Patents

Literature

128results about How to "High tensile bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic silicon modified styrene-acrylic emulsion for ceramic tile back adhesive and preparation method thereof

InactiveCN107513125AFast dryingImprove water resistanceEster polymer adhesivesHydrocarbon polymer adhesivesAcrylic resinAdhesive

The invention discloses and provides organic silicon modified styrene-acrylic emulsion for a ceramic tile back adhesive and a preparation method thereof, and relates to the field of coating. The performance such as the drying speed, the water-resistant performance and the stretch bonding intensity of the styrene-acrylic emulsion system can be improved. The organic silicon modified styrene-acrylic emulsion can be used for the ceramic tile back adhesive, and the process requirement of pasting immediately after the brushing can be met. The organic silicon modified styrene-acrylic emulsion disclosed by the invention is prepared from the following raw materials in parts by weight: 0.5 to 3 parts of organic silicon modified monomers, 15 to 25 parts of styrene, 25 to 35 parts of alkyl acrylate, 0.6 to 1 part of unsaturated carboxylic acid, 0.6 to 2 parts of functional crosslinking monomers, 1 to 4 parts of emulsifying agents, 0.2 to 0.4 part of water-soluble peroxide initiators, 0.1 to 0.2 part of oxidization-reduction initiators, 0.1 to 5 parts of pH regulators and 45 to 60 parts of deionized water, wherein the weight part sum of the organic silicon modified monomers, the styrene, the alkyl acrylate, unsaturated carboxylic acid and the functional crosslinking monomers is 50 to 55 parts. The organic silicon modified styrene-acrylic emulsion for the ceramic tile back adhesive disclosed by the invention is applicable to the ceramic tile back adhesive.

Owner:安德士新材料(中山)有限公司

Anti-falling cement-based glue for tiles for exterior wall

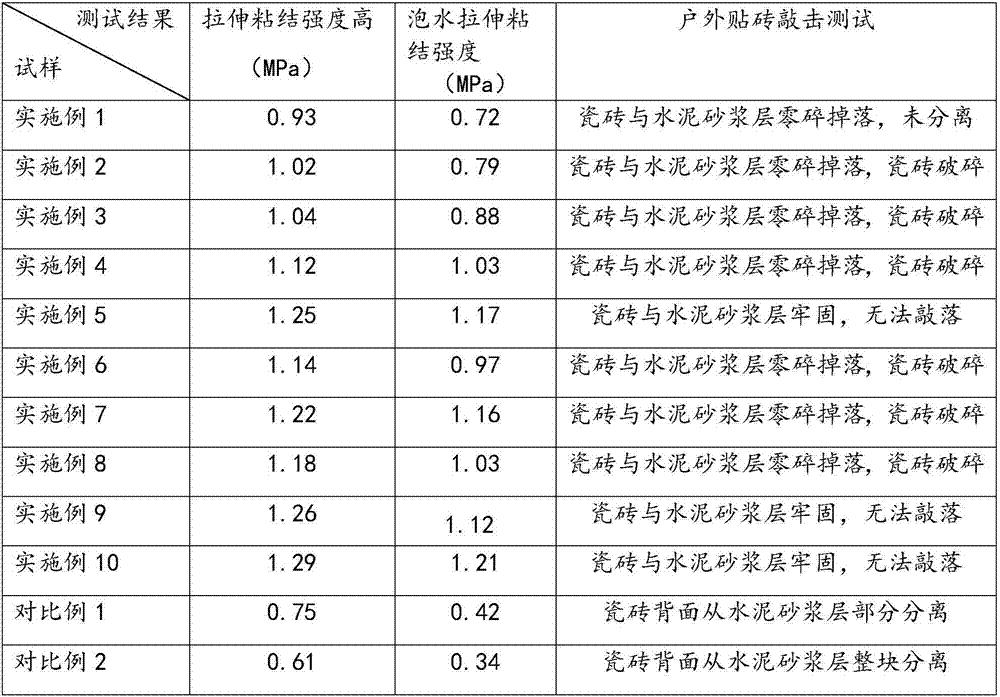

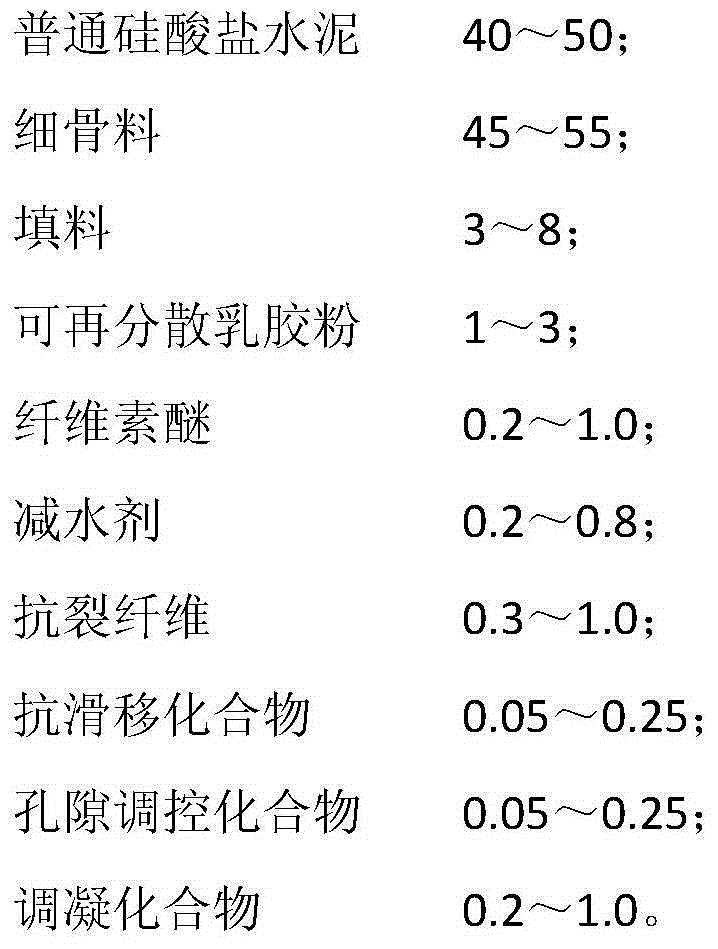

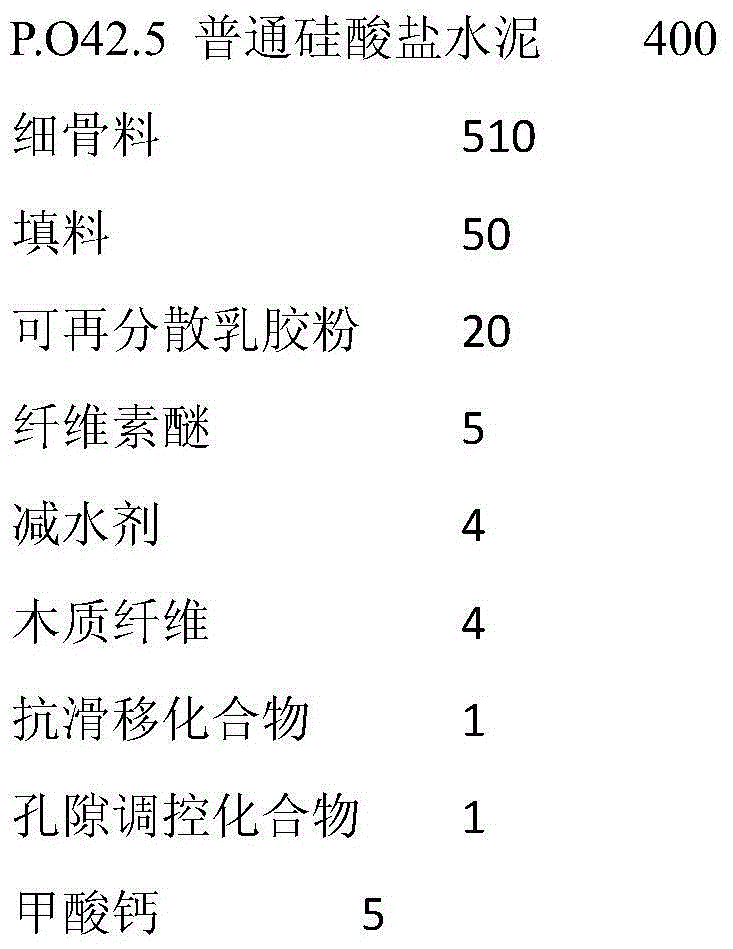

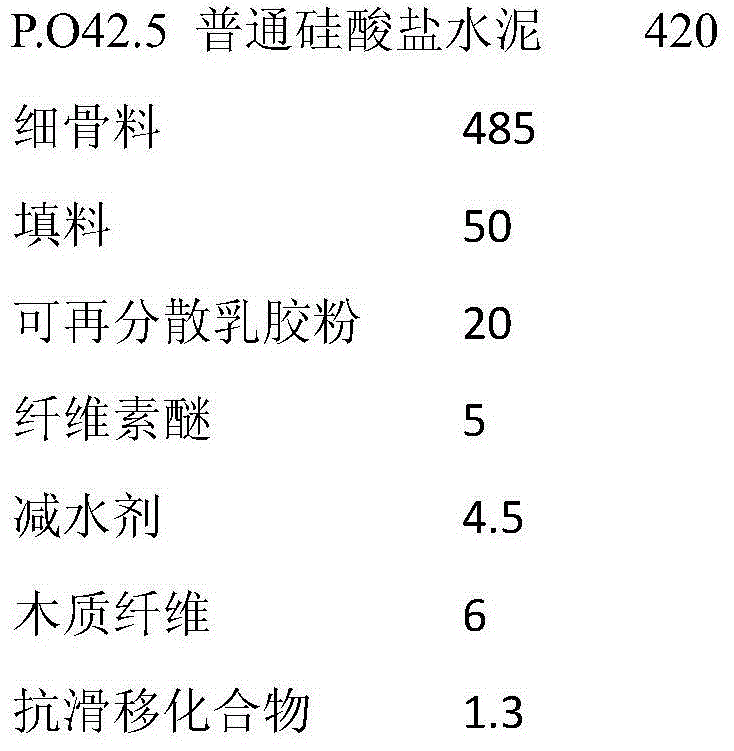

The invention provides anti-falling cement-based glue for tiles for an exterior wall. The glue is prepared from the following components in parts by weight: 40-50 parts of common silicate cement, 45-55 parts of fine aggregate, 3-8 parts of filler, 1-3 parts of redispersible powder, 0.2-1.0 part of cellulose ether, 0.2-0.8 part of a water reducer, 0.3-1.0 part of crack-resisting fiber, 0.05-0.25 part of an anti-sliding compound, 0.05-0.25 part of a porosity regulating compound, and 0.2-1.0 part of a set controlling compound. According to the anti-falling cement-based glue for tiles for the exterior wall provided by the invention, the anti-sliding falling performance of an adhesive for tiles is improved simultaneously from four aspects of improving the binding power, resisting shrinkage crack, resisting slippage and enhancing the weather resistance; the construction properties of the glue for tiles such as water retention, viscosity maintaining and the like can be remarkably improved, the original adhesive strength of the glue for tiles can be effectively enhanced, and the tensile bond strength of the glue for tiles if the glue for tiles is soaked in water, thermally aged and frozen and thawed can be improved to a great extent. The glue for tiles has good adaptability with other additives. The glue for tiles plays good roles of reducing water and increasing strength, reducing the cracking risk and optimizing the gap structure,

Owner:JIANGSU SOBUTE NEW MATERIALS

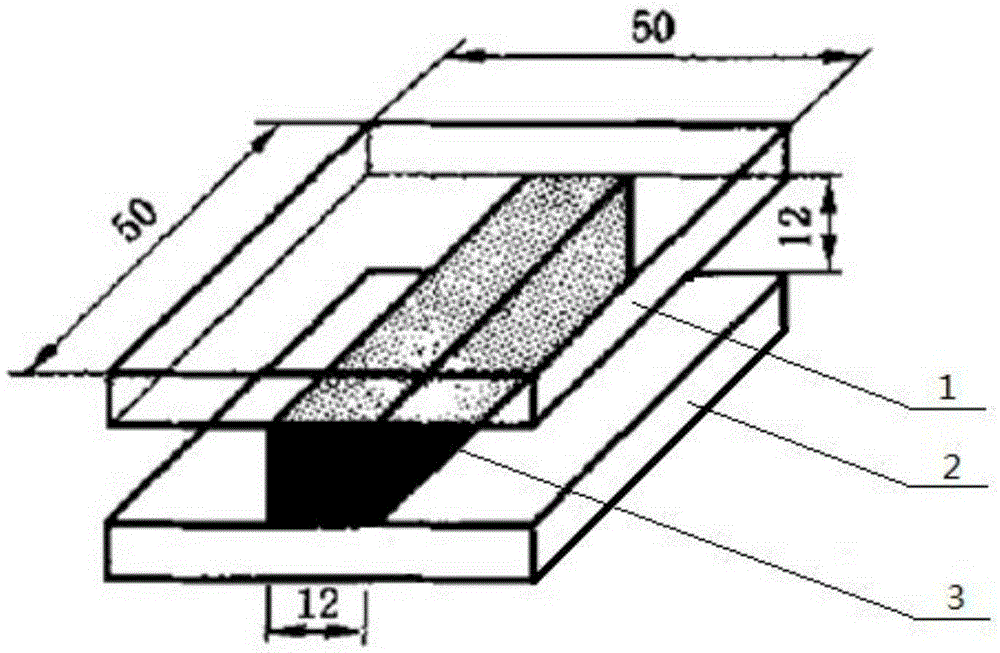

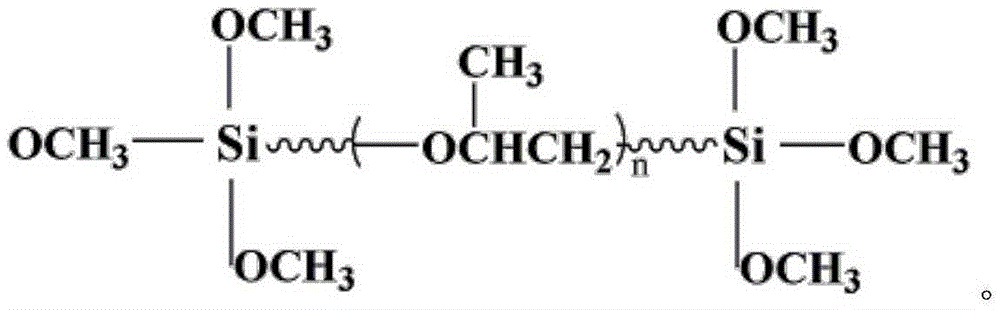

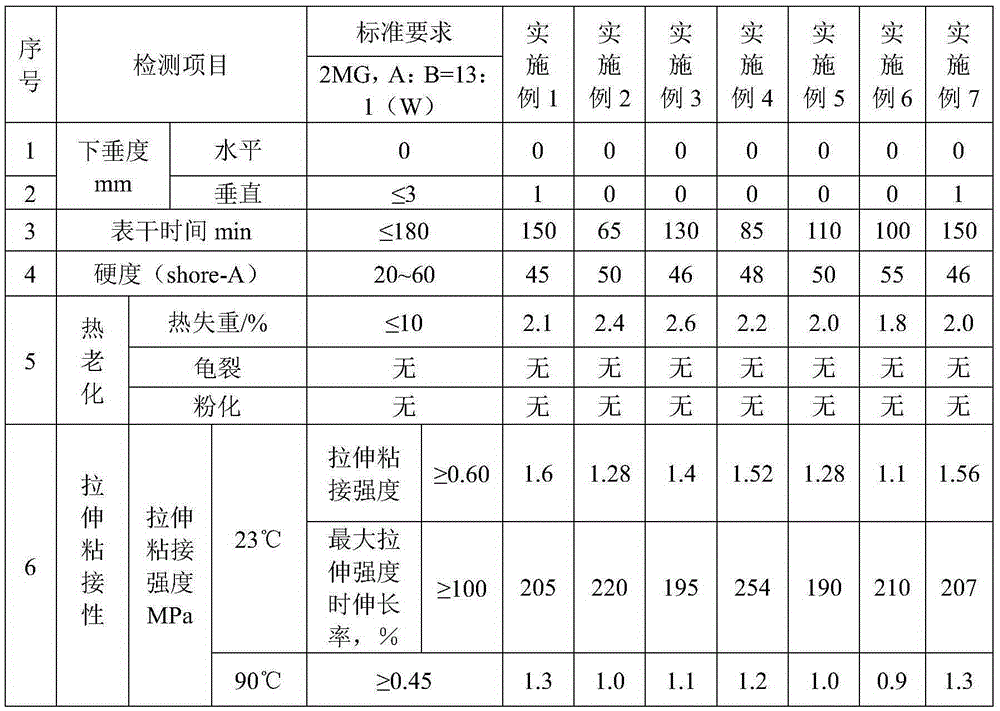

High-elongation two-component silicone structural adhesive and preparation method thereof

ActiveCN105255439AHigh elongationHigh tensile bond strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryCarbon black

The invention belongs to the field of two-component silicone structural adhesives, and particularly relates to a high-elongation two-component silicone structural adhesive and a preparation method thereof. The silicone structural adhesive comprises a component A and a component B; the component A comprises, by mass, 40-100 parts of basic polymers, 40-80 parts of nano calcium carbonate, 0.5-2 parts of ultraviolet light absorber and 5-10 parts of polydimethylsiloxane; the component B comprises, by mass, 40-100 parts of color paste, 5-25 parts of silane modified polymers, 0.5-2 parts of dewatering agents, 40-80 parts of cross-linking agents, 10-50 parts of coupling agents, 0.2-3 parts of organic bismuth catalysts, wherein the color paste comprises 100 parts of polydimethylsiloxane, 50 parts of high structure carbon black and 5 parts of gas-phase white carbon black; the component A is mixed with the component B according to the mass ratio ranging from 7:1 to 14:1. The silane modified polymers are added to the silicone structural adhesive, the elongation at the maximum tensile bonding strength can be effectively increased, and the high-elongation two-component silicone structural adhesive is suitable for structural bonding and sealing of super high-rise glass building curtain walls.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

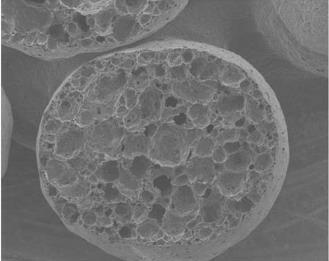

Glass bead with honeycomb holes and tile glue with glass bead

The invention provides a glass bead with honeycomb holes, which can be used as light-weight packing in dry mixed mortar. The glass bead is prepared by crushing a pure glass product recycled industrially or civilly into glass powder of below 400 meshes, uniformly mixing the glass powder, a foaming agent and an adhesive, and then fusing, swelling, cooling and screening the mixture under the condition of high temperature of 800-820 DEG C. The glass bead is a regular spherical particle with a rough appearance and has a honeycomb meshed structure internally; the particle size is 0.1-5mm; the stacking density is 310-460kg / m<3>; and the barrel pressure intensity is 2.6-2.8MPa. The glass bead with the honeycomb holes is regular in appearance, high in compression strength and low in water absorption rate, is used as the light-weight packing in the dry mixed mortar, has the characteristics of large volume yield and the like, is easy to construct and is an ideal material which replaces expanded perlite to be used as the light-weight packing in the dry mixed mortar. The invention also provides tile glue with the honeycomb-hole glass bead. The tile glue comprises the following raw materials in percentage by weight of: 45-50% of portland cement, 15-20% of glass bead with honeycomb holes, 10-15% of heavy calcium carbonate, 10-15% of fine sand and 6-9% of additive.

Owner:广东龙湖科技股份有限公司

Inorganic colorized decoration mortar and preparation method thereof

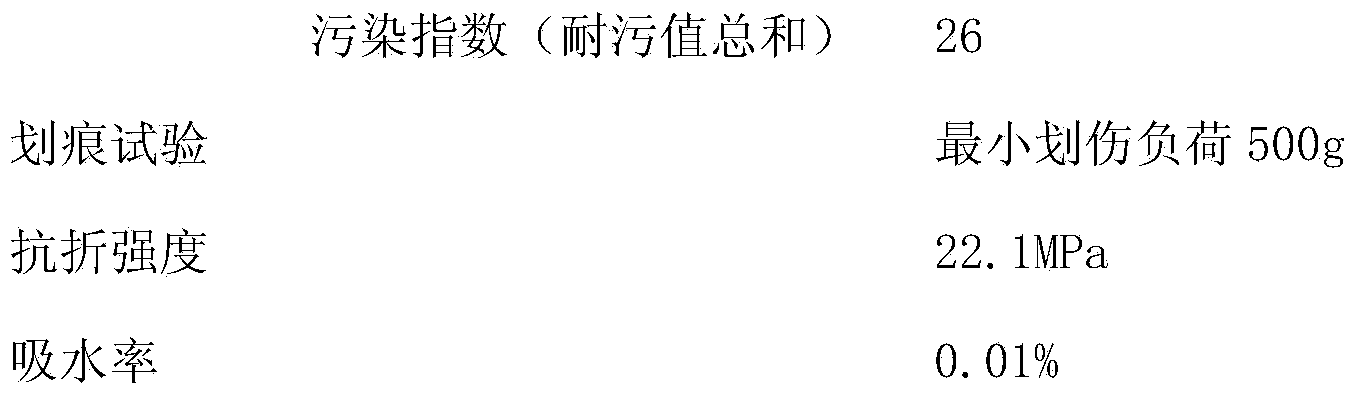

The invention which belongs to the technical field of building materials concretely relates to an inorganic colorized decoration mortar and a preparation method thereof. The motor is characterized in that the motor comprises the following components, by weight, 15-40% of cement, 40-70% of an aggregate, 1-30% of an auxiliary material, 0.5-5.0% of nanoscale micropowder, 0.5-4.0% of a thixotropic agent, 0.1-3% of an early strength agent, 1-10% of a dispersant, 0.1-1.5% of a thickener, 0.1-1.5% of a water repellent and 0.01-8% of a coloring agent, wherein the total weight percentage of all the components is 100%. The inorganic colorized decoration mortar prepared by uniformly mixing the components according to above proportions in a factory has the advantages of excellent cohesiveness with a wall base, very good hydrophobicity and permeability, and excellent contamination resistance, and the weatherability and the long-term stability are better than that of organic coatings. The inorganic colorized decoration mortar can be prepared by adding 10-25% of water at a building site and uniformly and mechanically stirring when being used. The mortar can be directly daubed or sprayed on the base, so the mortar has the characteristics of simple construction and easy operation.

Owner:汪峻峰 +1

Quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and preparation method thereof

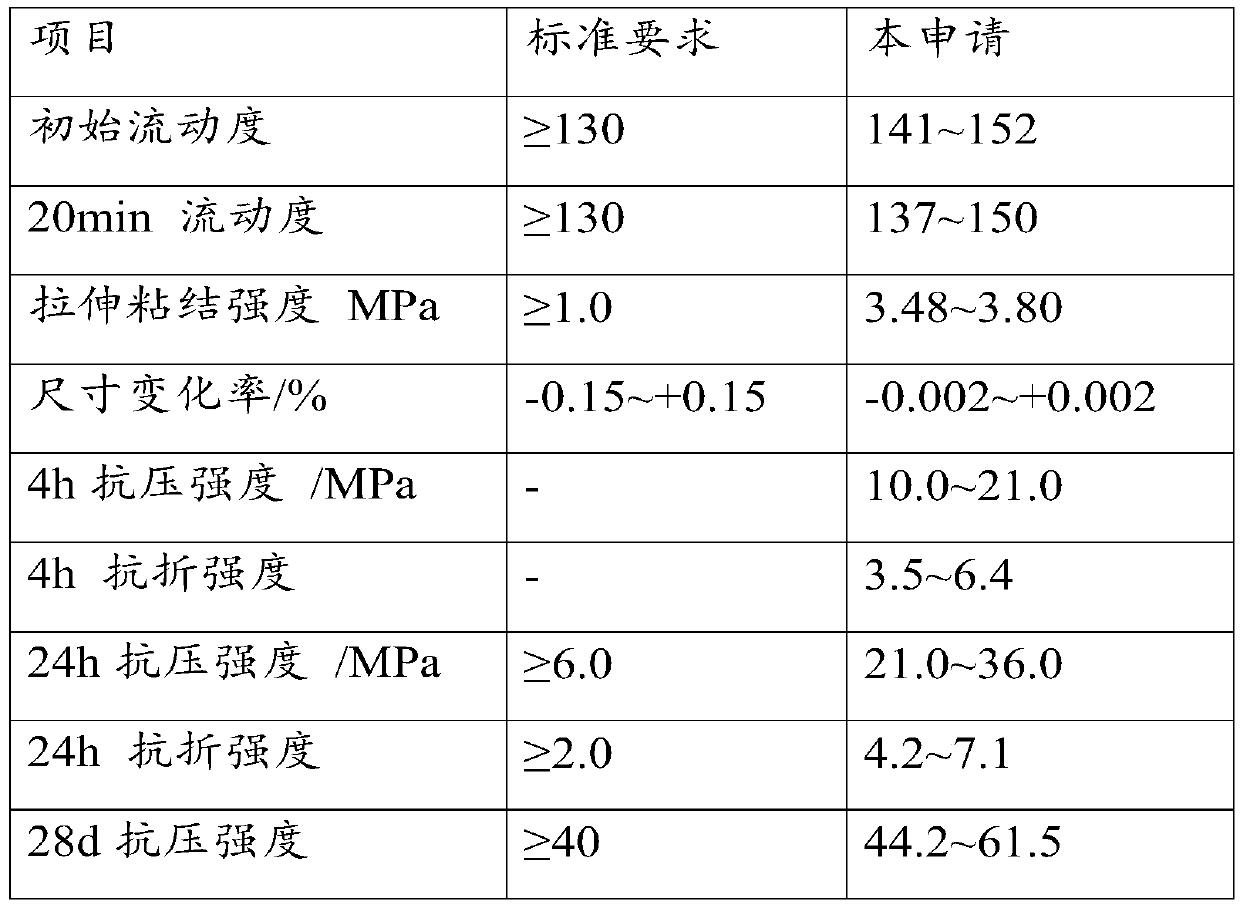

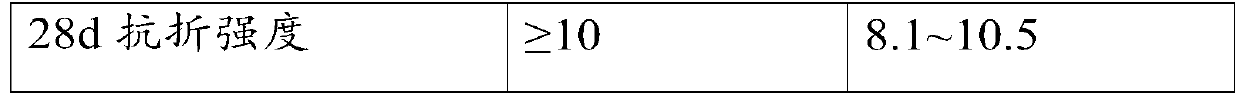

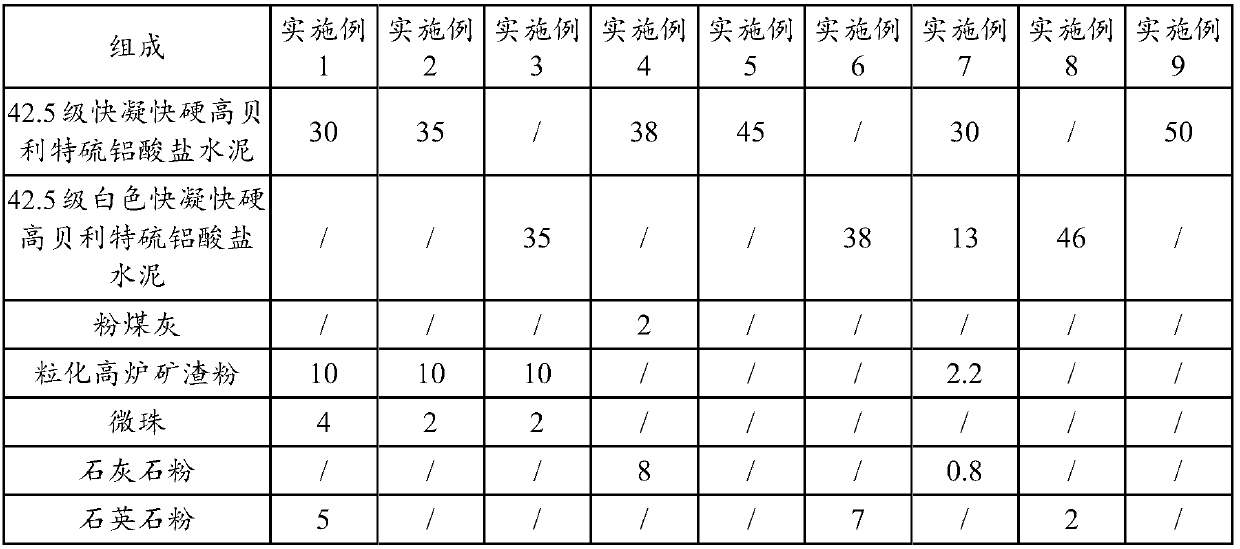

PendingCN109836106AImprove initial fluidityNo significant decrease in fluidity after 20 minutesAcid corrosionSlurry

The invention provides quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and a preparation method, and relates to the field of building materials. The mortar powder comprises the following raw materials in percentage by weight: 30%-50% of quick-cementing and -hardening high-belite sulphoaluminate cement, 46.19%-51.97% of a fine aggregate, 0.15%-0.3% of a waterreducing agent, 0%-0.04% of a thickening agent, 0.05%-0.2% of a defoaming agent, 0.5%-3.5% of latex powder, 0.075%-0.25% of a retarder and 0.15%-0.3% of a coagulation accelerator. The self-leveling mortar has the excellent properties of acid corrosion resistance, small shrinkage, high tensile bonding strength, high setting and hardening speed and the like, and is suitable for self-leveling floors,industrial floors, civil floors, artistic floors and the like in an acid salt environment.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

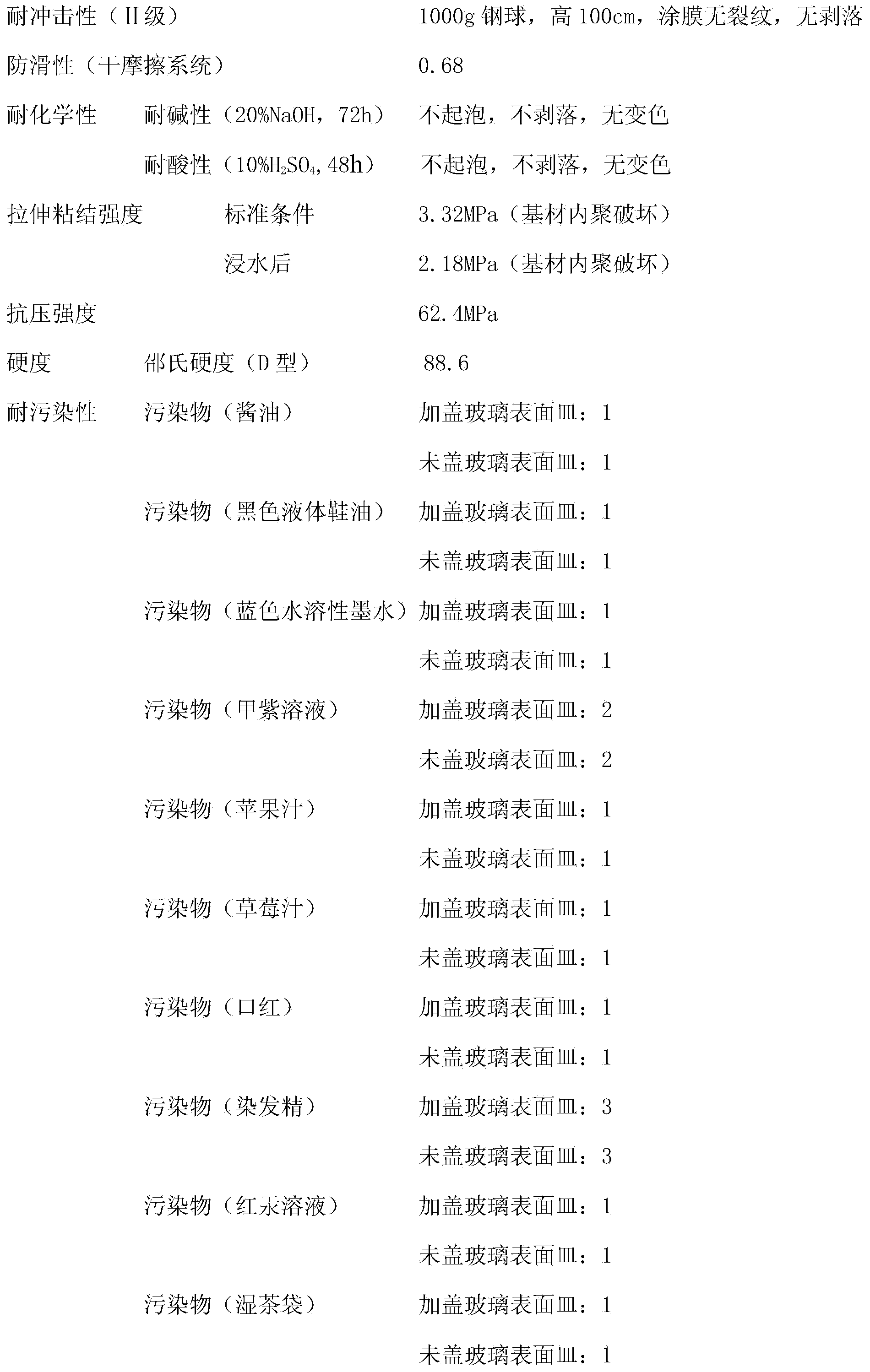

Water-borne epoxy resin flooring paint, flooring and construction process of water-borne epoxy resin flooring paint

ActiveCN103627309AImprove wear resistanceImprove impact resistancePolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyMass ratio

The invention relates to a water-borne epoxy resin flooring paint, and belongs to the technical field of chemical materials. The water-borne epoxy resin flooring paint comprises finishing paint and priming paint, the finishing paint comprises the following components in parts by mass (100 parts in total): 73-80 parts of polyurethane, 20-27 parts of water-borne auxiliary B, the 20-27 parts of water-borne auxiliary B contains 5-8 parts by mass of dispersing agent, 2-3 parts by mass of preservative, 5-8 parts by mass of feeling agent and 5-8 parts by mass of wetting agent; the priming paint comprises a component A, an epoxy resin hardener in a mass ratio of 1: 2.5, the component A (100 parts in total) comprises 60-75 parts by mass of epoxy resin, 2-3 parts by mass of pigment, 18-21 parts by mass of filler, and 1-20 parts by mass of water-boron auxiliary A; and the water-boron auxiliary A comprises the dispersing agent, the preservative, the feeling agent and the wetting agent. According to the water-boron epoxy resin flooring paint, the problem that the existing flooring paint is bad in skid resistance is overcome.

Owner:中山市诚美涂料有限公司

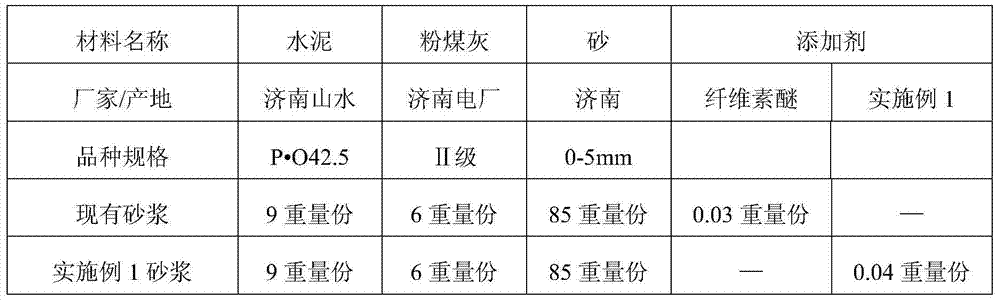

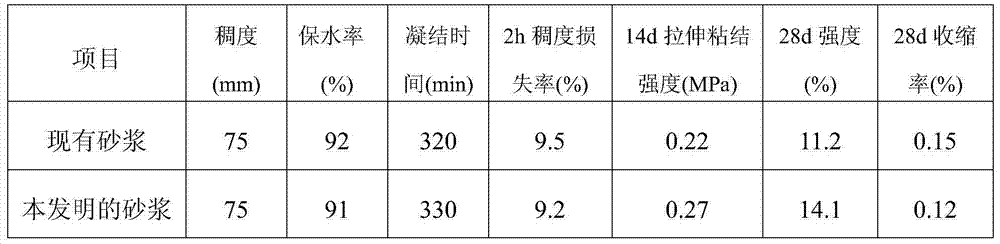

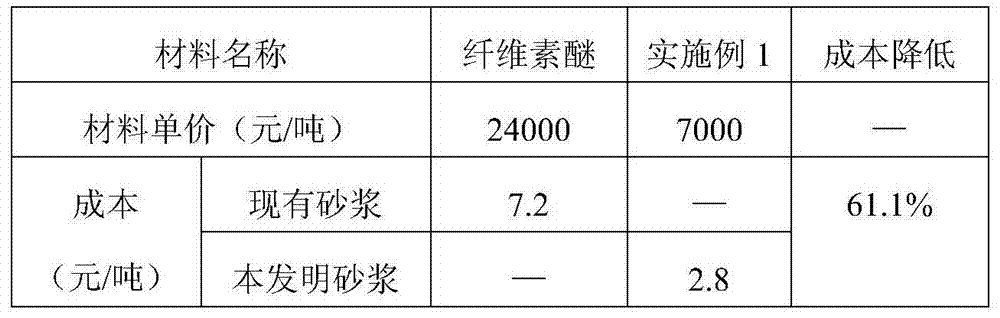

Water-retaining, thickening and reinforcing additive for cement mortar and cement mortar containing additive

The invention discloses a water-retaining, thickening and reinforcing additive for cement mortar and cement mortar containing the additive, wherein the additive is corn straw cellulose or / and modified corn straw cellulose. The water-retaining, thickening and reinforcing additive for cement mortar and the cement mortar containing the additive, disclosed by the invention, have the beneficial effects that the water-retaining, thickening and reinforcing additive for cement mortar is a green environment-friendly product which is free from toxicity, peculiar smell, pollution and corrosivity; if the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is doped into cement mortar, the water-retaining property of mortar can be effectively improved; the water-retaining property of freshly mixed mortar is more than 90% and meets standard requirements; simultaneously, the intensity of mortar is obviously increased; the use amount of cement is effectively reduced; the intensity of mortar is increased by above 25%; the 14d tensile adhesive intensity is increased by above 13%; the cost of the water-retaining and thickening material is reduced by above 16%; a utilization way of the industrial by-product, namely cellulose, separated from corn straws, is effectively provided; furthermore, the utilization value is higher. The cost of the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is 4000-8000 yuan / ton, and the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is wide in source of used raw materials, proper in cost, convenient to use, high in operability and beneficial to popularization.

Owner:SHANDONG HUASEN CONCRETE

Anti-crack plaster mortar for outer wall of building and method for preparing anti-crack plaster mortar

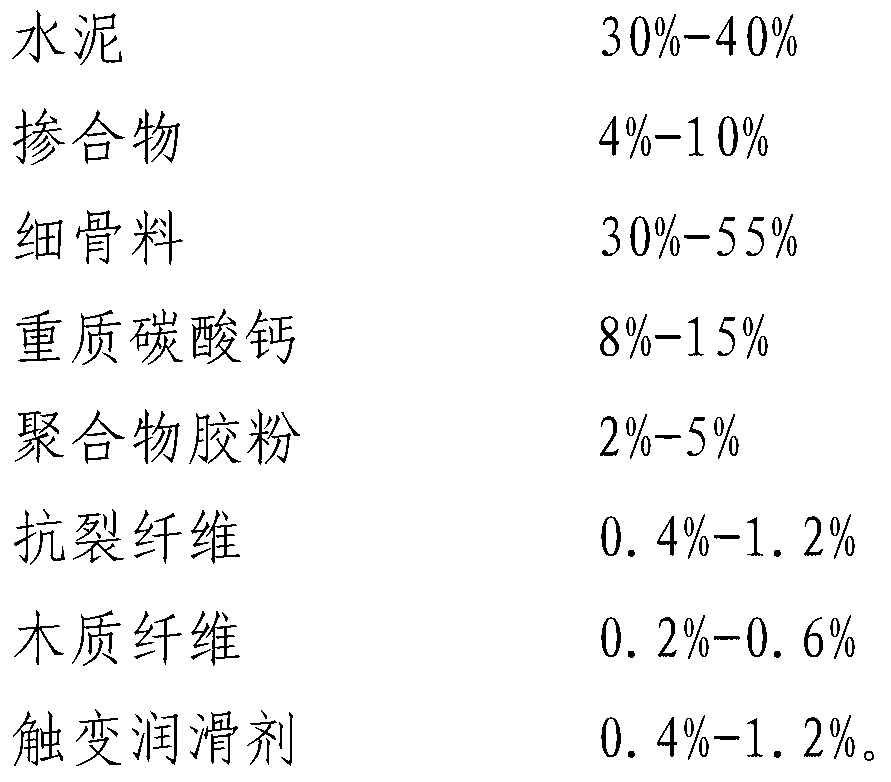

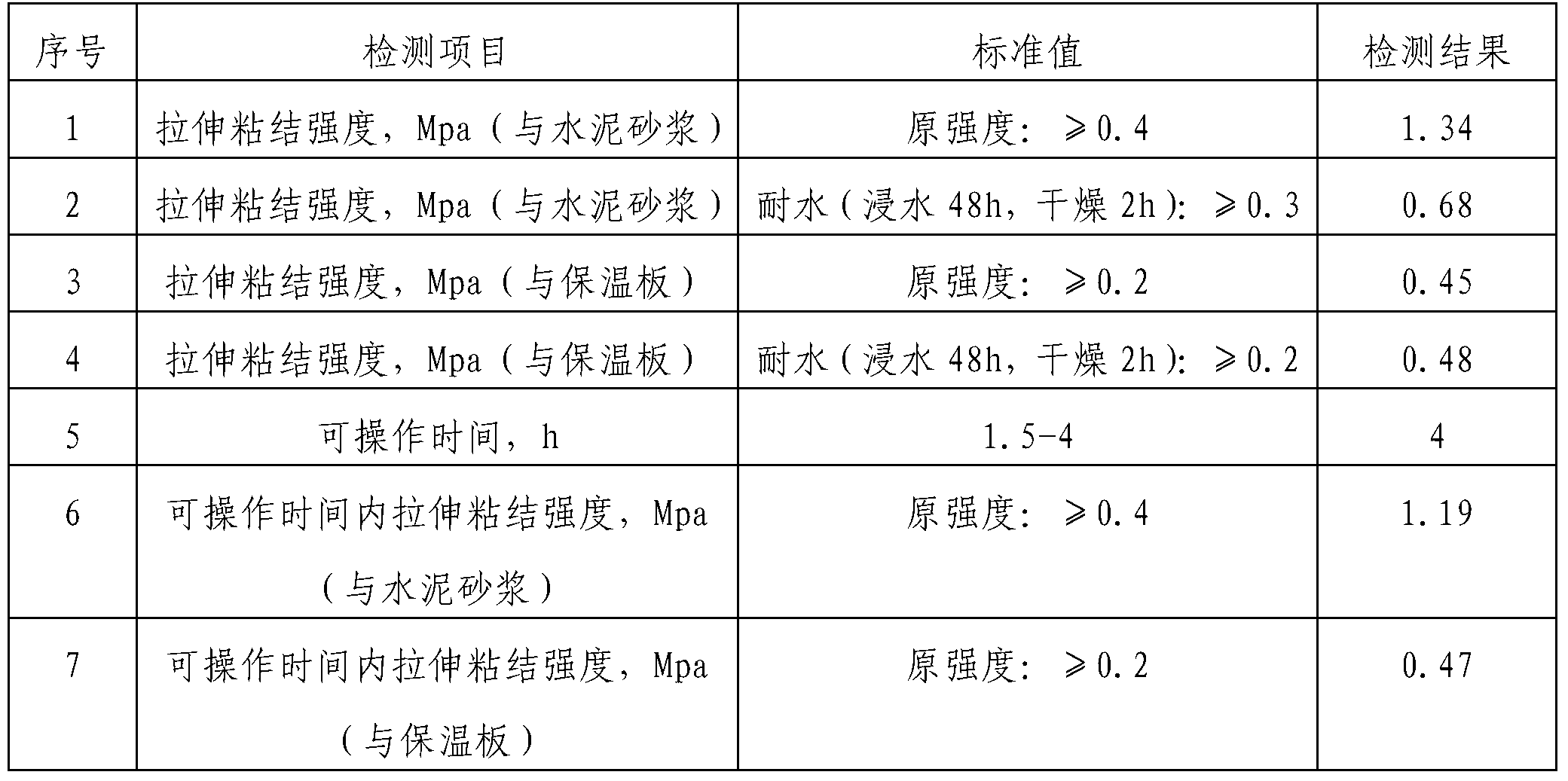

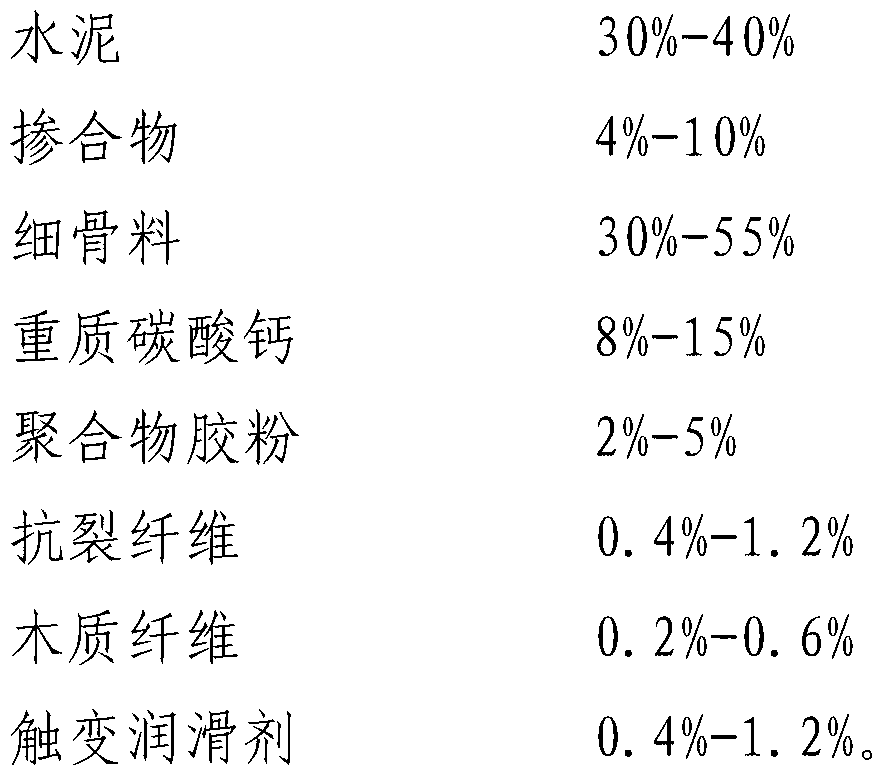

The invention belongs to the field of building materials, and in particular relates to anti-crack plaster mortar for an outer wall of a building and a method for preparing the anti-crack plaster mortar. The anti-crack plaster mortar for the outer wall of the building comprises the following raw materials in percentage by weight: 30 to 40 percent of cement, 4 to 10 percent of blend, 30 to 55 percent of fine aggregate, 8 to 15 percent of heavy calcium carbonate, 2 to 5 percent of polymer rubber powder, 0.4 to 1.2 percent of anti-crack fiber, 0.2 to 0.6 percent of wood fiber and 0.4 to 1.2 percent of a thixotropic lubricant. The anti-crack plaster mortar for the outer wall of the building is high in tensile adhesive strength and high in workability and flexibility; a water leakage crack is not formed in plaster after eighty high-temperature to water-spraying cycles and thirty heating to freezing cycles; phenomena of chalking, hollowing, peeling and the like are avoided; the anti-crack plaster mortar is high in crack resistance, good in construction property and low in cost, and does not stick to a tool during construction.

Owner:上海宝冶工程技术有限公司

Bonding mortar special for ultrathin heat insulation board and preparation method of bonding mortar

InactiveCN102531483AHigh tensile bond strengthHigh strengthInsulation systemUltimate tensile strength

The invention discloses a bonding mortar special for an ultrathin heat insulation board and a preparation method of the bonding mortar. The preparation method comprises the following steps of: precisely metering materials, including 20 to 40 parts of cement, 45 to 65 parts of quartz sand, 0 to 25 parts of filler, 0 to 10 parts of an auxiliary and the like; feeding the cement into a mixing stirrer for stirring; then feeding the auxiliary; after the auxiliary is uniformly dispersed, feeding the filler and the quartz sand; and stirring without gravity to obtain the bonding mortar. The bonding mortar and the preparation method thereof disclosed by the invention have the advantages that: the mortar special for the ultrathin heat insulation board is used as a product mated with a heat insulation system, so that the tensile bonding strength of the ultrathin heat insulation board is improved greatly; therefore, the safety is realized after the ultrathin heat insulation board is mounted on a wall; and furthermore, the bonding mortar has the characteristics of environment friendliness, economy, high strength and the like.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL +1

Silicone sealant with ultra-high strength and preparation method of silicone sealant

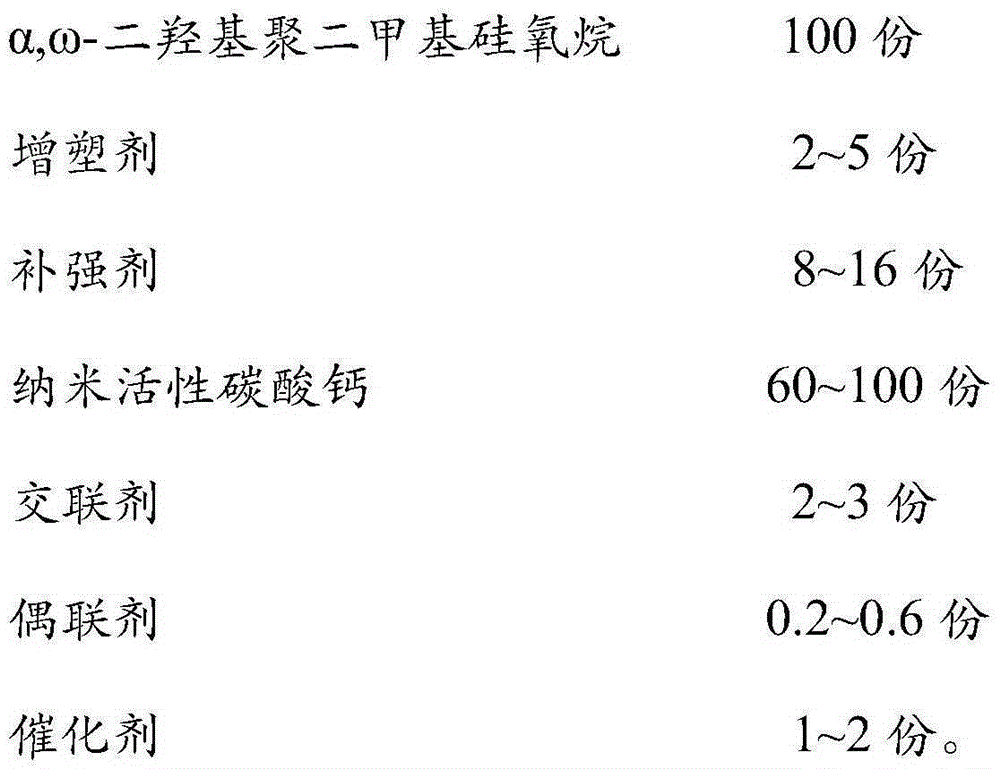

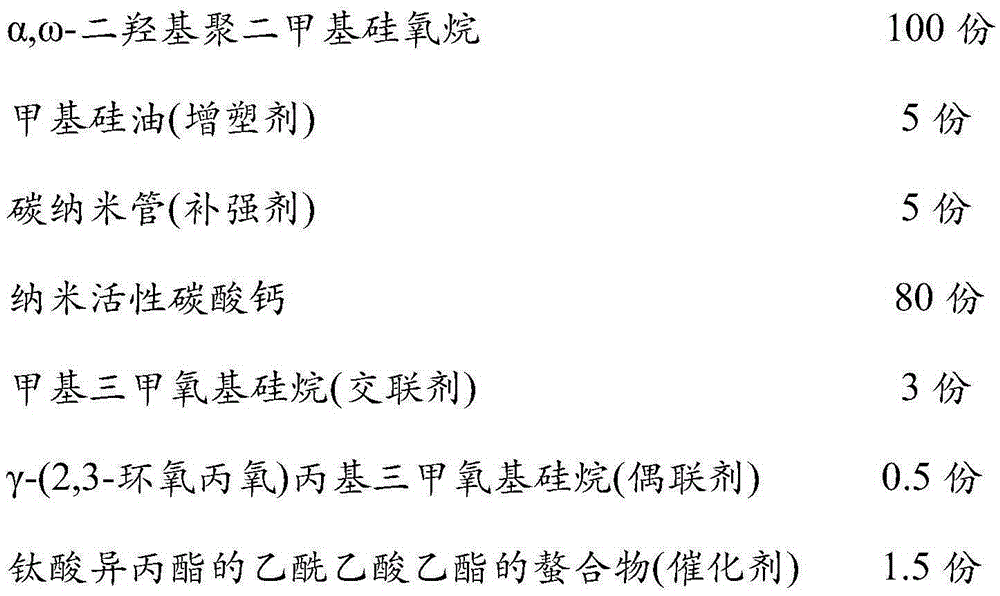

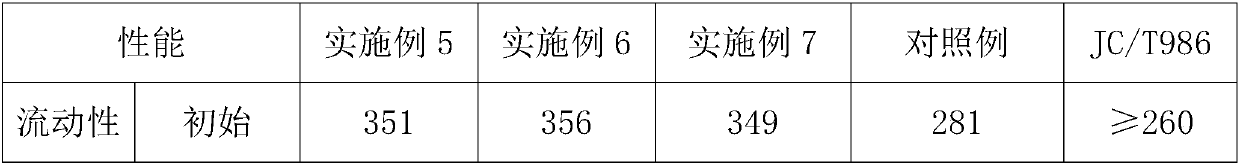

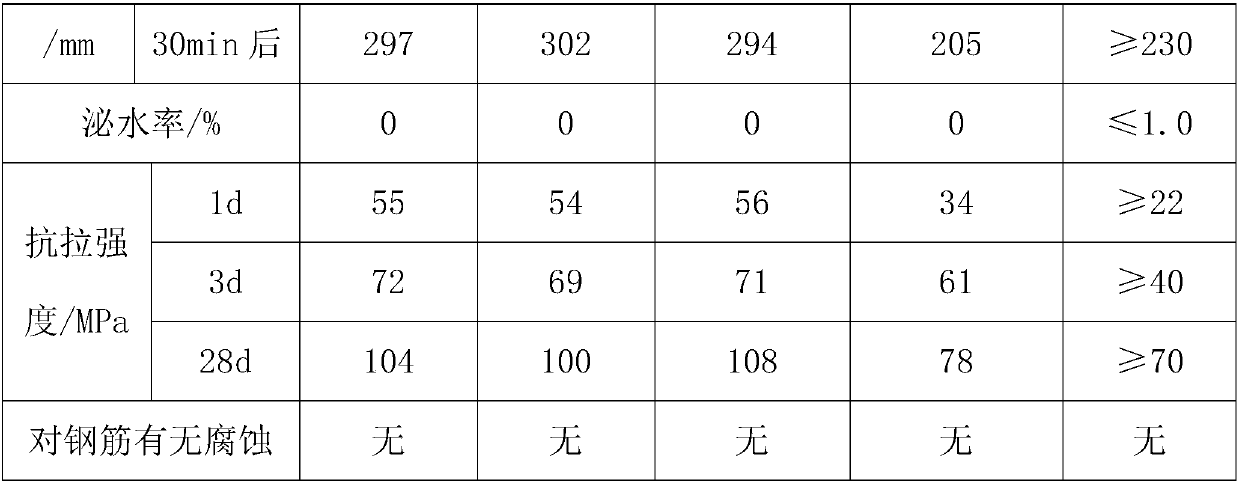

ActiveCN105368379AHigh mechanical strengthHigh viscosityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkPolymer science

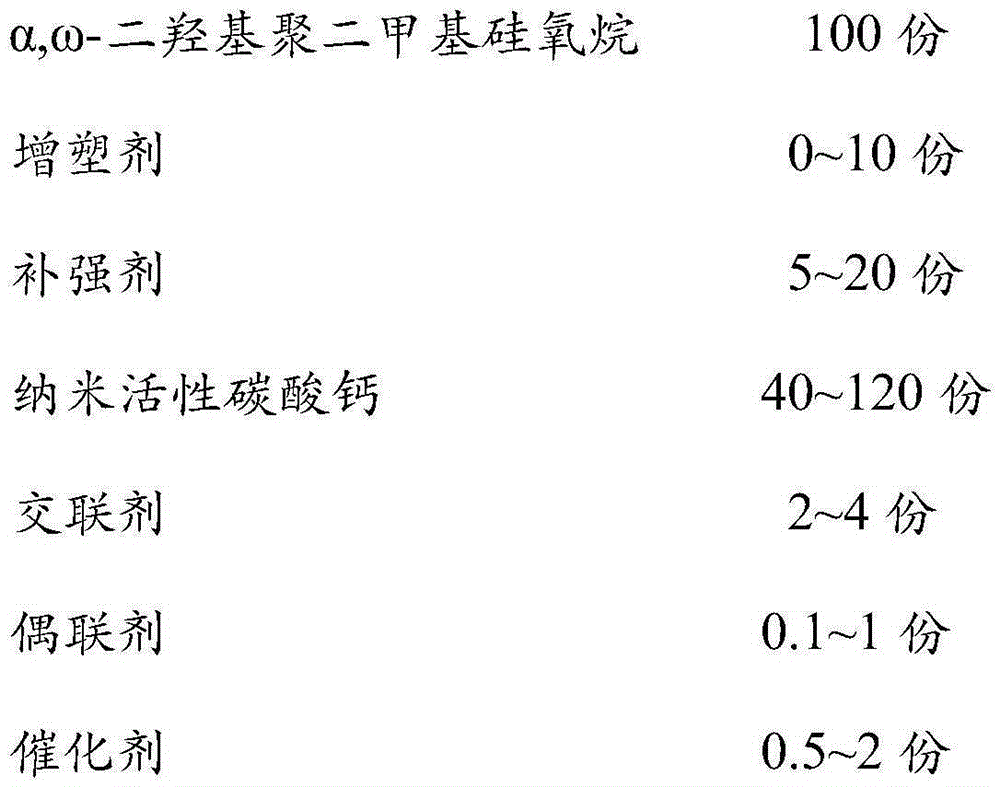

The invention discloses a silicone sealant with ultra-high strength and a preparation method thereof. The silicone sealant is prepared from raw materials including alpha, omega-dihydroxyl polydimethylsiloxane, a plasticizer, a reinforcing agent, active nano-calcium carbonate, a cross-linking agent, a coupling agent, a catalyst and the like. The silicone sealant with the ultra-high strength is high in hardness and has very high tensile adhesive strength and zero bonding failure area under the conditions of the temperature of subzero 30 DEG C-90 DEG C, immersion in water, water-ultraviolet illumination and the like, and the technical situation of low strength of the conventional silicone sealant is effectively improved.

Owner:GUANGZHOU BAIYUN CHEM IND

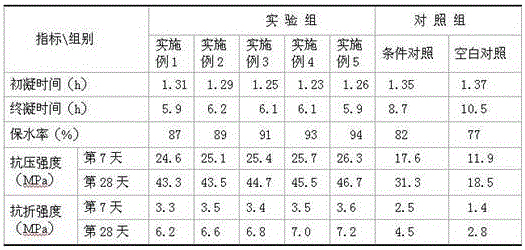

Grouting material for assembly type building reinforcement connection sleeve

InactiveCN107686314AGood water retentionIncreased compressive and flexural strength of mortarRebarPliability

The invention discloses a grouting material for an assembly type building reinforcement connection sleeve. The grouting material is prepared from the following raw materials in percentage by weight: 45-60% of cement, 30-45% of fine aggregates, 1-2% of an enhancer, 0.05-0.1% of a de-foaming agent, 7-10% of a phosphogypsum composite expanding agent, 0.5-0.8% of a polycarboxylic acid water reducer, 0.05-0.09% of a retarder, and 0.08-0.2% of an early strength agent, wherein the phosphogypsum composite expanding agent is a mixture of modified phosphogypsum, phosphorus slag micro powder and wollastonite. According to the grouting material disclosed by the invention, continuously graded fine sand and quartz sand are used as fine aggregates to match with the cement for use, the fine aggregates andthe cement are reasonably proportioned, and the phosphogypsum composite expanding agent is added, so that cement paste is very compact after being hardened; the grouting material is greatly improvedin strength, is matched with the enhancer, the retarder, the polycarboxylic acid water reducer and the early strength agent for use, so that mortar has good water-retaining property, plasticity and flexibility; and tensile bonding strength as well as mortar and brickwork tensile bonding strength are obviously improved, comprehensive properties are good, and using requirements of an assembly type building are met.

Owner:无为县严桥双龙建材厂(普通合伙)

Gypsum-based self-leveling repair mortar and preparation method thereof

The invention provides gypsum-based self-leveling repair mortar and a preparation method thereof. The repair mortar is prepared from the following components in parts by weight: 40 to 60 parts of building gypsum, 40 to 60 parts of quartz sand, 0 to 10 parts of stone powder, 0.1 to 0.2 part of a gypsum retarder, 0.01 to 0.02 part of a water-retaining agent, 0.01 to 0.02 part of rubber powder, 0.05to 0.15 part of a defoaming agent and 0.1 to 0.15 part of a water reducing agent. The preparation method comprises the following steps: uniformly mixing the building gypsum, the quartz sand and the stone powder in proportion, sequentially adding the gypsum retarder, the water-retaining agent, the rubber powder, the defoaming agent and the water reducing agent, uniformly mixing, adding water, and uniformly stirring and mixing to obtain the repair mortar. The repair mortar is high in tensile bonding strength, capable of achieving rapid repairing of gypsum-based self-leveling ground, convenient to repair, high in efficiency and free of shrinkage and cracking on the ground in the later period, and the problem that the gypsum-based self-leveling ground cracks and cannot be completely repaired is well solved.

Owner:HENAN QIANGNAI NEW MATERIALS CO LTD

Adhesive mortar for ceramic tile

The invention relates to a mortar and provides an adhesive mortar for a ceramic tile. The adhesive mortar for the ceramic tile contains tailings, is high in tensile adhesive strength and low in cost, does not pollute the environment, and has a heat preservation effect. The adhesive mortar for the ceramic tile comprises the following materials in parts by weight: 30-35 parts of ecological cement, 0.5-0.6 part of polyving akohol, 30-50 parts of tailings, 5-10 parts of polypropylene monofilament, 1.3-2.8 parts of a defoamer, 12-17 parts of a water reducer, 17-19 parts of coal ash, 7-9 parts of glass bead, 21-32 parts of ceramic sand, 1.5-2.5 parts of cellulose ether, 4-8 parts of redispersible powder and 70-90 parts of water, wherein the ceramic sand comprises sand grains with the grain diameters of 0.10-2.0 mm and with a plurality of pores not communicated in the surfaces.

Owner:荣达新型建材(福建)集团有限公司

Preparation method of flame-retarding cement-based interface mat used in exterior wall external insulation

InactiveCN102515641AHigh tensile bond strengthImprove flame retardant performancePolymer scienceSlurry

The invention discloses a preparation method of a flame-retarding cement-based interface mat used in exterior wall external insulation. The method is characterized in comprising the steps that: quartz powder, a solid fire retardant, and cement are well mixed, such that inorganic powder is prepared; high-molecular polymer emulsion, deionized water, an antifoaming agent, and a bactericide are well mixed, such that a polymer agent material is obtained; the inorganic powder and the polymer agent material are well mixed in a mixing apparatus, such that a flame-retarding cement-based interface slurry is prepared; the flame-retarding cement-based interface slurry is coated onto a surface of a reinforced glass fiber mat by using an adhesive tape coating machine; the mat is subject to bake-drying, rectifying, edge-trimming, and coiling, such that the flame-retarding cement-based interface mat used in exterior wall external insulation is prepared. With the provided method, the prepared flame-retarding cement-based interface mat can be composed onto surfaces of inorganic insulation materials such as rigid foam polyurethane, phenol formaldehyde, and XPS, such that surface flame-retardance of the insulation plates can be improved, and tensile adhesive strength between the insulation plates and polymer mortar can improved. The preparation method is advantaged in simple technology, low one-time investment, and high processing efficiency.

Owner:YANTAI ZHENGHAI NEW MATERIALS

Light-weight thermal insulation anti-crack plastering gypsum

The invention belongs to the technical field of building materials and construction, and particularly relates to light-weight thermal insulation anti-crack plastering gypsum. The plastering gypsum comprises the following components of: in percent by weight, 15-20% of vitrified microbeads, 45-50% of gypsum, 20-25% of cement, 5-10% of fly ash, 3-5% of silica fume, 0.5% of hydroxy propyl methyl cellulose, 0.3-0.5% of polypropylene fiber, 3-5% of redispersible latex powder and 0.5-0.8% of a silicone hydrophobic agent, and water accounts for 90% of the total mass of the components. The light-weightthermal insulation anti-crack plastering gypsum has good thermal insulation heat-shielding performance and good crack resistance, and the defects of easy crack and low thermal insulation coefficientof existing plastering gypsum are overcome; meanwhile, the plastering gypsum has good constructability, water retention and a sound insulation effect, can be widely applied to inner and outer walls ofbuildings, has simple construction and a broad market application prospect, and can meet requirements of construction of a resource-friendly society in China.

Owner:TAIYUAN UNIV OF TECH

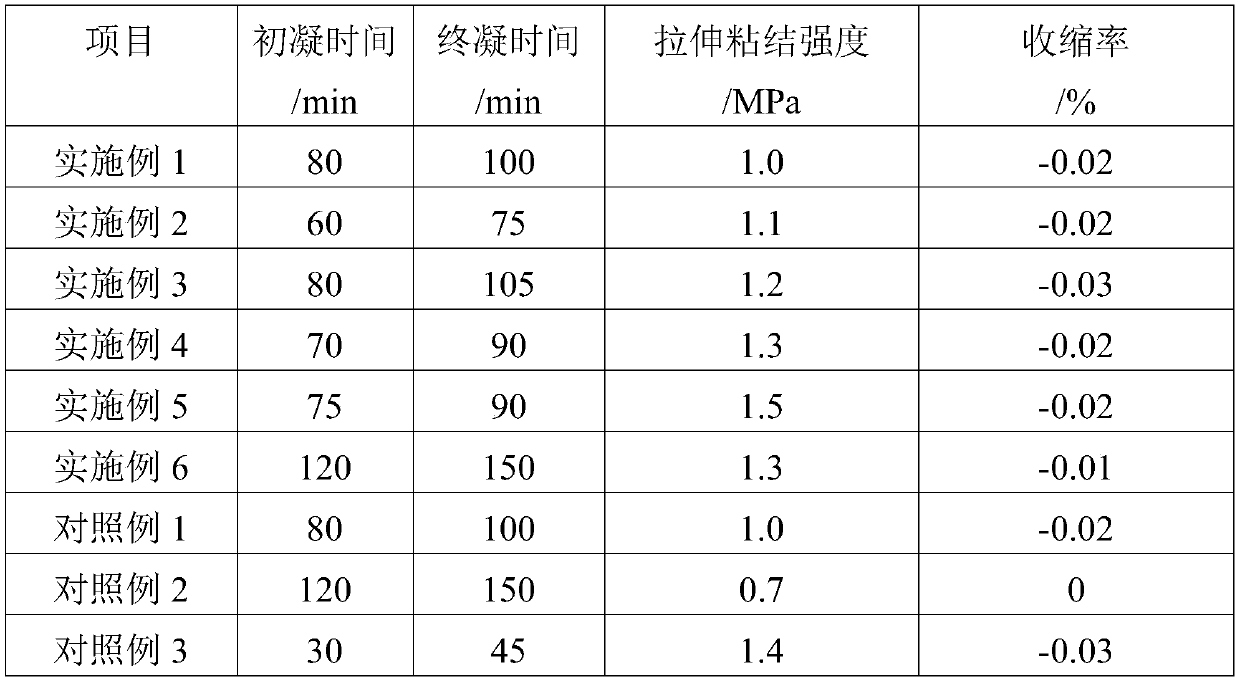

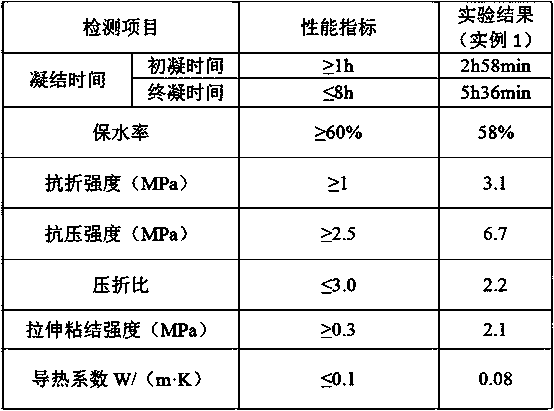

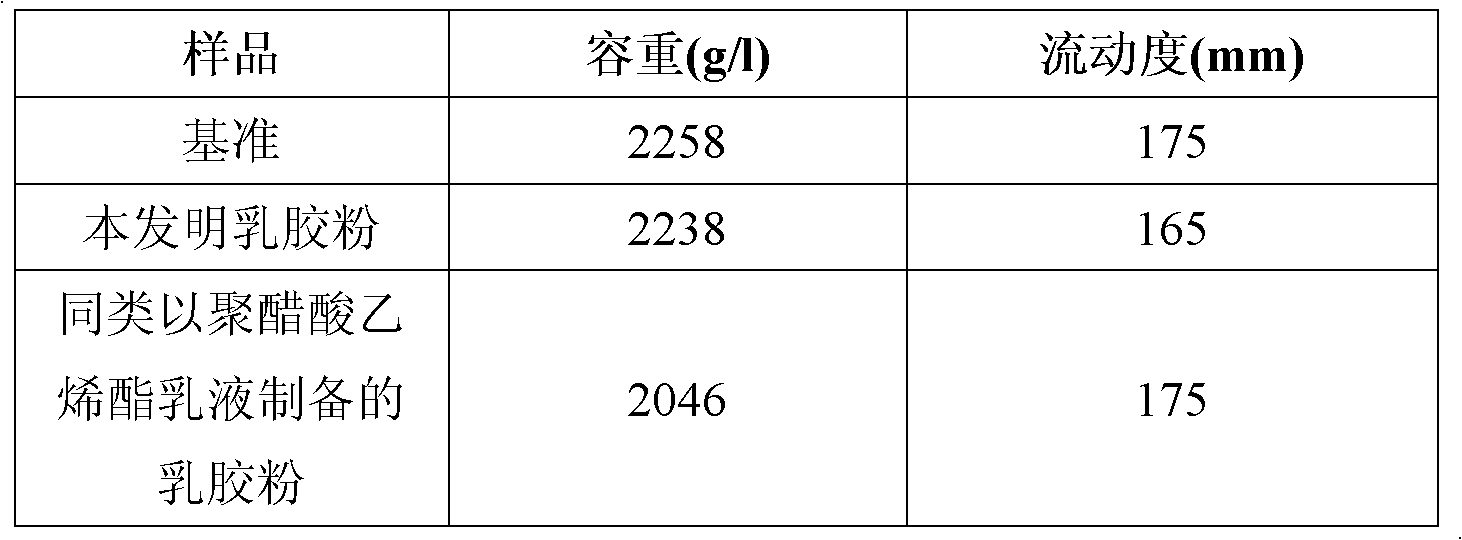

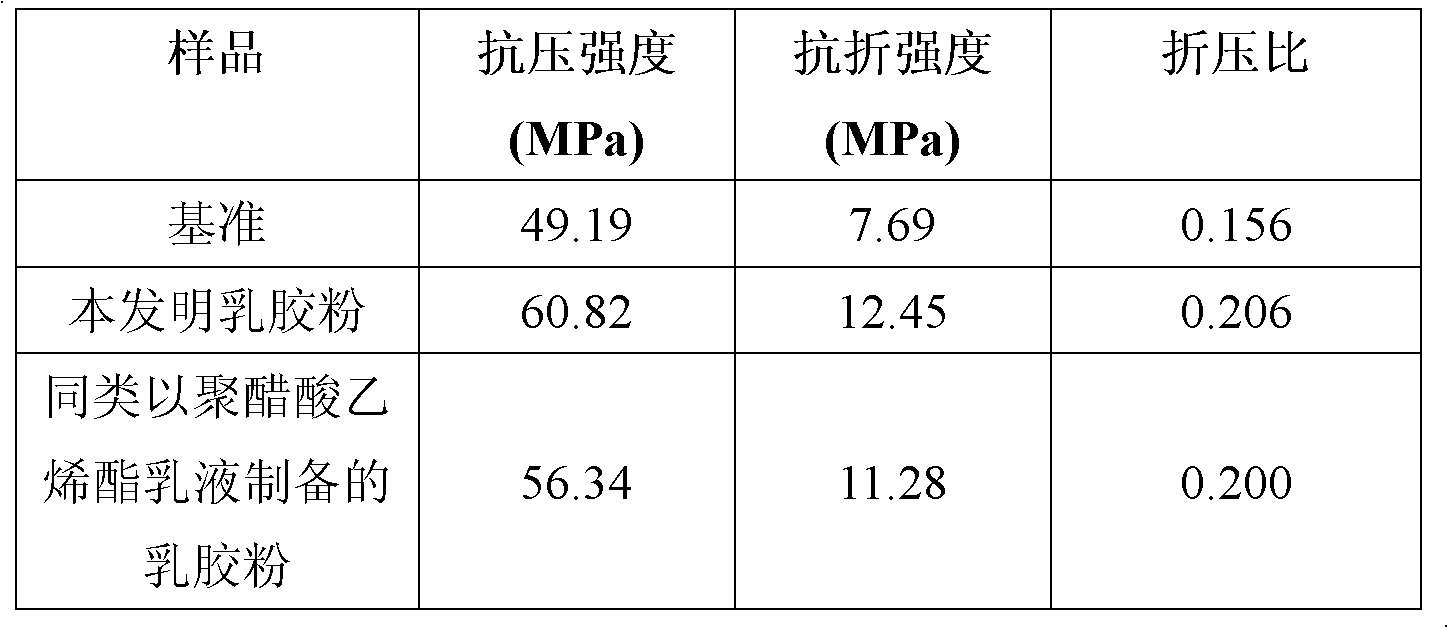

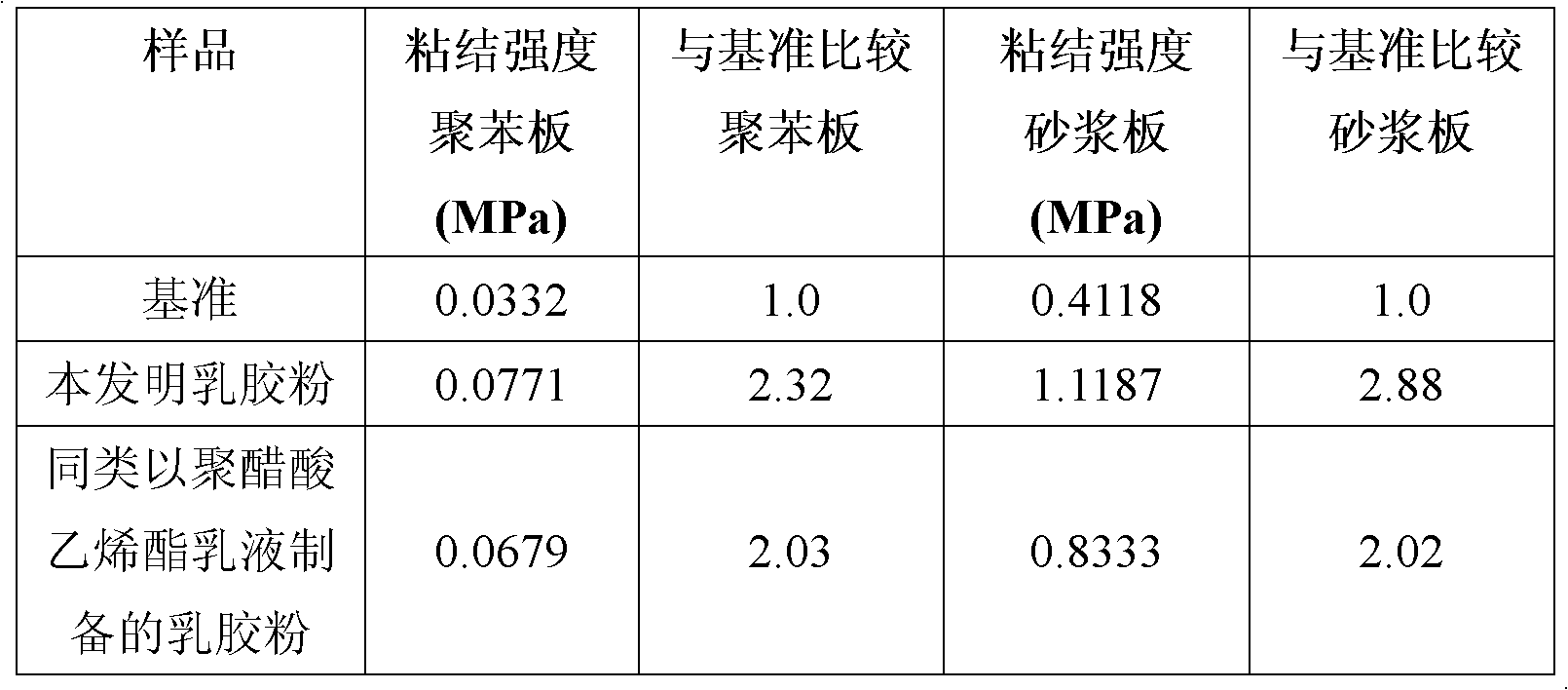

Vinylacetate nonsoap emulsion, redispersible rubber powder and preparation methods thereof

The invention relates to vinylacetate nonsoap emulsion, redispersible rubber powder and preparation methods thereof. The vinylacetate nonsoap emulsion comprises the following components in percentage by mass: 5 to 10 percent of protective colloid, 0.1 to 0.5 percent of sodium bicarbonate, 30 to 60 percent of vinylacetate, 5 to 30 percent of tertiary vinyl carbonate, 5 to 30 percent of butyl acrylate, 0.5 to 5 percent of emulsifier, 0.1 to 0.5 percent of initiator and the balance of water. The redispersible rubber powder is prepared by spray-drying the mixture of the following components in percentage by mass: 70 to 80 percent of vinylacetate nonsoap emulsion, 5 to 15 percent of protective colloid, 5 to 15 percent of anticaking agent and the balance of water. Compared with the conventional dispersible polymer powder, the redispersible rubber powder can improve the new stirring performance, mechanical performance and adhesive performance of modified mortar obviously.

Owner:JIANGSU SOBUTE NEW MATERIALS

Addition agent having synergistic effect on cement and preparing method

InactiveCN105693131AImprove physical and mechanical propertiesWide variety of sourcesSodium phosphatesNitrilotriacetic acid

The invention discloses an addition agent having a synergistic effect on cement.The addition agent is prepared from, by weight, 5.4-5.8 parts of nitrilotriacetic acid, 1.8-2.4 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 2.4-2.7 parts of triisopropanolamine, 3.7-4.3 parts of acrylamide, 3.2-3.5 parts of alpha-sodium-olefinsulfonate, 3.3-3.6 parts of useless lubricating oil, 3.9-4.4 parts of lauryl sodium sulfate, 4.9-5.7 parts of urea, 2.2-2.5 parts of calcium lignosulfonate, 0.6-0.8 parts of molasses, 2.6-3.0 parts of sodium thiosulfate, 2.1-2.5 parts of a silicone lubricating agent, 1.5-1.9 parts of a fluorine-containing lubricating agent, 2.1-2.5 parts of polysorbate-80 and 2.3-2.7 parts of sorbitol.The construction efficiency can be improved effectively, price is low, the enhancing effect is remarkable, fallen dust is reduced, resources are saved, the raw materials are wide in source, and the manufacturing technology is simple.

Owner:王金奎

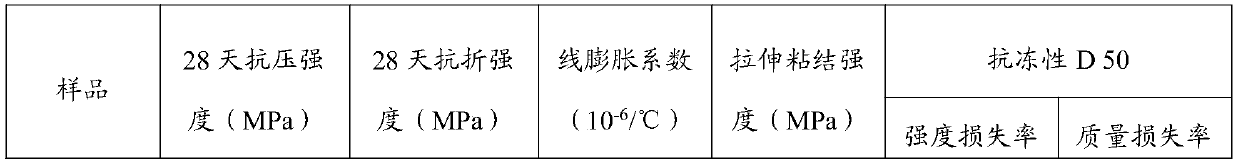

Low linear expansion coefficient epoxy resin based cement concrete road fast repairing material and preparation method thereof

The invention provides a low linear expansion coefficient epoxy resin based cement concrete road fast repairing material and a preparation method thereof, and belongs to the technical field of a building material. The epoxy resin based cement concrete road fast repairing material provided by the invention is prepared from the following ingredients in parts by weight: 100 parts of epoxy resin, 30 to 50 parts of curing agents, 5 to 10 parts of toughening agents, 5 to 15 parts of diluents, 50 to 100 parts of modified coal gasification slag, 50 to 100 parts of waste ceramic powder and 400 to 600 parts of medium sand. The modified coal gasification slag is prepared from coal gasification slag through roasting activation and modification reaction. The epoxy resin based cement concrete road fastrepairing material provided by the invention has the advantages of low linear expansion coefficient, small deformation quantity along with temperature change, high intensity, good bonding performance,high durability and low production cost, and is favorable for the popularized application of the epoxy resin mortar.

Owner:鄂尔多斯市慧达科技有限公司

Reinforcing agent for bonding bricks

The invention discloses a reinforcing agent for bonding bricks. The reinforcing agent is prepared from a powder component and a liquid component, which are mixed evenly at the ratio of 2 to 1 in use, wherein the powder component is prepared from the following raw materials: 30%-45% of 42.5 ordinary portland cement, 51.5%-68.8% of 30-60mesh quartz sand, 1%-3% of redispersible powder VAE, and 0.2%-0.5% of hydroxypropyl methyl cellulose ether with the viscosity being 40000 / mPa.s; and the liquid component is prepared from the following raw materials: 40%-60% of acrylic emulsion and 40%-60% of water. The reinforcing agent is coated on the back surface of each brick, and then is dried, and the bricks are pasted by adopting a cement-based adhesive. According to the reinforcing agent disclosed by the invention, the tensile adhesive strength between the adhesive and the bricks is improved; the situations of hollowing and dropping of the bricks after being pasted are reduced; and the bricks are relatively firm and safe to paste.

Owner:上海曹杨建筑粘合剂厂

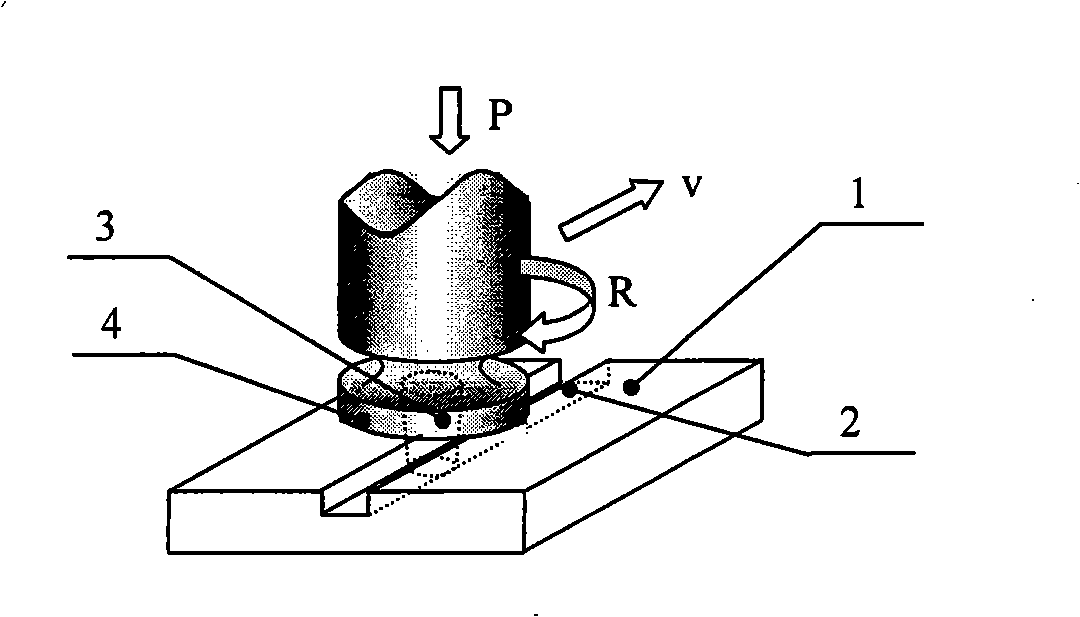

Method for preparing titanium alloy/hydroxylapatite gradient composite coating

InactiveCN101327337AFacilitates atomic diffusionHigh tensile bond strengthCoatingsProsthesisMachine partsHydroxylapatite

The invention discloses a gradient compound coating of a titanium alloy / hydroxyapatite and a preparation method thereof. The surface of the titanium alloy to be made is polished, cleaned and baked; 2 to 10 perforated flutes of 2mm multiplied by 2mm to 4 mm multiplied by 4mm are processed on the surface of the titanium alloy every 12mm; all the flutes are parallel to each other and are filled with powder; the titanium alloy filled with powder is placed on a tool with a heating device and is fixed and clamped; the titanium alloy is stirred by friction under the conditions that the room temperature rises to 350 DEG C to 500 DEG C, the rotation speed of a stirrer head ranges from 450 r / min to 850 r / min; the horizontal speed ranges from 28 mm / min to 90 mm / min, with an angle of inclination of 2.5 DEG. The rear area of a stirring area is provided with a cooling device, with the machining parts protected by argon gas. By a stirring method, the HA powder is stirred on the surface of the titanium alloy, thus forming viscoplasticity, speeding up the atom proliferation between the titanium alloy and the HA powder, and generating a chemical bond. The tensile-bonding strength is raised from 24.8MPa in the prior art to ranging from 65 MPa to 103MPa.

Owner:NANTONG MING YU NEW MATERIAL TECH CO LTD +1

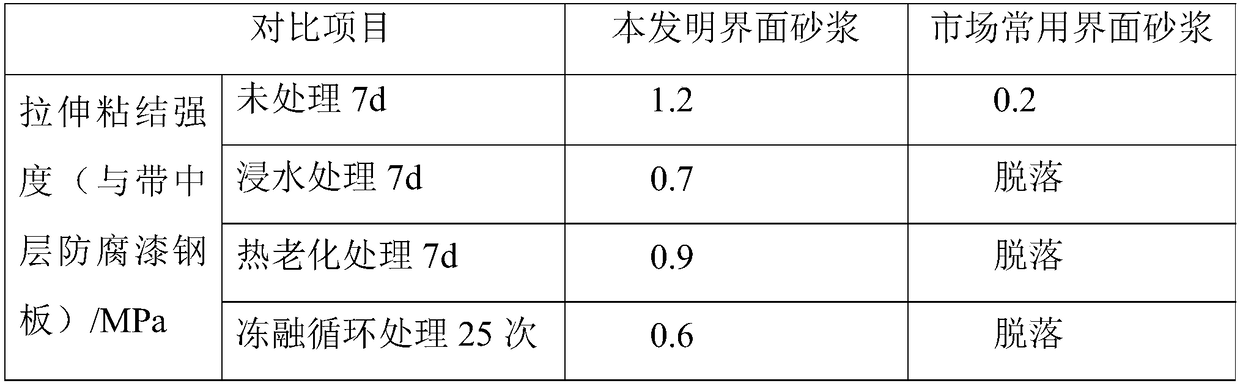

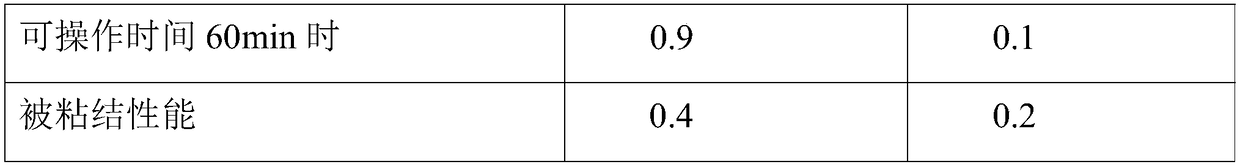

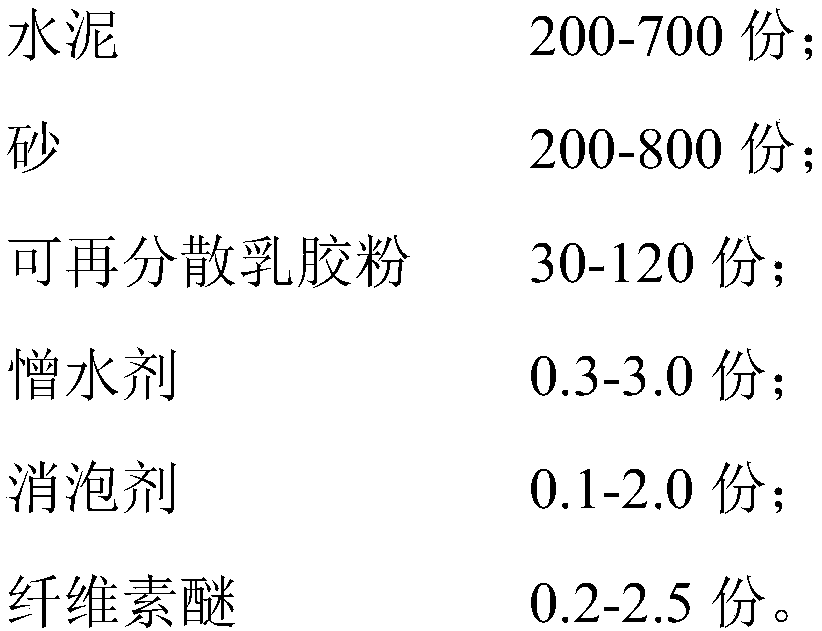

Interface mortar for steel structural exterior wall with anticorrosive coating layer

ActiveCN109020370AGood tensile bond strengthHigh tensile bond strengthCovering/liningsFreeze thawingCellulose

The invention relates to an interface mortar for a steel structure outer wall with an anticorrosive coating layer. The interface mortar comprises, by weight, 200-700 parts of cement, 200-800 parts ofsands, 30-120 parts of redispersible latex powder, 0.3-3.0 parts of a water repellent, 0.1-2.0 parts of a defoaming agent and 0.2-2.5 parts of cellulose ether. The interface mortar can effectively ensure the adhesion with the surface of a steel structure base layer with the anticorrosive coating layer, and has good bonded performance with a thermal insulation mortar, a bonding mortar, a plasteringmortar, a waterproof mortar and other mortars. Compared with traditional interface mortars for concrete and the masonry base layer, the interface mortar in the invention has the advantages of good affinity with the surface of the steel structure with the anticorrosive coating layer, high tensile bond strength, good bonded performance, small decrease of the tensile bond strength after water immersion, freeze-thawing and heat treatment, good durability, and meeting of the requirements of the use environment of the steel structure exterior wall with the anticorrosive coating layer.

Owner:HANGXIAO STEEL STRUCTURE

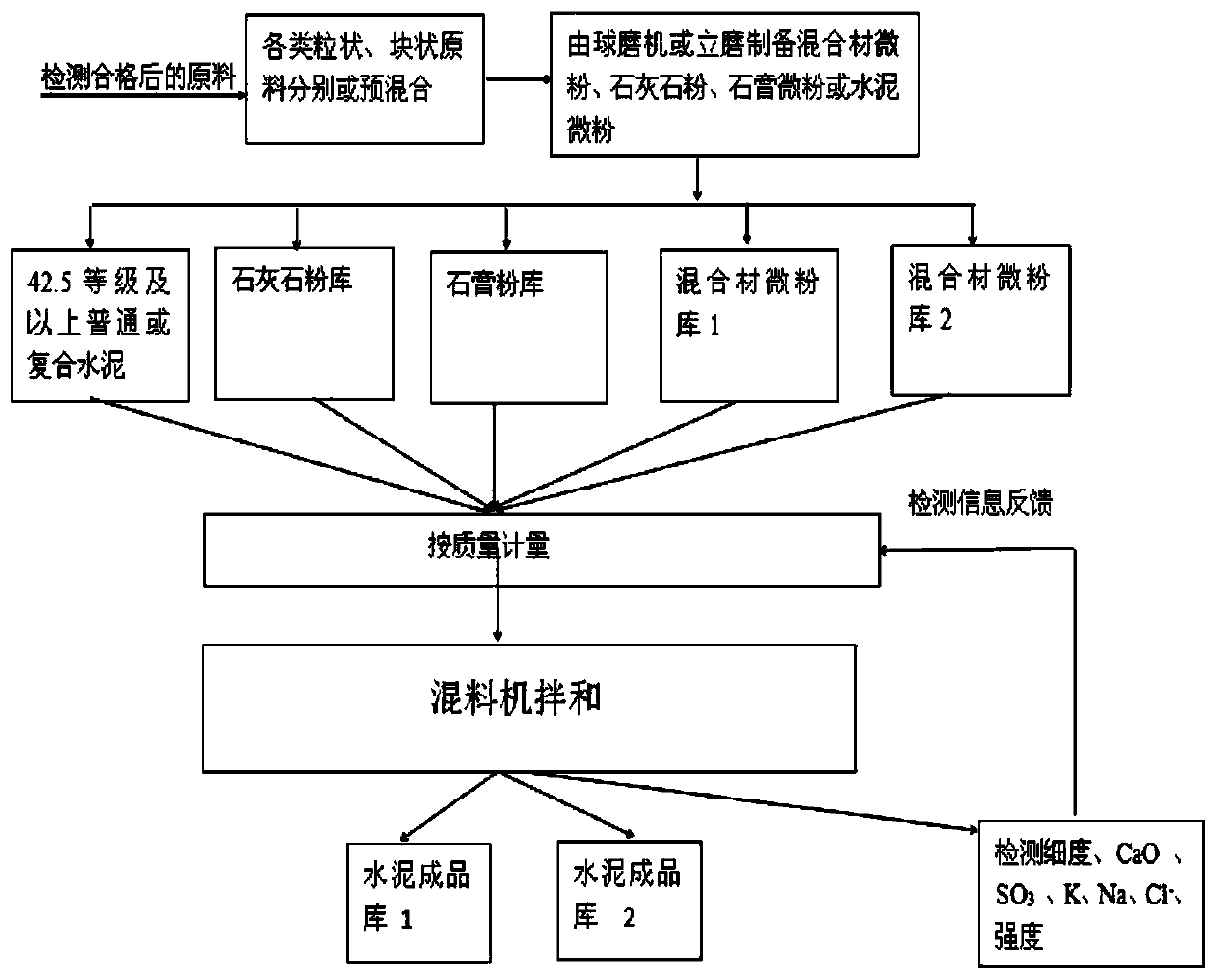

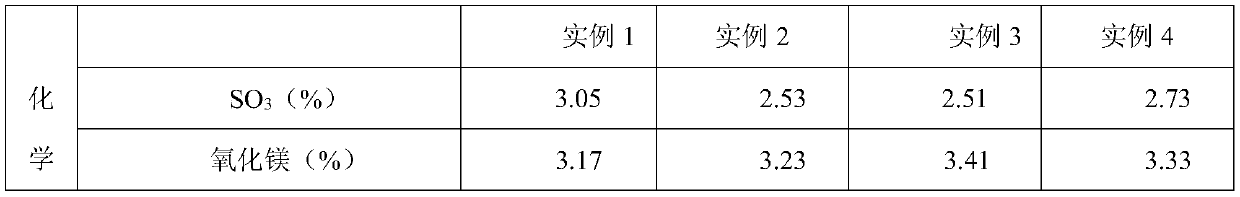

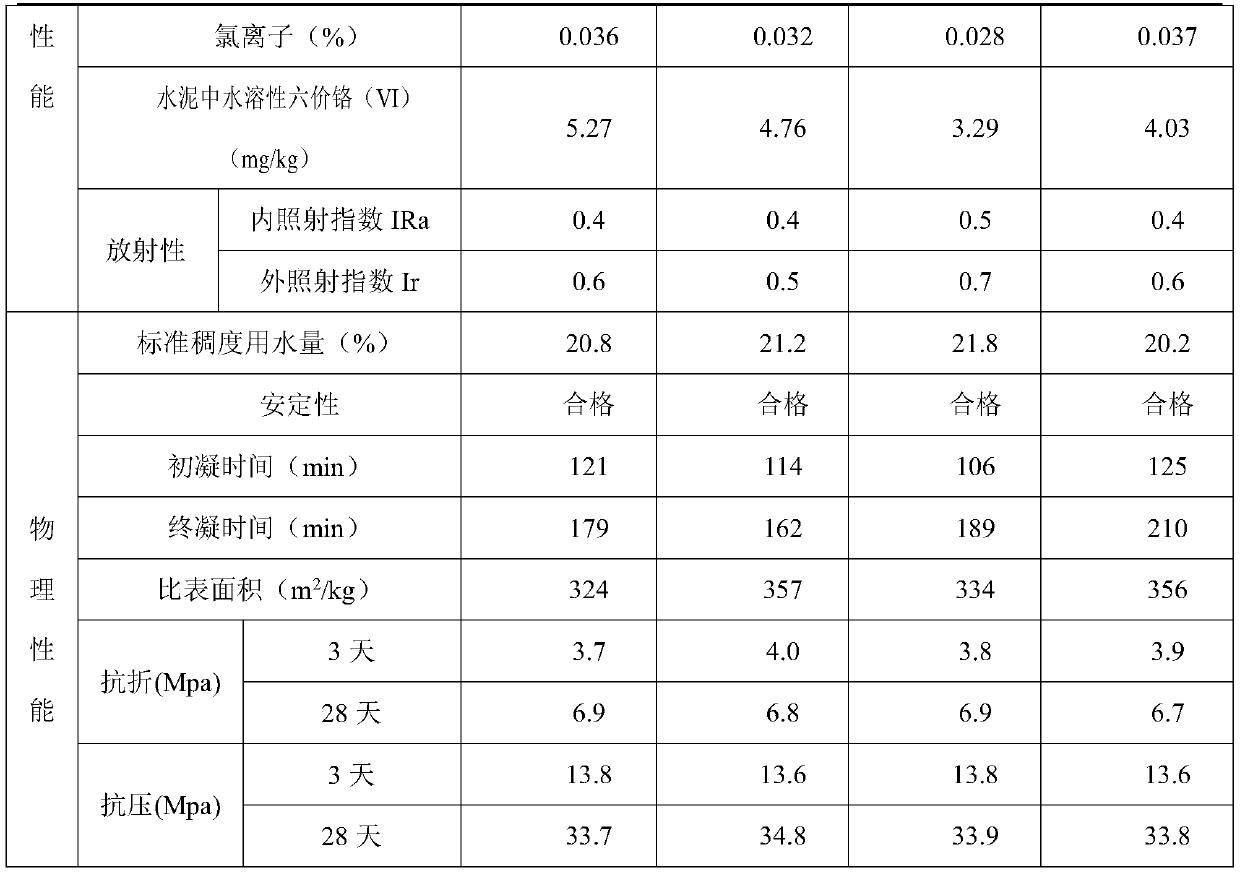

Special mixed cement for on-site preparation of concrete as well as preparation method and application

The invention relates to the field of cement and concrete. The invention discloses special mixed cement for on-site preparation of concrete as well as a preparation method and application. Except formixing and grinding cement clinker and other raw materials, the mixed cement is prepared from the following components in percentage by mass: 60%-80% of general Portland cement of the 42.5 grade or above, 3.0%-6.0% of gypsum, 5%-15% of limestone, 2%-29% of an admixture and 0.5%-3.0% of a functional additive. The general Portland cement with the grade of 42.5 or above meets the requirements of GB175, and parameters of the general Portland cement are controlled such that the mass ratio of the micro powder less than or equal to 3 [mu]m is less than or equal to 10%, the one-day compressive strength is less than or equal to 12 MPa, the 3-day compressive strength is more than or equal to 20 MPa, the 28-day compressive strength is more than or equal to 45 MPa, the water consumption of the standard consistency of the cement paste is less than or equal to 28%, the alkali content is less than 0.6% in terms of 0.658 K2O + Na2O, and the chloride ion content is less than 0.06%. The raw materials are wide in source, the mixed cement can be directly used for preparing or premixing concrete on site, no admixture or functional additive needs to be added again, crack resistance, workability and themechanical property of the concrete are improved, and construction operation is simplified.

Owner:程菲 +1

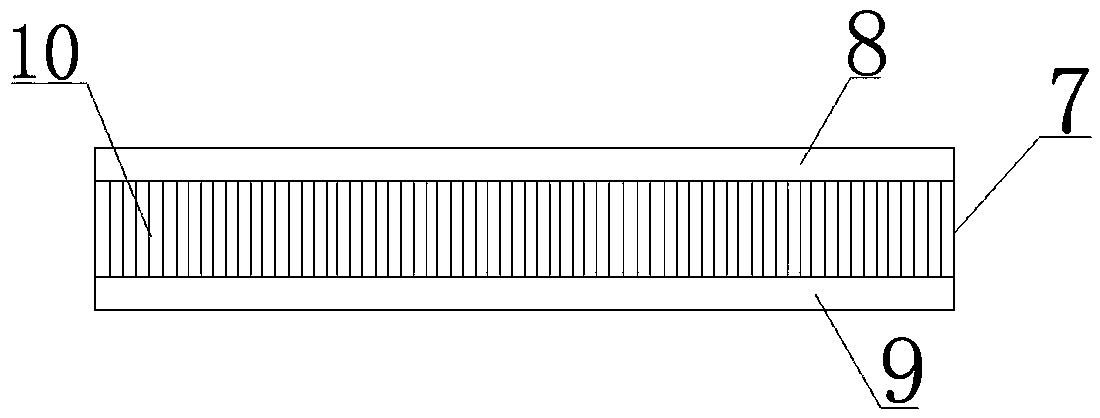

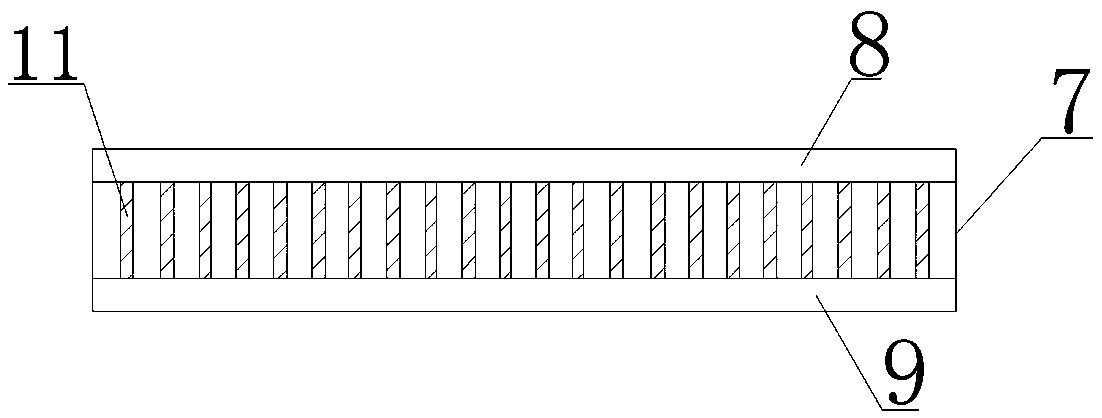

Lightweight dismantle-free heat insulation template integrated composite heat insulation system and manufacturing technology thereof

PendingCN110258867AReduce manual labor intensityEnhanced deformation stressWallsClimate change adaptationInsulation layerManufacturing technology

The invention belongs to a lightweight dismantle-free heat insulation template integrated composite heat insulation system and manufacturing technology thereof. The lightweight dismantle-free heat insulation template integrated composite heat insulation system comprises a cast-in-place concrete base wall body, a heat insulation template inner protective layer, an organic heat insulation material layer, seamed reinforced glass wool or a rock wool board inorganic material insulation layer, and a polymer mortar layer are sequentially arranged on the outer side of the cast-in-place concrete base wall body, and are fixedly mounted and connected with the cast-in-place concrete base wall body through pre-embedded anchoring connecting parts, and the outer surface of the seamed reinforced glass wool or the rock wool board inorganic material insulation layer is coated with the polymer mortar layer. The lightweight dismantle-free heat insulation template integrated composite heat insulation system has the advantages that structure design is reasonable, the lightweight, high intensity and low heat conductivity performance are achieved, the comprehensive cost can be lowered, the load of buildings is relieved, the whole thickness of the mortar layer on the outer surface of the wall body is advantageously controlled, and the safety of anti-cracking, anti-falling-off and anti-fire is improved.

Owner:河南省澳科保温节能材料技术开发有限公司

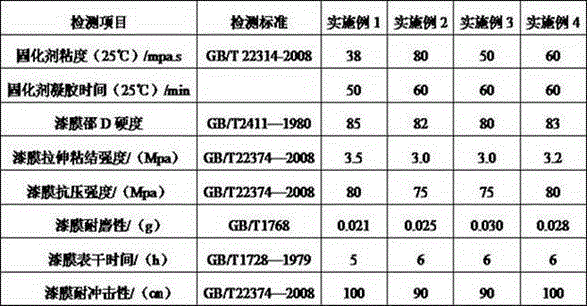

Modified polyether amine curing agent and preparation method and application thereof

The invention discloses a modified polyether amine curing agent and a preparation method thereof. The modified polyether amine curing agent is prepared from, by weight, 40-60 parts of a polyether amine curing agent, 20-30 parts of a phenol synergy additive, 5-20 parts of phenylcarbinol and 5-20 parts of 2,4,6-tris(dimethylaminomethyl)phenol. The prepared modified polyether amine curing agent is small in viscosity, long in gelation time and easy to prepare. An epoxy resin paint film prepared through the modified polyether amine curing agent is good in impact resistance, high in tensile adhesive strength, good in wear resistance and excellent in overall performance.

Owner:惠州市彩田化工实业有限公司 +1

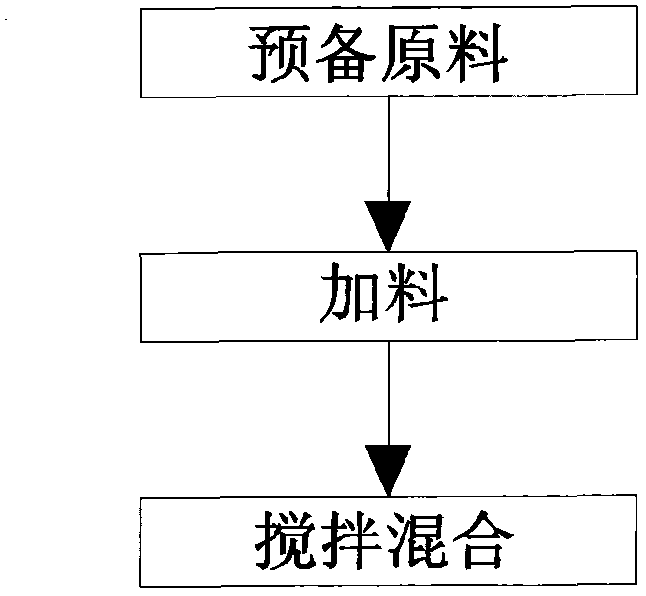

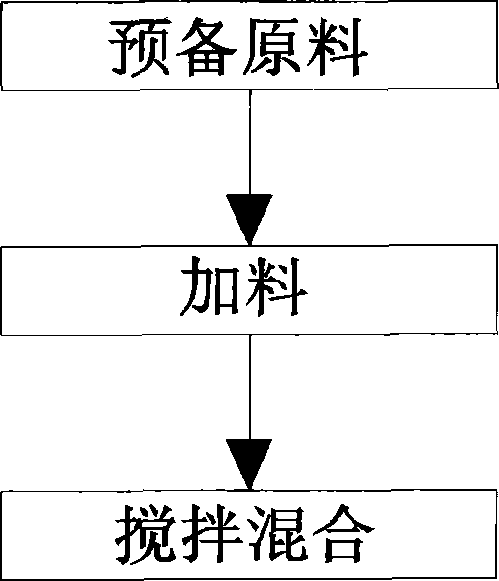

Preparation method of cracking-resistance and maintenance-free plastering mortar, product and construction method thereof

InactiveCN102690086ASimple preparation processEasy to implementCovering/liningsChemistryBonding strength

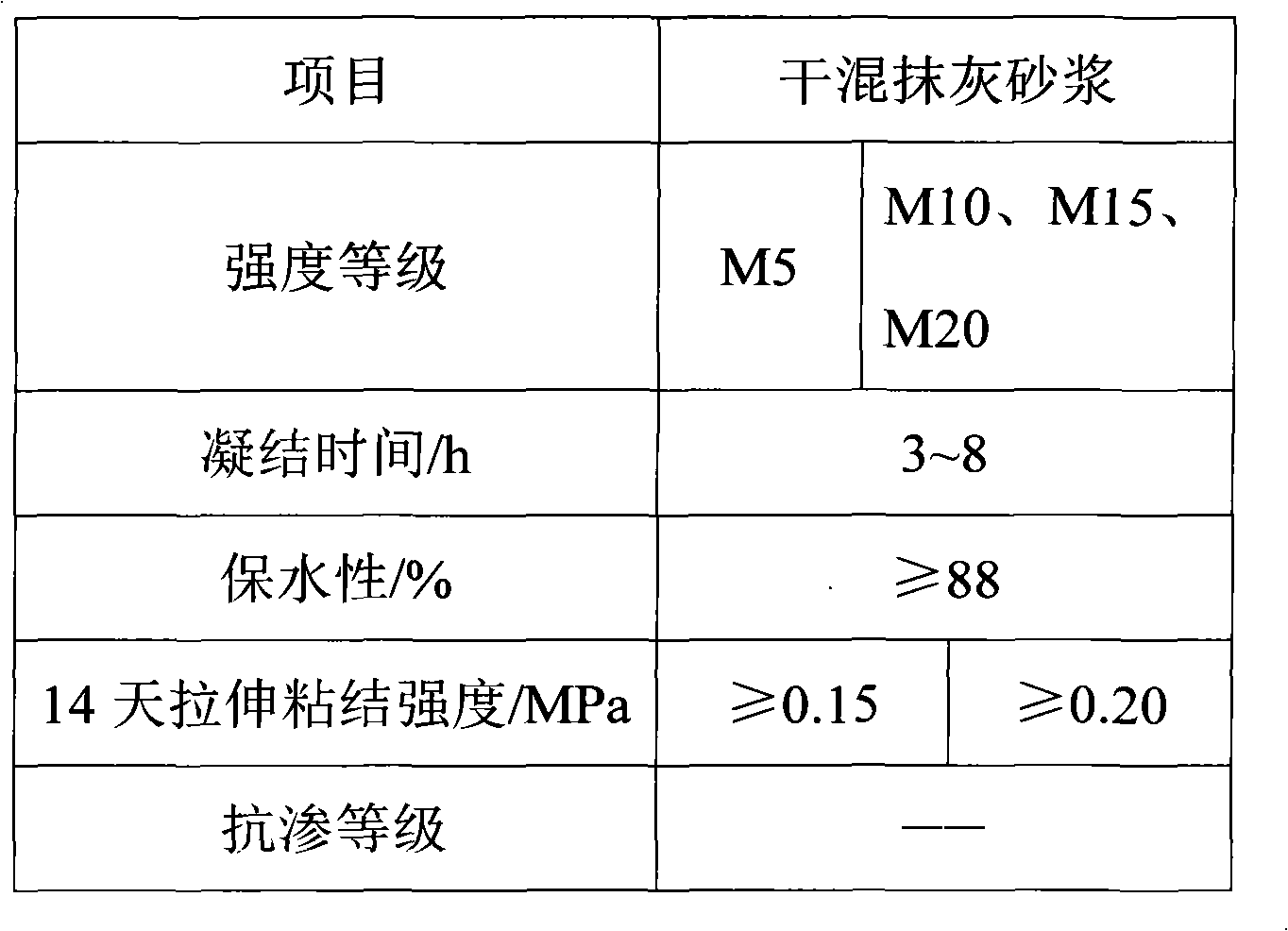

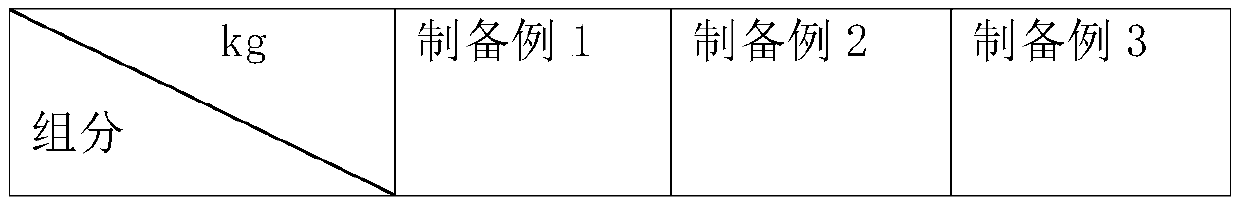

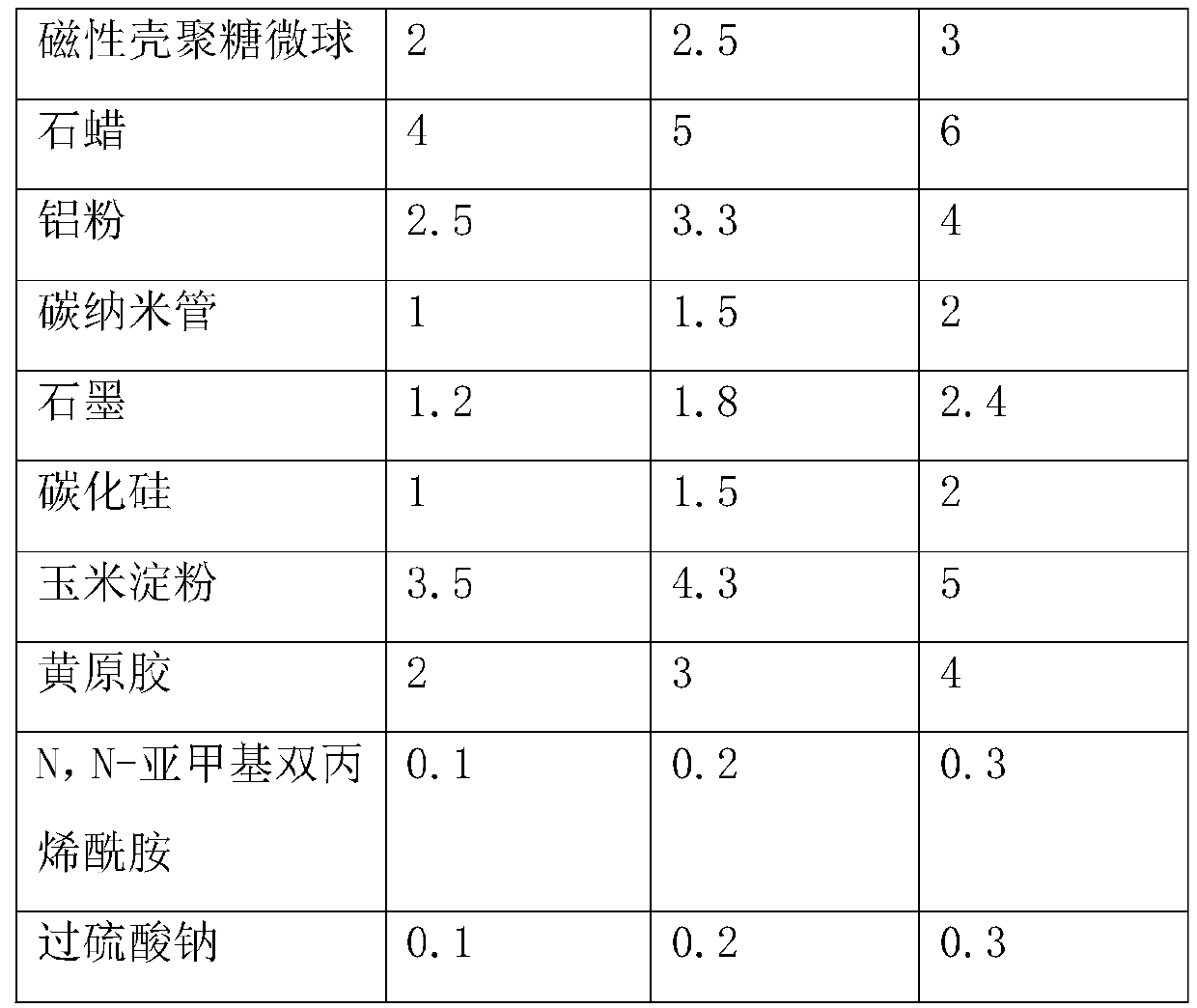

The invention discloses a preparation method of a cracking-resistance and maintenance-free plastering mortar, which comprises the following steps of: (1) preparing raw materials; (2) feeding; and (3) stirring and mixing, so as to prepare the improved plastering mortar. The invention also discloses a product prepared by using the preparation method and a construction method of the product. The method provided in the invention has the advantages of simple preparation process, easiness in implementation and high production efficiency. The product provided in the invention has the advantages of reasonable formulation design, high strength, good workability, easy construction, better stretching and bonding strength, difficulty in cracking, generation of no dusting or hollowing, less maintenance or no maintenance, and the maintenance cost is effectively reduced. The construction method provided by the invention has the advantages of simple process, easiness in implementation and good plastering effect, the construction period is shortened, the construction efficiency is effectively improved and the construction method is beneficial to wide generalization and application.

Owner:张立功

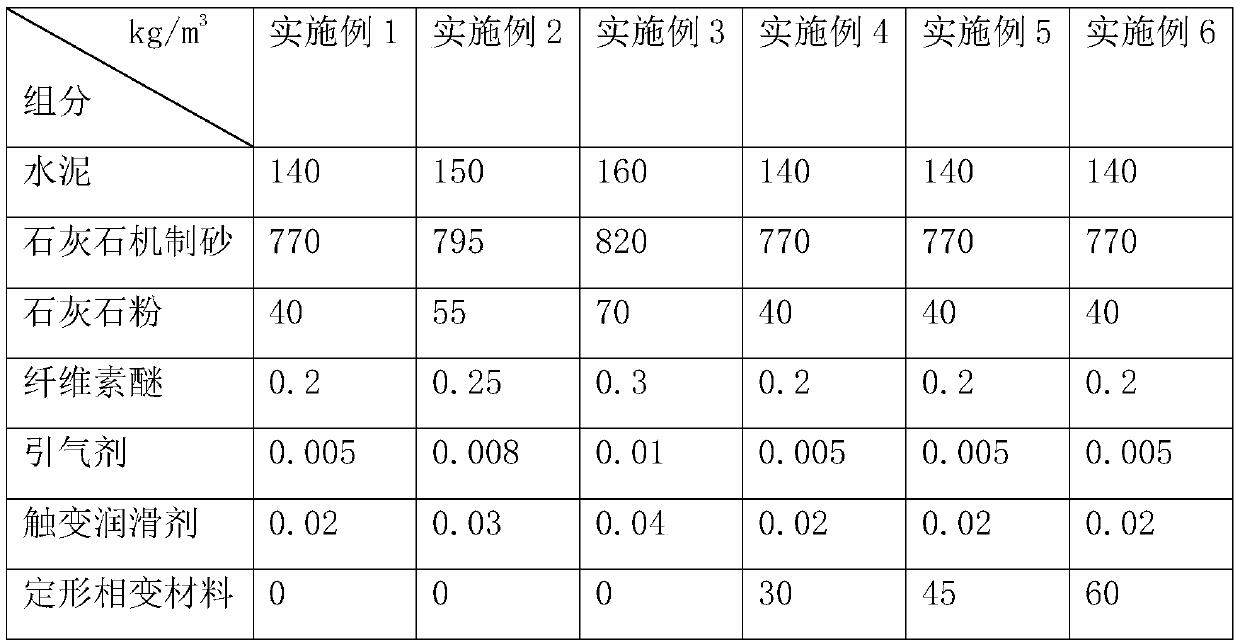

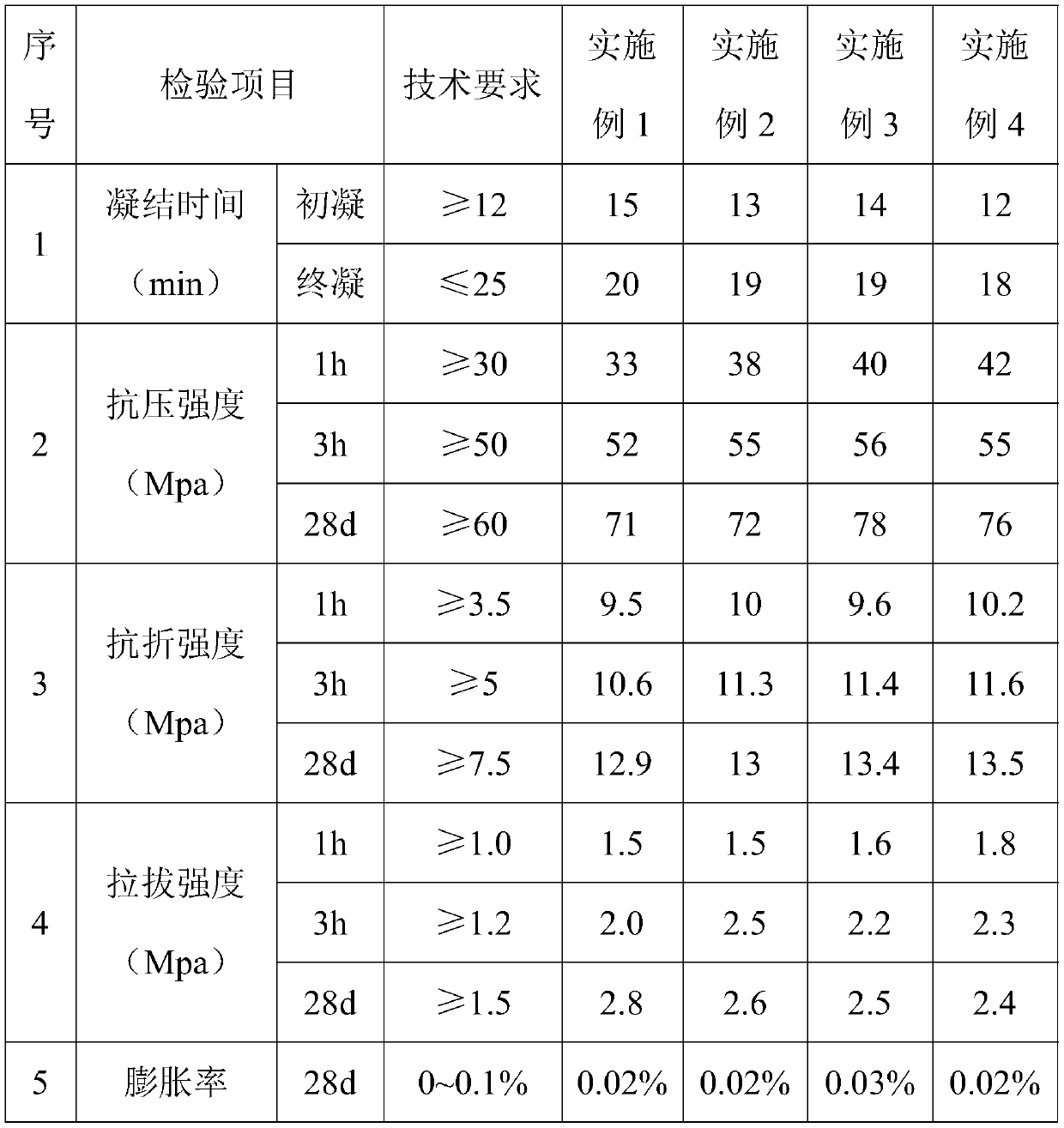

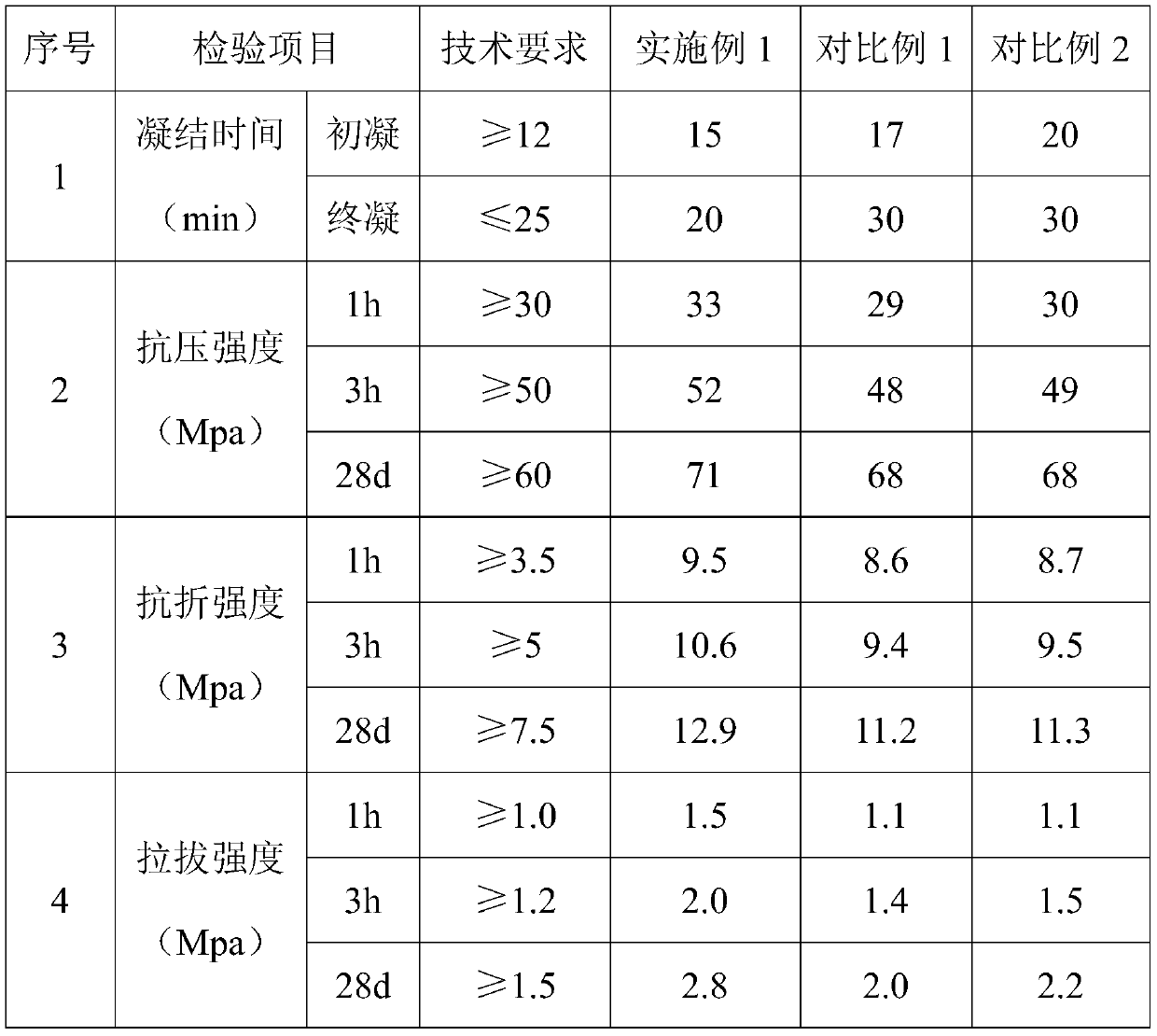

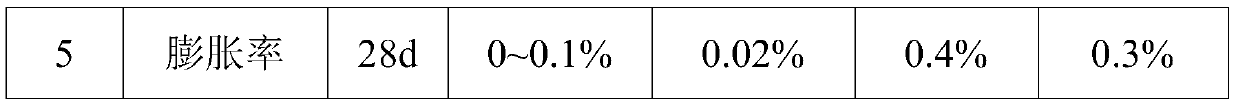

Full-machine-made sand plastering mortar taking limestone as aggregate and preparation method thereof

The invention discloses full-machine-made sand plastering mortar taking limestone as aggregate and a preparation method of the full-machine-made sand plastering mortar. The full-machine-made sand plastering mortar taking limestone as the aggregate comprises the following components in parts by weight: 140-160 parts of cement, 770-820 parts of limestone machine-made sand, 40-70 parts of limestone powder, 0.2-0.3 part of cellulose ether, 0.005-0.01 part of an air entraining agent and 0.02-0.04 part of a thixotropic lubricant. Wherein the limestone machine-made sand and the limestone powder are prepared by crushing high-calcium stones, the fineness modulus of the limestone machine-made sand is 2.5, and the fineness modulus of the limestone powder is 0.07. The full-machine-made sand plasteringmortar taking limestone as the aggregate has the advantages of less bleeding, good workability, strong binding power after construction, no shrinkage, no hollowing, smooth and flat surface, low raw material cost, no secondary pollution, heat conduction, good heat dissipation and capability of adsorbing formaldehyde and purifying air.

Owner:湖州三中新型建材科技有限公司

Special moisture-holding thickening agent for masonry mortar and production method thereof

The invention relates to a special moisture-holding thickening agent for masonry mortar and a production method thereof. The special moisture-holding thickening agent is composed of a moisture-holding thickening component, a water reducing component and an enhancing component, wherein the moisture-holding thickening component is prepared from the following materials in parts by weight: 17-22 parts of desulfurized gypsum, 45-55 parts of secondary fly ash and 25-35 parts of hydroxypropyl methyl cellulose; the water reducing component is prepared from 15-25 parts of wood celluloses in parts by weight; and the enhancing component is prepared from the following materials in parts by weight: 18-22 parts of carbide slag, 7-13 parts of calcium lignosulphonate, 750-830 parts of fine sand and 57-63 parts of primary fly ash. Through applying the special moisture-holding thickening agent to masonry mortar, the adhesiveness and bonding strength between a pressed concrete brick and masonry mortar can be improved, the purposes of reducing the overall shrinkage of a pressed concrete brick masonry and improving the shearing strength of the masonry are achieved, and the problem that micro-cracks appear on wall bodies because the binding power between a pressed concrete brick and masonry mortar is poor can be solved.

Owner:MUDANJIANG GUANGMING NEW WALL MATERIALS

Rapid repairing material for airport parking apron and preparation method thereof

The invention belongs to the technical field of airport parking lane maintenance, and particularly relates to a rapid repairing material for an airport parking apron and a preparation method thereof.The repairing material is prepared from the following components: high-belite sulphoaluminate cement, wollastonite powder, a powder defoaming agent, a water repellent, quartz powder, acrylic acid redispersible latex powder, a polycarboxylate superplasticizer, a medium-term early strength agent, an early retarder, low-viscosity HPMC, fine aggregates, heat-resistant fibers and polymer fibers. The repairing material disclosed by the invention has high bonding force, and is free from hollowing and cracking after being repaired; the strength can reach C65 or above; the toughness is high, and the impact resistance is more than 20 times that of common concrete; low-temperature cyclic freezing and thawing at -40 DEG C or below can be resisted; acid and salt corrosion resistance; thermal expansionand cold contraction coefficients are consistent; synchronous displacement between cold and hot circulation and original concrete is ensured; and moreover, navigation can be performed only by maintaining for 2 hours after construction, and therefore, the rapid repairing material for an airport parking apron is suitable for rapid maintenance and repair of airport roads.

Owner:广州协堡建材有限公司

Veneer mortar, preparation method and use method thereof

The invention belongs to the field of mortar and specifically discloses veneer mortar, a preparation method and a use method thereof. The mortar comprises the following raw materials in parts by weight: 140-170 parts of cement, 70-80 parts of superfine slag powder, 20-30 parts of coal ash, 40-50 parts of sulfur-fixing ash, 600-700 parts of quartz sand, 10-20 parts of emulsion powder, 0.1-0.3 partof water-retaining agent, 2-4 parts of a water reducer, 2-4 parts of a water repellent, 1-1.5 parts of a de-foaming agent and 3-5 parts of pigment. The preparation method for the veneer mortar comprises the following steps: accurately weighting the raw materials by weight ratio, putting the raw materials into a dry mixing device and then mechanically and uniformly stirring, thereby acquiring a required product. The veneer mortar provided by the invention has excellent overall performances and can solve the problems of resource shortage of traditional cement admixtures, such as superfine slag powder and coal ash, limited recycling ways and low use ratio of sulfur-fixing ash.

Owner:成都宏基建材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com