A 35kV and below high-voltage AC-DC wall-piercing bushing and its preparation method

A kind of wall bushing, AC and DC technology, applied in cable/conductor manufacturing, conductor/cable insulation, cable and other directions, can solve the development direction that cannot meet the miniaturization of electrical equipment, complex capacitor core structure, complex process flow and other problems, to achieve the effect of convenient transportation and installation, reducing size and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

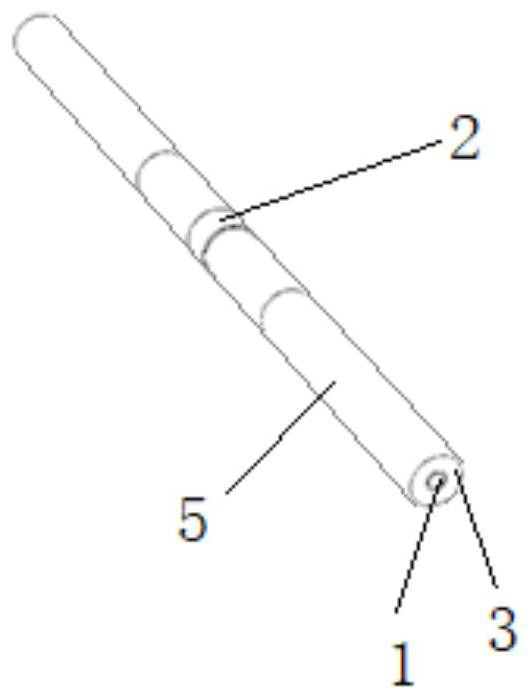

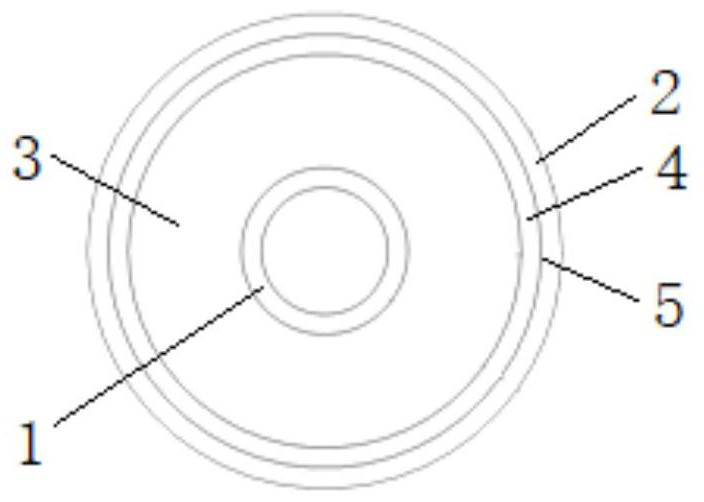

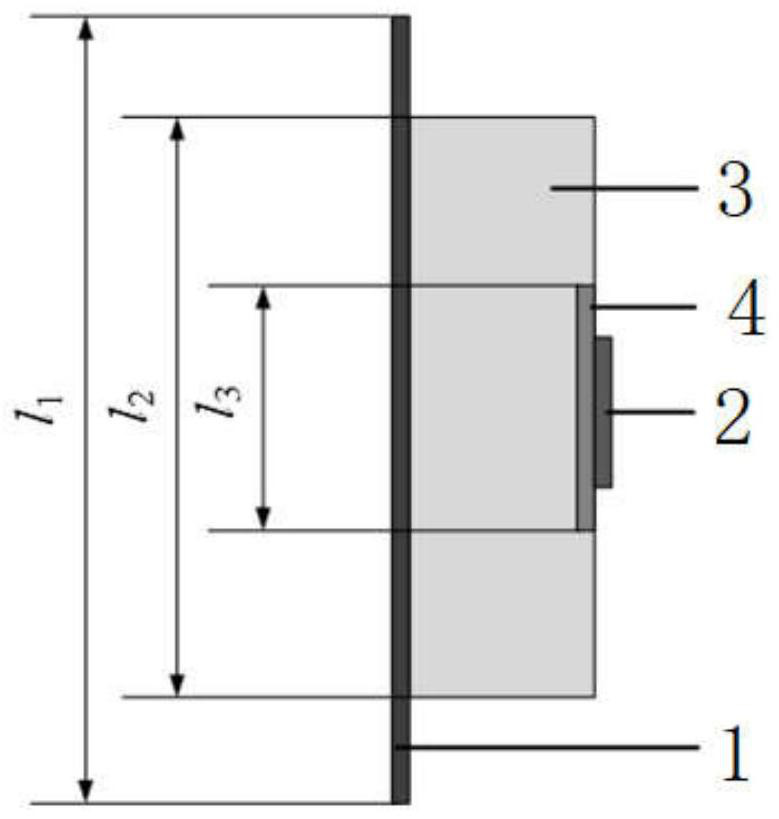

[0054] The present embodiment also provides a method for preparing a high-voltage AC and DC wall bushing of 35kV and below, comprising the following steps:

[0055] 1) The main insulation is obtained by multi-layer co-extrusion;

[0056] 2) using the high temperature vulcanization curing method or the vacuum casting method to obtain the electrode extension layer 4, and installing the electrode extension layer 4 on the outside of the main insulation;

[0057] 3) The outer edge of the flange 2 is chamfered, and the flange 2 is installed on the outside of the electrode extension layer 4;

[0058] 4) Install a plurality of outer insulating sheds 9 on the outer sides of the main insulation on both axial sides of the flange 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com