An epoxy-based nonlinear conductive coating and its preparation process

A nonlinear, epoxy-based technology, used in epoxy resin coatings, coatings, conductive coatings, etc., can solve the problems of high cost, difficult on-site application, difficult to achieve uniform coating, etc., and achieve low cost and good nonlinearity. Conductivity characteristics, effect of good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

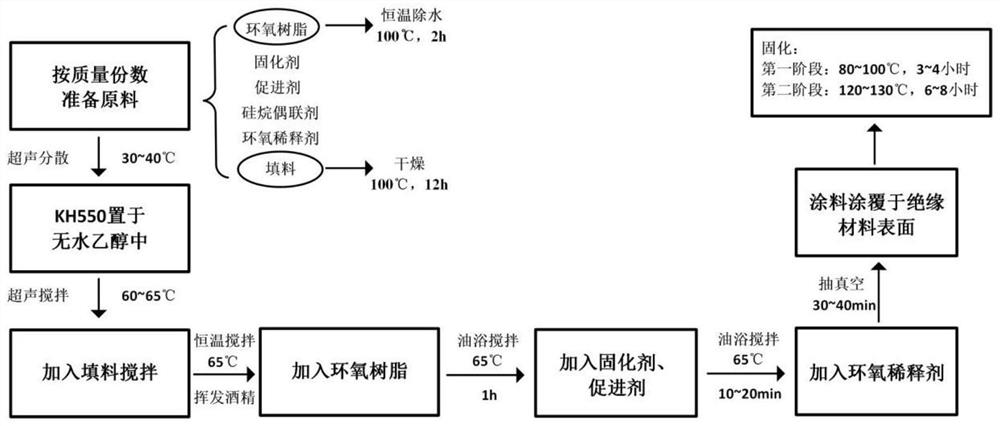

[0045] An epoxy-based nonlinear conductive coating with the function of regulating the charge on the surface of an insulator. The schematic diagram of its preparation process is shown in figure 1 , the specific preparation steps are as follows:

[0046] 1) Weigh each raw material according to the proportion, each raw material and its parts by weight are: 100 parts of epoxy resin, 80 parts of liquid anhydride curing agent, 0.5 part of accelerator, 10 parts of epoxy diluent, 9.5 parts of silicon carbide, 0.475 parts of silane coupling agent; place the weighed epoxy resin in a constant temperature oven at 100°C for 2 hours to remove moisture; dry the silicon carbide powder in a constant temperature oven at 100°C for 12 hours;

[0047] 2) Place the weighed silane coupling agent KH550 in a certain amount of absolute ethanol, and ultrasonically disperse it in a water bath at 35°C for 20 minutes to obtain a uniformly dispersed ethanol solution of KH550;

[0048] 3) Add silicon carbi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com