Preparation method of intelligent insulation material with low packing ratio and non-linear conductance characteristics

An insulating material and nonlinear technology, applied in the field of preparation of intelligent insulating materials, can solve the problems of mechanical and mechanical properties deterioration of composites, high percolation threshold, improve uneven electric field distribution, avoid field intensity regional concentration, mechanical Performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

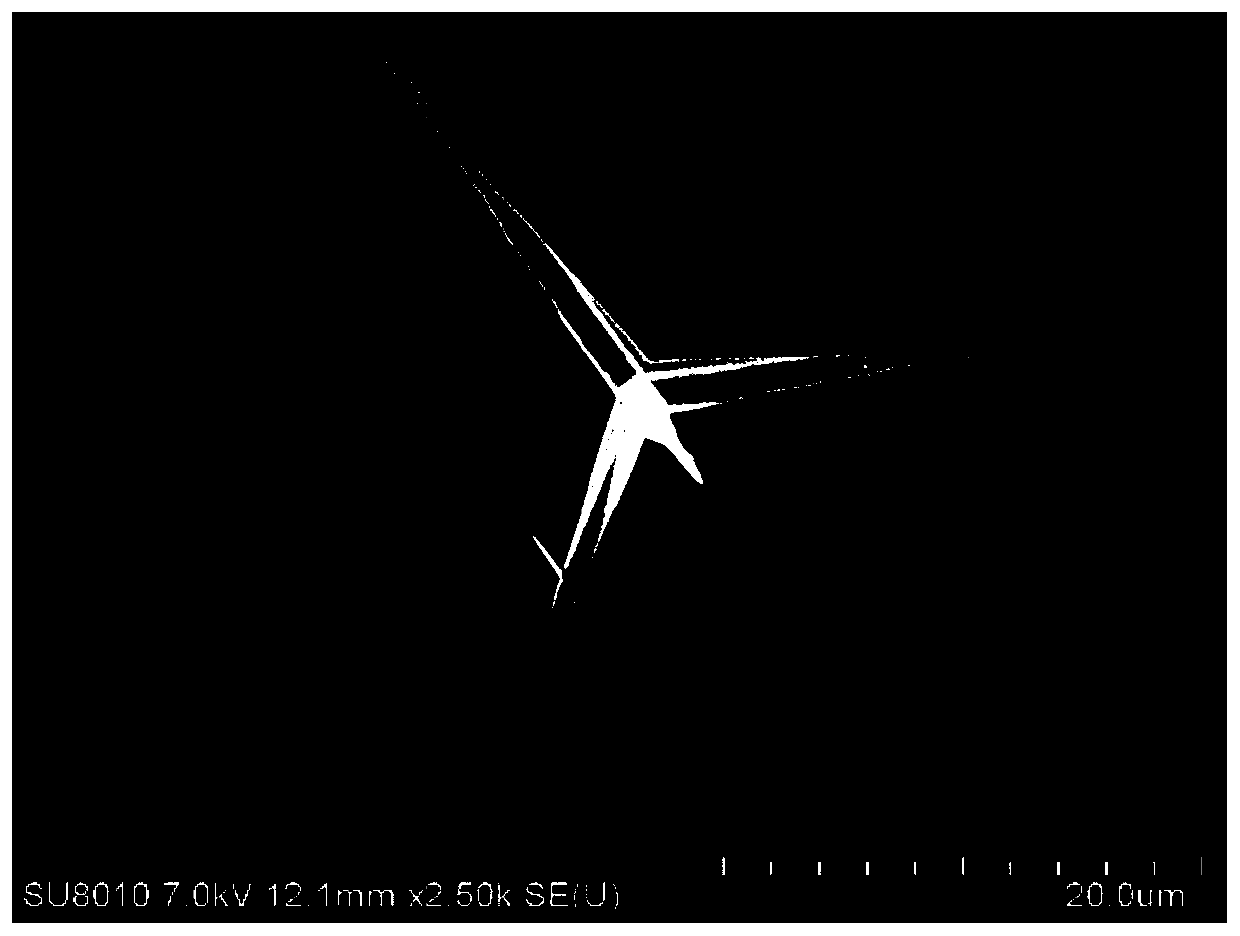

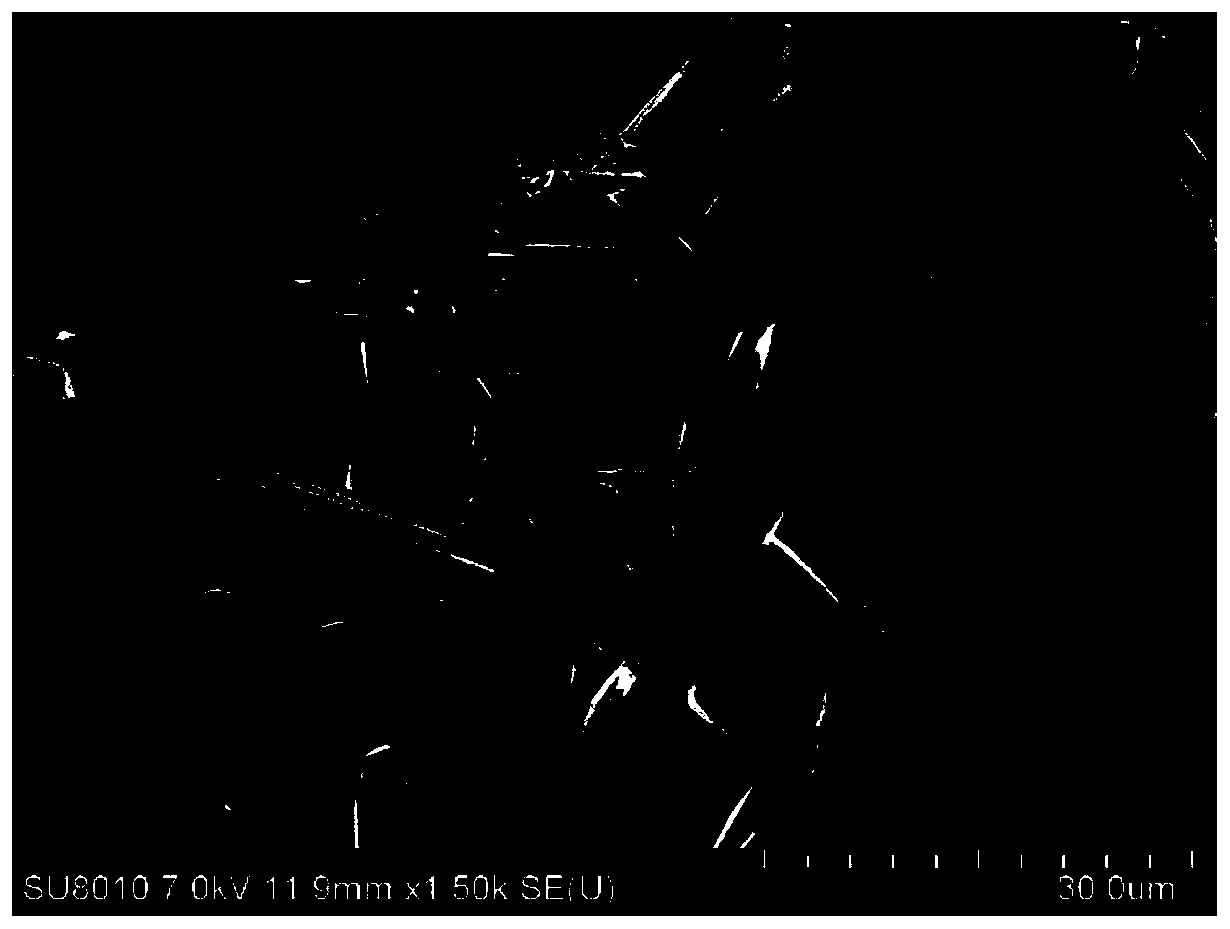

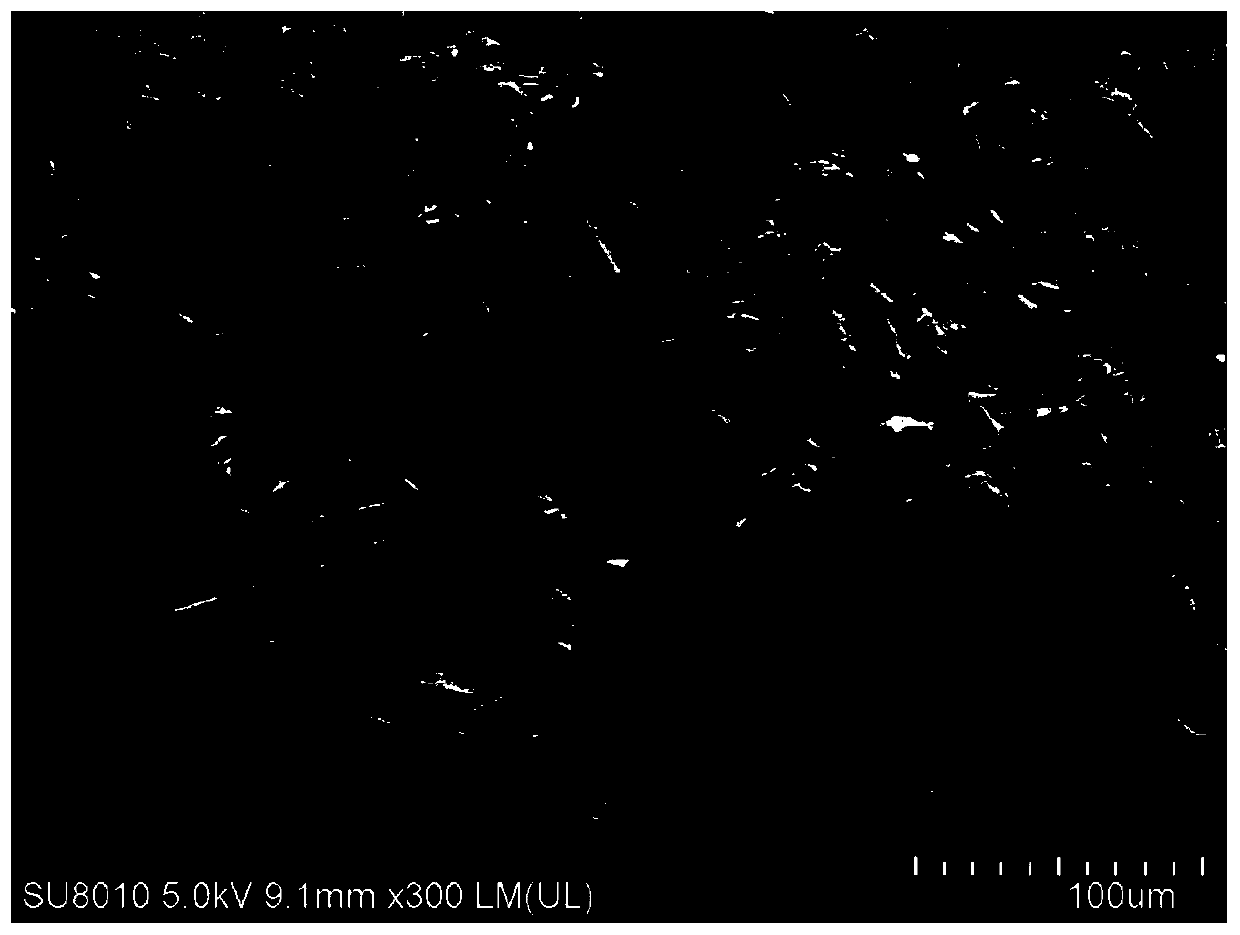

Image

Examples

Embodiment 1

[0034] ① Surface modification:

[0035] A. First place T-ZnOw in a vacuum drying oven at 100°C and dry continuously for 8 hours (hours);

[0036] B. Then get 5g deionized water, 10g silane coupling agent KH570, 40g (gram) absolute ethanol to be made into the ethanol solution of coupling agent;

[0037] C. Adjust the pH value of the ethanol solution of the coupling agent to 3 with hydrochloric acid, and hydrolyze it at room temperature for 1 hour to obtain a hydrolyzate;

[0038] D. Simultaneously disperse 100g of dried tetraacicular zinc oxide whiskers and 100g of absolute ethanol in a beaker for 1h to make a dispersion;

[0039] E. Pour the hydrolyzate into the dispersion, and stir in a constant temperature water bath at 60°C (temperature) and 800 rpm for 5 hours to obtain a stirring solution;

[0040] F. Place the stirred liquid in a suction filtration device for suction filtration, then take 100g of absolute ethanol and deionized water to wash, and repeat the washing twic...

Embodiment 2

[0047] ① Surface modification:

[0048] A. First place T-ZnOw in a vacuum drying oven at 100°C and dry continuously for 9 hours (hours);

[0049] B. Then get 2g deionized water, 4g silane coupling agent KH570, 16g (grams) absolute ethanol to make the ethanol solution of coupling agent;

[0050] C. Adjust the pH value of the ethanol solution of the coupling agent to 3.5 with hydrochloric acid, and hydrolyze at room temperature for 1 hour to obtain a hydrolyzate;

[0051] D. Simultaneously disperse 50g of dried tetraacicular zinc oxide whiskers and 50g of absolute ethanol in a beaker for 1h to make a dispersion;

[0052] E. Pour the hydrolyzed liquid into the dispersion liquid, and stir in a constant temperature water bath at 70°C (temperature) and 600 rpm for 4 hours to obtain a stirred liquid;

[0053] F. Place the stirred liquid in a suction filtration device for suction filtration, then take 100g of absolute ethanol and deionized water to wash, and repeat the washing twice; ...

Embodiment 3

[0060] ① Surface modification:

[0061] A. First place T-ZnOw in a vacuum drying oven at 100°C and dry continuously for 10 hours (hours);

[0062] B. Then get 8g deionized water, 16g silane coupling agent KH570, 64g (gram) dehydrated alcohol to be made into the ethanol solution of coupling agent;

[0063] C. Adjust the pH value of the ethanol solution of the coupling agent to 3.8 with hydrochloric acid, and hydrolyze it at room temperature for 1.5 hours to obtain a hydrolyzate;

[0064] D. Simultaneously disperse 130g of dried tetraacicular zinc oxide whiskers and 130g of absolute ethanol in a beaker for 1h to make a dispersion;

[0065] E. Pour the hydrolyzed liquid into the dispersion liquid, and stir in a constant temperature water bath at 80°C (temperature) and 500 rpm for 4 hours to obtain a stirred liquid;

[0066] F. Place the stirred liquid in a suction filtration device for suction filtration, then take 100g of absolute ethanol and deionized water to wash, and repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com