resin-based composite material and preparation method thereof

A nano-filler, core-shell structure technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of low breakdown strength of nonlinear insulating materials, and achieve low equipment prices, simple process flow, and excellent nonlinearity. Effects of Conductivity Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

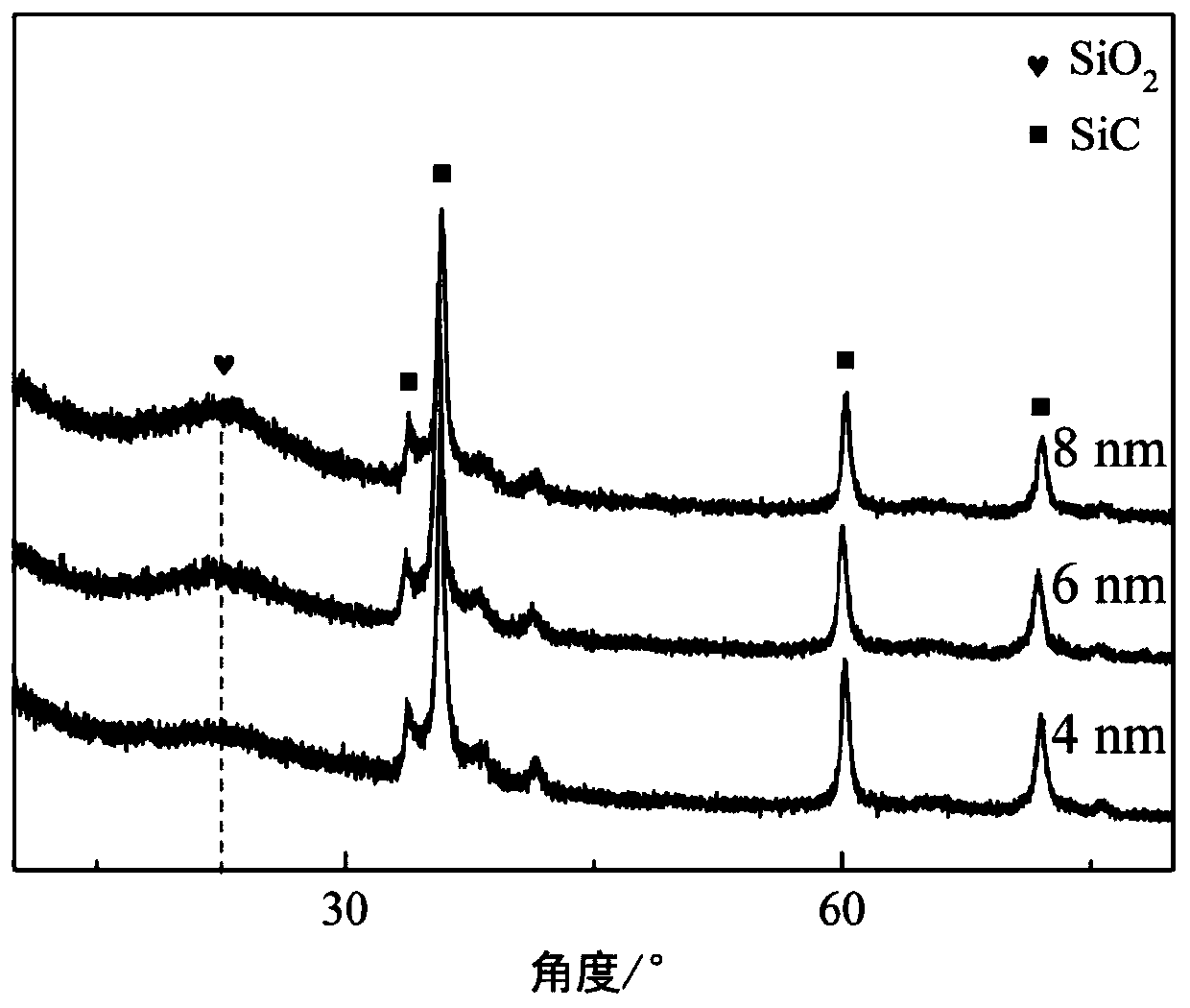

[0036] A SiC@SiO 2 Core-shell structured nanofiller / epoxy resin matrix composite doped with 5wt.% SiC@SiO 2 core-shell structured nanofillers, the SiC@SiO 2 The core-shell nanofiller uses nano-SiC particles as the core layer, and the core layer is coated with SiO with a thickness of 6nm. 2 Shell.

[0037]The present invention introduces silicon dioxide with excellent insulating performance into the dielectric composite material in order to properly improve the breakdown strength while improving the non-linear conduction characteristic of the dielectric material. Compared with single-component nanofillers, nanofillers with a core-shell structure can better improve amphiphilicity, improve weather resistance, wear resistance, reduce friction, prevent corrosion, and improve stability. There is a synergistic effect between components, which can Endowing materials with two or more properties greatly expands the application range of nanomaterials.

Embodiment 2

[0039] A SiC@SiO 2 Core-shell structured nanofiller / epoxy resin matrix composite doped with 5wt.% SiC@SiO 2 core-shell structured nanofillers, the SiC@SiO 2 The core-shell nanofiller uses nano-SiC particles as the core layer, and the core layer is coated with SiO with a thickness of 6nm. 2 Shell. In this example, SiC@SiO 2 The particle size of the core-shell structure nano filler is 50-75nm.

[0040] SiC@SiO provided by the present invention 2 The particle size of the core-shell nanofiller is 50-75nm. Due to the small particle size of the filler, a certain degree of agglomeration will inevitably occur, but the particle size of the formed particle clusters is all below 1 μm, which is still a nanoscale filler. These The particle clusters can be evenly dispersed in the epoxy resin matrix, which can not only endow the composite material with excellent nonlinear electrical conductivity and breakdown strength, but also ensure the mechanical properties of the composite material,...

Embodiment 3

[0043] A SiC@SiO 2 The preparation method of core-shell structure nano filler / epoxy resin matrix composite material, the steps are as follows:

[0044] Step 1. Preparation of nano-SiC particles:

[0045] Add SiC particles into absolute ethanol according to a certain mass-volume ratio, and obtain nano-SiC particles through ultrasonic dispersion, grinding, and drying. Uniform nano-SiC suspension;

[0046] Step 2. Preparation of SiC@SiO 2 Core-shell nanofiller:

[0047] Add ammonia water to the nano-SiC suspension obtained in step 1 according to a certain volume ratio, stir the obtained nano-SiC reaction system for a certain period of time at the first rotational speed, and place the obtained nano-SiC reaction system under the condition of 60° C. The mixed solution of ethyl silicate and ethanol is continuously stirred at the second speed for a certain period of time, and then the reaction system is left to stand. After standing for a certain period of time, the supernatant is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com