Steel wire rope rear deformer

A deformer and steel wire rope technology, applied in the mechanical field, can solve the problems of easily scratched steel wire ropes, difficult to adjust the distance, etc., and achieve the effect of simple structure and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

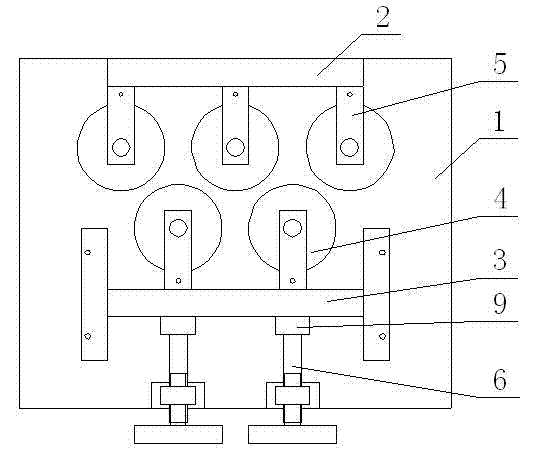

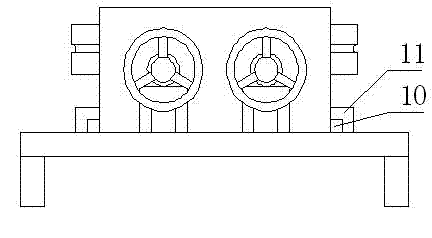

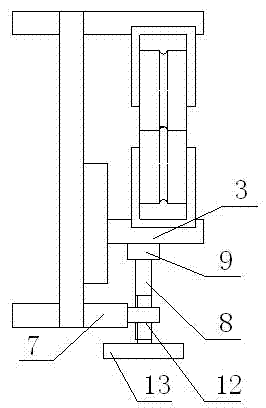

[0011] As shown in the figure, the wire rope rear deformer of the present invention includes a base 1, an upper pressing plate 2, a lower pressing plate 3, two rows of deformation pulleys 4, and an adjustment device 6, and the upper pressing plate 2 is fixed on the base 1, and the The lower pressing plate 3 is arranged parallel to the upper pressing plate 2 on the base 1, the bottom of the lower pressing plate 3 is provided with a bump 10, and the corresponding position of the base 1 is provided with a sliding groove 11 to cooperate with the bump 10 , the lower platen 3 can move up and down along the base 1, a row of U-shaped brackets 5 are respectively arranged on the opposite sides of the upper platen 2 and the lower platen 3, and the bottom of the U-shaped brackets 5 is fixed on the upper platen 2 or the lower platen 3, and the adjacent U-shaped brackets in the two rows of U-shaped brackets 5 are staggered up and down, the deformation pulley 4 is installed in the groove o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com